An adjustable equipment support platform mechanism

A technology for supporting table and equipment, applied in supporting machines, mechanical equipment, electromechanical devices, etc., can solve problems such as difficulty in realizing fast and accurate adjustment, complexity, etc., and achieve the effects of avoiding force interference, reducing manufacturing costs, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

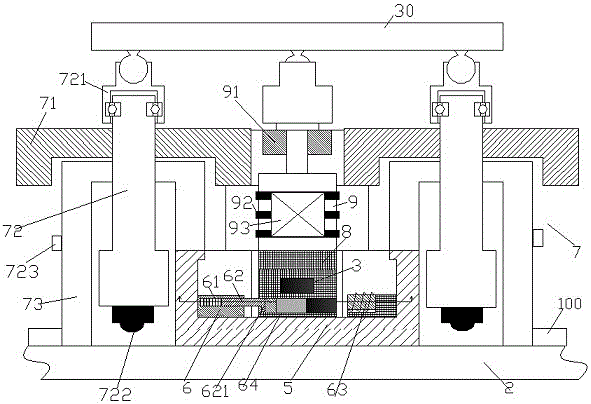

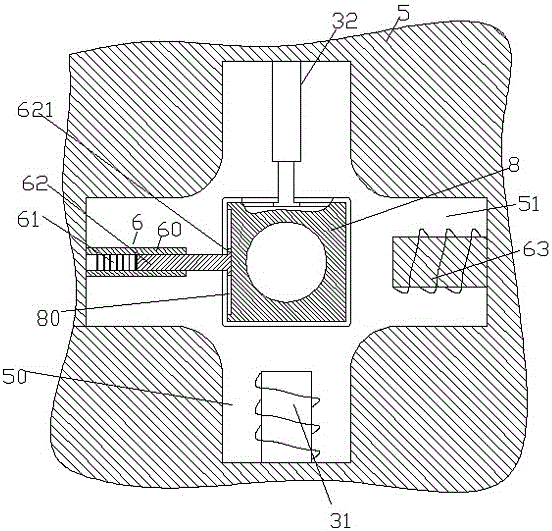

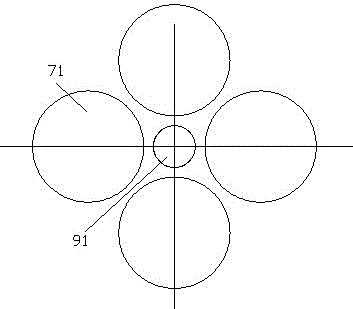

[0009] Combine below Figure 1-3 The present invention will be described in detail.

[0010] An adjustable equipment support platform mechanism according to an embodiment, comprising a fixed base 2, four lifting adjustment assemblies 7 uniformly distributed in the circumferential direction arranged on the fixed base 2, and the four lifting adjustment assemblies 7 7 supported support table 30, wherein each of the four lifting adjustment assemblies 7 includes a sliding bracket 73 that is slidably fitted with the fixed base 2 and can slide in the radial direction, and the sliding bracket 73 The threaded hole in the upper end surface of 73 is threadedly matched with the lifting screw 72, the hinge joint 721 connected with the upper end of the lifting screw 72 through bearings, and is fixedly connected with the lifting screw 72 and is located on the upper end surface of the sliding bracket 73 and the upper end of the sliding bracket 73. The screw tooth sleeve 71 between the hinged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com