Motor vehicle and rear-end module therefor

A technology for motor vehicles and the rear of the vehicle, which is applied to the connection between the body and the frame, vehicle components, and the layout of the fuel supply of the internal combustion engine. Problems such as force transmission can be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

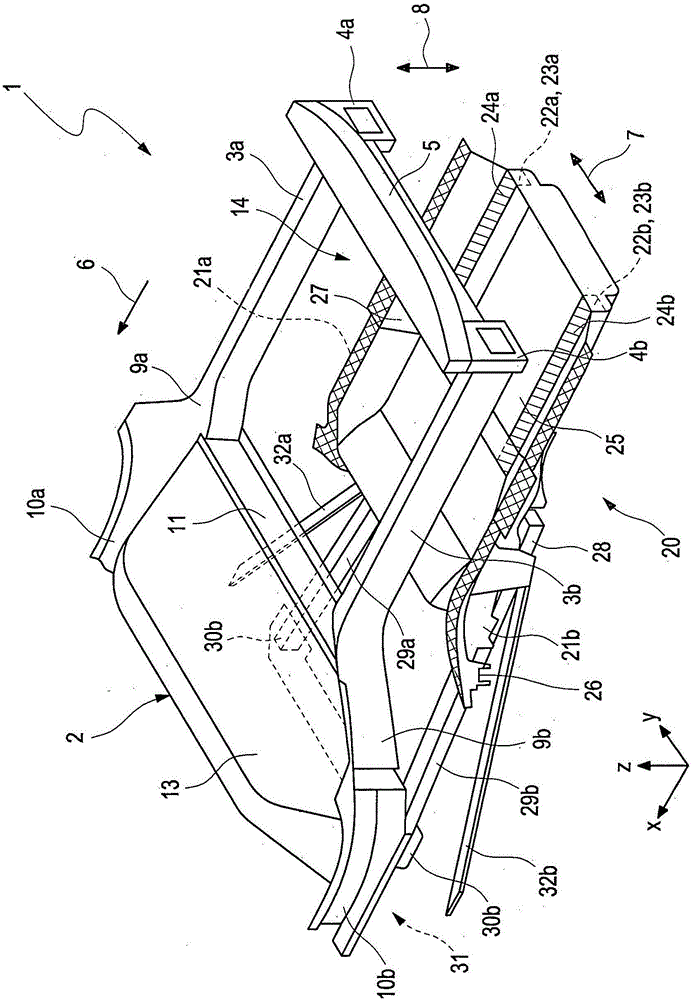

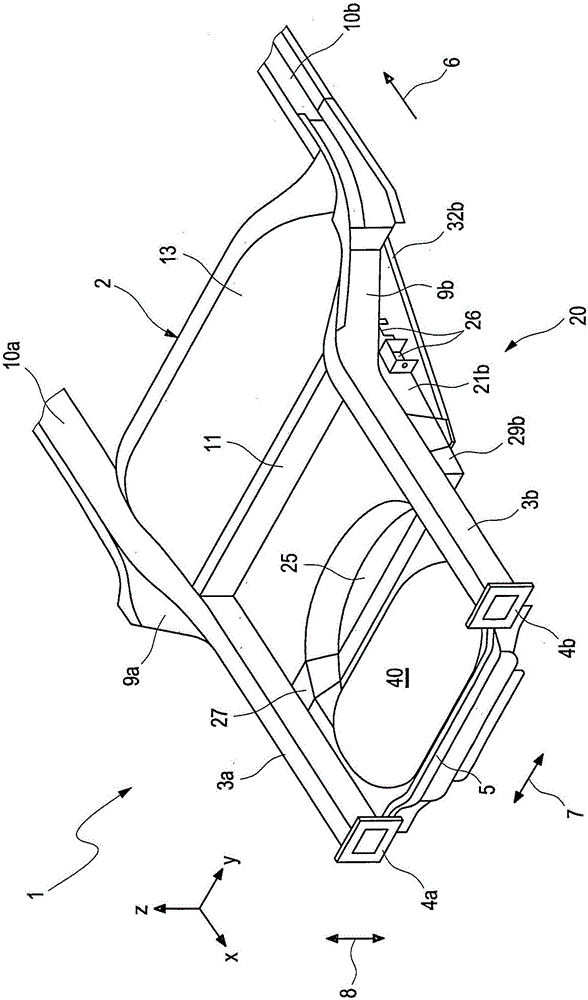

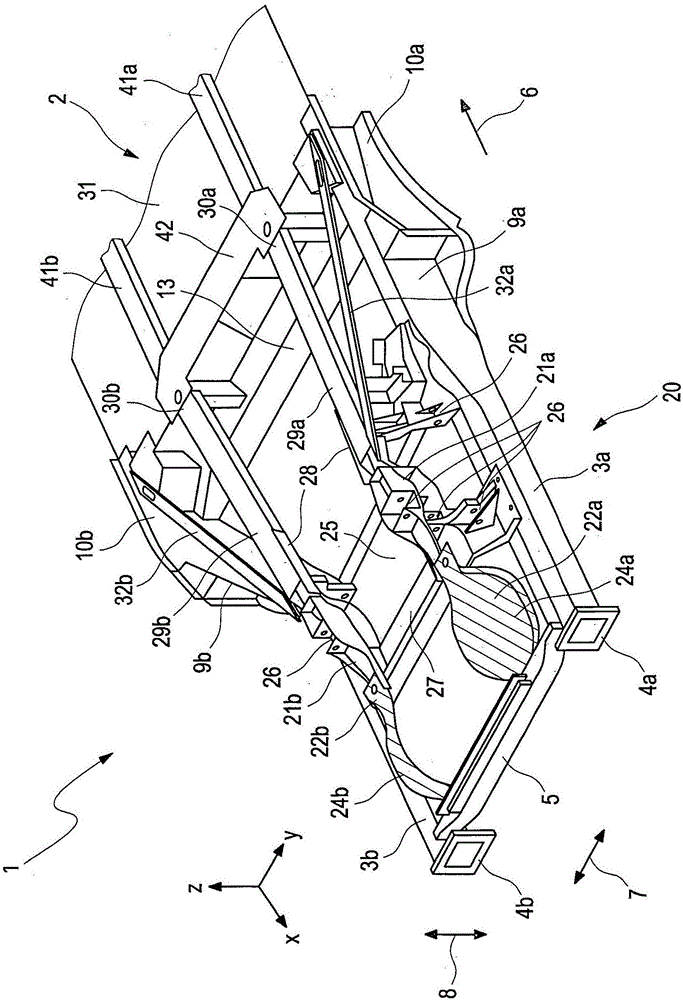

[0032] The motor vehicle 1 according to the invention has a body 2 . below, in Figures 1 to 5 Only a partial structure of such a body 2 , in particular the rear body structure, is shown in FIG. The body 2 has two rear longitudinal members 3a, 3b, which are part of the body-in-white structure. The longitudinal beams 3 a , 3 b are, for example, box-shaped and each have a rear-side end 4 a , 4 b. In the region of the rear-side ends 4 a , 4 b , the longitudinal beams 3 a , 3 b are connected by means of a rear cross member 5 .

[0033] For further explanation, the direction indicated by arrow 6 is the direction of travel of the vehicle or the direction of the longitudinal axis of the vehicle (x-axis). The transverse direction of the vehicle is indicated by the double arrow 7 . In this case, the transverse direction of the vehicle corresponds to the usual y-direction. The vertical direction of the vehicle (z direction) is indicated by the double arrow 8 . At the front end in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com