Start-up method of gasoline hydro-upgrading catalyst containing molecular sieve

A gasoline hydrogenation and hydrogenation upgrading technology, applied in the petroleum industry, refined hydrocarbon oil and other directions, can solve the problems of difficulty in ensuring the stability of catalyst activity, inability to use passivation, etc., so as to avoid the loss of catalyst activity and improve the activity stability. , the effect of stable start-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

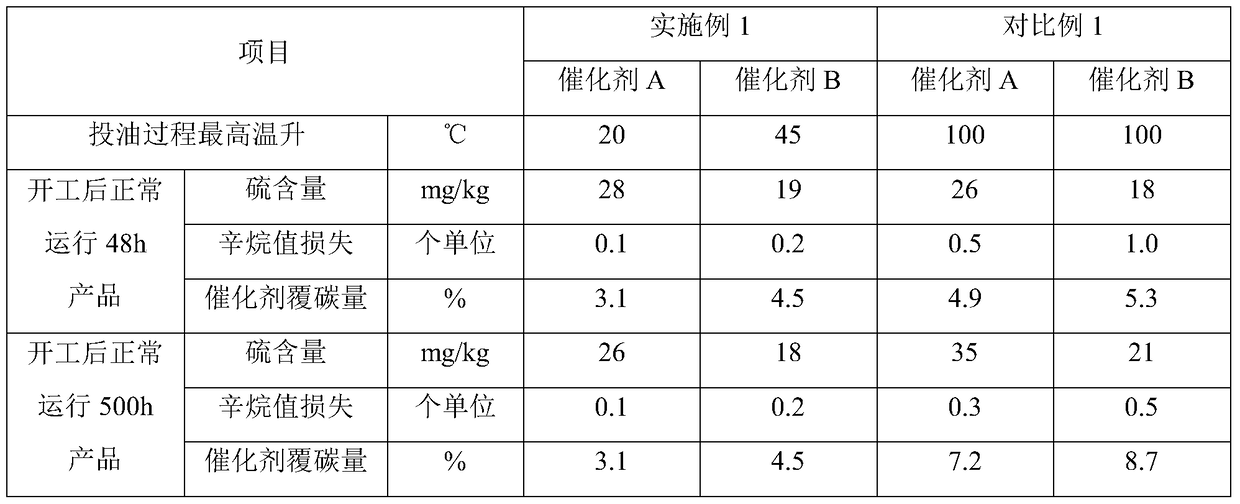

Embodiment 1

[0024]Fill 500ml of gasoline hydro-upgrading catalyst A into a 500ml adiabatic bed hydrogenation reactor, and contact with hydrogen and naphtha for 40 hours for activation treatment. The activation reaction temperature is 270°C, the reaction pressure is 2.0MPa, and the volume space velocity is 3.0h- 1. The volume ratio of hydrogen to oil is 400:1.

[0025] After the catalyst activation is completed, the inlet temperature of the reactor is lowered to 250°C, and the FCC gasoline and naphtha are introduced into the reaction system at the same time according to the FCC gasoline raw material oil volume of 252g / h and naphtha oil volume of 468g / h; Increase the inlet temperature of the reactor at a heating rate of 3°C / h until the inlet temperature of the reactor reaches 315°C;

[0026] The inlet temperature of the reactor is lowered to 300°C, and the FCC gasoline and naphtha are introduced into the reaction system at the same time according to the amount of FCC gasoline raw material o...

Embodiment 2

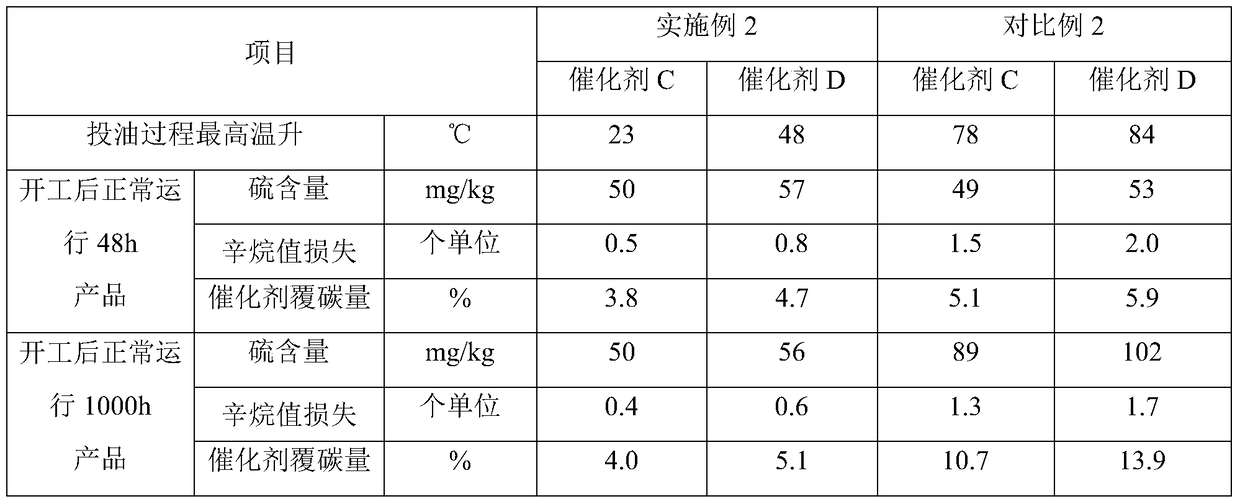

[0035] Fill 500ml of gasoline hydrogenation upgrading catalyst C into a 500ml adiabatic bed hydrogenation reactor, contact with hydrogen and naphtha for 35 hours for activation treatment, the activation reaction temperature is 240°C, the reaction pressure is 2.4MPa, and the volume space velocity is 2.0h- 1. The volume ratio of hydrogen to oil is 450:1.

[0036] After the activation of the catalyst, the inlet temperature of the reactor was lowered to 230°C, and coked gasoline and catalytic reformed oil were introduced into the reaction system at the same time according to the amount of coked gasoline raw material oil of 230g / h and the amount of catalytic reformed oil of 346g / h; Increase the inlet temperature of the reactor by 10°C / h until the inlet temperature of the reactor reaches 310°C;

[0037] Reduce the inlet temperature of the reactor to 285°C, and introduce coked gasoline and catalytic reformed oil into the reaction system at the same time according to the amount of cok...

Embodiment 3

[0046] Apply gasoline hydro-upgrading catalyst A to a 1.2 million tons / year catalytic cracking gasoline hydrogenation unit. Contact with hydrogen and naphtha for 48 hours for activation treatment. The activation reaction temperature is 260°C, the reaction pressure is 1.9MPa, the volume space velocity is 1.8h-1, and the volume ratio of hydrogen to oil is 260:1. After the activation, according to the flow rate of FCC gasoline raw material of 64t / h and the flow rate of hydrorefined oil product of 78t / h, FCC gasoline and hydrorefined oil are introduced into the reaction system at the same time, and the system sends out products 142t / h at the same time; according to 20 °C / h increase the inlet temperature of the reactor until the inlet temperature of the reactor reaches 310°C;

[0047] Reduce the inlet temperature of the hydro-upgrading reactor to 300°C, and introduce the catalytic cracking gasoline and hydro-refined oil into the reaction system at the same time according to the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com