Starting method of heavy catalyst containing molecular sieve low-boiling point sulfide

A sulfide and catalyst technology, which is applied in the field of heavy catalyst containing molecular sieve low boiling sulfide, can solve the problems that it is difficult to ensure the stability of catalyst activity and passivation, so as to avoid the loss of catalyst activity and improve stability , the effect of stable start

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

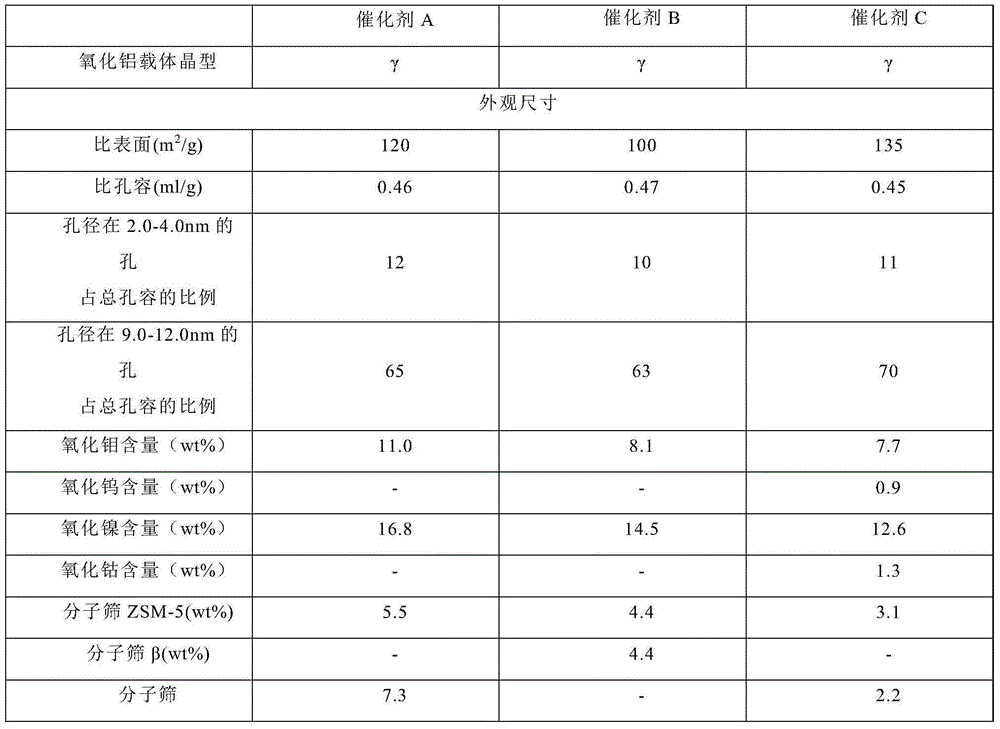

[0025] The composite molecular sieve of 5kg aluminum oxide powder, 0.84kg ZSM-5 and SAPO-11 (the weight percentage of ZSM-5 in the composite molecular sieve is 45%) and 0.3kg of turnip powder were kneaded for 5min, and 0.2kg of phosphoric acid was dissolved in 4L water, added to the mixed powder, kneaded and extruded into rods, dried in the air at 100°C, and calcined at 600°C for 5 hours to obtain an Al2O3 carrier containing molecular sieves.

[0026] Dissolve 5.23kg of ammonium molybdate and 18.66kg of nickel acetate in 32L of ammonia water, stir until completely dissolved to form an impregnating solution, impregnate it on the carrier, dry it in the air at 120°C, bake at 420°C for 5 hours, and use 55% sulfur Catalyst A was obtained by impregnating the thioether compound for 4h.

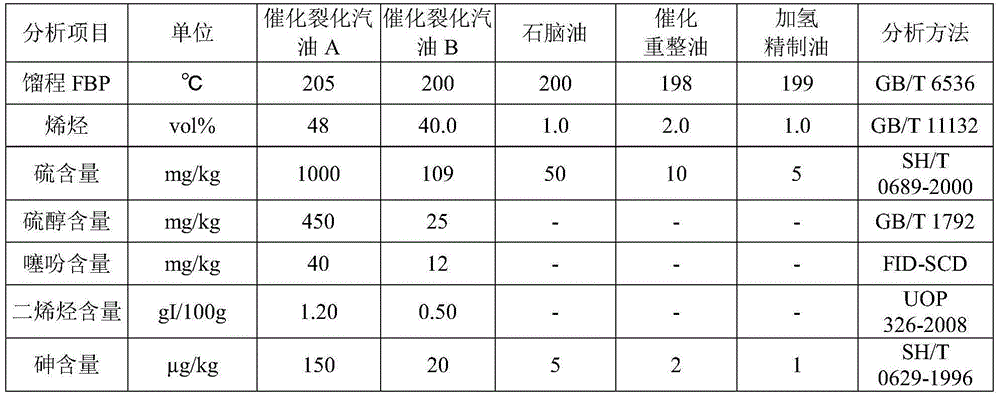

[0027] Fill 500ml of the above catalyst A into a 500ml adiabatic bed hydrogenation reactor, contact with hydrogen and naphtha for 40 hours for activation treatment, the activation reaction temperatur...

Embodiment 2

[0034] Knead 270g of alumina powder, 15g of ZSM-5, 15g of β and 15g of turnip powder for 5 minutes, dissolve 15g of glacial acetic acid in 250ml of water, add it to the mixed powder, knead and extrude into strips, and dry in air at 120°C. Calcined at 540°C for 4 hours to obtain an Al2O3 carrier containing molecular sieves.

[0035] Dissolve 19.62g of ammonium molybdate and 79.96g of nickel acetate in 140ml of ammonia water, stir until completely dissolved to form an impregnating solution, impregnate it on the carrier, dry it in the air at 120°C, and bake it at 450°C for 4 hours, using 55% sulfur The thioether compound was impregnated for 4h to obtain catalyst B.

[0036] Fill 100ml of the above-mentioned catalyst B in a 100ml adiabatic bed hydrogenation reactor, contact with hydrogen and naphtha for 35 hours for activation treatment, the activation reaction temperature is 240°C, the reaction pressure is 2.4MPa, the volume space velocity is 2.0h-1, hydrogen oil The volume rati...

Embodiment 3

[0043] Knead the compound molecular sieve of 22.4kg aluminum oxide powder, 1.6kg ZSM-5 and SAPO-11 (the weight percentage of ZSM-5 in the compound molecular sieve is 60%) and 1.2kg kale powder for 5min, and dissolve 1.12kg glacial acetic acid In 16.8L of water, added to the mixed powder, kneaded and extruded into rods, dried in the air at 110°C, and calcined at 490°C for 6 hours to obtain an Al2O3 carrier containing molecular sieves.

[0044] Add 1.52kg ammonium molybdate and 0.36kg ammonium metatungstate to 1.44L ammonia water and stir until completely dissolved, then add 4.42kg basic nickel carbonate, stir until completely dissolved, then add 0.64kg cobalt nitrate, stir to completely dissolve Prepare impregnating liquid, impregnate on carrier, dry in air at 110°C, bake at 440°C for 6 hours, impregnate with sulfide compound containing 55% sulfur for 4h, and obtain catalyst C.

[0045] Fill 500ml of the above-mentioned catalyst C into a 500ml adiabatic bed hydrogenation reacto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com