Carding machine drive belt tensioner

A technology of tensioning device and transmission belt, which is used in deburring device, fiber processing, textile and papermaking, etc., can solve the problems of serious elongation, lengthy and insufficient solution of the carding machine transmission belt, and achieve the effect of ensuring the tensioning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

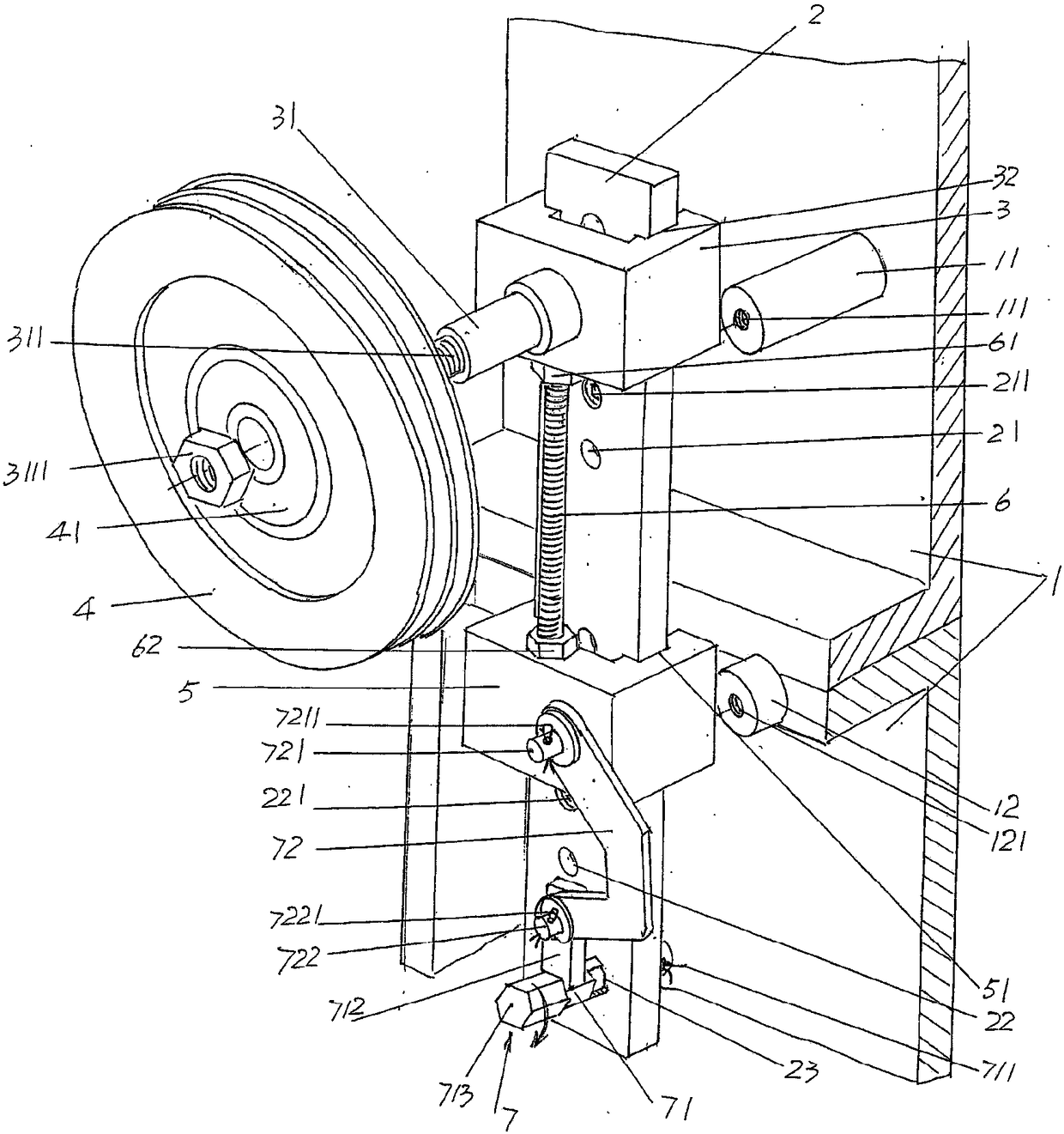

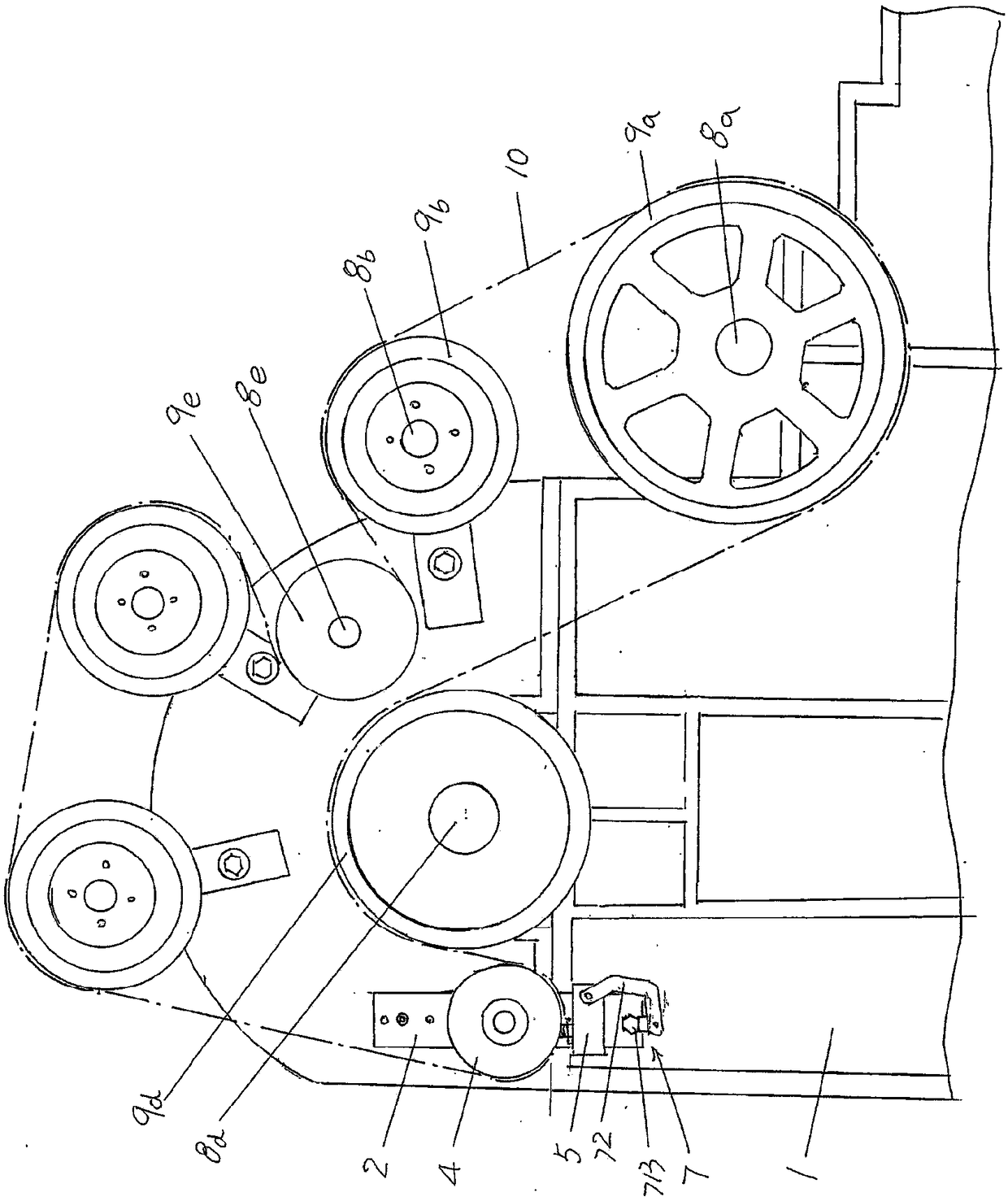

[0022] In order to understand the technical essence and beneficial effects of the present invention more clearly, the applicant will describe in detail the following examples, but the descriptions of the examples are not intended to limit the solutions of the present invention. Equivalent transformations that are only formal but not substantive should be regarded as the scope of the technical solution of the present invention.

[0023] In the following descriptions, all concepts related to directionality or orientation of up, down, left, right, front and rear are based on figure 1 As far as the position and state of the present invention are concerned, it cannot be understood as a special limitation on the technical solution provided by the present invention.

[0024] See figure 1 , shows the wallboard 1 belonging to the structural system of the carding machine. According to professional knowledge, there are a pair of wallboards 1 facing each other. Since the power transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com