Patents

Literature

34results about How to "No floating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

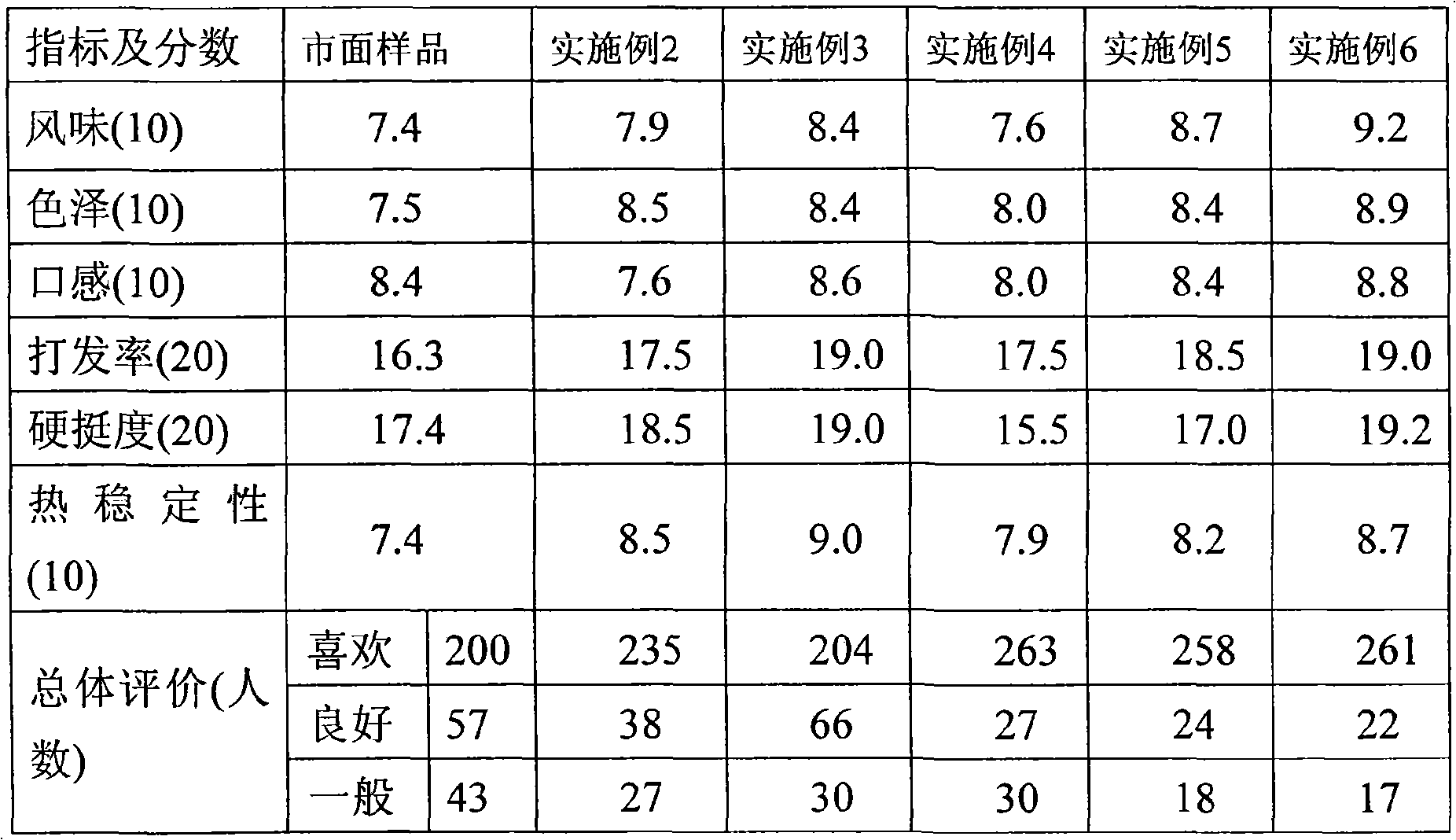

Mixed unsalted butter and producing method thereof

ActiveCN101301009ARich pure frankincenseUniform and delicate tissue stateCream preparationSterile environmentPreservative

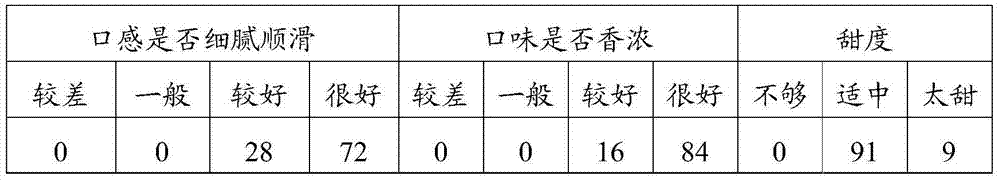

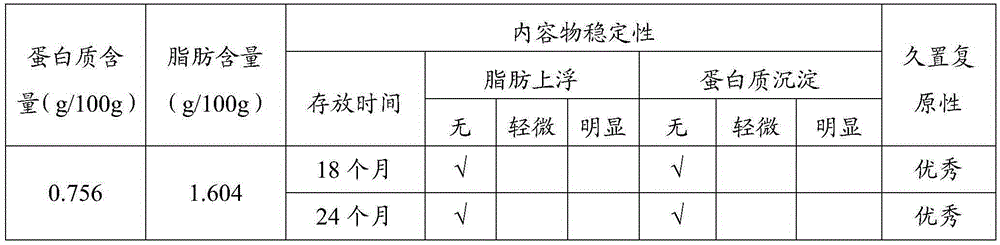

The present invention discloses a whipping unsalted cream and a production process thereof, the stirred unsalted butter of the invention contains the following components in 100g of raw material: 80 to 98g of unsalted butter, 0. 5 to 19g of milk, 0. 1 to 0. 8g of emulsifier, 0. 1 to 0. 8g of stabilizer, 0. 0 to 0. 1g of pigment, 0. 0 to 0. 05g of preservative and balance of water, preferably, nutrition enhancer is added. The production process includes the following steps of raw milk acceptance, the separation of unsalted butter, the addition of milk, emulsifier, stabilizing agent, pigment and preservative, pasteurization, UHT sterilization, homogenization, cooling, on line addition of nutrition enhancer in sterile environment and packaging. The product of the invention has smooth taste, high whipped topping, rich nutrient and long collapse period, and the shelf life is prolonged by the adoption of UHT sterilization and aseptic package and on line addition of nutrition energizing agent.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Pipeline floating connecting device with backing function

ActiveCN105501470AIsolate docking failureDoes not affect normal docking operationCosmonautic vehiclesCosmonautic component separationMotor driveEngineering

The invention provides a pipeline floating connecting device with a backing function; the pipeline floating connecting device comprises a backing floating assembly, a backing slide body, a top cover, a ball support, an outer housing, a pressure spring, an extension spring, a torsion spring and a locking lever; the device is fixedly connected with a combined drive mechanism on a service aircraft through the outer housing, and is coupled with a refill-receiving joint arranged on a service-receiving aircraft; when a single motor drives multi-set pipeline floating connecting devices to do pipeline jointing work, and certain set pipeline floating connecting device and the refill-receiving joint cannot complete jointing because of attitude deviation, the jointing between other pipeline floating connecting devices and corresponding refill-receiving joints will not be affected, thus ensuring subsequent high pressure gas-liquid refill and normal break operations; the pipeline floating connecting device is simple in structure, reliable in motions, and can realize fault self-isolation function.

Owner:SHANGHAI AEROSPACE SYST ENG INST

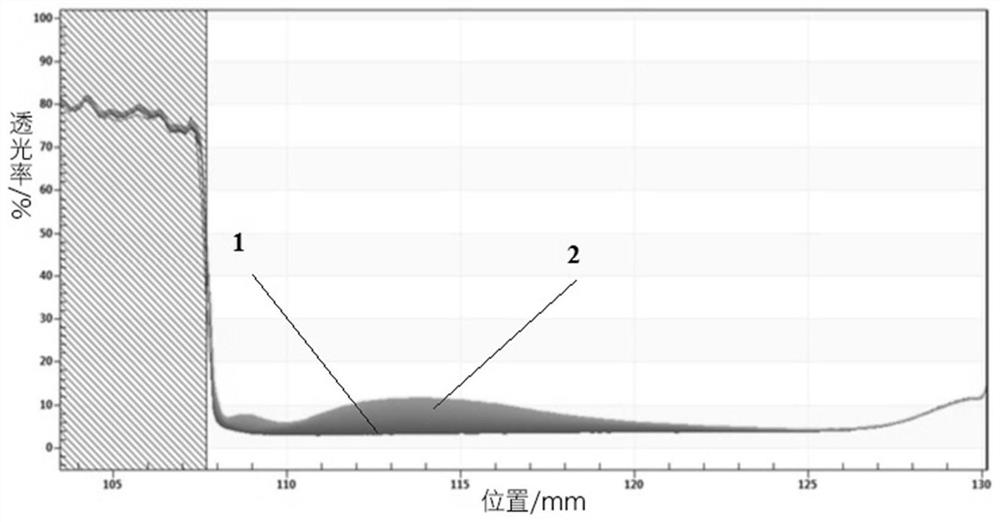

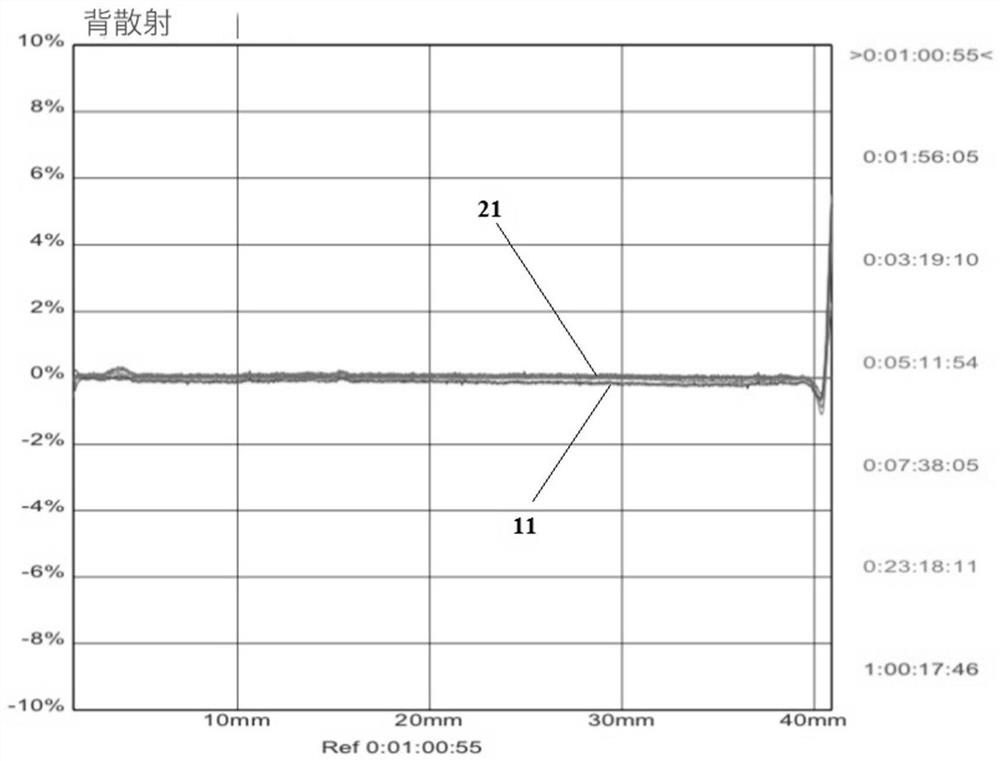

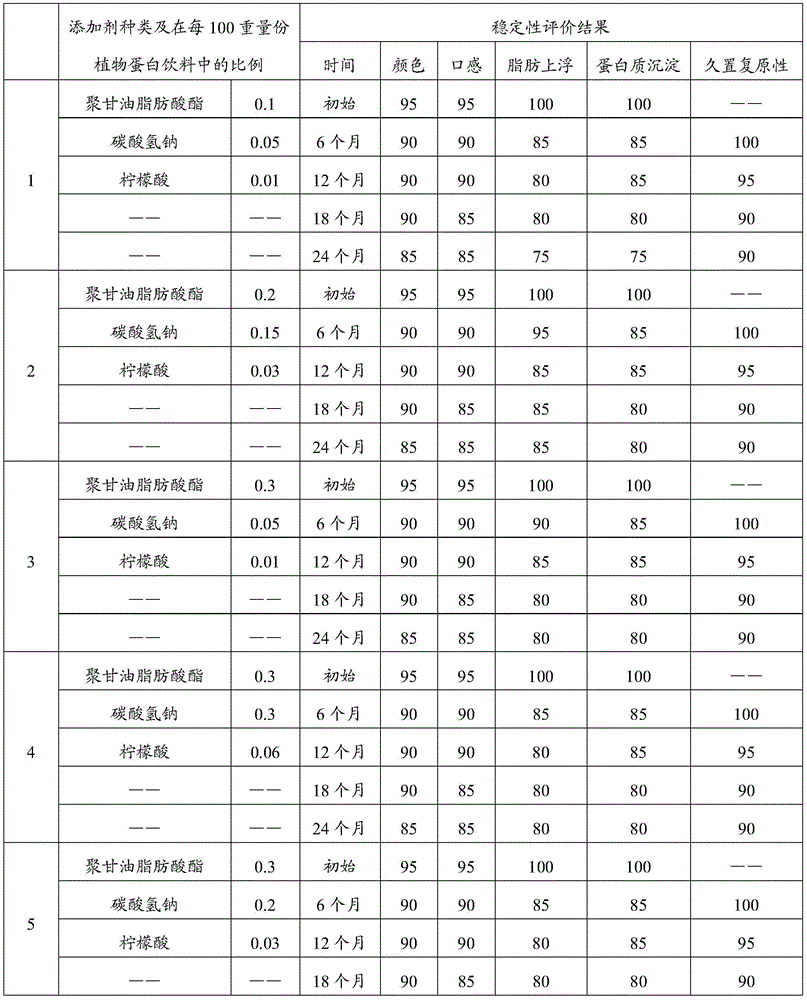

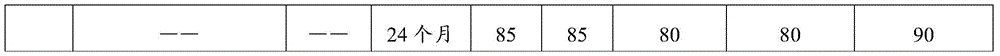

Method for improving stability of vegetable protein drinks

ActiveCN104738191AImprove stabilityAdd less typesMilk substitutesFood scienceHydroxycitric acidChemistry

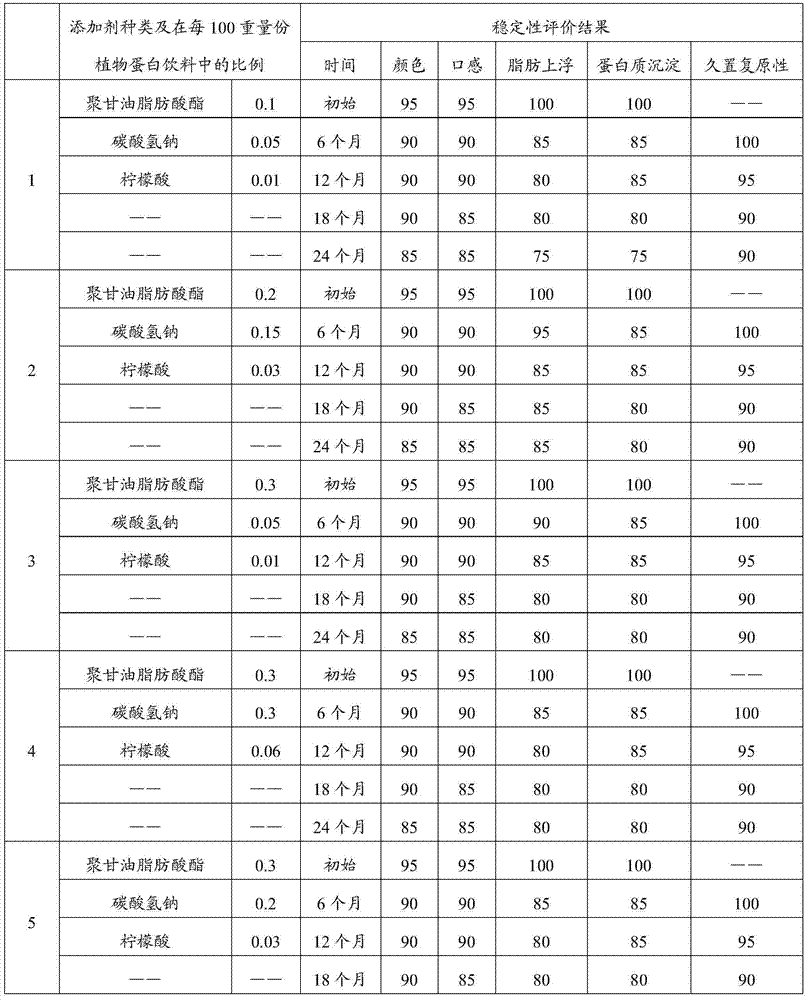

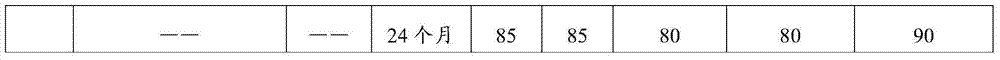

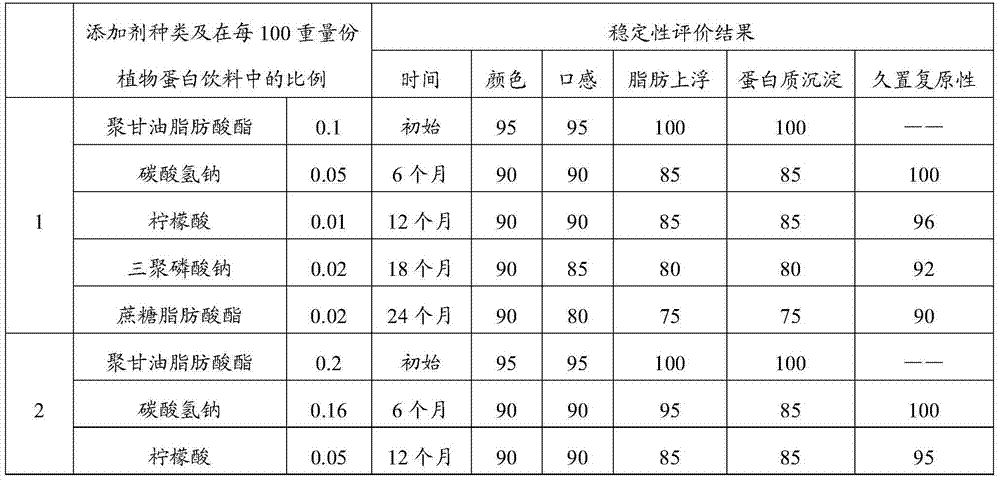

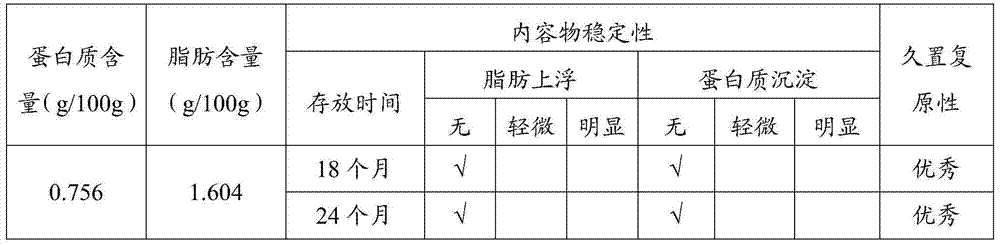

The invention discloses a method for improving stability of vegetable protein drinks, and belongs to the technical field of processing of plant protein drinks. According to the method, 0.1 to 0.45 part by weight of polyglycerol fatty acid ester, 0.05 to 0.45 part by weight of sodium bicarbonate, or 0.02 to 0.45 part by weight of sodium tripolyphosphate, or combination of polyglycerol fatty acid ester, sodium bicarbonate, or 0.01 to 0.1 part by weight of citric acid, or 0.02 to 0.2 part by weight of sodium tripolyphosphate, or sucrose fatty acid ester, or combination of sodium tripolyphosphate and sucrose fatty acid ester are added into every 100 parts by weight of plant protein drinks during a process of processing the plant protein drinks. By virtue of the method, the stability of the prepared plant protein drinks can be effectively improved; the properties of the prepared plant protein drinks can be stabilized for more than one year and the plant protein drinks are free of fat floating and protein precipitation on the premise that a small amount of additives of less species is added.

Owner:承德露露股份公司

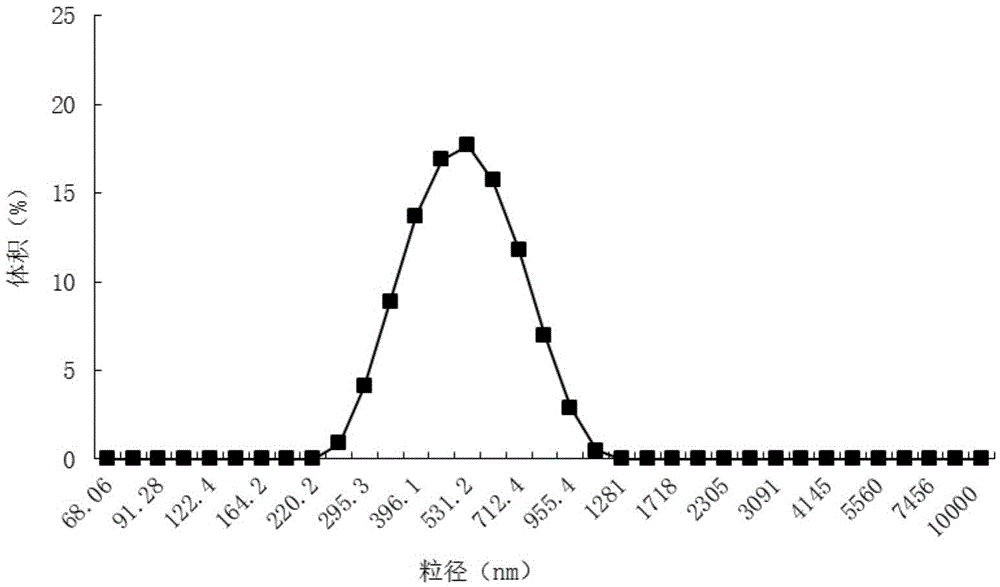

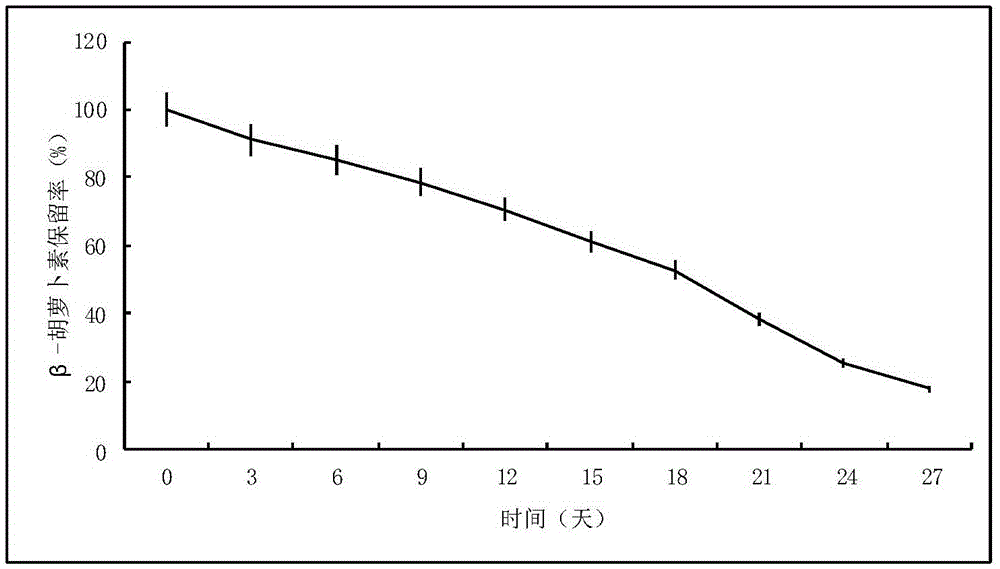

Beverage emulsion with coloring and flavoring functions and preparation method thereof

The invention belongs to the technical field of food additives and functional food and particularly relates to a beverage emulsion with coloring and flavoring functions and a preparation method thereof. The preparation method comprises the following step that 1, modified starch and hydrophilic colloid are weighed out according to a certain proportion and dissolved in water with the temperature of 60 DEG C to 80 DEG C, an emulgator and an antioxidant are added, and a water phase is obtained; 2, citrus fruit peel oil or fruit oil, edible vegetable oil and a weighting agent are weighed out according to a certain proportion, when the mixture is heated to be 140 DEG C to 150 DEG C, carotenoid is added and fast stirred to be dissolved, an antioxidant is added after the mixture is cooled, and even stirring is carried out to obtain an oil phase; 3, at room temperature, the oil phase is slowly added to the water phase for high-speed shearing, and a crude emulsion is obtained; 4, the crude emulsion is homogenized through a high-pressure homogenizer, and the beverage emulsion uniform in particle size is obtained. The beverage emulsion is used for food, has multiple functions, can increase the turbidity of a beverage, and is used for coloring the beverage, and certain fragrance is given to the food.

Owner:CHINA AGRI UNIV

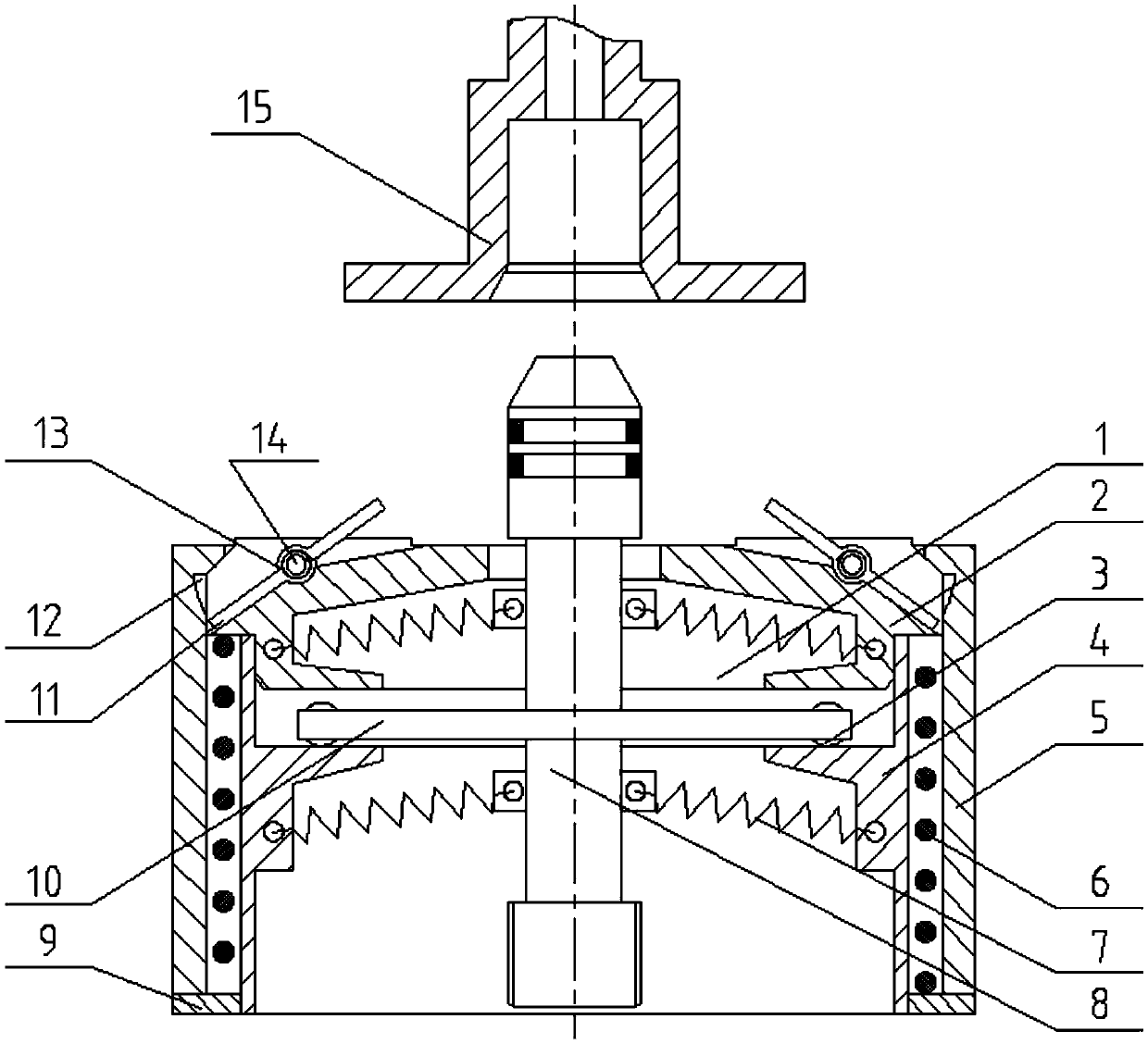

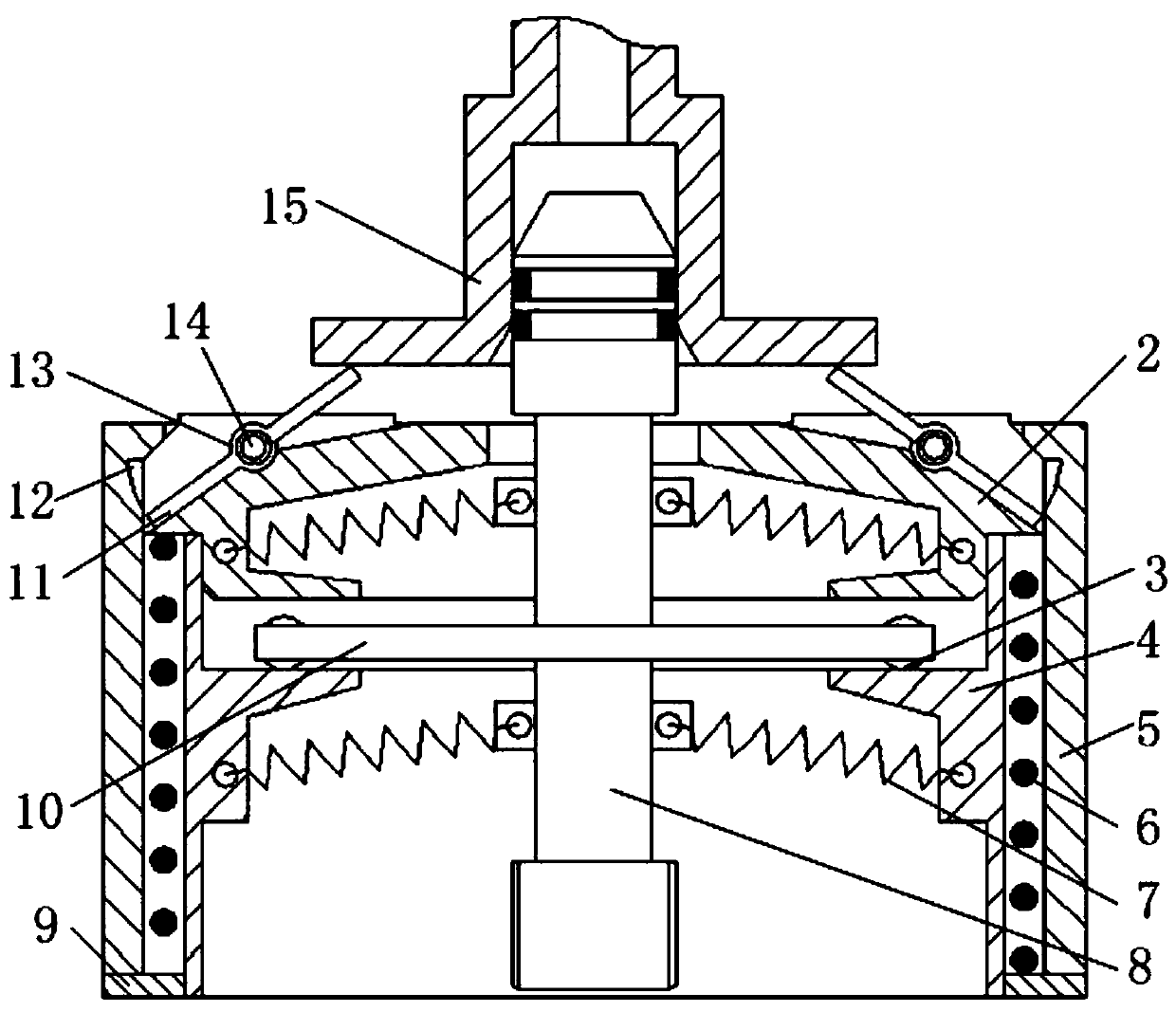

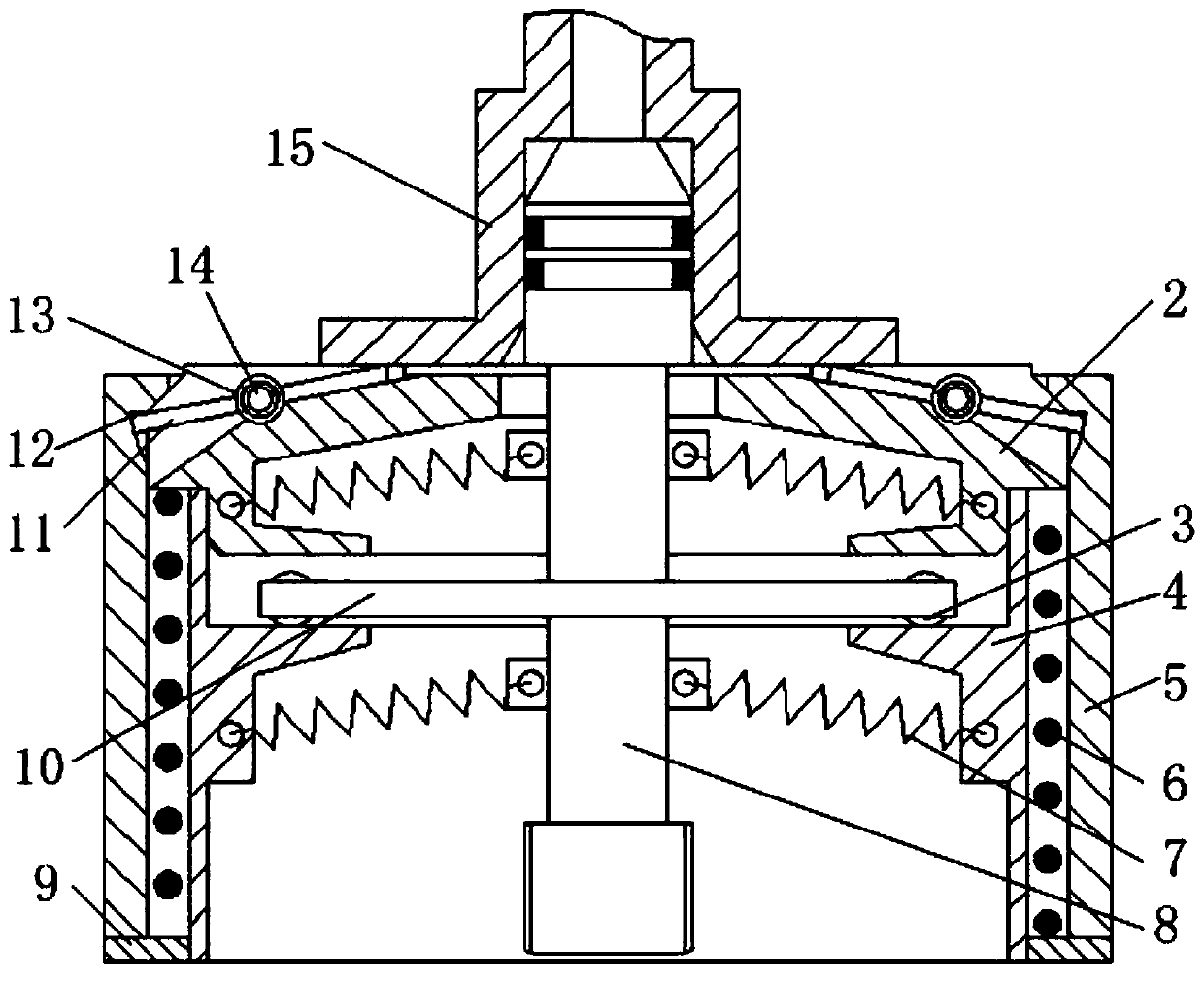

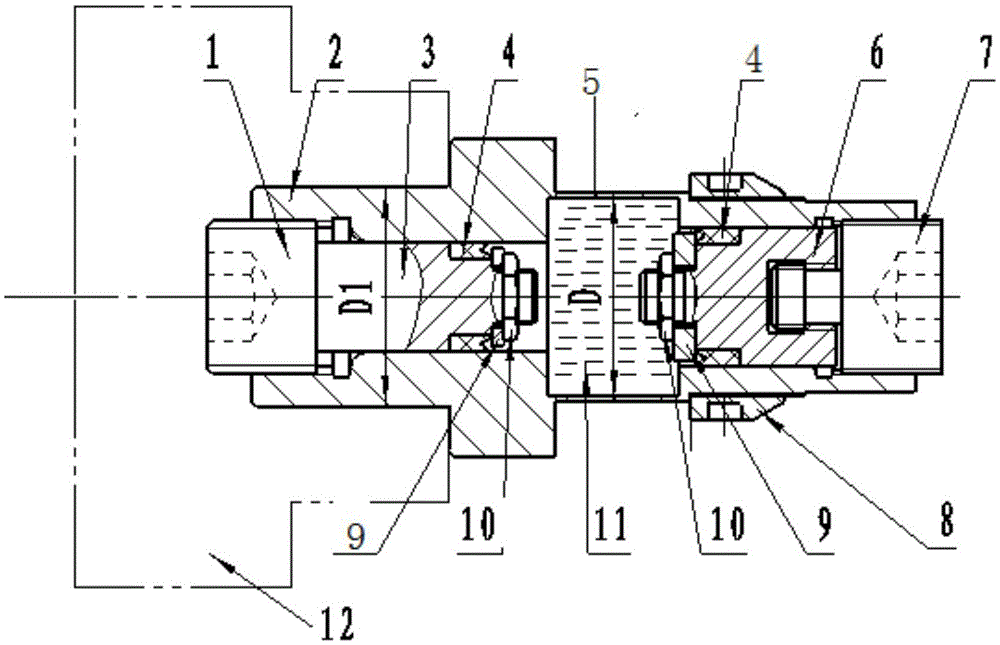

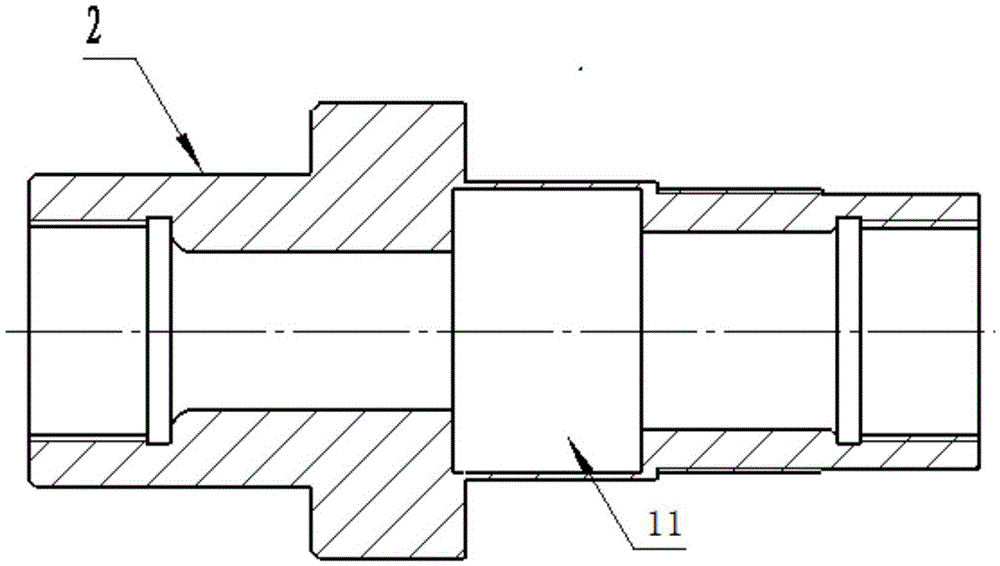

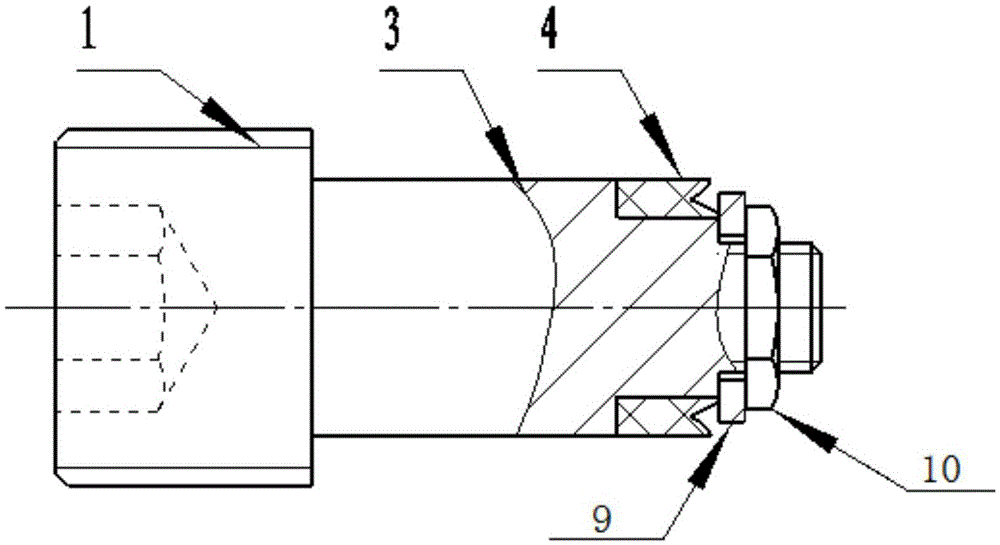

Hydraulic tensioning clamping mandrel for thin-wall shaft sleeve

InactiveCN105458317AReliable positioning and clampingSimple structureExpansion mandrelsEngineeringMachine tool

The invention discloses a hydraulic tensioning clamping mandrel for a thin-wall shaft sleeve. The hydraulic tensioning clamping mandrel is provided with a mandrel body located to the end face of a machine tool chuck or a spring sleeve. A step shaft table for locating the end face of a part to be machined is manufactured on the mandrel body, and step holes for assembling of plungers and a hydraulic oil cavity communicated with the step holes are formed in the two ends. The left pressure adjusting plunger (3) is sealed at the left end of the hydraulic oil cavity from the leftward step hole of the mandrel body (2), the right pressure adjusting plunger (6) is sealed at the right end of the hydraulic oil cavity from the rightward step hole of the mandrel body, and a closed container is formed. The to-be-machined part assembled on a rightward barrel of the mandrel body is clamped between the end face of the step shaft table of the mandrel body and a compressing nut (10) through the compressing nut (10). Sealing screws (7) are screwed down to drive the plungers to move and compress hydraulic oil in the hydraulic oil cavity, and the to-be-machined part clamped on the external circle tensioning mandrel body on the thin wall of the hydraulic oil cavity is expanded through pressure generated by the hydraulic oil cavity under the action of oil pressure. The hydraulic tensioning clamping mandrel is easy to manufacture and high in clamping precision, and a clamping area is stable and reliable in clamping.

Owner:SICHUAN LINGFENG AVIATION HYDRAULIC MACHINERY

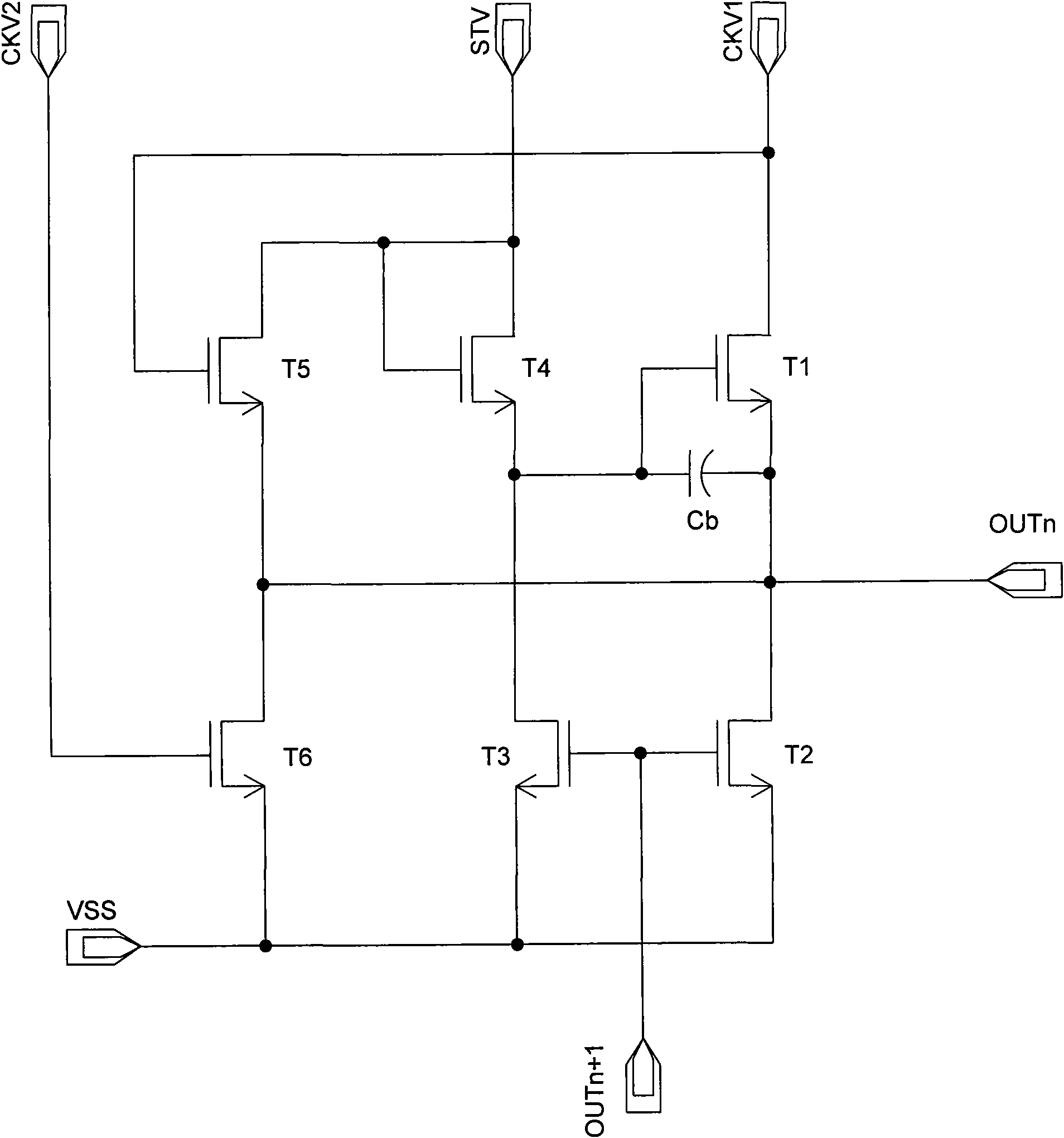

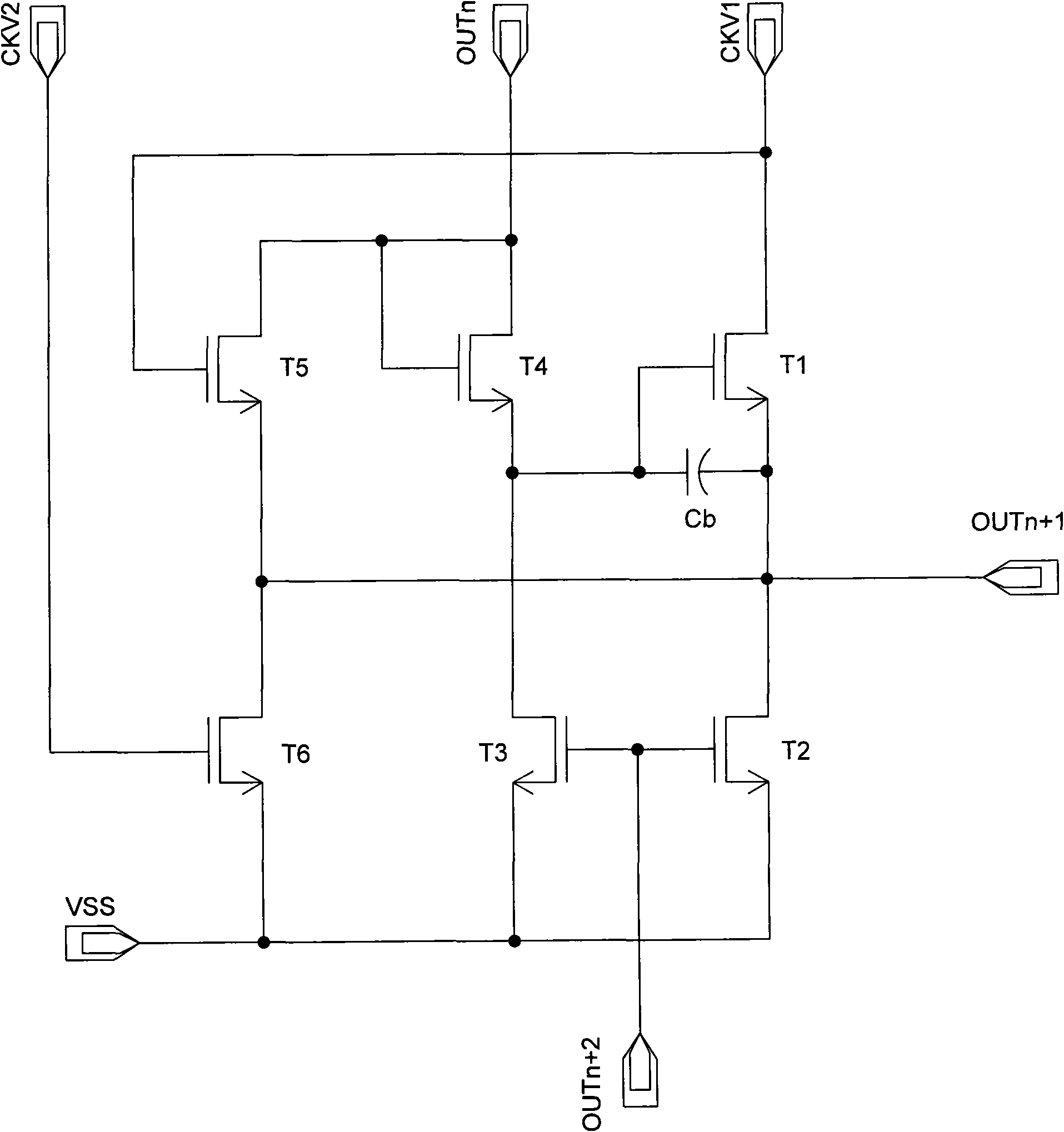

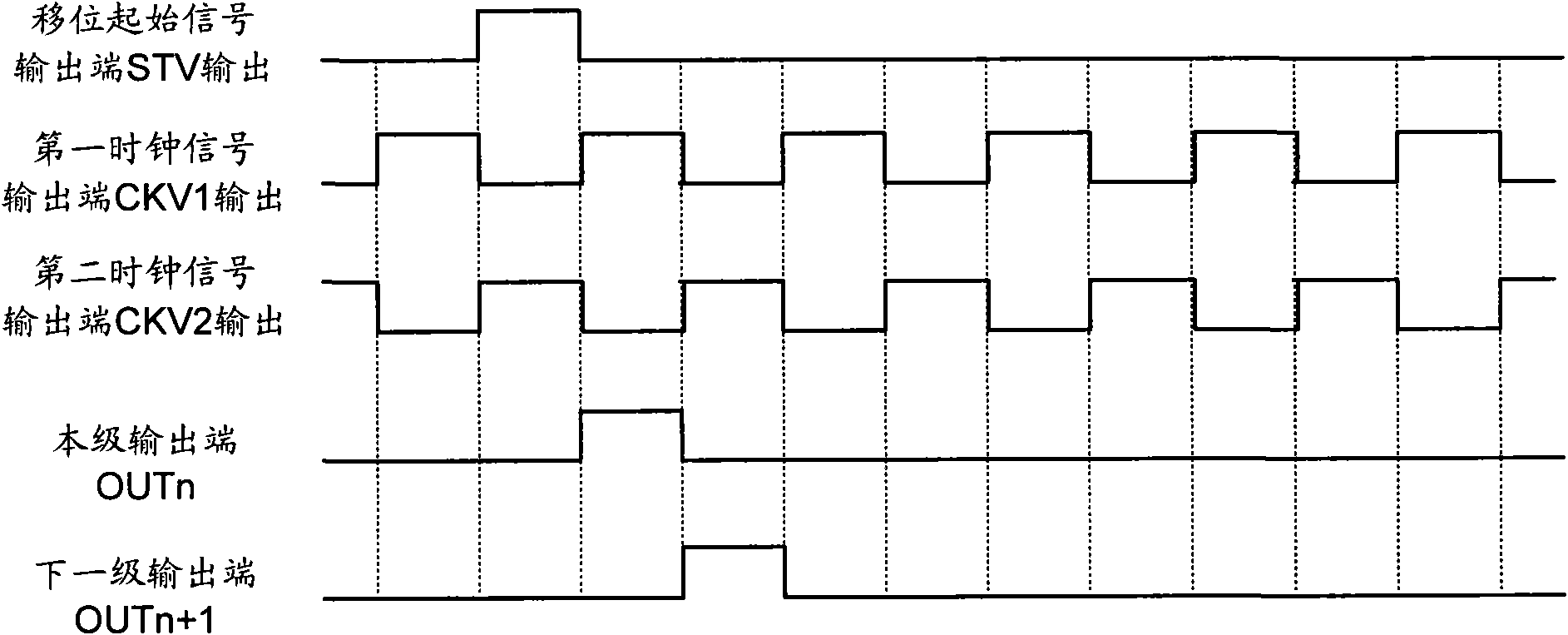

Shift register and grid electrode driving device thereof

ActiveCN101556830ARemain inactiveFloating gridStatic indicating devicesDigital storageCapacitanceShift register

The invention relates to a shift register and a grid electrode driving device thereof. The shift register comprises six thin film transistors directly fabricated on an array substrate; a capacitor is arranged between the grid electrode and the source electrode of the first thin film transistor; the drain electrode of the first thin film transistor is connected with the output end of a first clock signal; the grid electrode of the second thin film transistor is connected with the grid electrode of the third thin film transistor; the grid electrode of the fourth thin film transistor is connected with the drain electrode thereof; the drain electrode of the fourth thin film transistor is connected with the output end of a shift initial signal or the output end of the preceding grade, and the source electrode of the fourth thin film transistor is connected with the grid electrode of the first thin film transistor; the grid electrode of the fifth thin film transistor is connected with the output end of the first clock signal; and the grid electrode of the sixth thin film transistor is connected with the output end of a second clock signal. The invention keeps the invalid state of the output end of the current grade, ensures that grid lines can not drift and can not be affected by other noise voltages connected with the grid lines and guarantees that the shift register is in a reliable invalid state and can not result in misoperation.

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

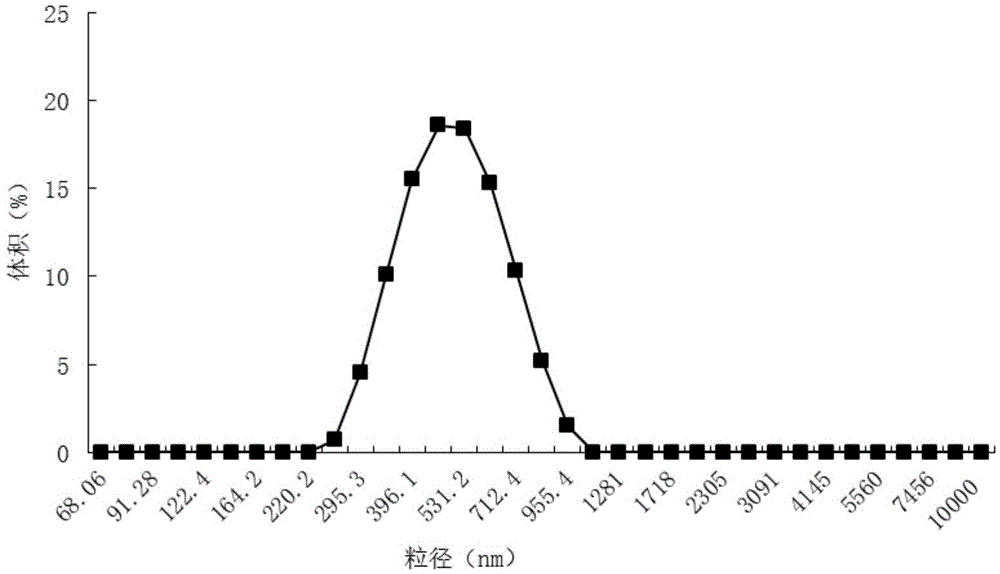

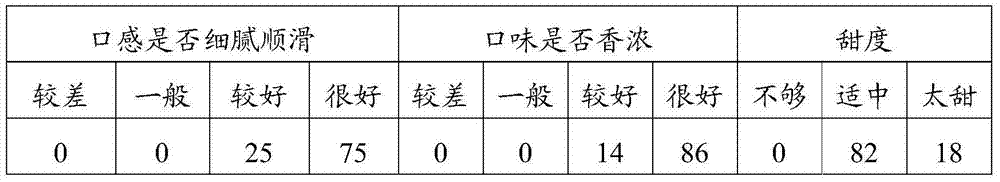

Processing method of composite vegetable protein drink

The invention discloses a processing method of composite vegetable protein drink, and belongs to the technical field of processing of vegetable protein drink. The processing method comprises the following steps: (1) adding 0.1-2.5 parts of apricot kernel, 0.1-2.5 parts of walnut kernel, 0.1-5 parts of peanut kernel, 0.1-12 parts of a sweetening agent and 0.1-1 part of a compound stabilizer to a blending container, adding water to 100 parts by weight, and stirring and mixing evenly; (2) decocting; (3) sequentially homogenizing at 85-95 DEG C under 20-10MPa of pressure and 15-40MPa of pressure; and (4) canning, sealing and sterilizing, wherein the composite stabilizer in the step (1) comprises the following raw materials in parts by weight: 0.1-0.45 part of polyglycerol fatty acid ester, 0.05-0.45 part of sodium bicarbonate or 0.02-0.45 part of sodium tripolyphosphate or combination of sodium bicarbonate and sodium tripolyphosphate, and 0.01-0.1 part of citric acid or 0.02-0.2 part of sucrose fatty acid ester or combination of citric acid and sucrose fatty acid ester; the apricot kernel, the walnut kernel and the peanut kernel in the step (1) are added to the blending container in a form of a minced material or slurry; and the composite vegetable protein drink prepared by the processing method is good in stability.

Owner:承德露露股份公司

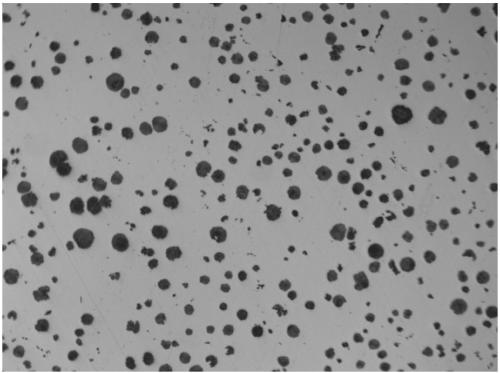

Control method for increasing number of graphite nodule by solid solution strengthening ferrite nodular cast iron with thick and large cross section

ActiveCN109402491AGuaranteed performanceGuaranteed uniformityProcess efficiency improvementPerformance indexSolid solution strengthening

The invention discloses a control method for increasing the number of graphite nodules by solid solution strengthening ferrite nodular cast iron with a thick and large cross section, which comprises the following steps: selecting materials: 50-70 percent of pig iron and 30-50 percent of scrap steel; smelting: adding the materials into an electric furnace for smelting, wherein the tapping temperature of the molten iron is 1420-1450 DEG C; spheroidizing: adding a spheroidizing agent, adding a covering agent on the spheroidizing agent, and then spheroidizing, wherein the spheroidizing temperatureis 1420-1450 DEG C; inoculating: adding a silicon-aluminum-calcium-barium type inoculant during a primary inoculation, and respectively adding the inoculant on the surface of the covering agent and the other side of a ladle dam before tapping, wherein the distribution proportion is 50 percent; adding a trace amount of alloy Sb along with the flow of the molten iron during casting, wherein the adding amount of the alloy Sb is 0.003-0.005% of the total amount of the molten iron, molding, casting and cooling: ensuring that the casting opening temperature is controlled to be <= 300 DEG C, and thecasting is obtained by air cooling after the casting is opened. The control method has the advantages of obtaining higher number of the graphite nodules, ensuring a metallographic structure and goodconsistency of performance indexes, thereby improving the quality of the castings and prolonging the service life.

Owner:宁波日星铸业有限公司

Plant-based milk tea beverage and preparation method

PendingCN112586576ARealize the design conceptShort molecular chainTea extractionCoffee extractionBiotechnologyAntioxidant

The invention relates to the technical field of milk tea beverages, and provides a plant-based milk tea beverage and a preparation method aiming at the current situation that milk tea on the market ismilk-based milk tea and is lack of a full-plant-based milk tea beverage without animal milk fat. The beverage is prepared from the following components: a plant base material, a tea raw material, a coffee raw material, a stabilizer, a fat base material, an emulsifier, an antioxidant, nisin, an acidity regulator, a sweet component, nuts and the like; the plant base material is one or more of hulled rice or powder and coconut milk of cereal crop fruits; and the fat base material is one or more of coconut powder, coconut oil, medium-chain triglyceride and sunflower seed oil. The pursuit of current consumers for the health concept is met, compared with milk-based milk tea or milk-based milk tea containing plant materials on the market, the concept of whole-plant-based milk tea is achieved, and the consumption requirements for being healthier, more nutritional and unique in taste are met.

Owner:HANGZHOU WAHAHA TECH

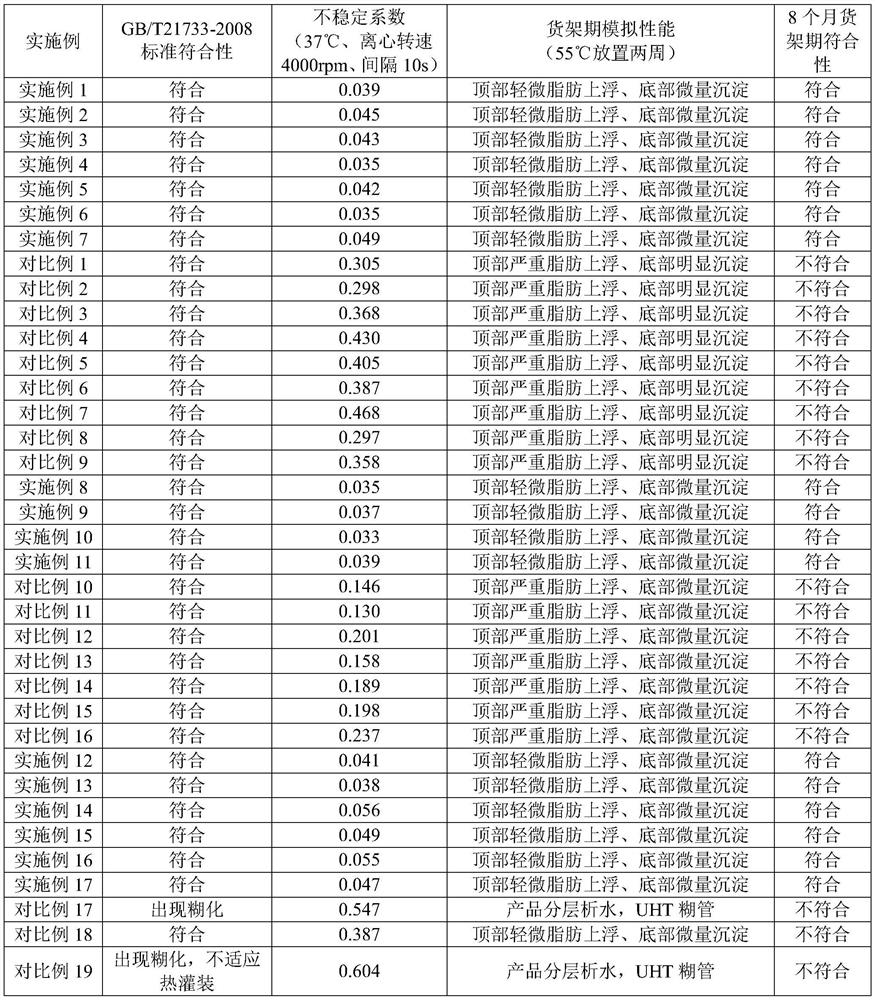

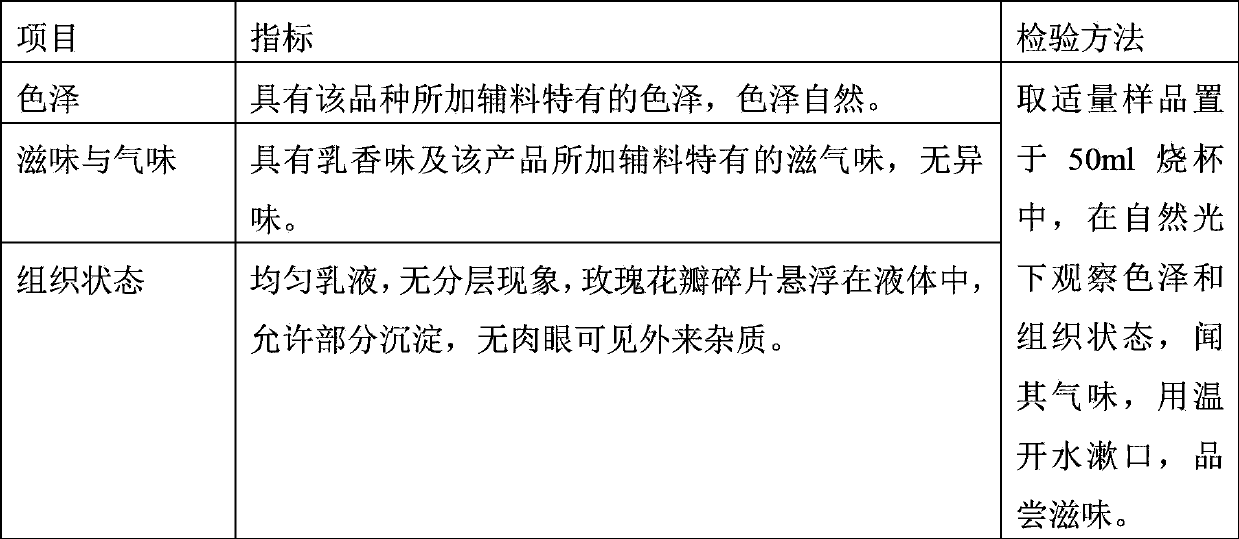

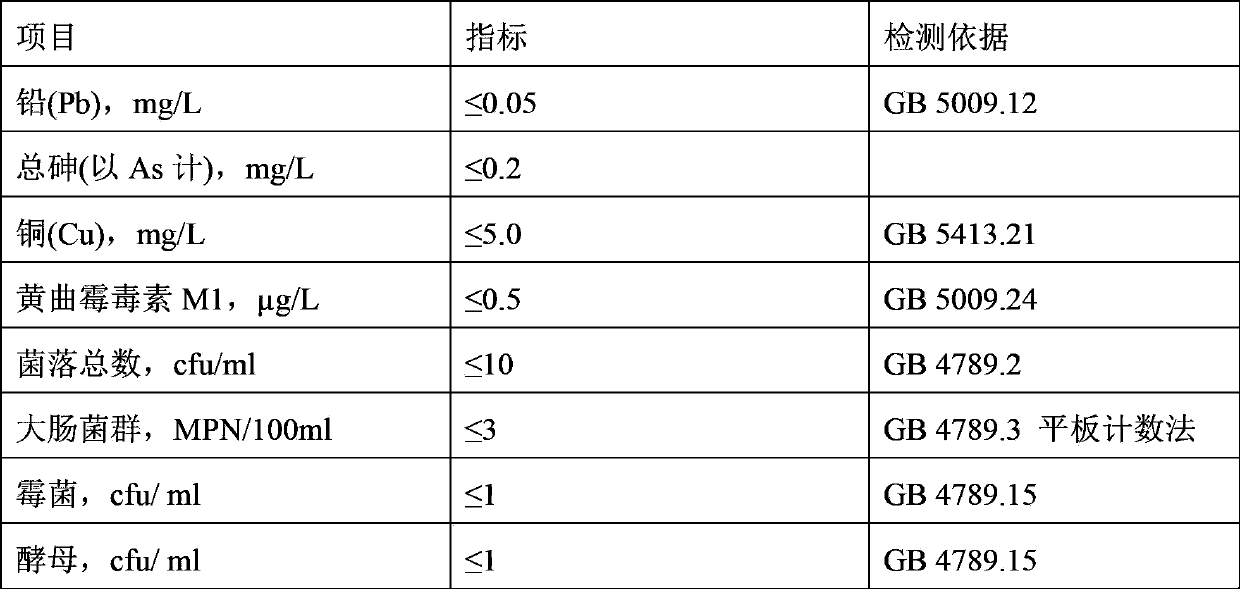

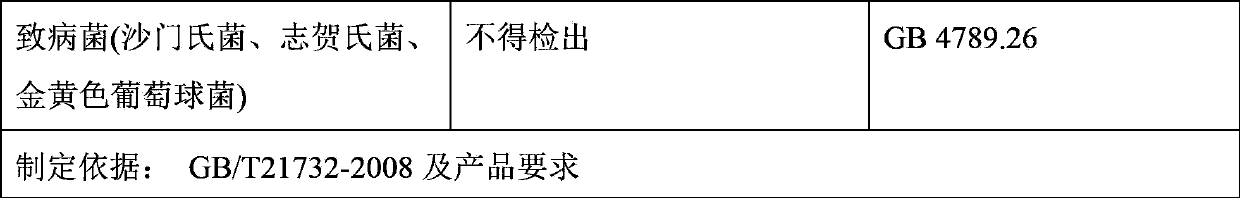

Milk beverage suitable for women to drink, and its preparation method

The invention relates to the field of liquid milk, and concretely relates to a milk beverage suitable for women to drink, and its preparation method. The milk beverage suitable for women to drink comprises, by weight, 500-800 parts of low fat milk, 10-80 parts of a red date juice, 10-80 parts of a wolfberry juice, 10-80 parts of a rose extract liquid, 0.5-1.0 part of rose petal chip, 0.3-2.5 parts of a thickening agent, and 5.0-10 parts of maltitol; and the fat content of the low fat milk is 1.0-1.5wt%. The liquid milk product contains the low fat milk, and the red date juice, the wolfberry juice, the rose extract liquid and the rose petal chip are specially added into the liquid milk product, and can be effectively combined with the proteins of the milk, so the milk beverage provided by the invention has the advantages of reasonable and balanced nutrition, and nutrition value improvement, and is suitable for specific people to drink.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

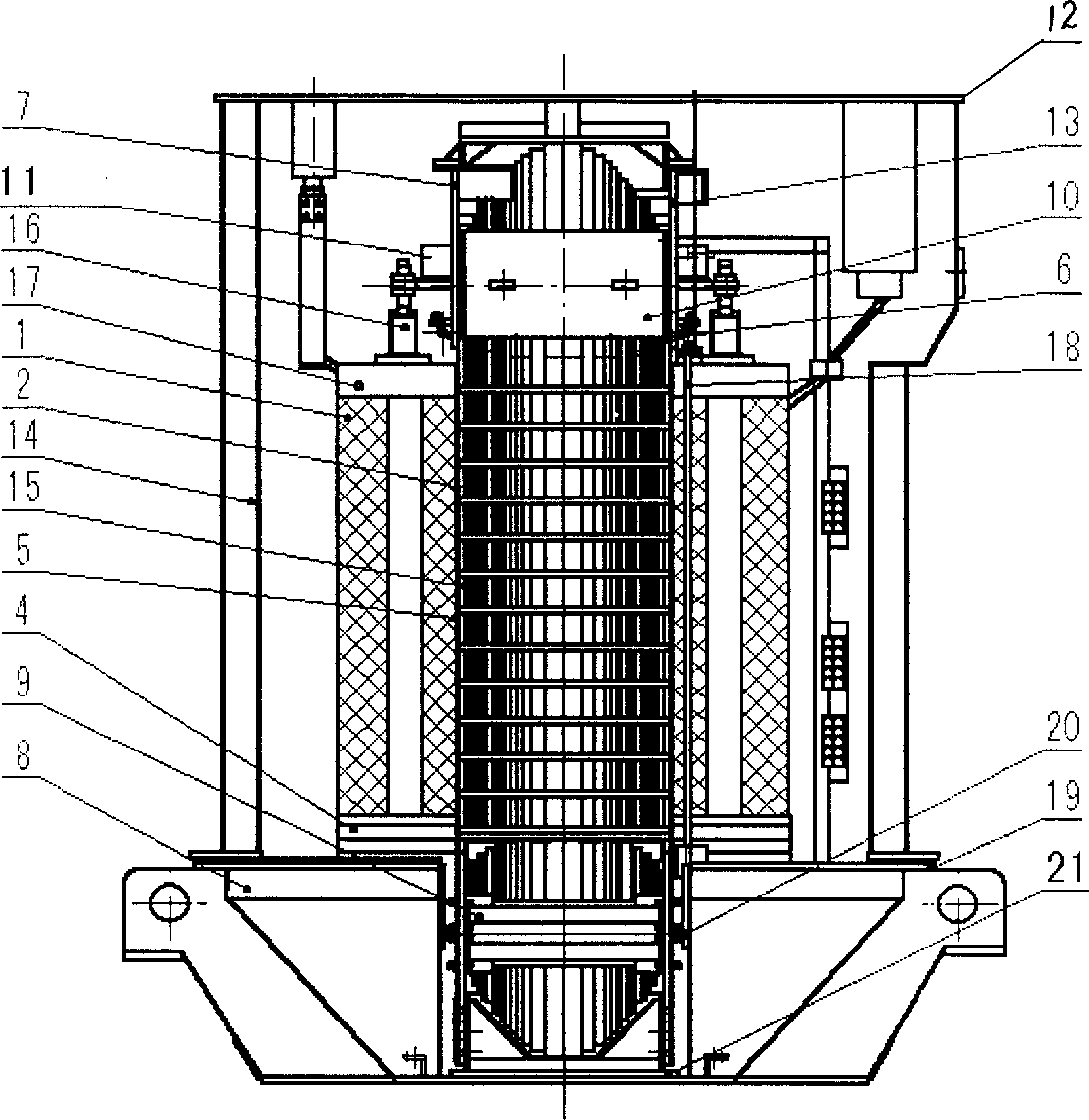

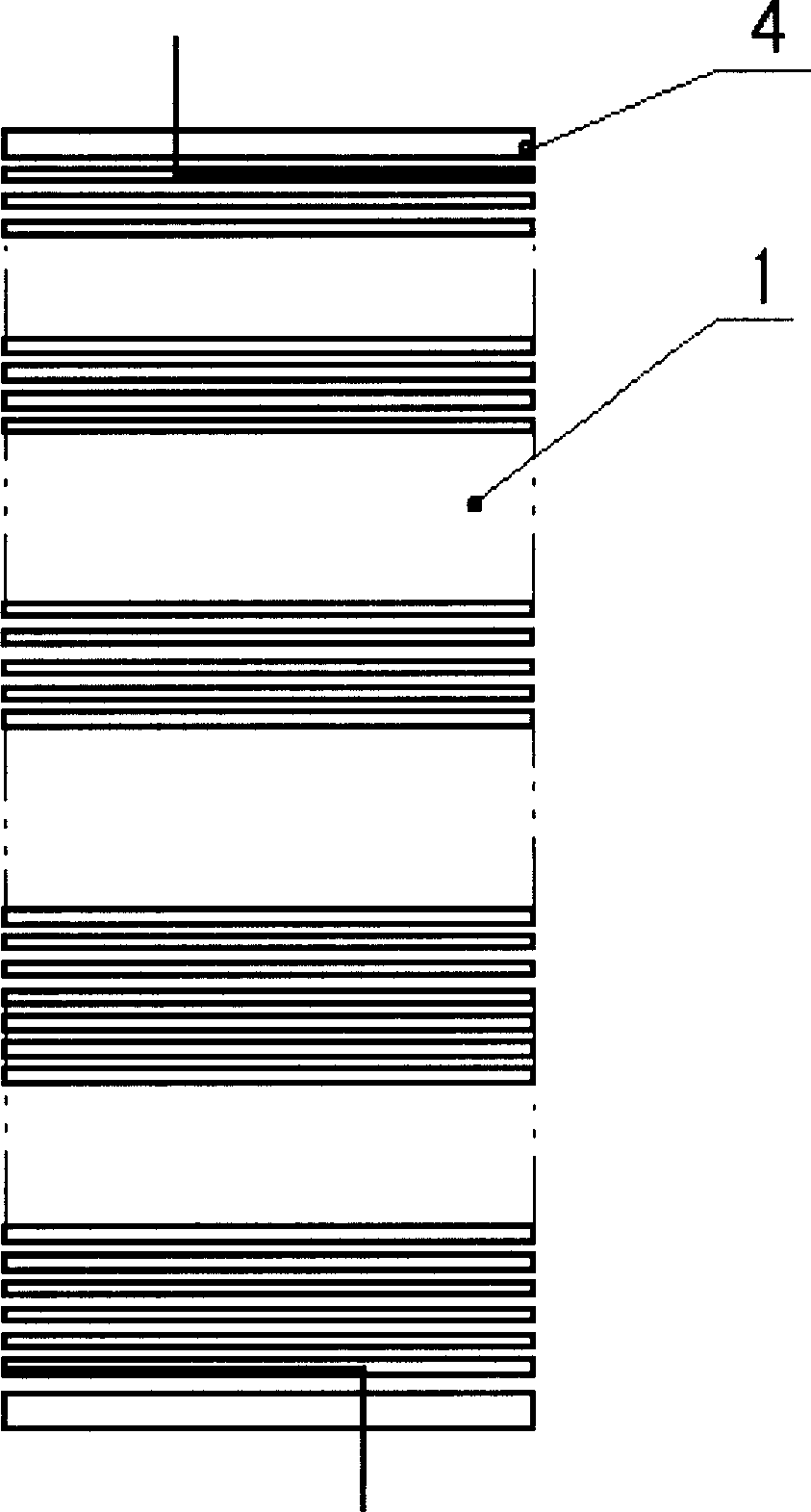

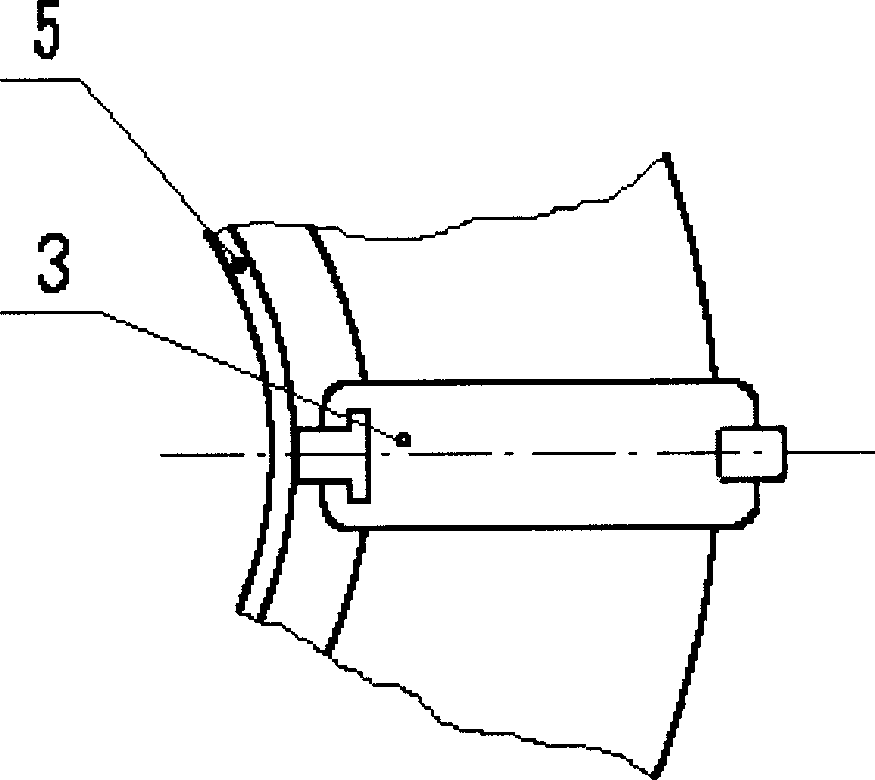

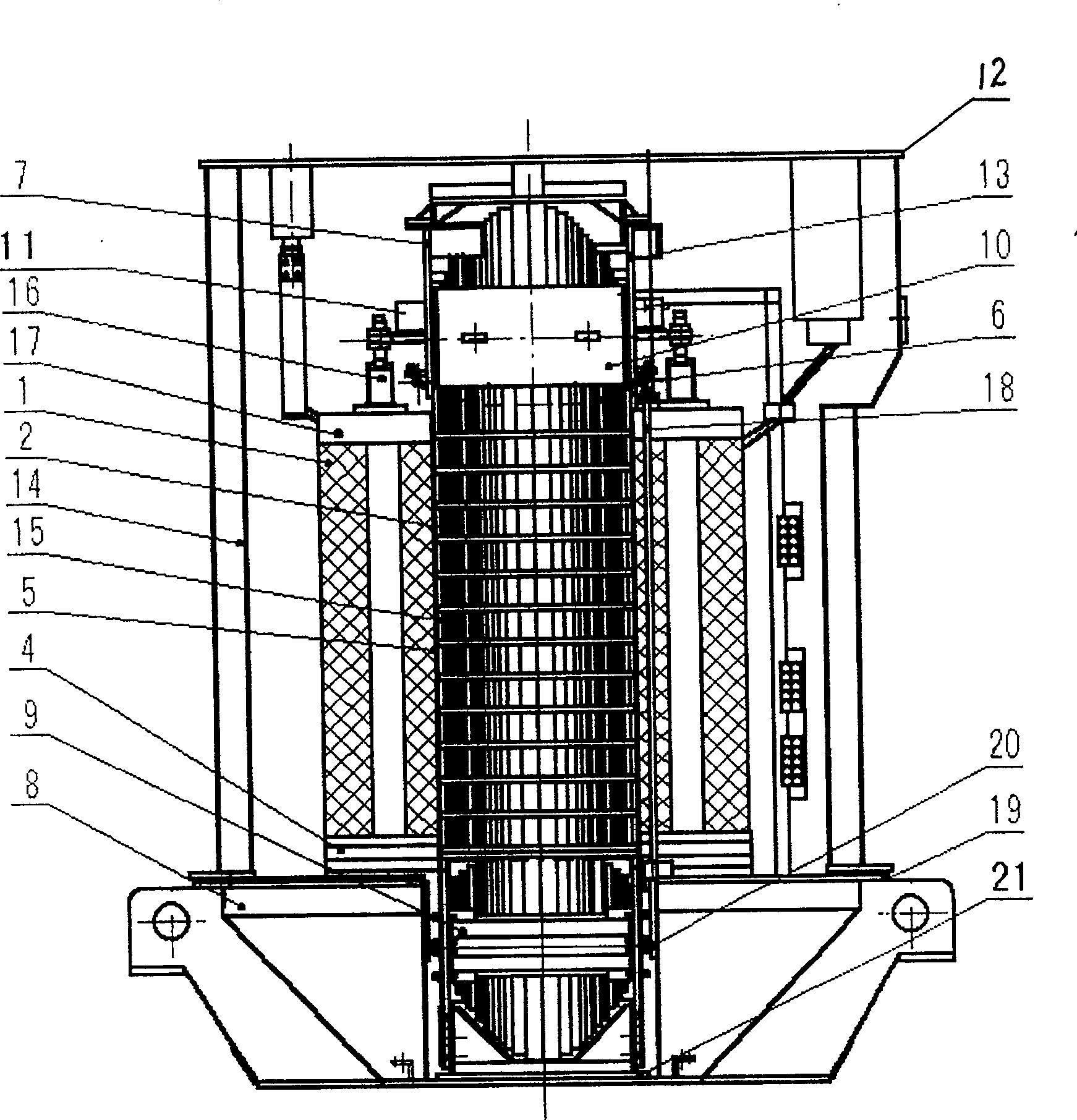

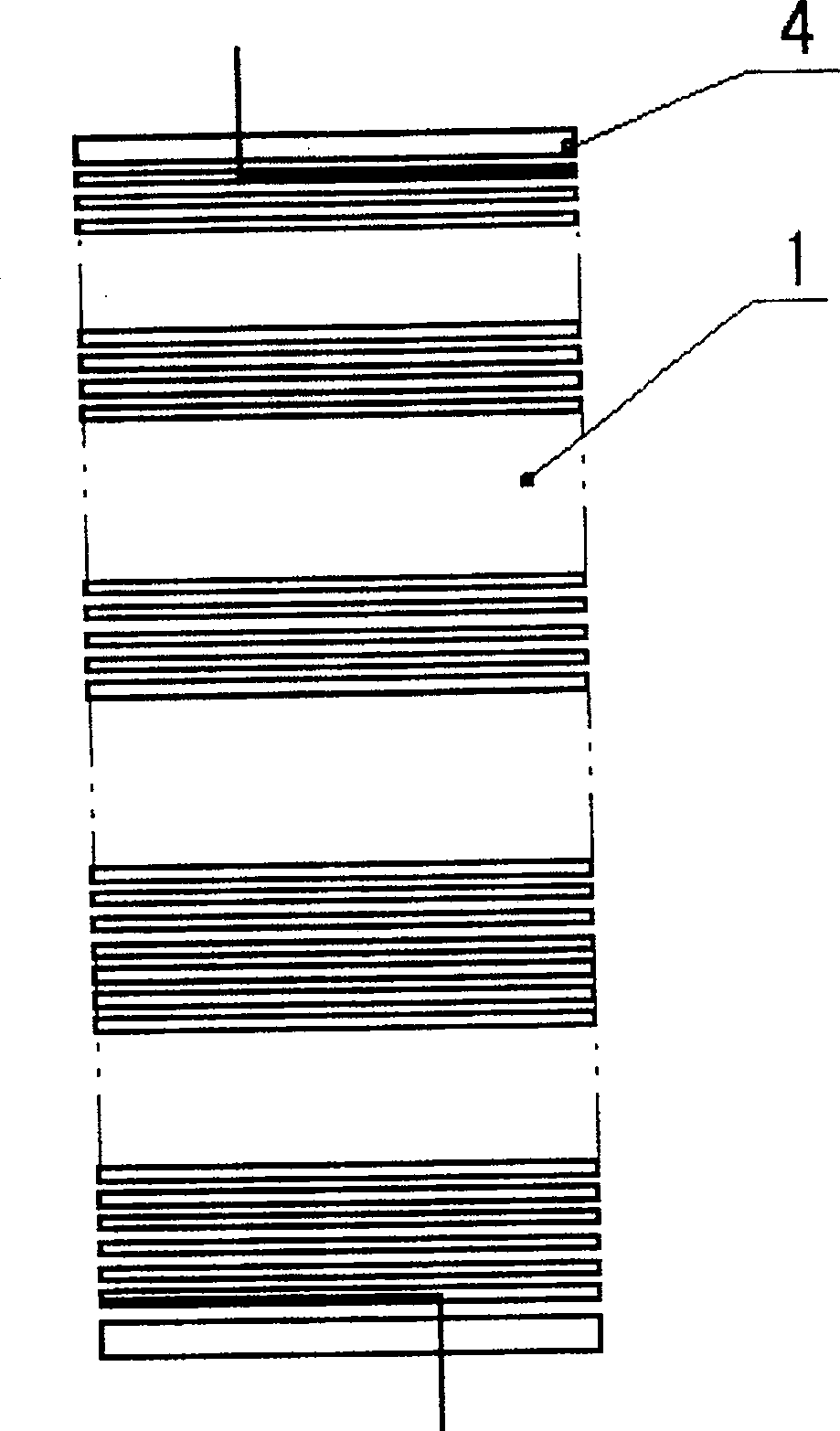

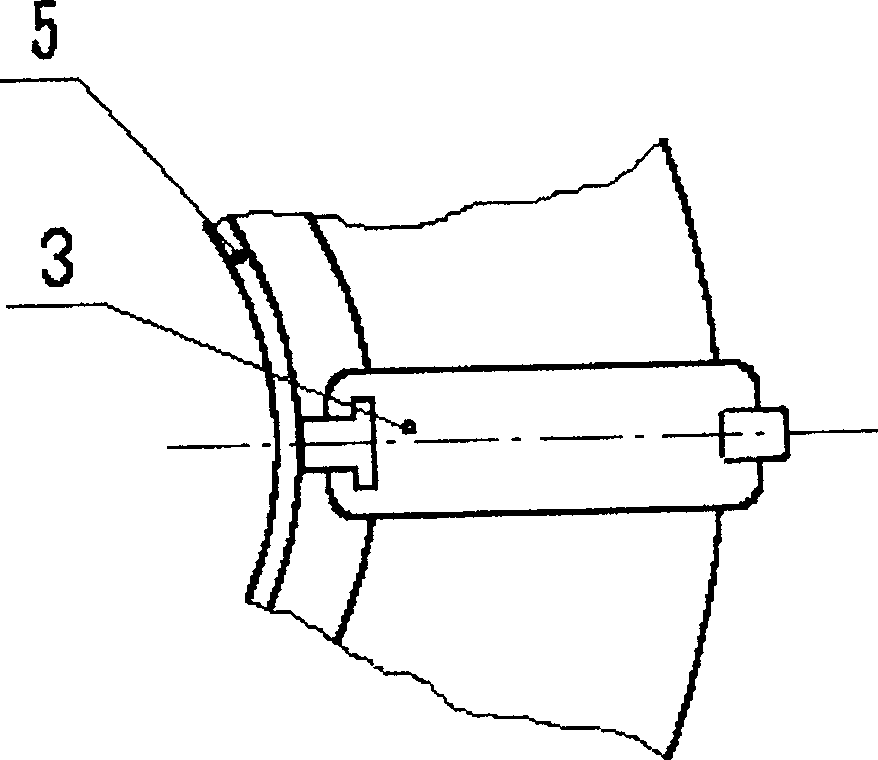

Railway high voltage traction transformer

ActiveCN1828790AUniform pressureNo horizontal displacementTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresFiberManufacturing technology

A railway high voltage traction transformer belongs to transformer manufacturing technology field. It contains casing with two bottom, main unit consisting of and iron core, oil tank having two sections, both end of winding having insulation end ring with inner fiber container, side beam, upward pull strap, foot pad, drawplate, high voltage and low voltage upper yoke clamping to form one hard entirety winding axial direction fastened through pressure nail and drawplate, upper part of tank set with four positioning device, main unit located on casing bottom. Said invention can prevent displacement or damage between casing and main unit in transportation process and without suspended core inspection in arriving site.

Owner:WOLONG ELECTRIC YINCHUAN TRANSFORMER

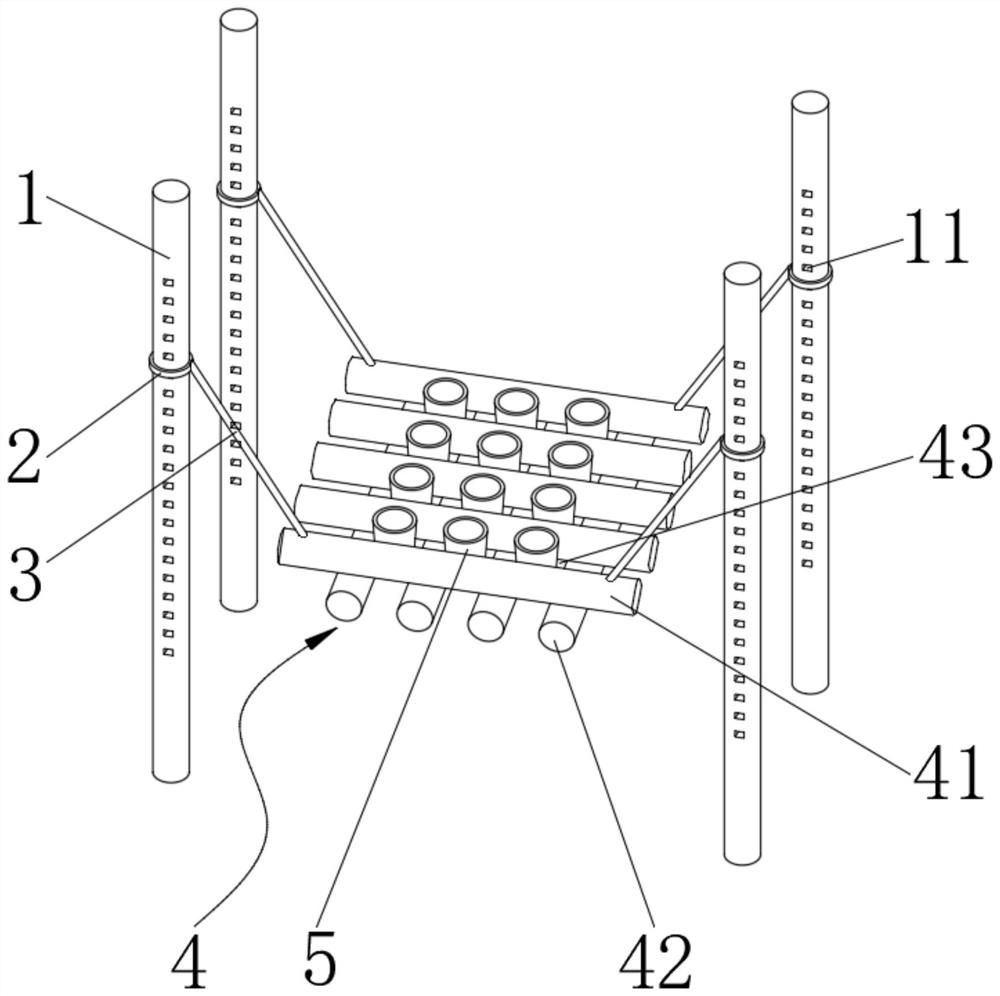

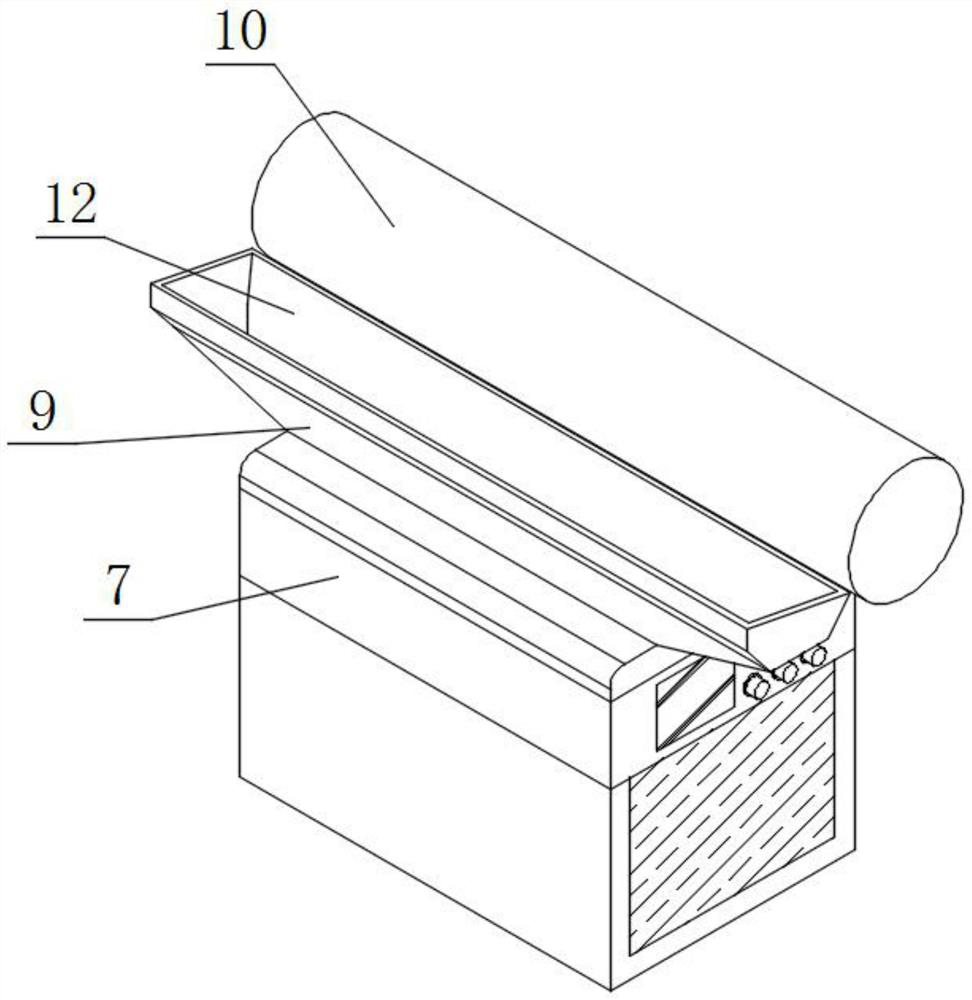

Submerged plant artificial floating bed capable of being lifted manually

PendingCN113924962ADepth of needsAvoid deformationAgriculture gas emission reductionCultivating equipmentsEnvironmental engineeringMechanical engineering

The invention discloses a submerged plant artificial floating bed capable of being lifted manually. The submerged plant artificial floating bed comprises a fixing pile, a first clamping groove, a slipknot, a first clamping block, a connecting rope, a floating bed body, a flowerpot, a second clamping groove, a rotating shaft, a shaft sleeve, a second clamping block, a torsion spring and a mounting groove, the floating bed body comprises a first plate layer, a second plate layer, a fixing groove and the mounting groove; and the first plate layer is distributed at the top end of the floating bed body, the second plate layer is distributed at the top end of the bottom end of the floating bed body, and the second plate layer is fixedly connected to the outer wall of the bottom end of the first plate layer. According to the submerged plant artificial floating bed capable of being lifted manually, compared with an existing artificial floating bed body for submerged plants, the depth of the floating bed body can be adjusted along with the height of the water surface, so that the required depth of plants is met; the purification capability is strong, and the operation is simple; and the submerged plant artificial floating bed capable of being lifted manually is low in cost and high in strength, materials are not prone to deformation or decay, the flowerpot cannot float upwards, and the flowerpot is made of degradable materials, so that secondary pollution is avoided.

Owner:ZAOZHUANG UNIV

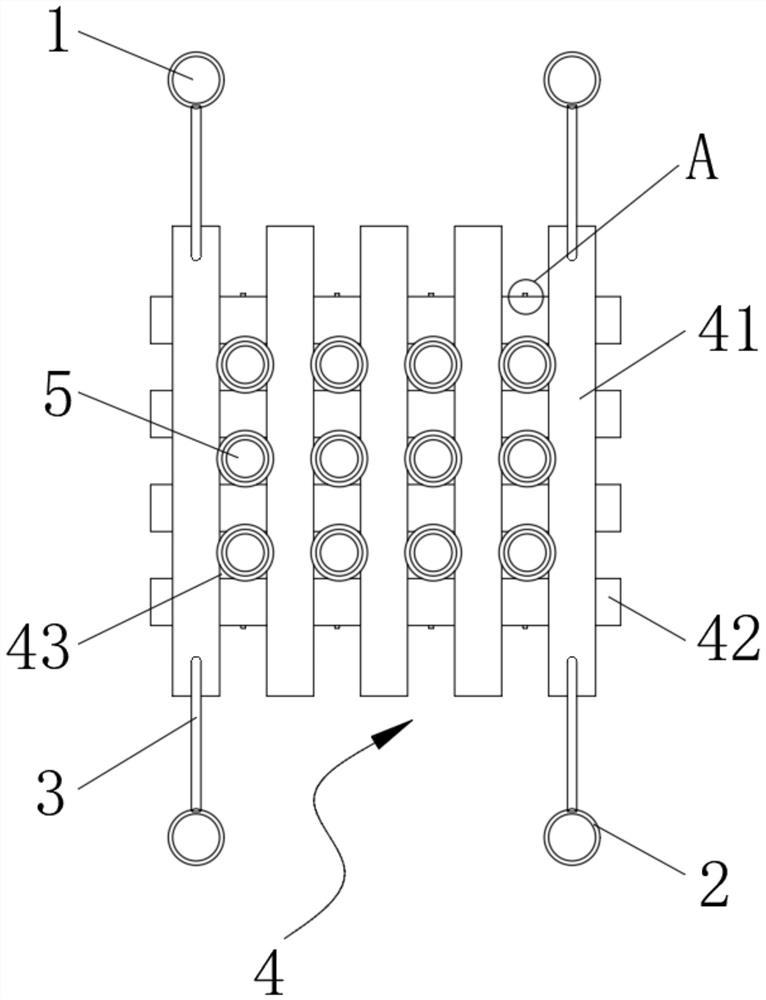

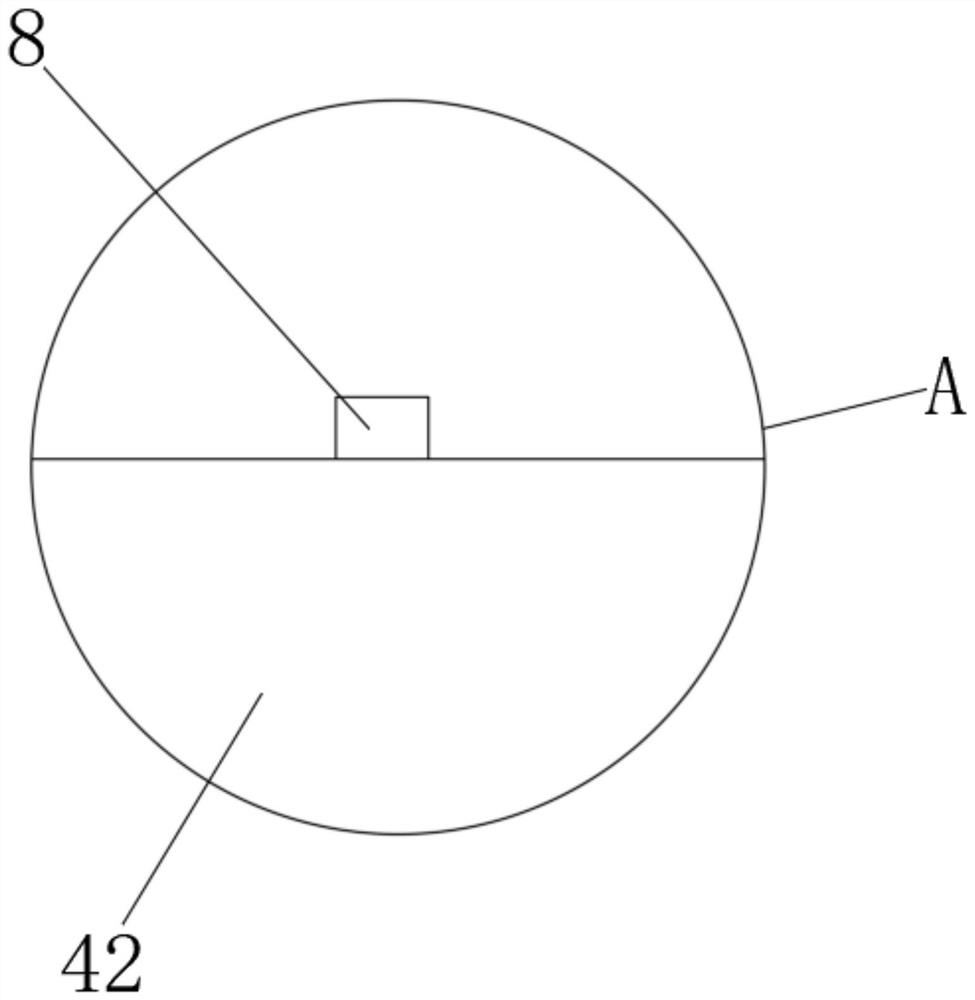

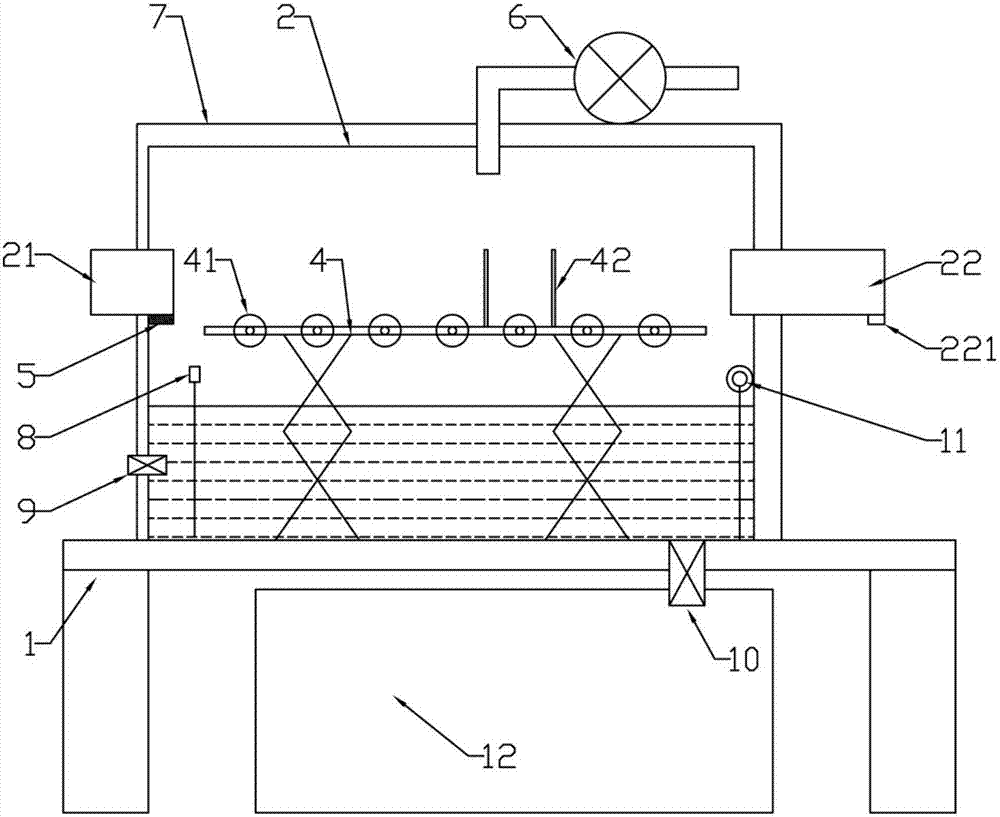

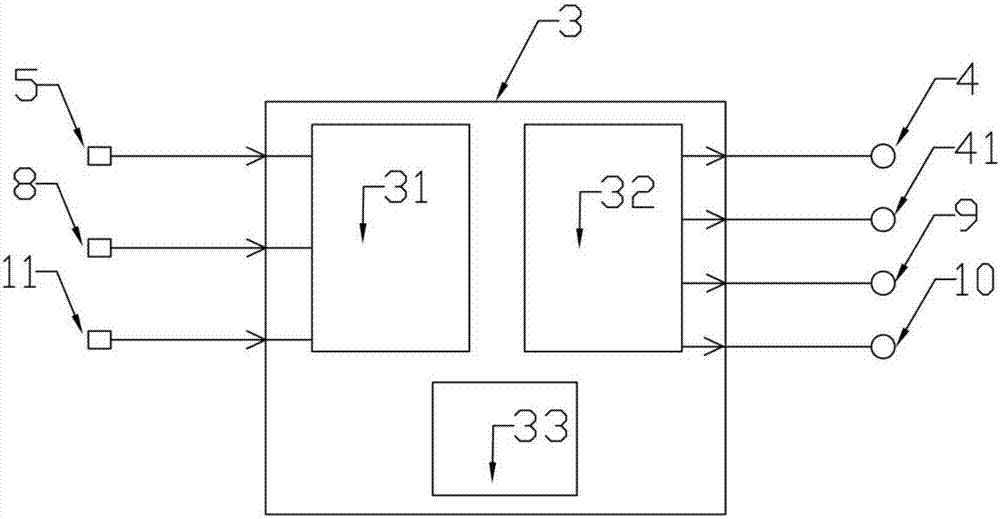

Liquid cooling profile extrusion sizing device

The invention discloses a liquid cooling profile extrusion sizing device, and relates to the field of cooling sizing after profile extrusion. The liquid cooling profile extrusion sizing device comprises a stand, and a cooling liquid box mounted on the stand; and a feed pipe and a discharge pipe are respectively arranged at the left and right ends of the cooling liquid box. The liquid cooling profile extrusion sizing device is characterized by further comprising a controller; cooling liquid is fed in the cooling liquid box; the cooling liquid box is longer than a profile; a lifting support frame is arranged in the cooling liquid box; multiple positioning conveying rollers are arranged on the support frame; when the support frame is ascended to the highest height, the conveying heights of the positioning conveying rollers and the height of the discharge pipe are on the same horizontal plane; when the support frame is lowered to the lowest height, the profile is totally dipped in the cooling liquid; and the feed pipe is provided with a pressure sensor for connecting with the controller. The liquid cooling profile extrusion sizing device is compact in structure, and enables the profile to be totally dipped in the cooling liquid in the cooling liquid box for quick cooling.

Owner:佛山市众禾铝业有限公司

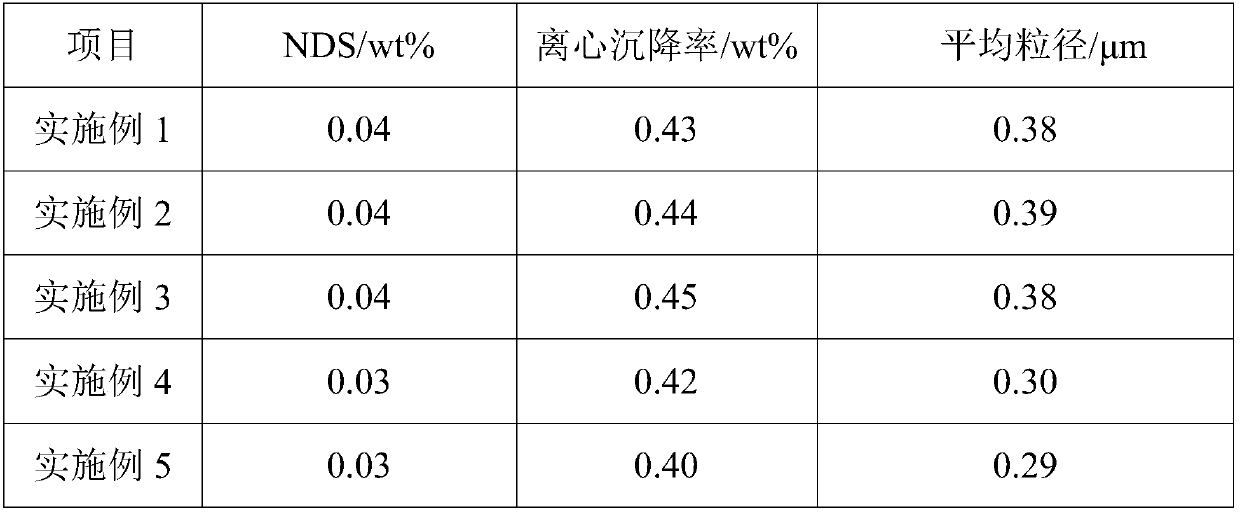

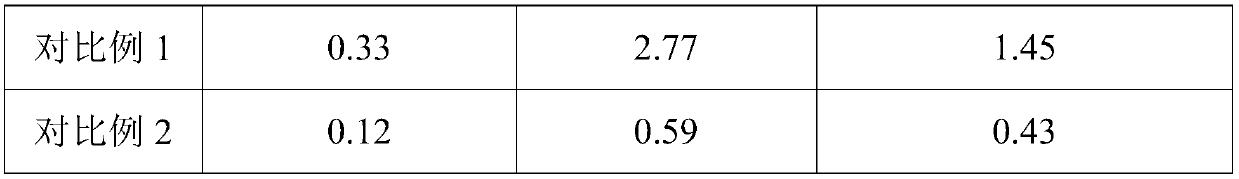

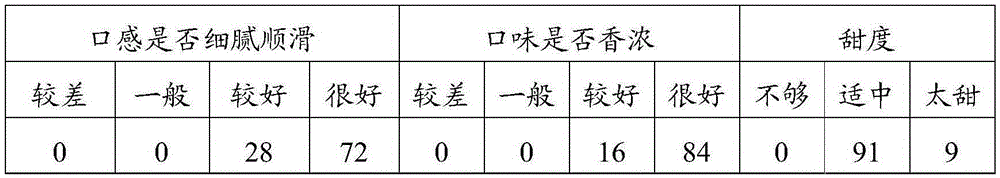

Preparation technology of bean milk

The invention discloses a preparation technology of bean milk. Through adoption of the technology, the routine operation that in the prior art, in order to avoid phenomena of floating up and precipitating of fat in soybean milk, bean dregs need to be wholly separated out, and if separation is not thorough, additives need to be externally added to avoid floating up and precipitating of fat in the soybean milk can be broken through. The inventor initiatively mixes soybeans with water for preparing pulp, then the obtained pulp is directly homogenized at 1150-1300bar, the space structures of soybean dietary fibers can be expanded, and the expanded space structures of the soybean dietary fibers can achieve the effect of stabilizing a bean milk system, so that the bean milk can be guaranteed notto generate the phenomena of floating up and precipitating of the fat, the bean dregs do not need to be separated, and the additives do not need to be externally added; and in addition, the bean milkis fine, smooth and soft in mouth feel, mellow and highly-fragrant. In addition, according to the bean milk disclosed by the invention, the soybean dietary fibers are not separated completely, and bran-new whole bean milk is prepared.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Control method for increasing the number of graphite nodules in solid solution strengthened ferritic ductile iron with thick and large section

ActiveCN109402491BEnsure consistencyStable and reliable gating systemProcess efficiency improvementPerformance indexDuctile iron

The invention discloses a control method for increasing the number of graphite nodules by solid solution strengthening ferrite nodular cast iron with a thick and large cross section, which comprises the following steps: selecting materials: 50-70 percent of pig iron and 30-50 percent of scrap steel; smelting: adding the materials into an electric furnace for smelting, wherein the tapping temperature of the molten iron is 1420-1450 DEG C; spheroidizing: adding a spheroidizing agent, adding a covering agent on the spheroidizing agent, and then spheroidizing, wherein the spheroidizing temperatureis 1420-1450 DEG C; inoculating: adding a silicon-aluminum-calcium-barium type inoculant during a primary inoculation, and respectively adding the inoculant on the surface of the covering agent and the other side of a ladle dam before tapping, wherein the distribution proportion is 50 percent; adding a trace amount of alloy Sb along with the flow of the molten iron during casting, wherein the adding amount of the alloy Sb is 0.003-0.005% of the total amount of the molten iron, molding, casting and cooling: ensuring that the casting opening temperature is controlled to be <= 300 DEG C, and thecasting is obtained by air cooling after the casting is opened. The control method has the advantages of obtaining higher number of the graphite nodules, ensuring a metallographic structure and goodconsistency of performance indexes, thereby improving the quality of the castings and prolonging the service life.

Owner:宁波日星铸业有限公司

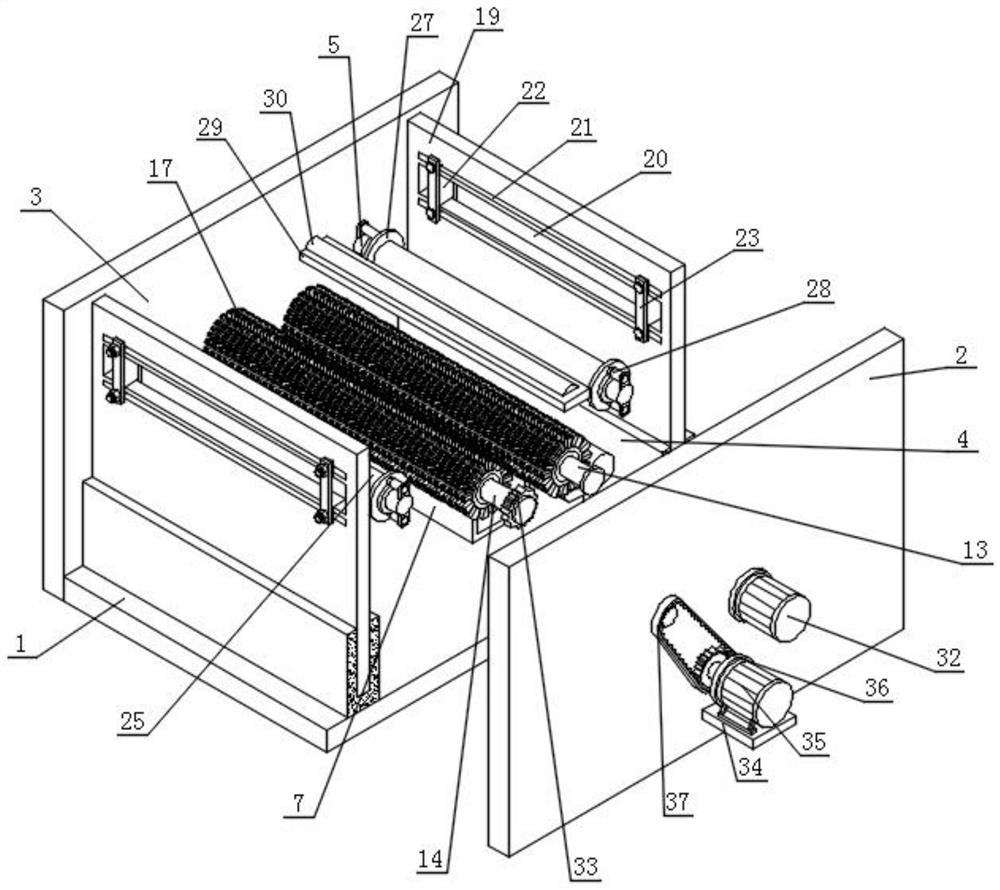

Textile operation equipment with thread layer carding structure

InactiveCN113897755APrompt disengagementImproves the effectiveness of carding operationsMechanical cleaningPressure cleaningStructural engineeringMechanical engineering

The invention discloses textile operation equipment with a thread layer carding structure. The equipment comprises a bottom plate, a front plate, a rear plate, U-shaped inserting plates, traction rollers and a fixing plate; the front plate and the rear plate are installed on the front face and the back face of the bottom plate respectively; the top of the bottom plate is provided with the two sets of U-shaped inserting plates arranged side by side; the front face of the rear plate is provided with the two sets of traction rollers arranged side by side; the fixing plate is installed on the back face of the front plate; and dust suction machines are installed at the bottom of the fixing plate and the top of the bottom plate correspondingly. Miscellaneous wool in a brush rod can be removed through a tooth groove plate, and then the miscellaneous wool is sucked through the dust suction machines; disassembly convenience is achieved among a connecting cylinder, the brush rod and a threaded sleeve; the distance between two sets of moving blocks and the distance between two sets of annular plates arranged in the front-back direction in the equipment are adjustable, so that the equipment has the adjusting and deviation preventing functions on textiles; and when the textiles are conveyed, water can be sprayed to prevent floating of the miscellaneous wool.

Owner:南通中邦丝织有限公司

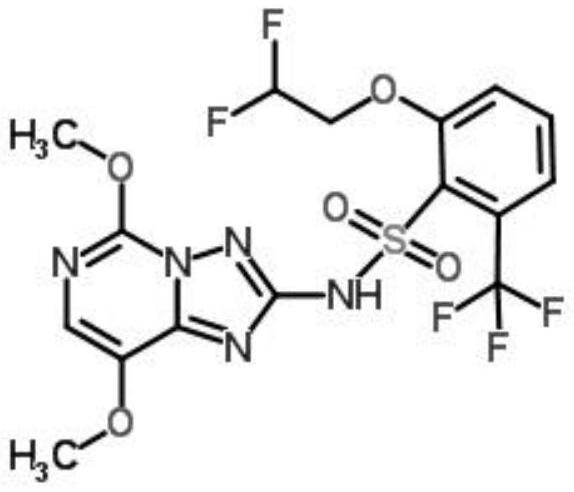

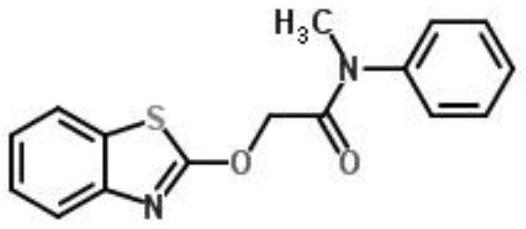

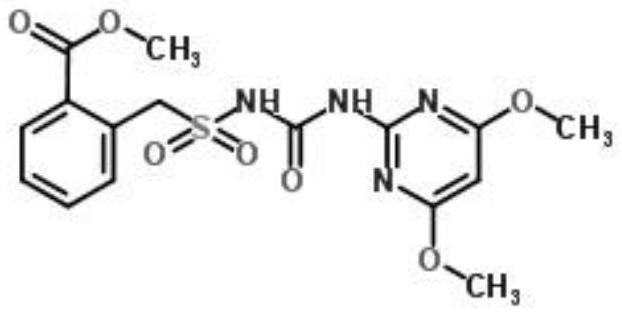

Paddy field weeding granule containing penoxsulam, mefenacet and bensulfuron methyl as well as preparation method and application thereof

PendingCN112155014AEffective controlImprove the effect of prevention and controlBiocideAnimal repellantsBensulfuron methylActive ingredient

The invention relates to a paddy field weeding granule containing penoxsulam, mefenacet and bensulfuron methyl as well as a preparation method and application of the paddy field weeding granule. The granule comprises a A-phase component, a B-phase component and a C-phase component, wherein the A-phase component comprises 70%-95% of a granule carrier, the B-phase component comprises 0.1%-30% of functional mother powder containing three active ingredients, namely penoxsulam, mefenacet and bensulfuron methyl, and the C-phase component contains 1%-40% of a coalescing agent; and the coalescing agent comprises a binder, an inducer and a warning color. The paddy field weeding granule containing penoxsulam, mefenacet and bensulfuron methyl is scientific and reasonable in design, is prepared by a coating film forming method, is good in film forming, glossy, good in wear resistance, free of caking, falling and dust, high in safety, capable of being separately spread, capable of being mixed witha fertilizer to be spread, convenient, rapid, easy to operate and capable of reducing labor.

Owner:TIANJIN HIGHPOINT PLANT PROTECTION

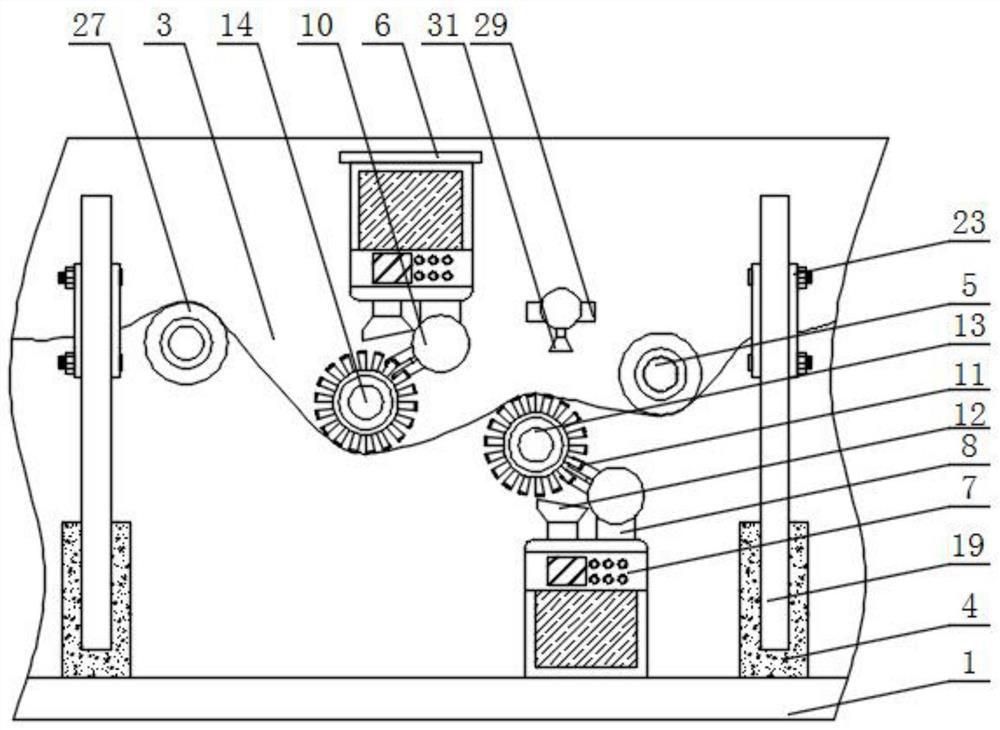

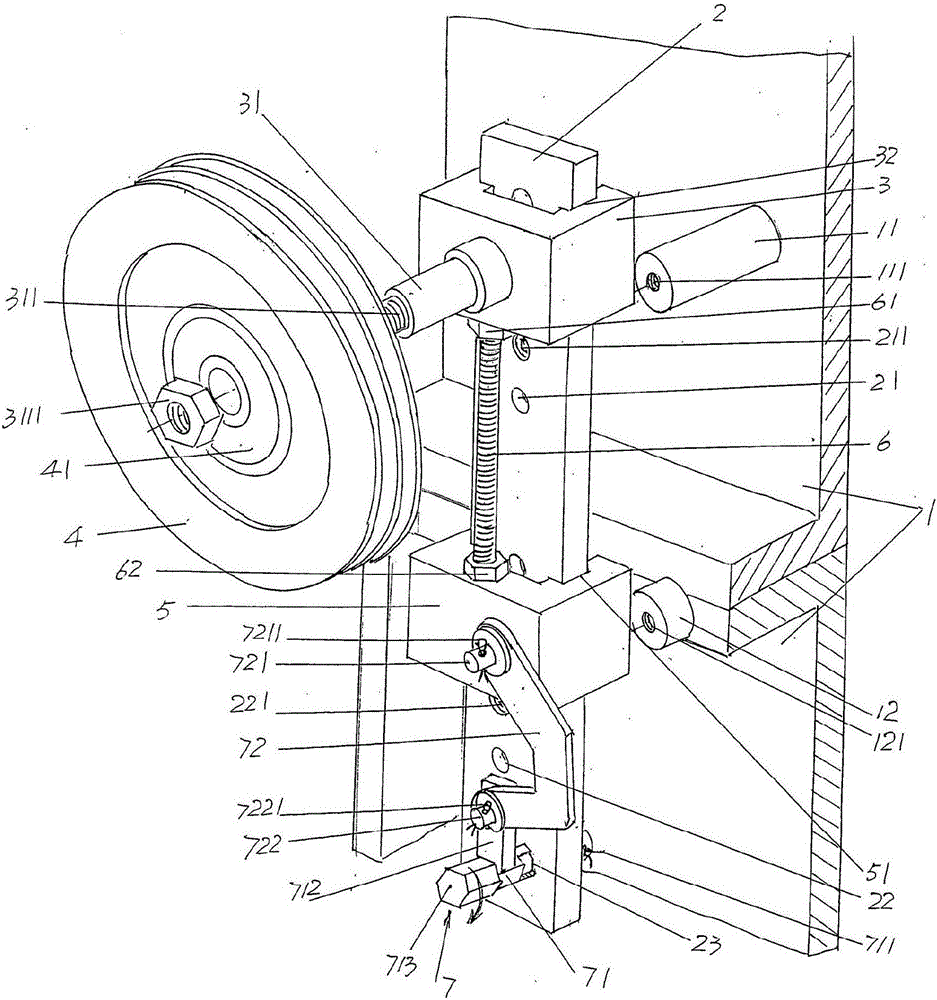

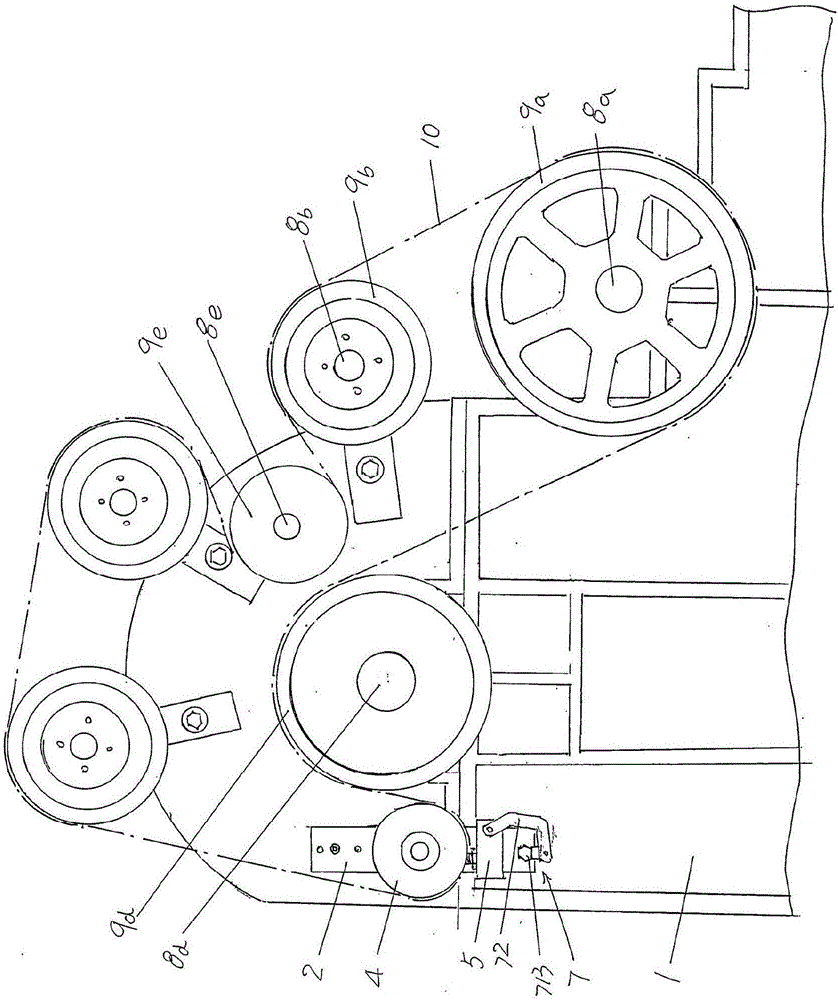

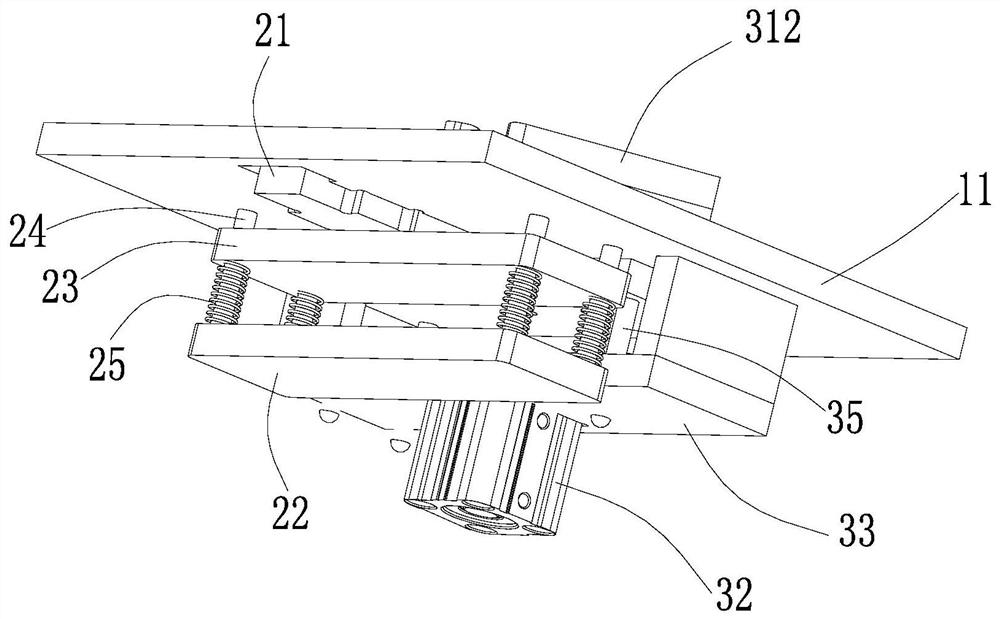

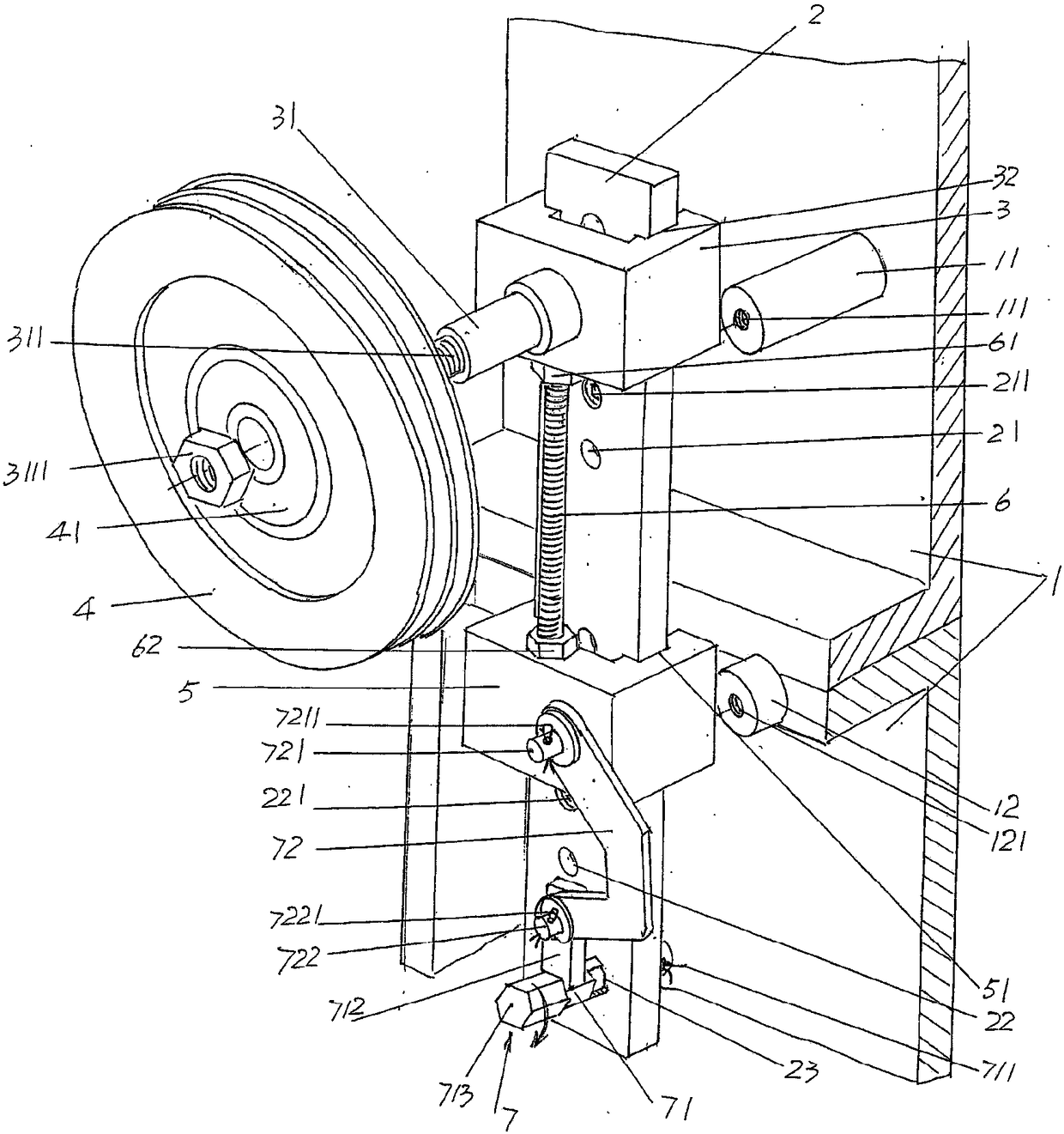

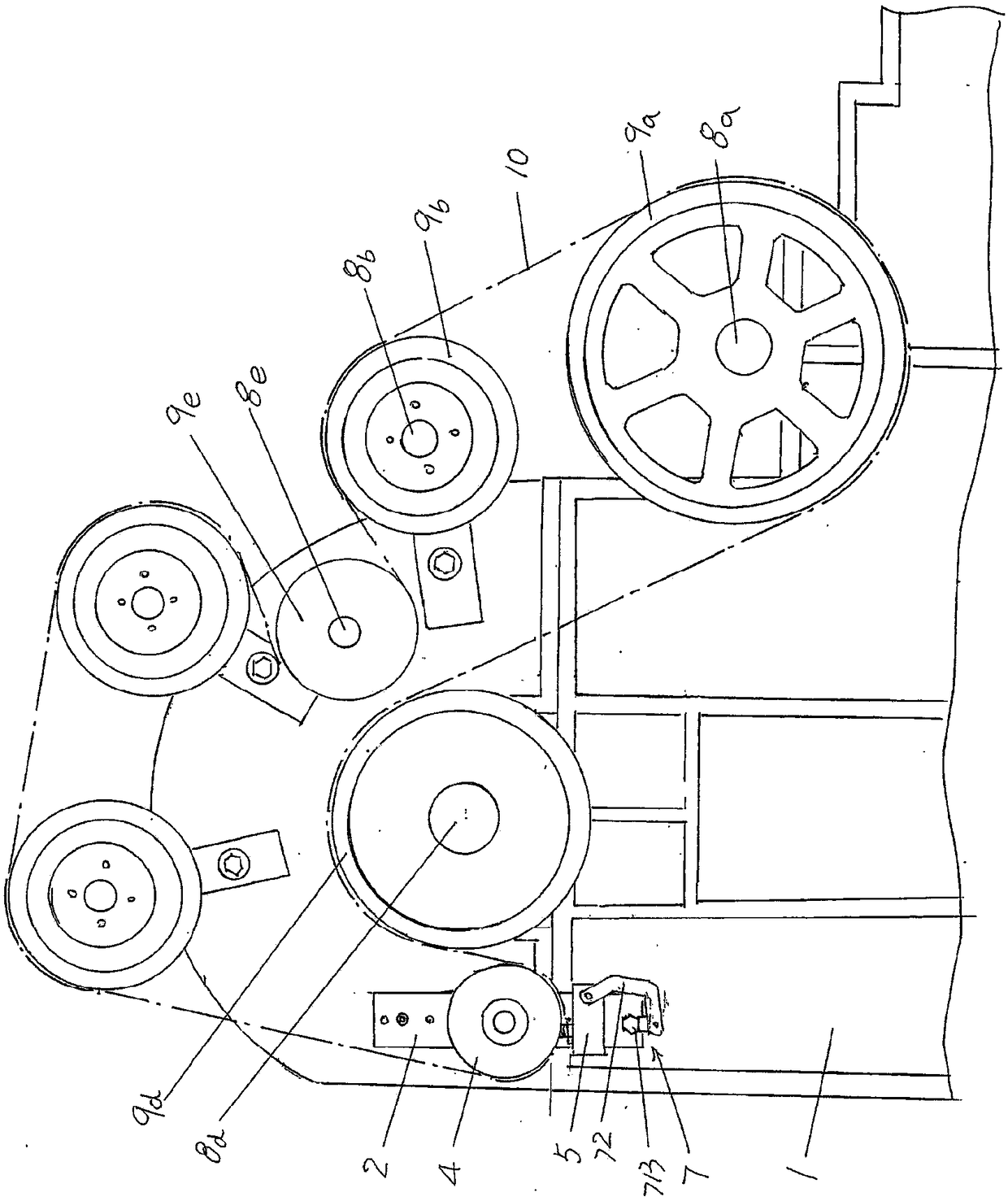

Transmission belt tensioning device of carding machine

ActiveCN106149107AEnsure tightening effectMeet tension adjustment requirementsCarding machinesEngineeringTransmission belt

The invention provides a transmission belt tensioning device of a carding machine. The carding machine comprises a wall plate. The transmission belt tensioning device comprises a guide rail plate, a lower sliding seat, an upper sliding seat, a traction regulating screw rod and a sliding seat locking mechanism, wherein the guide rail plate is connected to the outward side of the wall plate; the upper sliding seat is matched with the guide rail plate; one side, facing a tensioning wheel, of the upper sliding seat is provided with a tensioning wheel support half shaft; the tensioning wheel is arranged on the tensioning wheel support half shaft; the lower sliding seat is matched with the guide rail plate; the upper end of the traction regulating screw rod is matched with the upper sliding seat; the lower end of the traction regulating screw rod is matched with the lower sliding seat; the sliding seat locking mechanism is connected between the lower sliding seat and the guide rail plate. The selective regulating function is realized; the tensioning regulating requirements on redundant transmission belts are met; the lower sliding seat is limited in a regulated position through the sliding seat locking mechanism, and is maintained in the regulated positioned through the traction regulating screw rod and the upper sliding seat at the same time, so that the upper and lower sliding seats cannot generate the floating conditions; the tensioning effect of the tensioning wheel on the transmission belt is ensured.

Owner:JIANGSU YINGYANG NONWOVEN MASCH CO LTD

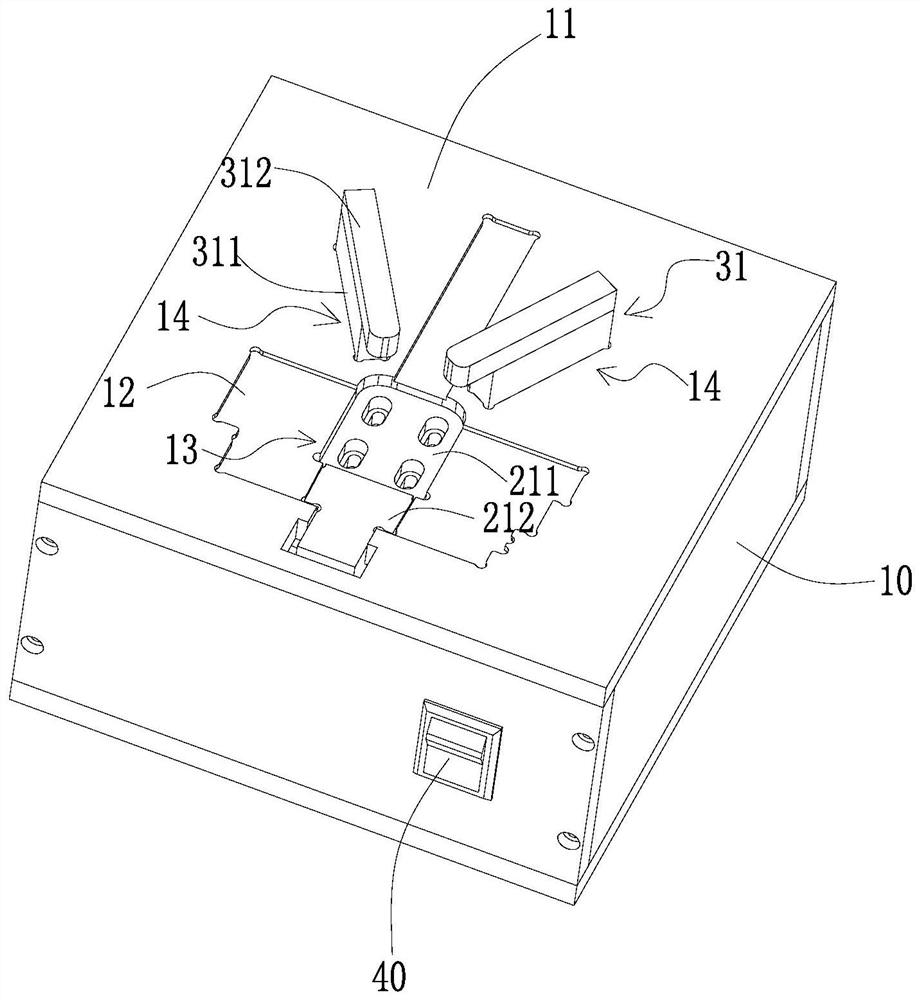

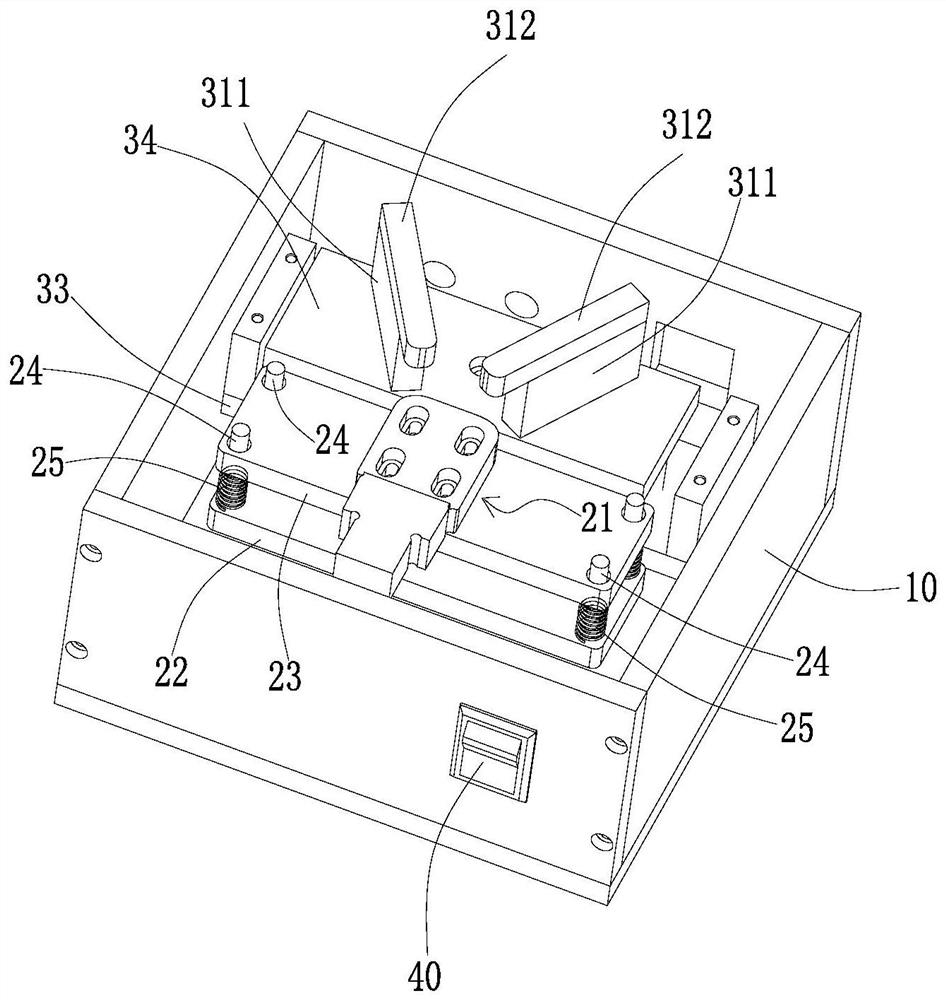

A kind of pneumatic coating method of charger

ActiveCN108382639BEnsure strict positioning placementSimple structurePackagingEngineeringMechanical engineering

The invention discloses a method for pneumatically cover a charger with a film. A pneumatic film covering jig comprises a jig shell. A charger fixing assembly and a lifting assembly are arranged in the jig shell. A protective film storage groove is formed in a top cover of the jig shell. A first through hole is formed in the protective film storage groove. A charger storage table of the charger fixing assembly is liftably arranged in the first through hole. The lifting assembly is provided with a charger pressing component. The method for pneumatically cover the charger with the film comprisesthe following steps that the protective film is positioned and placed in the protective film storage groove with the adhesive surface facing upwards, and the charger to be covered with the film is positioned and placed on the charger storage table; the charger is pressed and fixed by the charger pressing component; and all the surfaces of the charger are covered with the film, then the charger pressing component rises, and the charger is taken out. The method is mainly for chargers with multiple surfaces needing to be covered with protective films in complex shapes, and the protective film and the charger are positioned and placed accuracy and are prevented from floating in the film covering process, so that accurate film covering is ensured, and defects such as deviation and deflection are avoided.

Owner:深せん市奥达电源科技有限公司

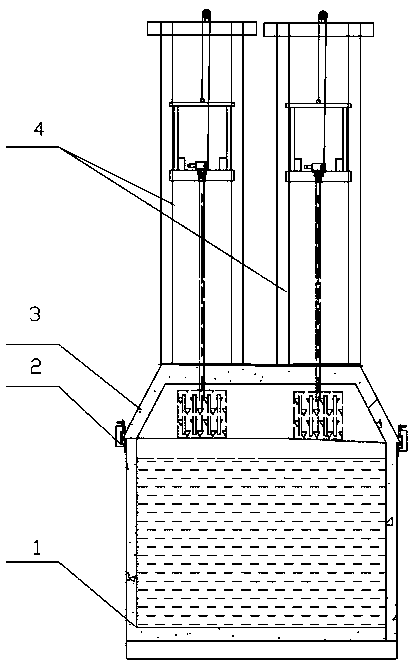

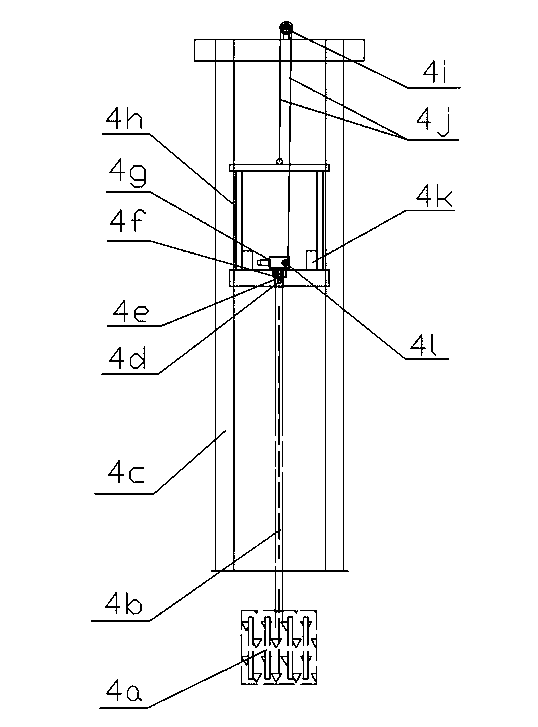

Multi-alloy step feed device for metallurgy smelting

The invention discloses a multi-alloy step feed device for metallurgy smelting. More than two alloy feeders are arranged on a ladle cover of a ladle; each of the alloy feeders comprises a bracket; a sliding frame is mounted in the bracket; a dual-output shaft belt motor reducer and counterweight iron are arranged on the sliding frame; a lifting wheel is mounted on one output shaft of the dual-output shaft belt motor reducer, and an electromagnetic clutch device is mounted on the other output shaft of the dual-output shaft belt motor reducer; a steel wire rope is sleeved onto a guide wheel assembly at the top of the bracket, and one end of the steel wire rope is connected with the sliding frame while the other end of the steel wire rope is connected with the lifting wheel; and an alloy frame is connected with a shaft sleeve fixed onto the electromagnetic clutch device through a connecting rod and a bolt. According to the multi-alloy step feed device for metallurgy smelting, the alloys are directly pressed into molten steel through a pressing-in device, are directly molten in the molten steel and cannot contact air so as to avoid oxidization and burning loss; the feeding amount of the alloys can be reduced while the absorption rate is greatly increased, so that the production cost is favorably reduced and the absorption and component uniformity of the alloys in the molten steel are improved at the same time; and the feeding process is simplified and the labor intensity is reduced.

Owner:LONGNAN LONGYI HEAVY RARE EARTH TECH CO LTD

Preparation method of rabbit-derived swine fever heat-resistant protective agent live vaccine

InactiveCN110179762ANo floatingHigh content of active ingredientsPowder deliverySsRNA viruses positive-senseTissue fluidFreeze-drying

The invention discloses a preparation method of rabbit-derived swine fever heat-resistant protective agent live vaccine. The preparation method comprises the following steps: 1) mashing a tissue: putting a spleen lymphoid tissue into a mashing cylinder, adding diluent, starting a mashing machine to perform mashing, and taking out an emulsifier after mashing; 2) filtering: filtering the mashed emulsifier into a glass bottle through a stainless steel net to obtain tissue fluid; 3) centrifuging: centrifuging the tissue fluid after filtering at 2800 to 4000 r / min for 5 to 15 minutes under the condition of controlling the temperature to be 10 DEG C or below; 4) performing secondary filtering: filtering the tissue fluid by using the stainless steel net after centrifuging; 5) mixing: adding a protective agent into the tissue fluid after secondary filtering; and 6) subpackaging and freeze-drying. Excessive residues and fat in the tissue fluie can be removed by a method of mashing, filtering, centrifuging and filtering. Thereby, the vaccine is purer and the effective component content is higher.

Owner:山西隆克尔生物制药有限公司

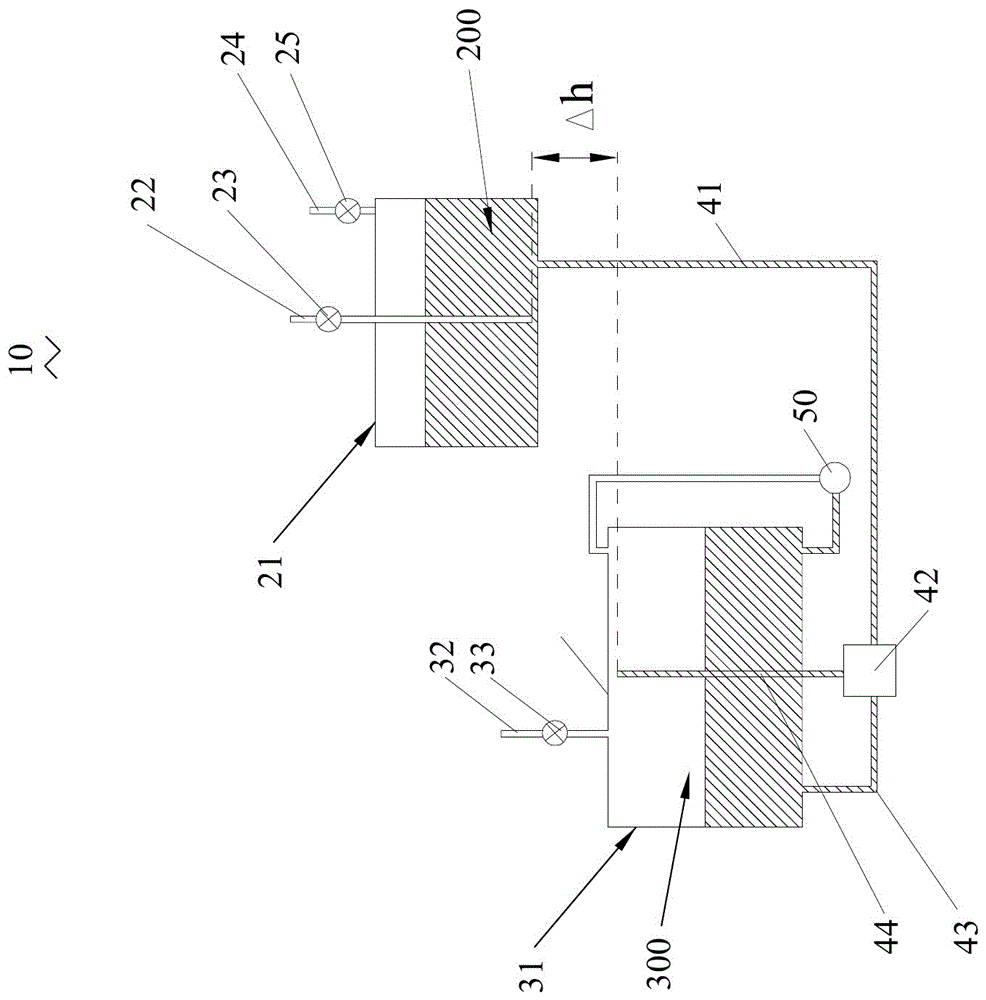

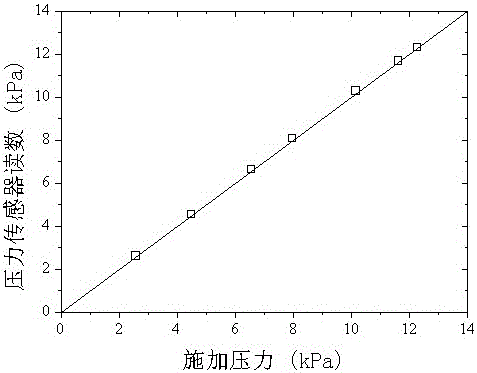

A high-precision low-pressure gas generating device capable of measuring flow velocity and its application method

InactiveCN103836341BHigh pressure accuracyImproved pressure stabilityPipeline systemsProduct gasEngineering

The invention provides a high-precision low-pressure gas generating device capable of measuring flow speed . The high-precision low-pressure gas generating device comprises a pressure supply component, a gas supply component and a connecting component connected between the pressure supply component and the gas supply component. Stable low-pressure gas is provided through position potential energy difference delta H of pressurizing liquid, pressure precision of the gas is high and can reach 0.1KPa, pressure stability of the provided gas is high, and gas pressure does not float; the flow speed of the gas can be measured, and measuring accuracy is high and is 1ml / s; the provided gas is not limited to be air and can be any gas; especially for flammable and explosive gas like methane, gas supply quantity is limited, so that safety is improved. The high-precision low-pressure gas generating device is simple in structure and low in cost. The invention further provides a using method of the device.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL +1

A method for improving the stability of vegetable protein beverage

ActiveCN104738191BImprove stabilityStable traitsMilk substitutesFood scienceBiotechnologySodium bicarbonate

The invention discloses a method for improving the stability of vegetable protein beverages, and belongs to the technical field of vegetable protein beverage processing. The method is as follows: during the processing of the vegetable protein beverage, adding the following components in parts by weight to every 100 parts of the vegetable protein beverage: 0.1-0.45 parts of polyglycerol fatty acid ester; 0.05-0.45 parts of sodium bicarbonate or 0.02 ~0.45 part of sodium tripolyphosphate or their combination; 0.01~0.1 part of citric acid or 0.02~0.2 part of sucrose fatty acid ester or their combination. The method can effectively improve the stability of the finally obtained vegetable protein beverage, and under the premise of adding few types and small amounts of additives, the properties of the obtained vegetable protein beverage can be kept stably for more than one year without fat floating and protein precipitation.

Owner:承德露露股份公司

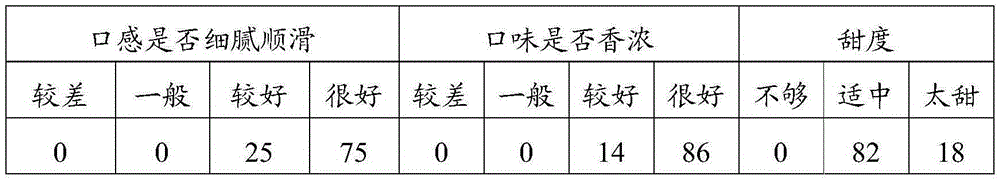

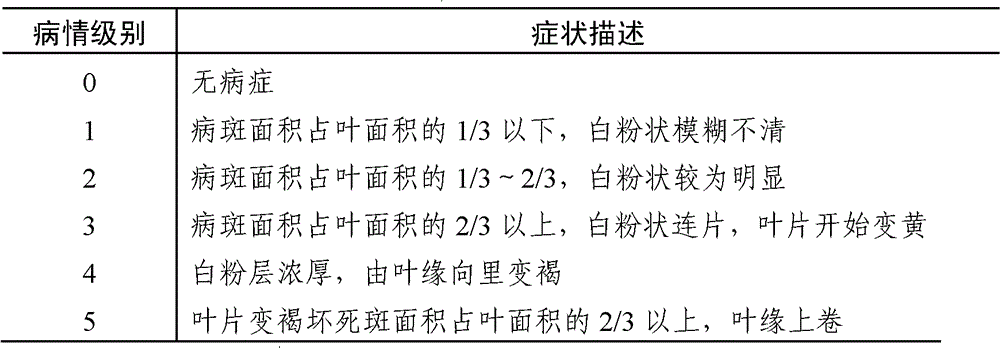

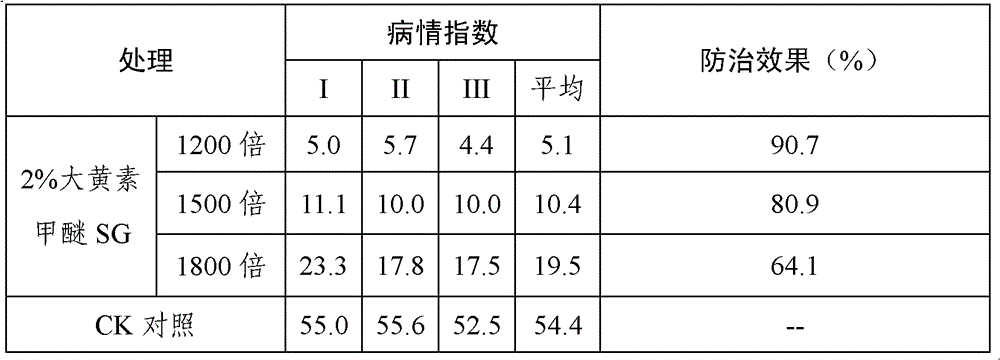

A kind of emodin methyl ether soluble granule and its preparation method and application

The invention provides a physcion soluble granule which comprises the following compositions by weight percent: 1-10% of physcion, 10-20% of auxiliary materials, 15-30% of surfactant, 25-50% of packing and 1-2% of penetrant. A preparation method of the granule comprises the following steps: mixing the physcion and beta-cyclodextrin in proportion, then grinding the mixture to obtain a pasty mixture of physcion and beta-cyclodextrin; drying the mixture to obtain a parent drug; mixing the parent drug with the surfactant, the packing and the penetrant, and pelleting to obtain the product. By using the process technology in the invention, the original drug molecules are placed into the large cavity of beta-cyclodextrin for embedding, and can be mutually dissolved with water. By using the granule, the active ingredients are effectively embedded, the decomposition of the active substances is prevented and the quality guarantee period of the product is prolonged.

Owner:INNER MONGOLIA KINGBO BIOTECH

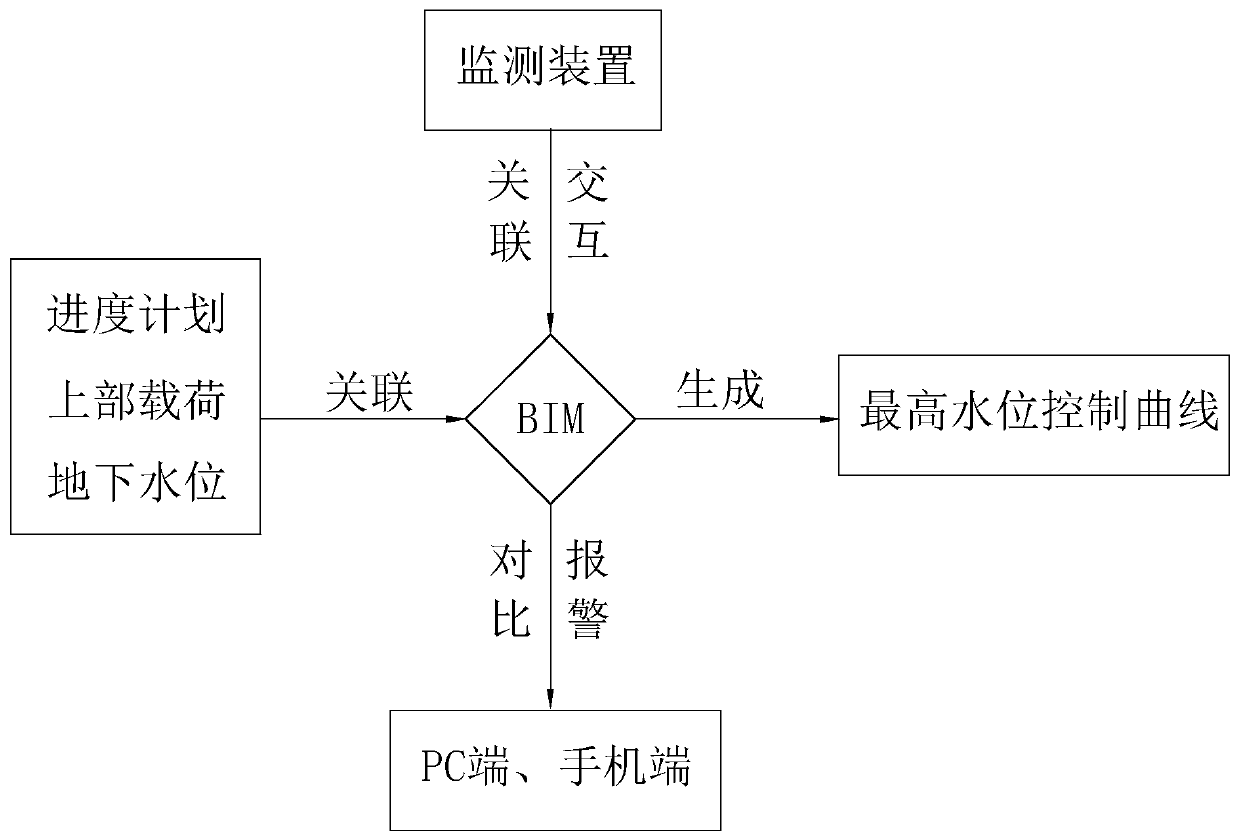

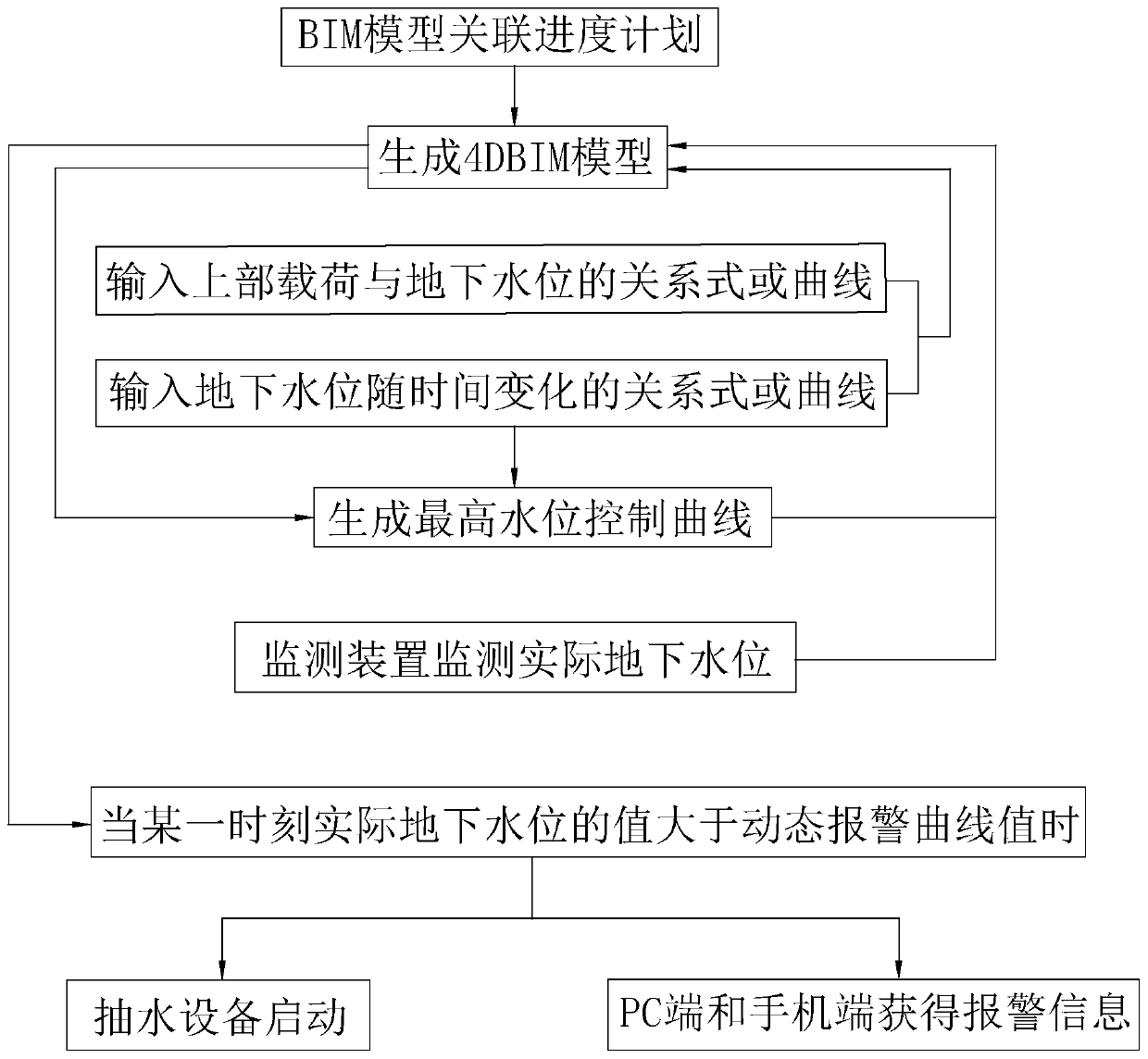

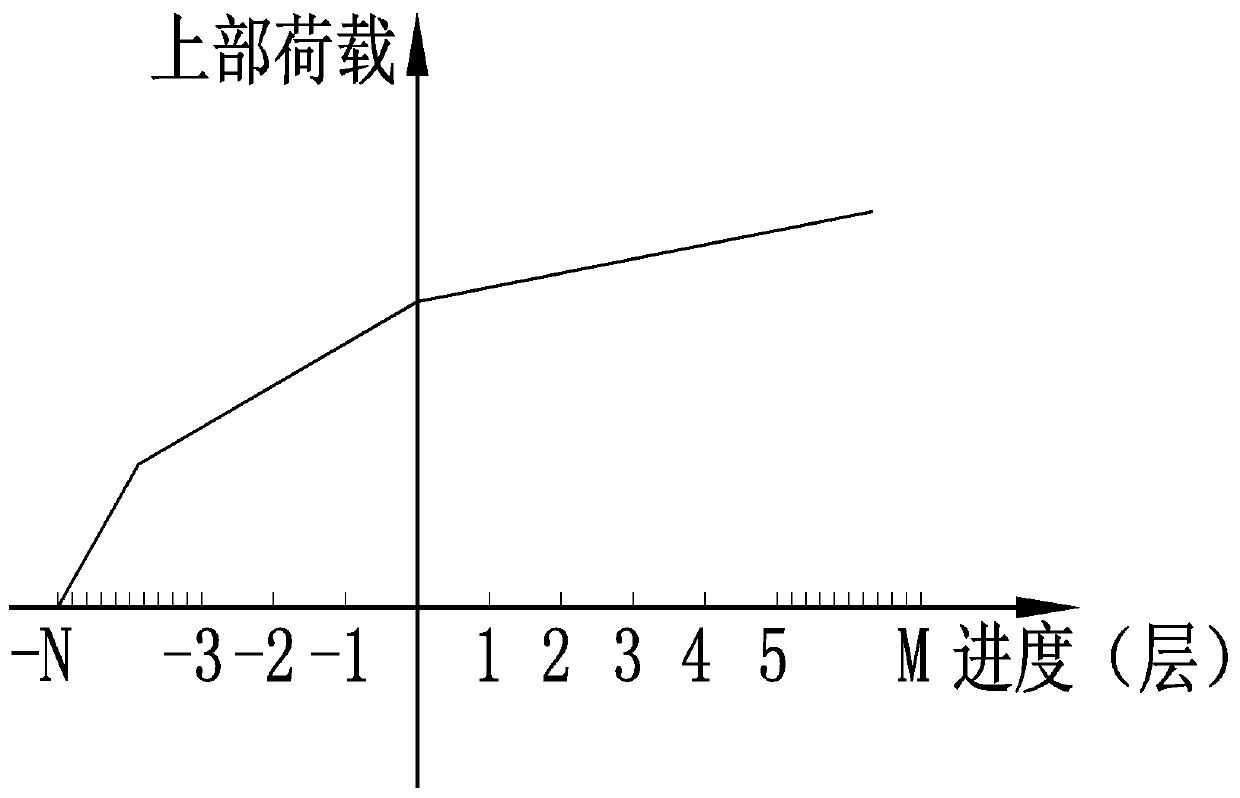

A method of dynamically controlling the anti-floating process of basement construction based on bim technology

ActiveCN110096757BImprove the probability of timely detection of alarm conditionsEnsure safetyGeometric CADDesign optimisation/simulationBasementProcess engineering

Owner:HANGZHOU TONGDA GRP

Composite phase change heat storage material and preparation method thereof

InactiveCN114163979AGood dispersionNo flocculationHeat-exchange elementsThermal engineeringHeat storage material

The invention relates to the technical field of phase change heat storage materials, in particular to a composite phase change heat storage material and a preparation method thereof. The composite phase change heat storage material comprises the following components: hexadecanol, expanded graphite and diatomite. The preparation method of the composite phase change heat storage material comprises the following steps: (1) mixing expanded graphite, diatomite and liquid hexadecanol, and heating and stirring; (2) after heating and stirring are finished, under the heating condition, vacuum adsorption is performed, and the composite phase change heat storage material is obtained. The phase-change heat storage material can rapidly extract and store energy, the energy storage capacity of the phase-change material can be fully utilized, the heat storage performance of the hexadecanol phase-change material is improved, the heat conductivity coefficient is increased by 5.18-5.7 times compared with that of hexadecanol, and the heat conductivity coefficient is increased by 46.52% to the maximum compared with that of a composite phase-change material only added with expanded graphite. And the composite phase change material provided by the invention is stable in performance and good in repeatability, and can be better applied to actual heat storage engineering.

Owner:青岛仟亿新材料科技有限公司

Railway high voltage traction transformer

ActiveCN100470689CGuaranteed mechanical strengthUniform pressureTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresFiberManufacturing technology

A railway high voltage traction transformer belongs to transformer manufacturing technology field. It contains casing with two bottom, main unit consisting of and iron core, oil tank having two sections, both end of winding having insulation end ring with inner fiber container, side beam, upward pull strap, foot pad, drawplate, high voltage and low voltage upper yoke clamping to form one hard entirety winding axial direction fastened through pressure nail and drawplate, upper part of tank set with four positioning device, main unit located on casing bottom. Said invention can prevent displacement or damage between casing and main unit in transportation process and without suspended core inspection in arriving site.

Owner:WOLONG ELECTRIC YINCHUAN TRANSFORMER

Carding machine drive belt tensioner

ActiveCN106149107BMeet tension adjustment requirementsEnsure tightening effectCarding machinesLocking mechanismEngineering

Owner:JIANGSU YINGYANG NONWOVEN MASCH CO LTD

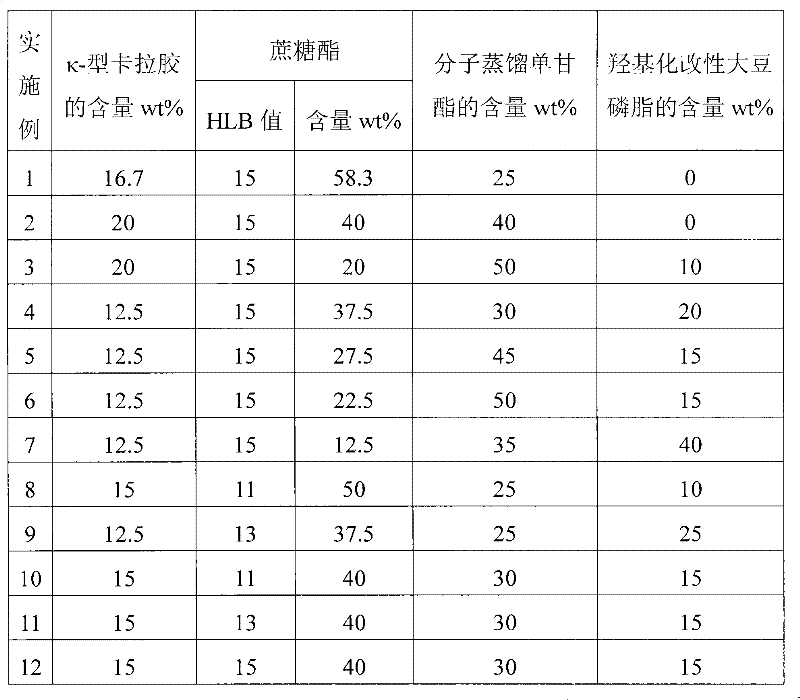

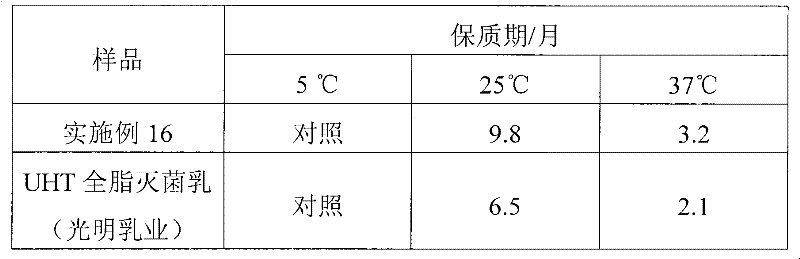

A compound emulsification stabilizer and ultra-high temperature sterilized milk containing it

The invention discloses a compound emulsion stabilizer containing 12.5 to 20 percent of k type carrageenan, 12.5 to 58.3 percent of HLB which is 11 to 15 of sucrose ester, 25 to 50 percent of molecular distilled monoglyceride and 0 to 40 percent of hydroxylating modified soybean phosphatide, wherein the percent is the mass percent of each component accounting for the total compound emulsion stabilizer. The invention also relates to ultra-high-temperature sterilized milk containing the compound emulsion stabilizer. By the compound emulsion stabilizer, the shelf life of an ultra-high-temperature sterilized milk product containing the compound emulsion stabilizer can be prolonged from 6 months to 9 months, the tissue state is favorable, and protein precipitation and obvious fat suspension can not occur; and the production pressure of an enterprise is further slowed down, the circulation period of batch products is increased, and the loss of the enterprise is lowered.

Owner:BRIGHT DAIRY & FOOD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com