A kind of pneumatic coating method of charger

A charger and coating technology, which is applied in the field of charger pneumatic coating, can solve the problems of coating offset, skew, heavy labor, etc., and achieve the effect of ensuring the positioning of the coating, accurate positioning and accurate coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

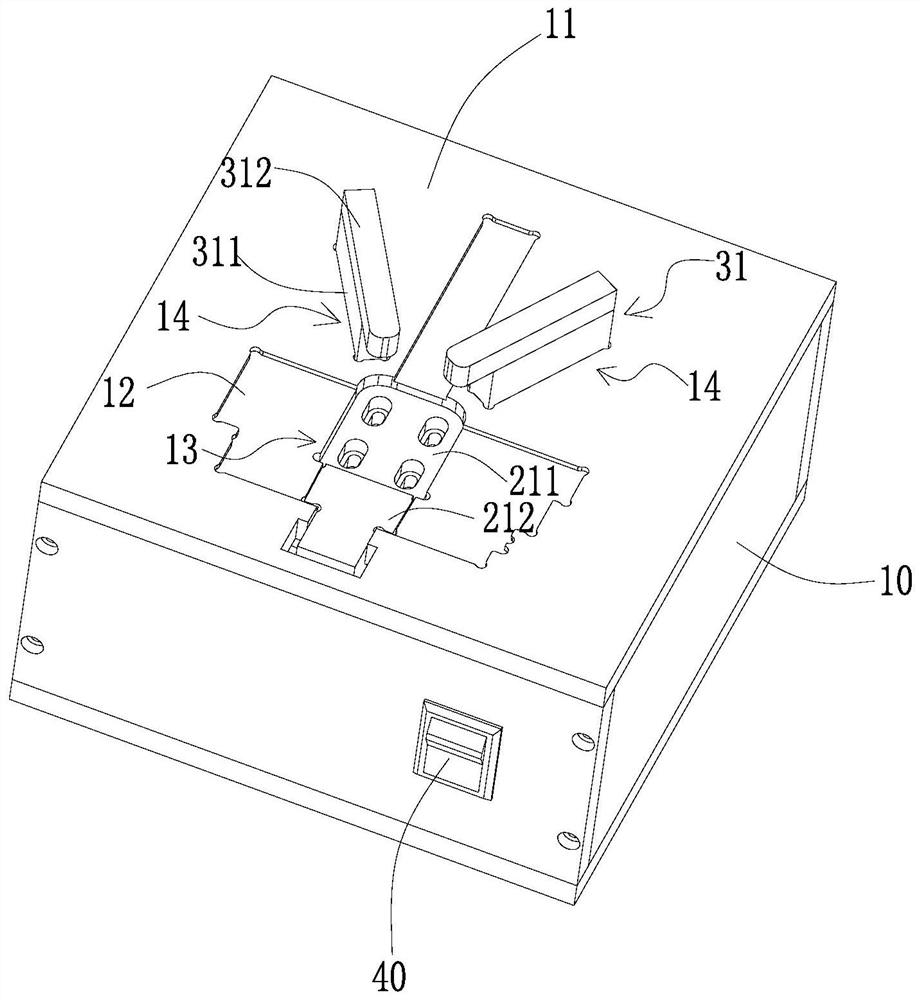

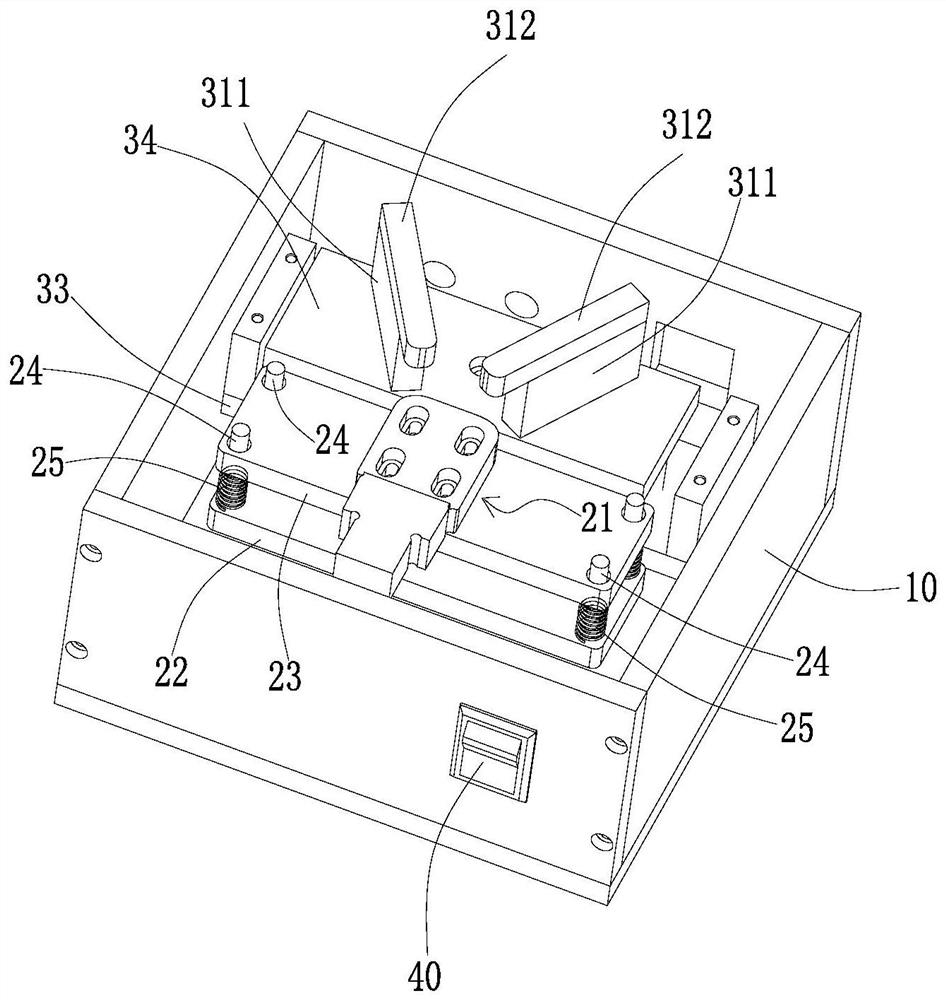

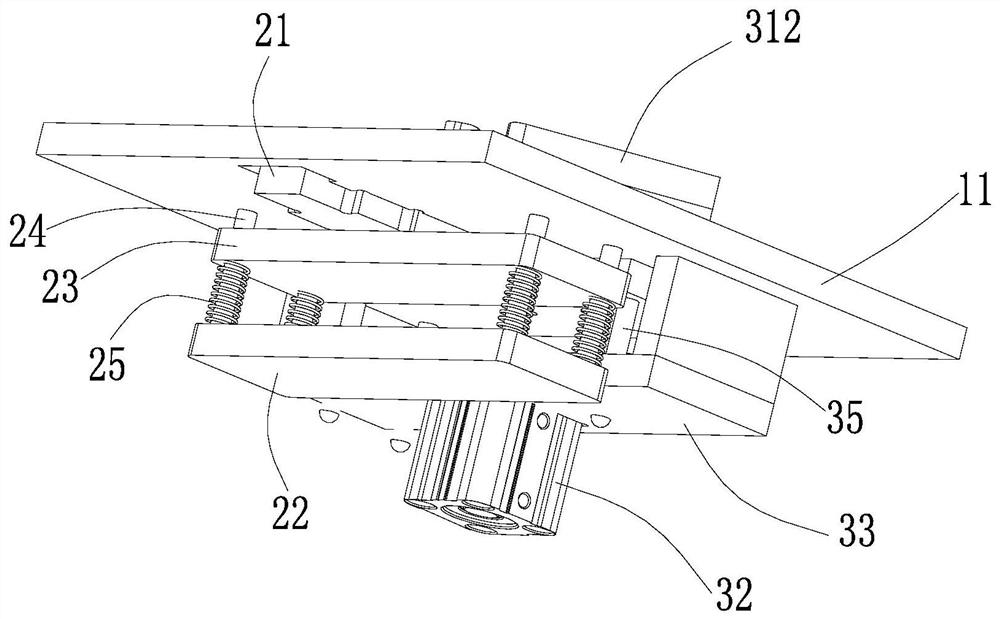

[0027] Such as Figure 1-4 As shown, a charger pneumatic coating jig includes a jig housing 10 , and a charger fixing assembly 20 and a lifting assembly 30 are arranged inside the jig housing 10 . The top cover 11 of the jig housing 10 is provided with a protective film placement groove 12, the protective film placement groove 12 is adapted to be set according to the shape of the protective film used, and the protective film placement groove 12 is provided with an adapter to be coated and charged. tor-shaped first through hole 13

[0028] The charger fixing assembly 20 includes a charger placement table 21 adapted to place a charger to be coated. The charger placement table 21 can be repeatedly pressed down and popped up to be arranged in the first through hole 13, and the initial state (bouncing) When starting) its upper surface is lower than the groove bottom of protective film placement groove 12, conveniently charger is placed accurately. In an embodiment, the charger fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com