A compound emulsification stabilizer and ultra-high temperature sterilized milk containing it

An emulsification stabilizer and ultra-high temperature sterilization technology, which is applied in the direction of dairy products, milk preparations, food preparation, etc., can solve problems such as the unsatisfactory stabilization effect of emulsification stabilizers, and achieve no protein precipitation, increase the circulation cycle, and organize good condition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

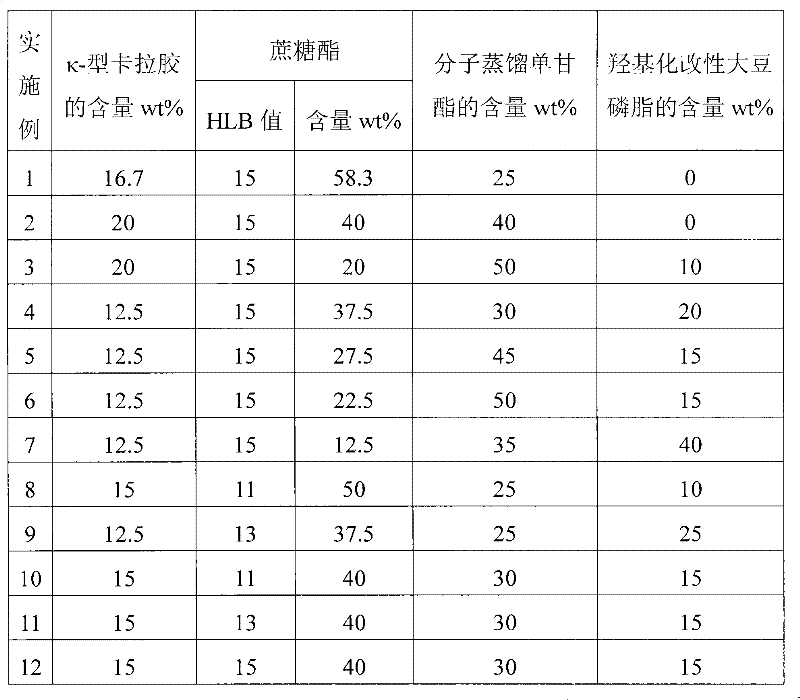

[0039] Table 2 shows examples 1 to 12 of the compounded emulsification stabilizer of the present invention. According to the formula in the table, the compounded emulsification stabilizer of the present invention can be prepared by simply mixing the components evenly.

[0040] Table 2 Compound emulsification stabilizer embodiment 1~12 of the present invention

[0041]

Embodiment 13

[0042] Embodiment 13 full-fat sterilized liquid milk product

[0043] Product formula (calculated per ton of final product):

[0044] raw material

Amount added

Milk (F≥3.1%, P≥2.9%, SNF≥8.1%)

998.8kg

The compound emulsion stabilizer prepared by embodiment 1

1.2kg

[0045] The preparation method comprises the following steps:

[0046] 1) Heat the pre-pasteurized milk stored at low temperature to 85°C;

[0047] 2) Using a water-powder mixer, add the compound emulsification stabilizer to the above milk, and stir for 10 minutes;

[0048] 3) Homogenize the mixed solution obtained in step 2), the homogenization temperature is 65°C, and the pressure is successively 15MPa and 3MPa;

[0049] 4) The homogenized liquid in step 3) is subjected to ultra-high temperature instantaneous sterilization, the sterilization condition is 137°C, and the sterilization time is 3 seconds;

[0050] 5) Cool the liquid obtained after the sterilization in step ...

Embodiment 14

[0053] Example 14 Partial skimmed sterilized liquid milk product

[0054] Product formula (calculated per ton of final product):

[0055] raw material

Amount added

Milk (F 1.0~2.0%, P≥2.9%, SNF≥8.1%)

999kg

The compound emulsion stabilizer prepared by embodiment 2

1.0kg

[0056] Its preparation method comprises the following steps:

[0057] 1) Pre-pasteurized milk that has been stored at low temperature and centrifuged at 50°C to remove fat;

[0058] 2) Add the cream part obtained in step 1) to the skim milk obtained in step 1), and control the physical and chemical indicators within the range of F 1.0-2.0%, P≥2.9%, SNF≥8.1%; heat the milk after standardization to 80°C;

[0059] 3) Using a water-powder mixer, add the compound emulsification stabilizer to step 2) milk, and stir for 10 minutes;

[0060] 4) Homogenize the mixed solution obtained in step 3), the homogenization temperature is 70°C, and the pressure is successively 15MPa ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com