Beverage emulsion with coloring and flavoring functions and preparation method thereof

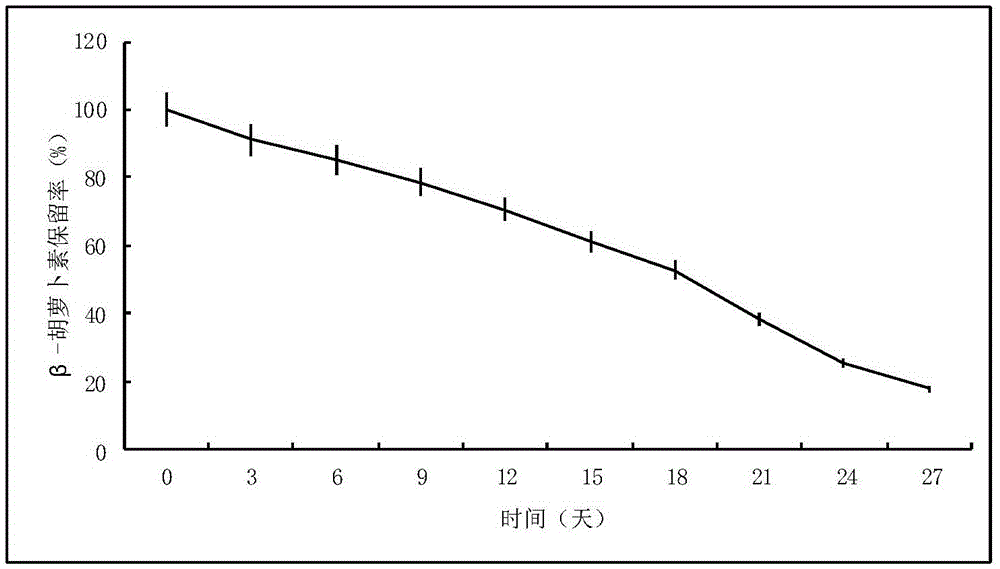

A beverage and functional technology, applied in the field of food additives and functional foods, can solve the problems of poor stability, inability to apply water-based foods, and limit wide application, etc., achieve low oil oxidation degree, simple and easy preparation method, and good chemical stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

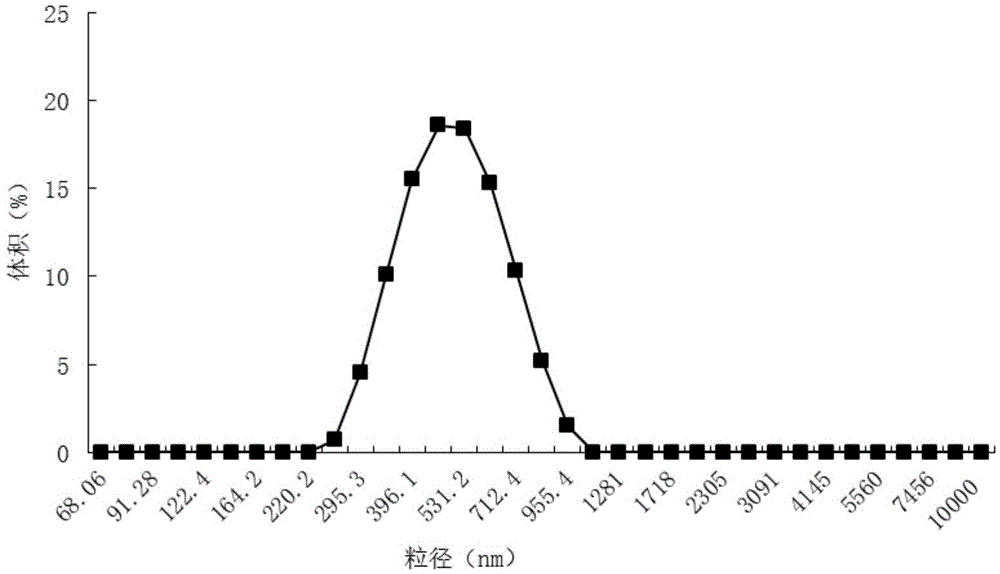

Embodiment 1

[0035] Weigh 64g of gum arabic and 107g of modified barley starch in 750g of water at 80°C, then add 3.75g of polyglycerol fatty acid ester, 0.2g of ascorbic acid, and 0.1g of sodium erythorbate and stir to obtain the aqueous phase; weigh 25g of orange peel oil and 9g Canola oil, 8g rosin glyceride, 16g sucrose diacetate hexaisobutyrate, heated, add 16.8g 30% β-carotene oil suspension at 140℃ and stir quickly to dissolve it, add 0.25 after cooling to room temperature g vitamin E, stir evenly to obtain the oil phase; then slowly add the oil phase to the water phase at room temperature and high-speed shearing at a rate of 10000 revolutions per minute, shearing for 10 minutes to obtain a coarse emulsion; homogenize the coarse emulsion through high pressure The machine performs at least two pressure homogenization, the homogenization temperature is 50°C, the homogenization pressure is 50MPa, and the homogenization is performed twice to obtain a beverage emulsion with uniform particl...

Embodiment 2

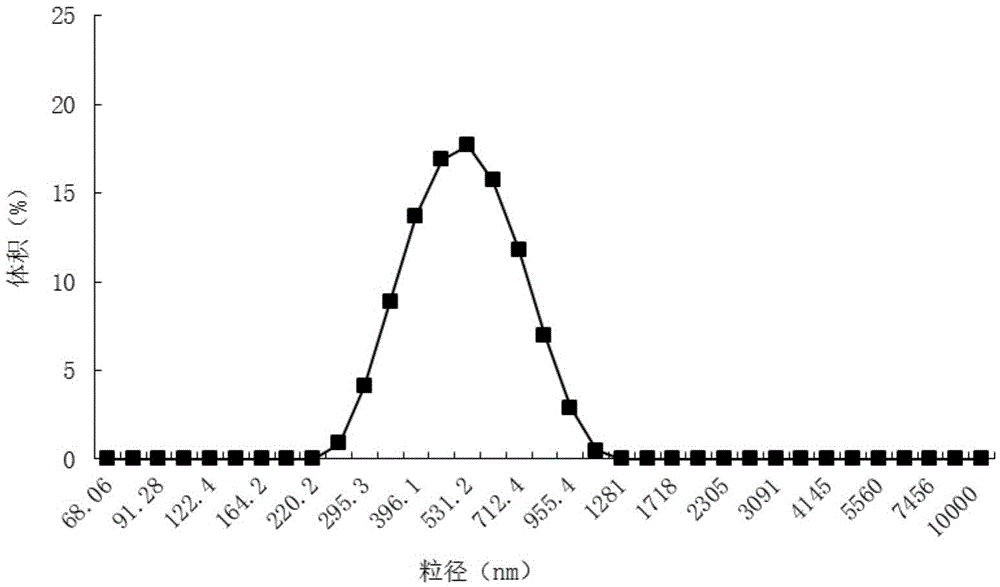

[0038] Weigh 64g beet pectin and 107g puritygumultra dissolved in 670g 80℃ water, then add 7.5g polyglycerol fatty acid ester, 0.2g ascorbic acid, 0.1g sodium erythorbate, stir well to obtain the water phase; weigh 40g orange peel oil, 10g corn oil , 22g glyceryl rosin, 44g sucrose diacetate hexaisobutyrate, heated, add 33g 30% β-carotene oil suspension at 140℃ and quickly stir to dissolve it, cool to room temperature, add 0.50g vitamin E, stir Obtain the oil phase uniformly; then slowly add the oil phase to the water phase at room temperature and high-speed shear at a rate of 10000 revolutions / min, shear for 10 minutes to obtain a coarse emulsion; pass the coarse emulsion through a high-pressure homogenizer at least twice Pressure homogenization, pre-heating temperature of 60°C before homogenization, homogenization pressure 55MPa, homogenization 3 times to obtain a beverage emulsion with uniform particle size and good stability.

[0039] After measurement, the beverage emulsion ...

Embodiment 3

[0041] Weigh 32g soybean polysaccharide, 32g β-cyclodextrin, 107g barley modified starch and dissolve it in 670g 80℃ water, then add 7.5g sucrose ester, 0.2g ascorbic acid, 0.1g sodium erythorbate, stir well to obtain the water phase; weigh 40g Lemon oil, 10g medium-chain triglycerides, 11g rosin acid glycerides, 22g sucrose diacetate hexaisobutyrate, heating, add 67g 30% β-carotene oil suspension at 140℃ and stir quickly to dissolve, cool After reaching room temperature, add 0.50g vitamin E, stir evenly to obtain the oil phase; then slowly add the oil phase to the water phase at room temperature with high-speed shearing at a rate of 10,000 revolutions / min, shearing for 10 minutes to obtain a coarse emulsion; The emulsion is subjected to at least two pressure homogenization through a high-pressure homogenizer, the pre-heating temperature is 65° C., the homogenization pressure is 45 MPa, and the homogenization is performed twice to obtain an emulsion with uniform particle size an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com