Liquid cooling profile extrusion sizing device

A shaping device and profile technology, applied in the direction of metal extrusion, metal extrusion control equipment, metal processing equipment, etc., can solve the problem of low cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

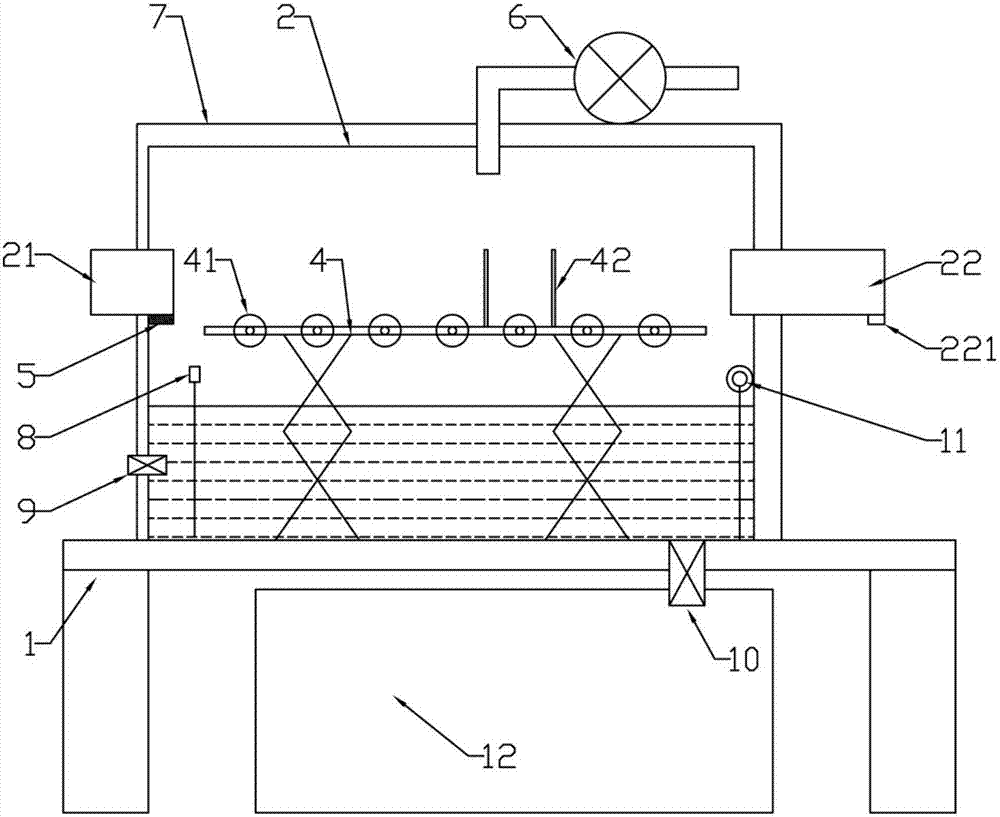

[0033] like figure 1 As shown, an embodiment of the present invention provides a liquid-cooled profile extrusion and sizing device to solve the technical problem of low cooling efficiency of the liquid-cooled sizing equipment of the profile extrusion machine.

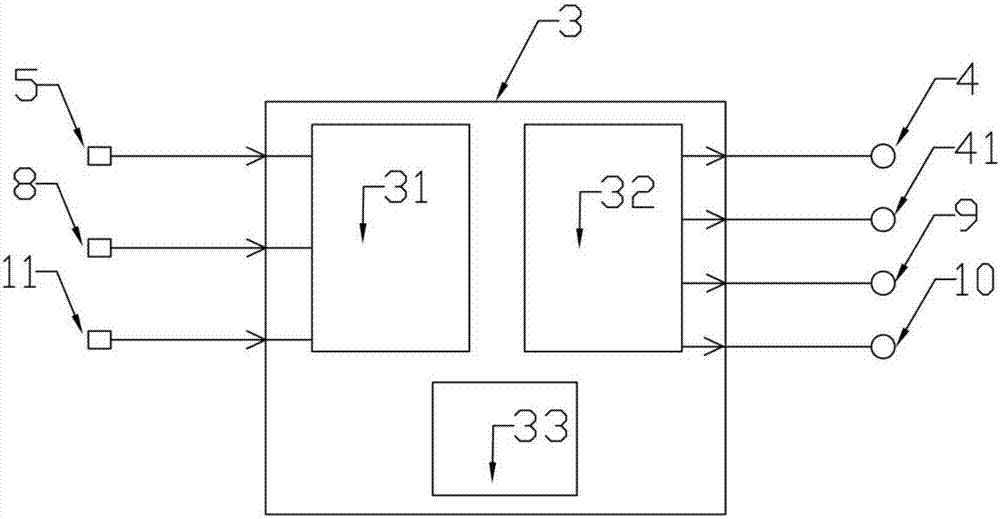

[0034] In order to solve the above problems, the present invention provides a liquid-cooled profile extrusion and shaping device, which includes a machine 1 , a cooling liquid tank 2 installed on the machine 1 , and a controller 3 .

[0035] The left end of the coolant tank 2 is provided with a feed pipe 21, the feed pipe 21 runs through the left side wall of the coolant tank 2, and the right end of the coolant tank 2 is provided with a discharge pipe 22; A pipe 22 runs through the right side wall of the coolant tank 2 .

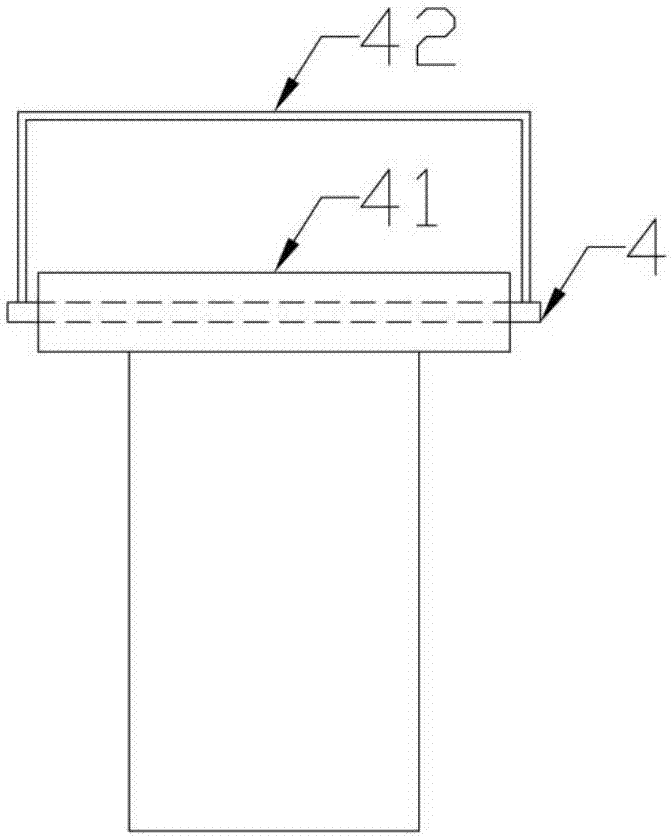

[0036] There is coolant in the coolant tank 2 . The length of the coolant tank 2 is longer than that of the profile. The inner bottom of the coolant tank 2 is connected with a liftable support fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com