Polyethylene colloidal particle batch production method

A mass production, polyethylene technology, applied in the field of polyethylene, to achieve the effect of good mixing effect and not easy to be damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

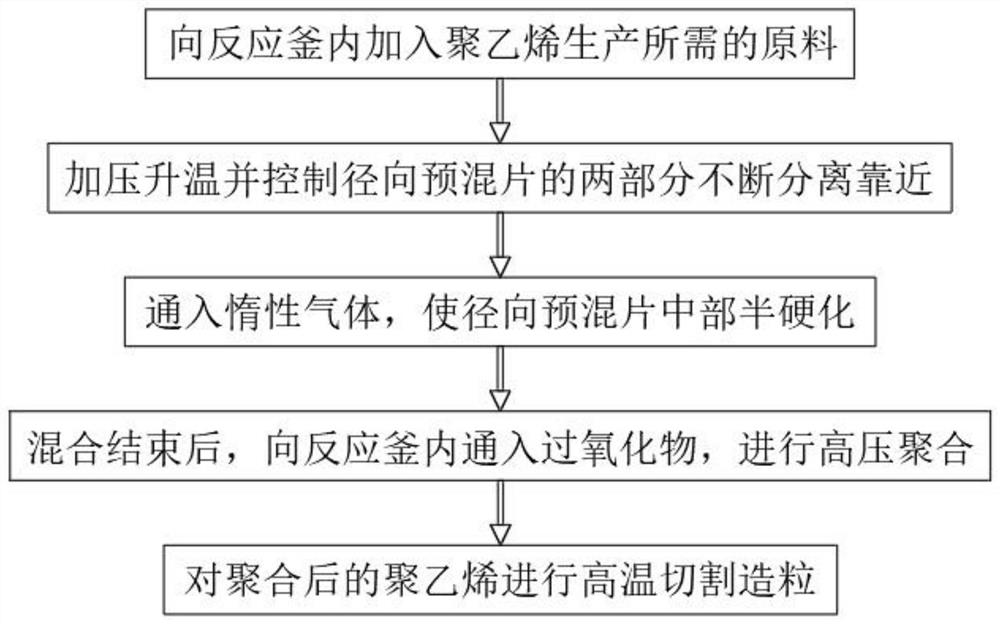

[0045] see figure 1 , a batch production method of polyethylene colloidal particles, comprising the following steps:

[0046] S1. Add the raw materials required for polyethylene production into the reactor;

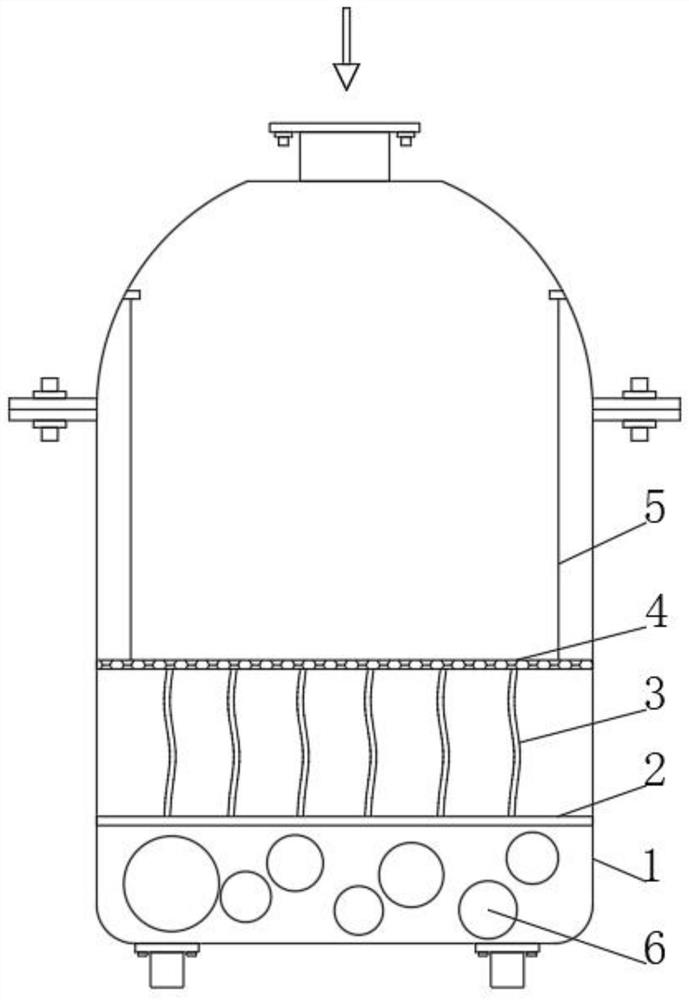

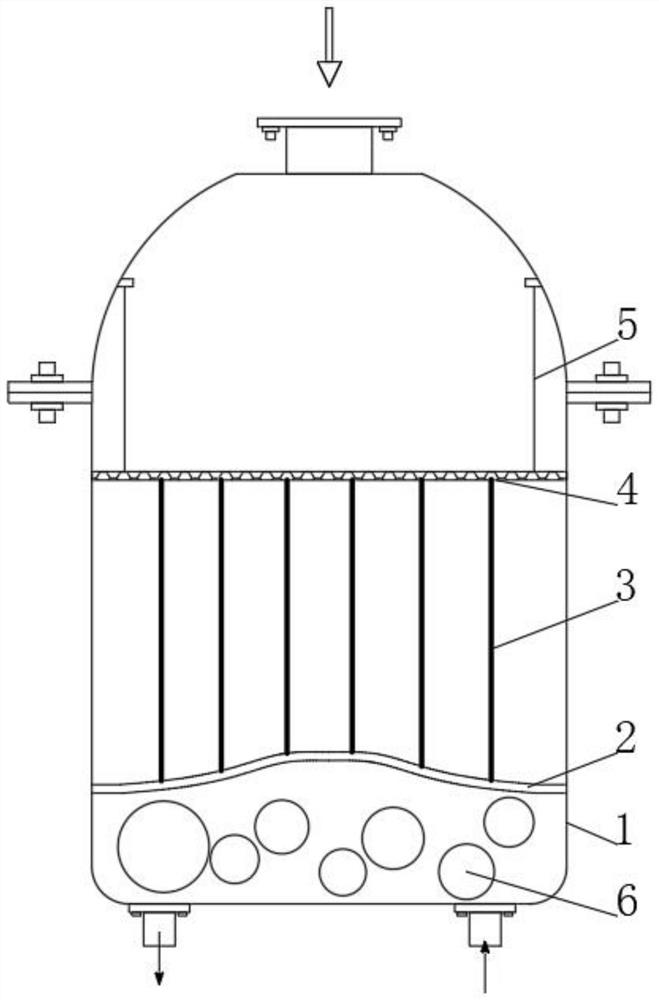

[0047] S2. Please refer to Figure 3-4 , pressurize and heat up the reactor, and then control the two parts of the radial premixing sheet in the reactor to be separated and approached continuously, so as to uniformly mix the raw materials in the reactor;

[0048] S3. Pass inert gas from the bottom of the reaction kettle to its interior to semi-harden the middle part of the radial premixing sheet, and increase the vibration amplitude of the radial premixing sheet to the raw materials when they are separated and approached;

[0049] S4, after mixing finishes, pass into peroxide in reactor, carry out high-pressure polymerization;

[0050] S5, performing high-temperature cutting and granulation on the polymerized polyethylene.

[0051] The raw materials in S1 include cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com