A method of improving exposure precision of hdi circuit board

A technology of exposure accuracy and circuit board, applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems of line deformation, affecting the performance of circuit board products, damage to adjacent layers of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

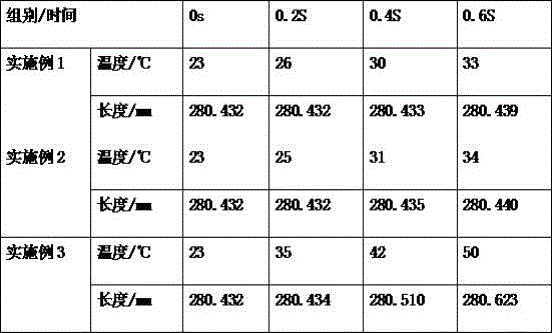

Embodiment 1

[0023] A method for improving the exposure accuracy of HDI circuit boards, comprising the following steps:

[0024] a. Drill 4 through-hole alignment holes through mechanical drilling on the non-line area of the four top corners of the copper clad laminate;

[0025] b. On the periphery of each through-hole alignment hole on the copper-clad laminate, remove the copper layer, and drill a blind hole alignment hole group at the position without the copper layer through laser drilling; the blind hole alignment hole group includes 8 Blind hole alignment holes surrounding the periphery of the through hole alignment holes;

[0026] c. In the exposure process, the film used is provided with through-hole targets and blind-hole targets corresponding to the through-hole alignment holes and blind hole alignment holes; before exposure, the through-hole alignment holes and through-hole targets are first Carry out pre-alignment so that the through-hole target and the corresponding through-...

Embodiment 2

[0033] A method for improving the exposure accuracy of HDI circuit boards, comprising the following steps:

[0034] a. Drill 4 through-hole alignment holes through mechanical drilling on the non-line area of the four top corners of the copper clad laminate;

[0035] b. On the periphery of each through-hole alignment hole on the copper-clad board, remove the copper layer, and drill a blind hole alignment hole group at the position without the copper layer through laser drilling; the blind hole alignment hole group includes 8 Blind hole alignment holes surrounding the periphery of the through hole alignment holes;

[0036] c. In the exposure process, the film used is provided with through-hole targets and blind-hole targets corresponding to the through-hole alignment holes and blind hole alignment holes; before exposure, first pass through the through-hole alignment holes and through-hole targets Carry out pre-alignment so that the through-hole target and the corresponding th...

Embodiment 3

[0043] A method for improving the exposure accuracy of HDI circuit boards, comprising the following steps:

[0044] a. Drill 4 through-hole alignment holes through mechanical drilling on the non-line area of the four top corners of the copper clad laminate;

[0045] b. On the periphery of each through-hole alignment hole on the copper-clad board, remove the copper layer, and drill a blind hole alignment hole group at the position without the copper layer through laser drilling; the blind hole alignment hole group includes 8 Blind hole alignment holes surrounding the periphery of the through hole alignment holes;

[0046] c. In the exposure process, the film used is provided with through-hole targets and blind-hole targets corresponding to the through-hole alignment holes and blind hole alignment holes; before exposure, first pass through the through-hole alignment holes and through-hole targets Carry out pre-alignment so that the through-hole target and the corresponding th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com