Railway high voltage traction transformer

A traction transformer, high-voltage technology, applied in the field of transformer manufacturing, can solve problems such as loose winding and iron core, displacement or damage of box body and device body, affecting transformer insulation strength, overload and short-circuit resistance, etc. The effect of balanced pressure and reasonable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

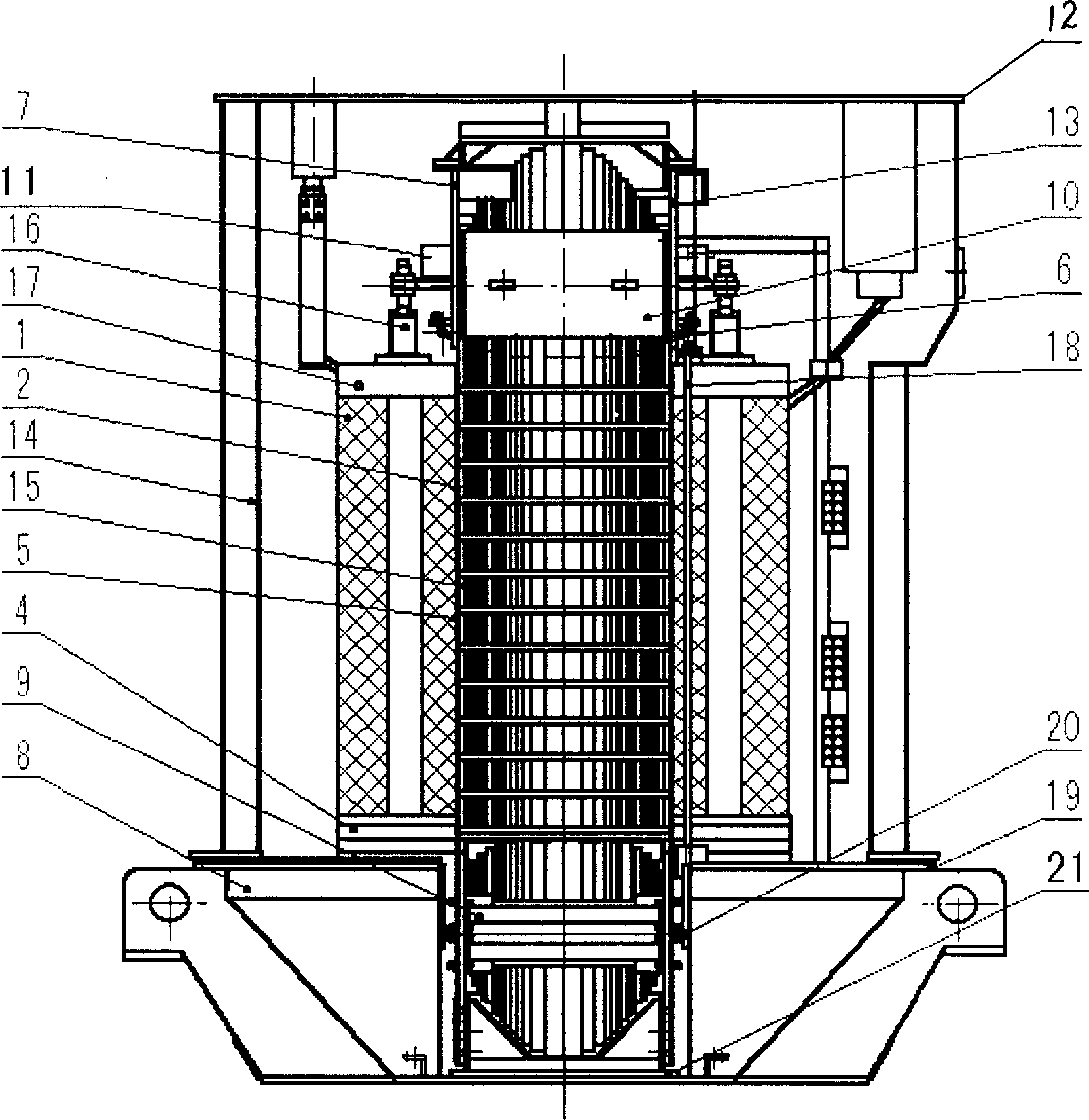

[0021] The present invention mainly comprises the casing 12 of band two casing bottoms 19, places the device body that winding 1 and iron core 2 constitute in casing 12, the fuel tank that is made of last fuel tank 14 and lower fuel tank 8.

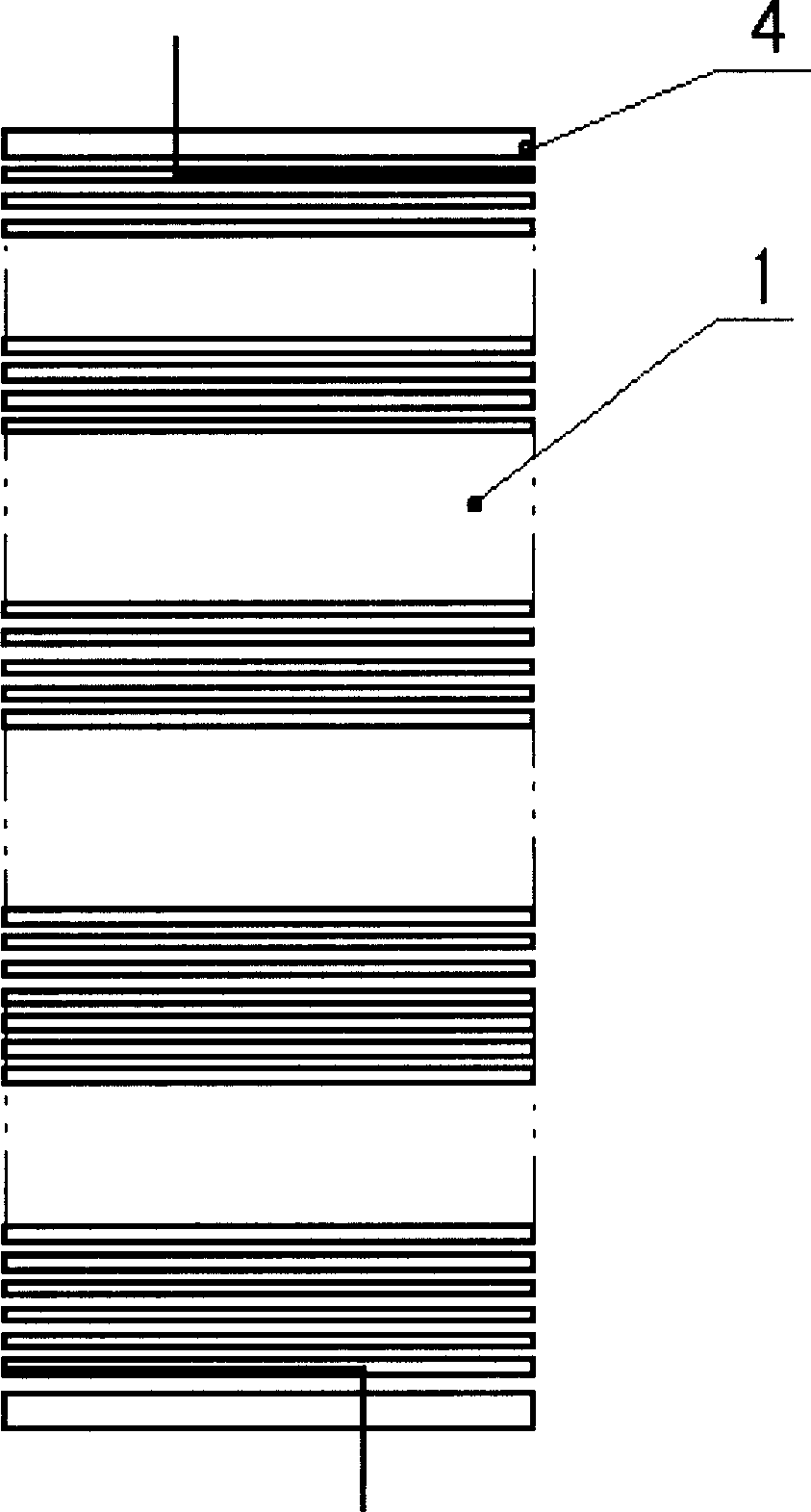

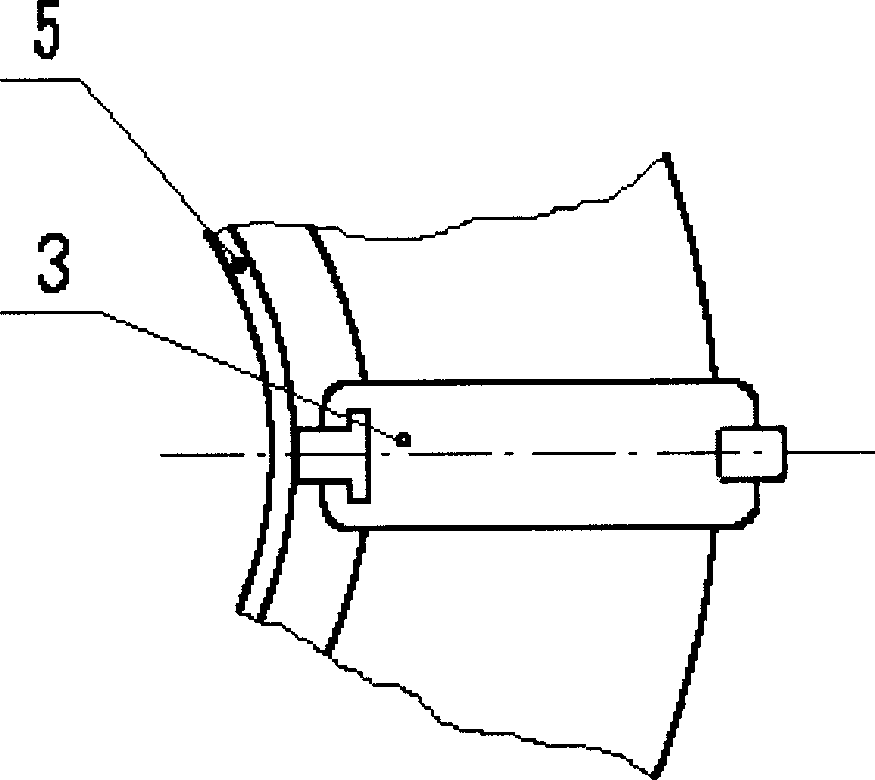

[0022] The struts and pads 3 in the winding 1 are all made of densified cardboard, and its elastic deformation is very small. The cardboard used for the insulating end ring 4 at both ends of the winding is also densified and then hot-pressed. A cardboard tube 5 is set on the inner diameter of the winding, and there are inner and outer stays to ensure the mechanical strength of the winding. not loose.

[0023] Set multiple drawstrings 6 at the upper and lower iron yokes to tighten the iron core 2, and add outer drawstrings 9 outside the lower part of the iron core to tighten the iron core. , The high-voltage upper clamp 13 and the low-voltage upper clamp 7 form a solid whole with the iron core.

[0024] A high-strength pressure plate 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com