Preparation technology of bean milk

A preparation process, soybean milk technology, applied in dairy products, milk substitutes, applications, etc., can solve the problems of fat floating and sedimentation, and achieve the effects of optimizing temperature, improving taste and aroma, and increasing the degree of expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

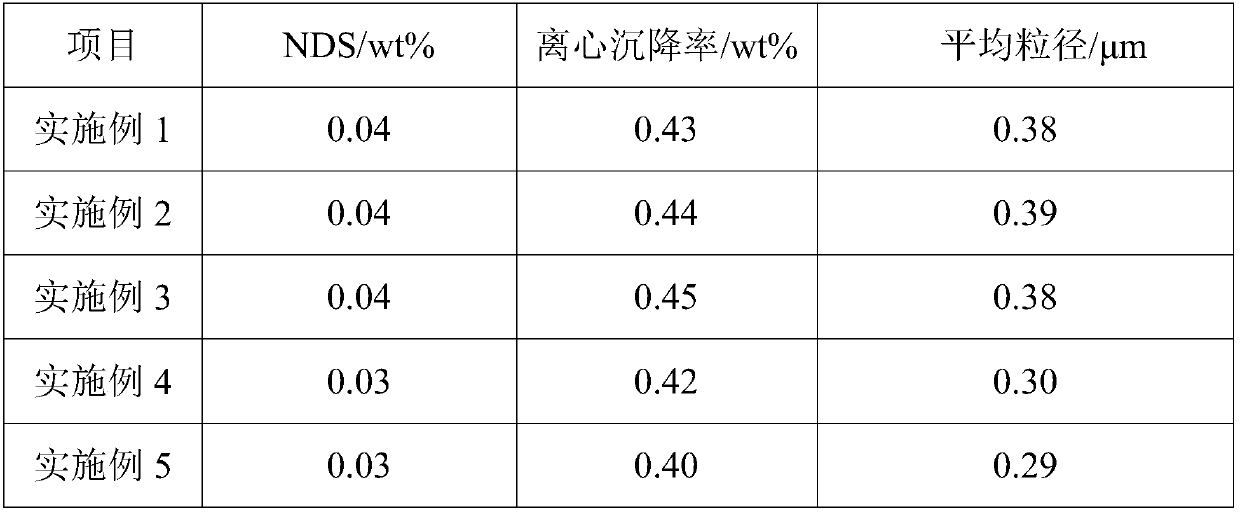

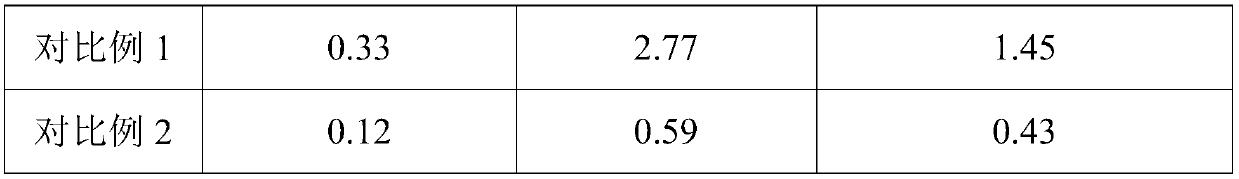

Examples

Embodiment 1

[0025] This embodiment provides a preparation process of soybean milk. The process includes the following steps:

[0026] (1) drying and peeling soybeans with 35% wet-based protein to make watercress;

[0027] (2) 133kg of watercress was mixed with 665kg of water at 70°C and refined until the average diameter of the particles in the slurry was 100 μm to obtain a slurry;

[0028] (3) Heat the slurry at 115°C for 80s, then vacuum flash at -40KPa, the temperature of the slurry after vacuum flashing is 85°C, and finally, cool to 5°C;

[0029] (4) Use a high-pressure plunger pump to pressurize the cooled slurry to an ultra-high pressure of 1150bar, spray it into the micro-jet homogeneous system at an average speed of 350m / s, and carry out micro-jet homogenization at 1150bar and 5°C. quality treatment;

[0030] (5) The temperature of the slurry homogenized by microjet rises to 40°C, and is cooled to 5°C;

[0031] (6) After detecting the protein content of the slurry, take a cert...

Embodiment 2

[0034] This embodiment provides a preparation process of soybean milk. The process includes the following steps:

[0035] (1) drying and peeling soybeans with 35% wet-based protein to make watercress;

[0036] (2) 133kg of watercress was mixed with 732kg of water at 73°C and refined until the average diameter of the particles in the slurry was 100 μm to obtain a slurry;

[0037] (3) Heat the slurry at 115°C for 80s, then vacuum flash at -50KPa, the temperature of the slurry after vacuum flashing is 85°C, and finally, cool to 8°C;

[0038] (4) Use a high-pressure plunger pump to pressurize the cooled slurry to an ultra-high pressure of 1200bar, spray it into the micro-jet homogeneous system at an average speed of 380m / s, and carry out micro-jet homogenization at 1200bar and 10°C. quality treatment;

[0039] (5) The temperature of the homogenized slurry rises to 40°C, and is rapidly cooled to 5°C;

[0040] (6) After detecting the protein content of the slurry, take a certain...

Embodiment 3

[0043] This embodiment provides a preparation process of soybean milk. The process includes the following steps:

[0044] (1) drying and peeling soybeans with 35% wet-based protein to make watercress;

[0045] (2) 133kg of watercress was mixed with 800kg of water at 75°C and refined until the average diameter of the particles in the slurry was 100 μm to obtain a slurry;

[0046] (3) Heat the slurry at 115°C for 80s, then vacuum flash at -60KPa, the temperature of the slurry after vacuum flashing is 85°C, and finally, cool to 5°C;

[0047] (4) Use a high-pressure plunger pump to pressurize the cooled slurry to an ultra-high pressure of 1250bar, spray it into the micro-jet homogeneous system at an average speed of 400m / s, and perform micro-jet homogenization at 1250bar and 0°C. quality treatment;

[0048] (5) The temperature of the homogenized slurry rises to 40°C, and is rapidly cooled to 5°C;

[0049] (6) After detecting the protein content of the slurry, take a certain am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com