Processing method of composite vegetable protein drink

A technology of vegetable protein beverage and processing method, applied in milk replacer, dairy products, application and other directions, can solve the problems of fat floating and protein precipitation, and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

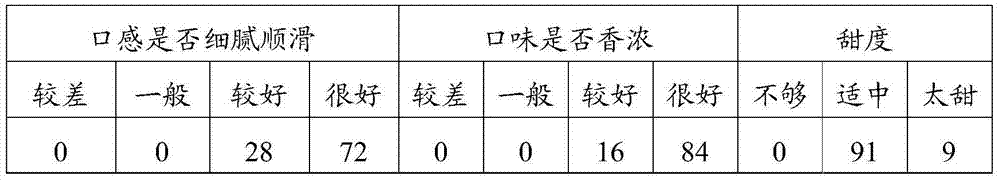

Embodiment 1

[0088] This embodiment provides a processing method of a compound vegetable protein drink made of almonds, walnut kernels and peanut kernels, comprising the following steps:

[0089] Step (1), select full-grained, insect-free, non-mildew-free almonds to peel, debitter and grind into a 40-micron grain size, select full-grained, insect-free, non-mildew-free walnut kernels to peel, After removing the astringency, grind it into a 40-micron particle size, select peanut kernels with full grains, no insects, and no mildew, peel them, remove the fishy smell, and grind them into a 40-micron particle size; successively grind 0.5 kg of almonds 0.5 kg walnut kernel mince, 2 kg peanut kernel mince, 7.5 kg sucrose, 0.2 kg polyglycerol fatty acid ester, 0.15 kg sodium bicarbonate, 0.02 kg sucrose fatty acid ester, 0.03 kg sodium tripolyphosphate, Add 0.02 kg of citric acid into the blending tank, add water to 100 kg, stir and mix evenly;

[0090] In step (2), add the mixture obtained in ste...

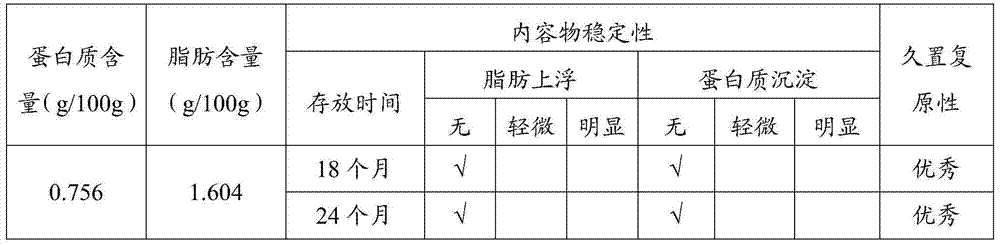

Embodiment 2

[0101] This embodiment provides a processing method of a compound vegetable protein drink made of almonds, walnut kernels and peanut kernels, comprising the following steps:

[0102] Step (1), select full-grained, insect-free, non-mildew-free almonds to peel, debitter and grind into a 50-micron grain size, select full-grained, insect-free, non-mildew-free walnut kernels to peel, After removing the astringency, grind it into a 50-micron particle size, select peanut kernels with full particles, no insects, and no mildew, peel them, remove the fishy smell, and grind them into a 50-micron particle size; successively grind 2 kg of almonds 1 kg of walnut kernels, 3 kg of peanut kernels, 12 kg of sucrose, 0.35 kg of polyglycerol fatty acid esters, 0.3 kg of sodium bicarbonate, 0.06 kg of sucrose fatty acid esters, and 0.03 kg of citric acid are added to the blending tank After adding water to 100 kg, stir and mix evenly;

[0103] In step (2), add the mixture obtained in step (1) int...

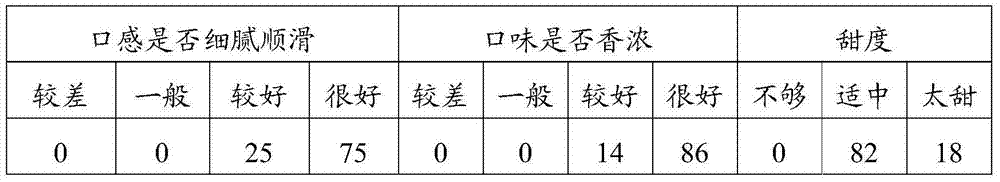

Embodiment 3

[0114] This embodiment provides a processing method of a compound vegetable protein drink made of almonds, walnut kernels and peanut kernels, comprising the following steps:

[0115] Step (1), select full-grained, insect-free, non-mildew-free almonds to peel, debitter and grind into a 60-micron grain size, select full-grained, insect-free, non-mildew-free walnut kernels to peel, After removing the astringency, grind it into a 60-micron particle size, select peanuts with full grains, no insects, and no mildew, peel them, remove the fishy smell, and grind them into a 60-micron particle size; successively grind 1 kg of almonds 0.5 kg walnut kernel mince, 2 kg peanut kernel mince, 3 kg xylitol, 0.1 kg acesulfame potassium, 0.2 kg polyglycerol fatty acid ester, 0.15 kg sodium tripolyphosphate, 0.08 kg sucrose Add fatty acid fat and 0.03 kg of citric acid into the blending tank, add water to 100 kg, stir and mix evenly;

[0116] In step (2), the mixture obtained in step (1) is adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com