A method for installing a three-span continuous steel bridge

An installation method and technology for steel bridges, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of not allowing piling construction, large hoisting radius, and increased safety risks, so as to reduce high-altitude welding operations and reduce transportation costs , the effect of reducing risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

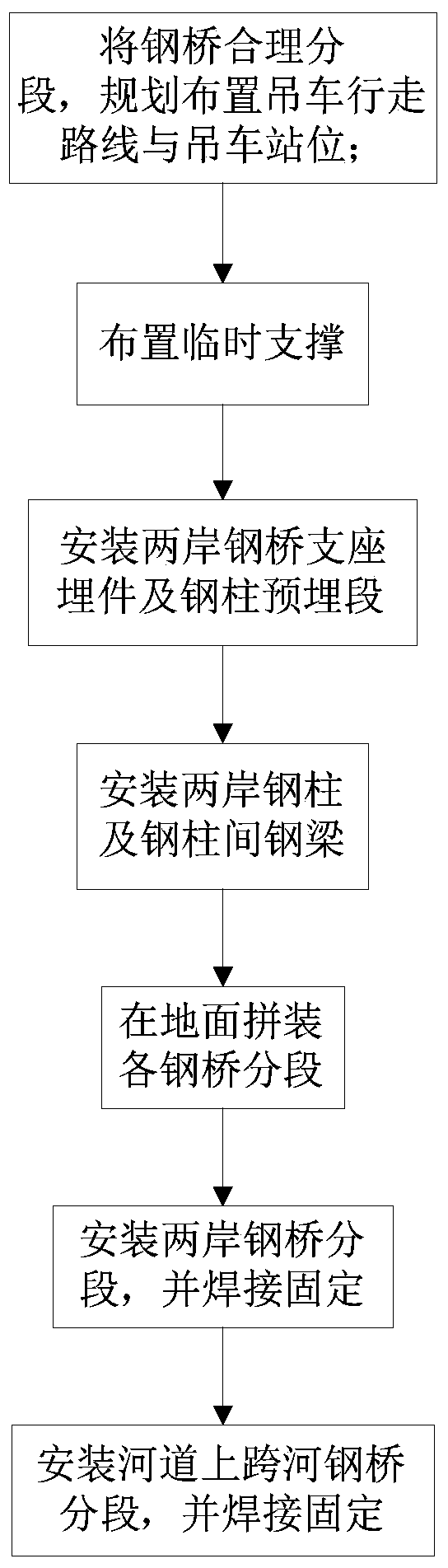

[0026] The invention relates to a method for installing a three-span continuous steel bridge, comprising the following steps:

[0027] 1. Reasonably divide the steel bridge into sections, plan and arrange the crane travel route and the crane station location.

[0028] For ease of installation, the steel bridge is divided into several segments. After the overall modeling of the steel bridge, the main steel structure of the steel bridge is initially divided into sections according to the installation plan, combined with the position of the temporary support and the rated weight capacity of the crane and lifting machinery. Calculate and analyze the hoisting radius of the crane according to the position of the center of gravity of the initially divided segment, and adjust it at any time to meet the hoisting requirements, and determine the final hoisting segment position.

[0029] 2. Arrange temporary support

[0030] The installation of the steel bridge is hoisted in sections. B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com