Mudstone sample, device and method for reshaping mudstone sample using cuttings

A mudstone and sample technology, which is applied in the field of mudstone samples and the device field of using cuttings to reshape mudstone samples, can solve problems such as the performance evaluation of mudstone layers in disaster-stricken sections and the difficulty in determining the location of abandoned wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The mudstone samples provided by the present invention are prepared from mudstone drilling debris. Through the mechanical evaluation of the remolded mudstone samples, the sealing performance of abandoned wells can be evaluated, and further reference can be made for whether to carry out workover operations.

Embodiment 2

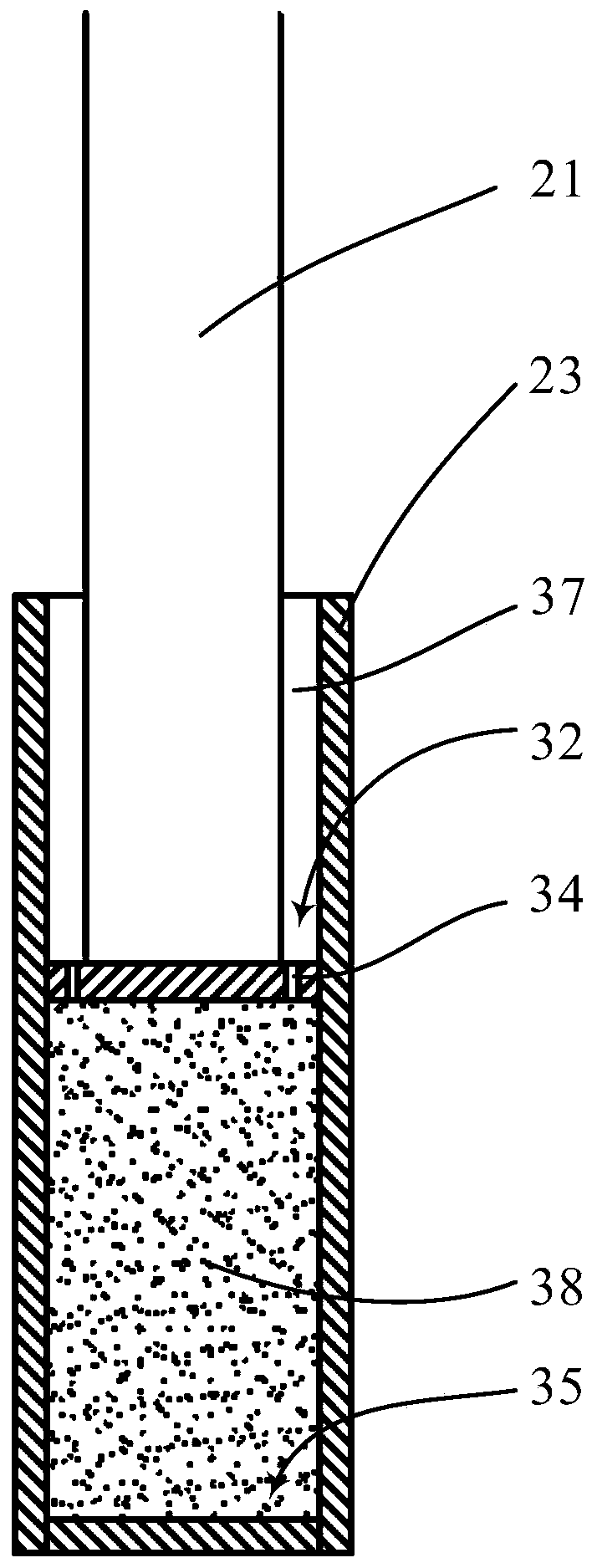

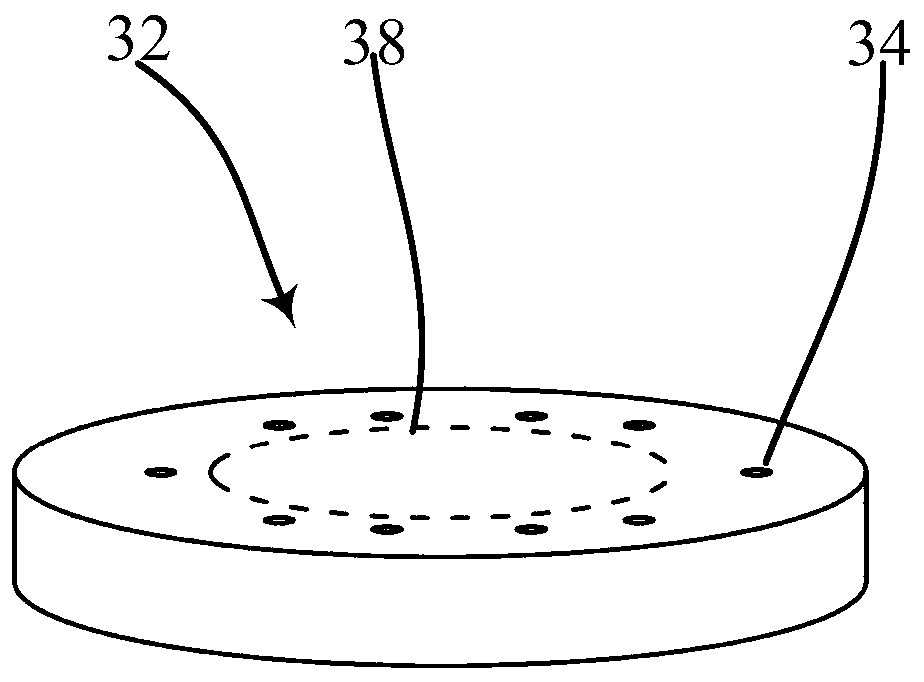

[0075] See attached Figure 1~3 The device for reshaping a mudstone sample using cuttings provided in Embodiment 1 of the present invention includes a sleeve 23, a bottom plate 35, a pressing plate 32 and a force applying mechanism. The shape of the bottom plate 35 is the same as the inner cross-sectional shape of the sleeve 23, so that the bottom plate 35 can be embedded in the sleeve 23; A sliding pair is formed between the bottom plate 35, the inner wall of the sleeve 23, and the pressure plate 32 to form a first accommodation space for the mudstone drilling debris 38 to be pressed; the bottom plate 35, the sleeve 23, and the pressure plate 32 are at least provided with A permeable hole is used to drain the water overflowing from the mudstone formation drilling debris 38 to be pressed during the pressing process; the force applying mechanism is used to provide a pressing force from the upper part of the pressing plate 32 to the mudstone formation drilling debris 38 to be pr...

Embodiment 3

[0084] See attached Figure 4 Unlike the device for reshaping mudstone samples using cuttings provided in Embodiment 1 of the present invention, the device for reshaping mudstone samples using cuttings provided in Embodiment 2 of the present invention further includes a support and a hydraulic mechanism 16 . The assembled sleeve 23 , bottom plate 35 , pressing plate 32 and force application mechanism are carried on the bracket, and the hydraulic mechanism 16 is used to control the force applied by the force application mechanism to the pressure plate. In this case, the pressing operation is more robust.

[0085] Wherein, the bracket includes an upper loading plate 1 , a lower loading plate 2 , and at least two uprights, and the two uprights include a first upright 3 and a second upright 4 . One end 5 of the first column 3 is rigidly connected to the upper loading plate 1, and the other end 8 of the first column 3 is rigidly connected to the lower loading plate 2; one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com