Device and method for measuring high-pressure leakage of orifice plate

A throttling orifice and high-pressure technology, which is applied in the direction of measuring devices, fuel injection devices, charging systems, etc., can solve the problem of increased leakage risk, affecting the flow of oil in and out of the orifice, and the inability to effectively measure the high pressure of the throttling orifice Oil leakage and other problems, to achieve the effect of good sealing performance, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific drawings and embodiments.

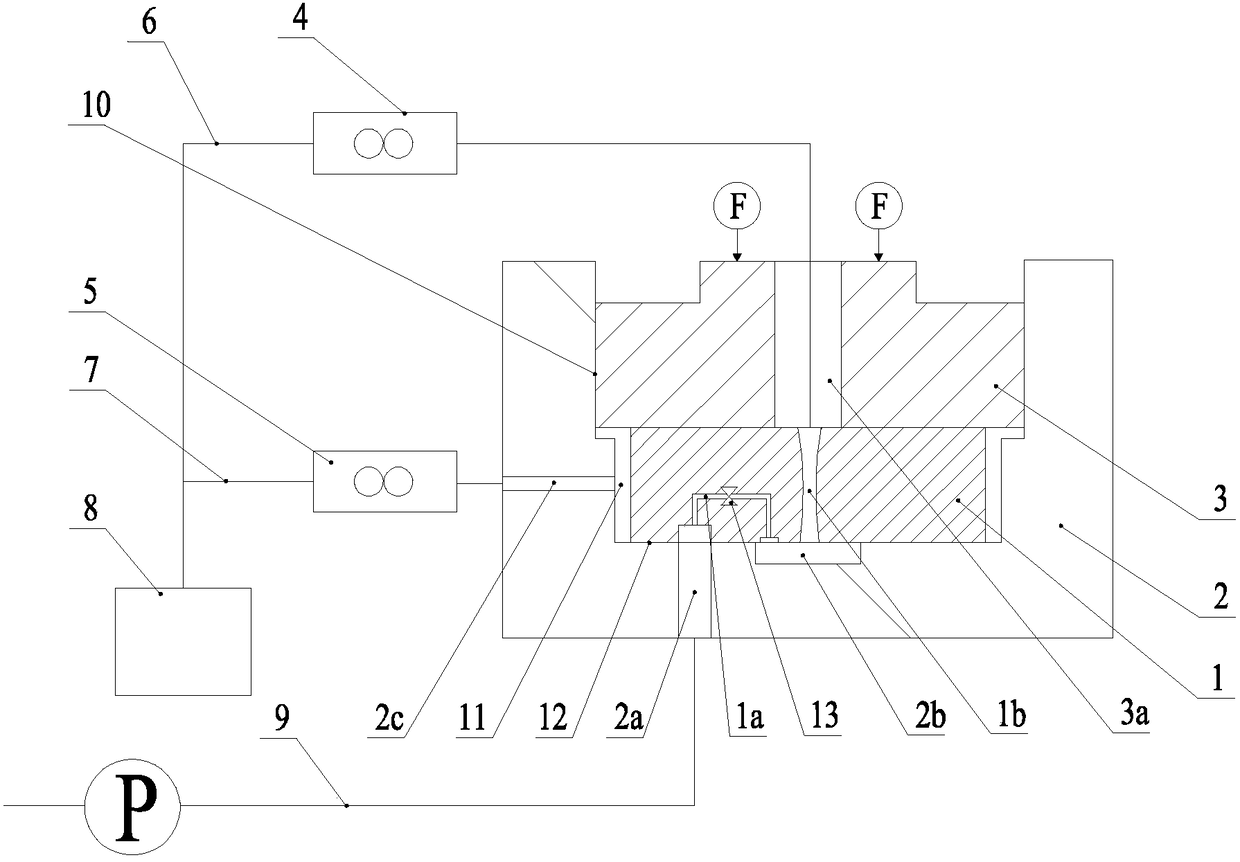

[0025] As shown in the figure: the device for measuring the high pressure leakage of the throttle orifice in the embodiment is mainly composed of the throttle orifice 1, the test orifice seat 2, the pressing block 3, the first flow meter 4, the second flow meter 5, the first flow meter A connecting pipeline 6, a second connecting pipeline 7, an oil tank 8, a test pipeline 9 and a valve 13 etc. are composed.

[0026] like figure 1 As shown, the test orifice seat 2 is provided with a concave cavity, and the bottom surface of the cavity is processed according to the specifications of the orifice seat surface on the injector body, so as to ensure that the throttle orifice 1 is installed on the device and assembled on the injector. The sealing surface formed when it is on the body is consistent. The throttling orifice 1 is placed in the concave cavity and pressed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com