A Method for Predicting the Sulfur Content in Blended Coal Smelting Coke

A technology that combines coal and sulfur content, applied in coke ovens, instruments, calculations, etc., can solve problems such as deviation of prediction results, and achieve the effects of improving prediction accuracy, eliminating the decrease in prediction accuracy and flexible use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

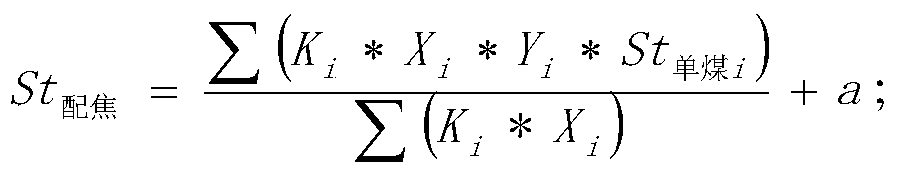

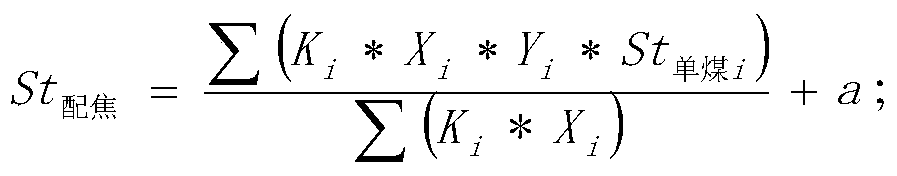

[0070] In the production of large coke ovens, Example 1 of the present invention predicts the method of sulfur content in blended coal smelting coke, using the sulfur content of a single type of coal and the conversion coefficient of sulfur content in the coking process of a single type of coal, the total coke rate and the amount of sulfur in the blended coal The matching ratio in the coke is used as a parameter to predict the sulfur content of the coke, and the calculation method of the sulfur content of the blended coal smelting coke is as follows:

[0071]

[0072] In the formula:

[0073] St. 配焦 : Predicted value of sulfur content in blended coal smelting coke, %;

[0074] St. 单煤i : Sulfur content of single coal i, %;

[0075] K i : Total coking rate of single coal i coking, %;

[0076] x i : The mass proportion of single coal i in blended coal, %;

[0077] Y i : Sulfur conversion coefficient of single coal i;

[0078] a: Correction value, used to correct the e...

Embodiment 2

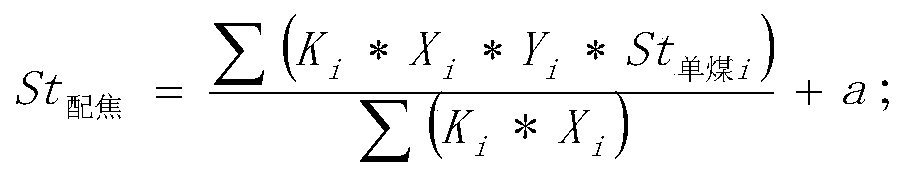

[0092] In the production of large coke ovens, the method for predicting the sulfur content of blended coal smelted coke described in Example 2 of the present invention is as follows:

[0093]

[0094] In the formula:

[0095] St. 配焦 : Predicted value of sulfur content in blended coal smelting coke, %;

[0096] St. 单煤i : Sulfur content of single coal i, %;

[0097] K i : Total coking rate of single coal i coking, %;

[0098] x i : The mass proportion of single coal i in blended coal, %;

[0099] Y i : Sulfur conversion coefficient of single coal i.

[0100] a: Correction value, used to correct the error between coking test and large coke oven production.

[0101] The sulfur content of the corresponding coke is predicted from the relevant data of multiple coal blending schemes, and then compared with the sulfur content of the coke produced by the large coke oven in actual production, the average value of all differences is the correction value a.

[0102] The sulfur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com