Intelligent rear-drive assembly of rear axle of electric vehicle

A technology for electric vehicles and rear axles, applied to transmission parts, belts/chains/gears, mechanical equipment, etc., can solve problems such as oil loss, unreasonable design of oil nozzles, etc., to prevent oil backflow and curb oil leakage the effect of the situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

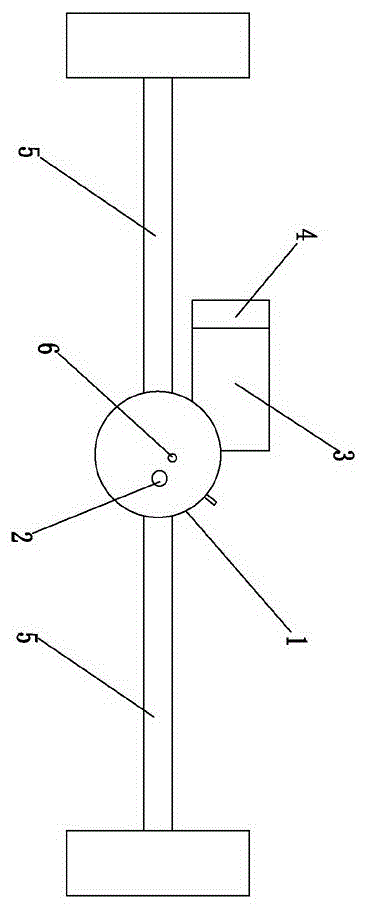

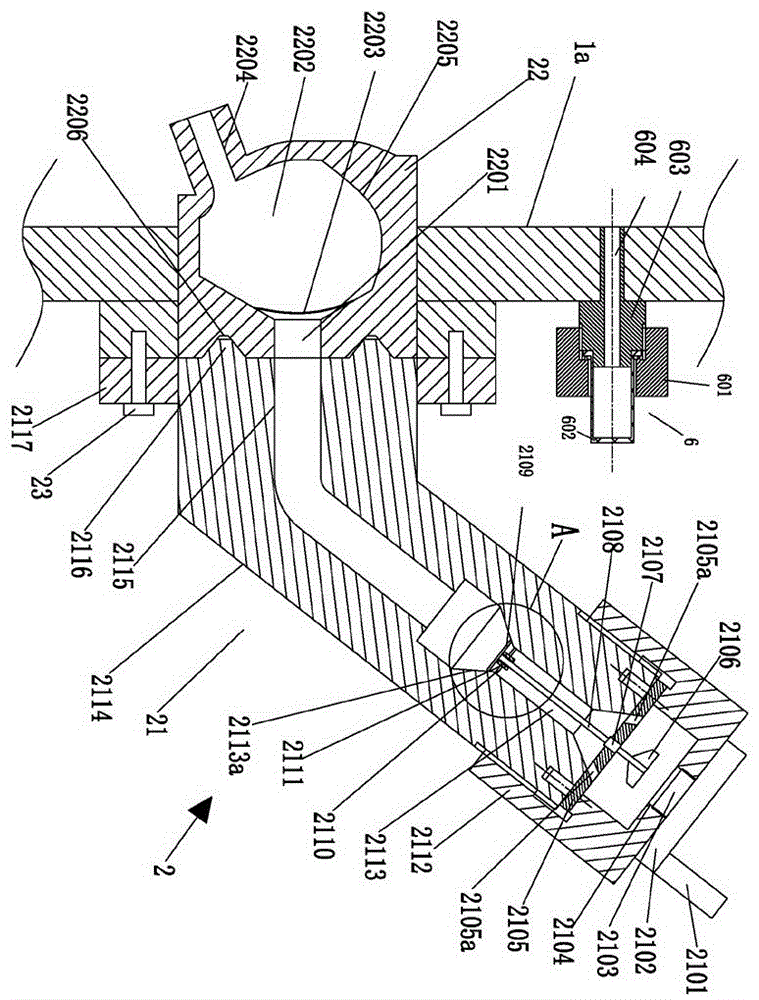

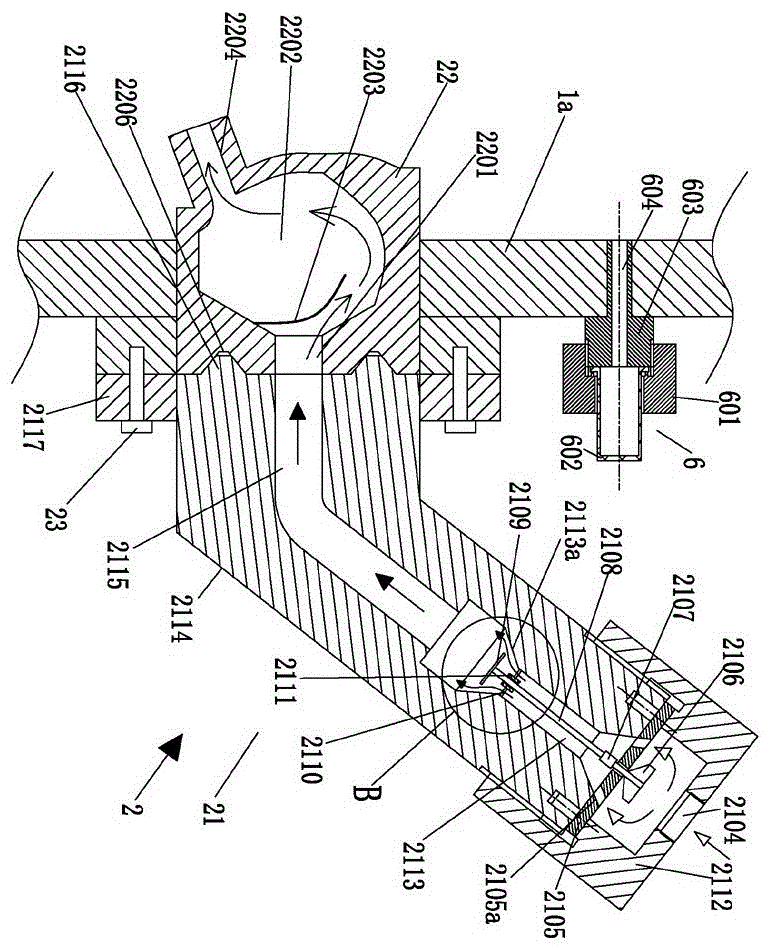

[0024] Such as Figure 1-5 As shown, a rear drive assembly of the rear axle of an intelligent electric vehicle includes a differential 1, a motor 3 that provides power input to the differential 1, a controller 4 for controlling the working state of the motor 3, and a pair of mounting On the axle shaft 5 at the power output end of the differential 1, the differential housing 1a of the differential 1 is equipped with an oil injection assembly 2 and a liquid level monitoring assembly 6, which can monitor the difference during the oil injection process. Whether the oil in the transmission housing 1a exceeds the rated height, the installation positions of the oil injection assembly 2 and the liquid level monitoring assembly 6 are close to the middle of the differential housing 1a.

[0025] The oil injection assembly 2 includes a flow guide 21 , an oil injection seat 22 detachably inserted on the differential case 1 a , and a screw 23 . The oil injection seat 22 is installed at a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com