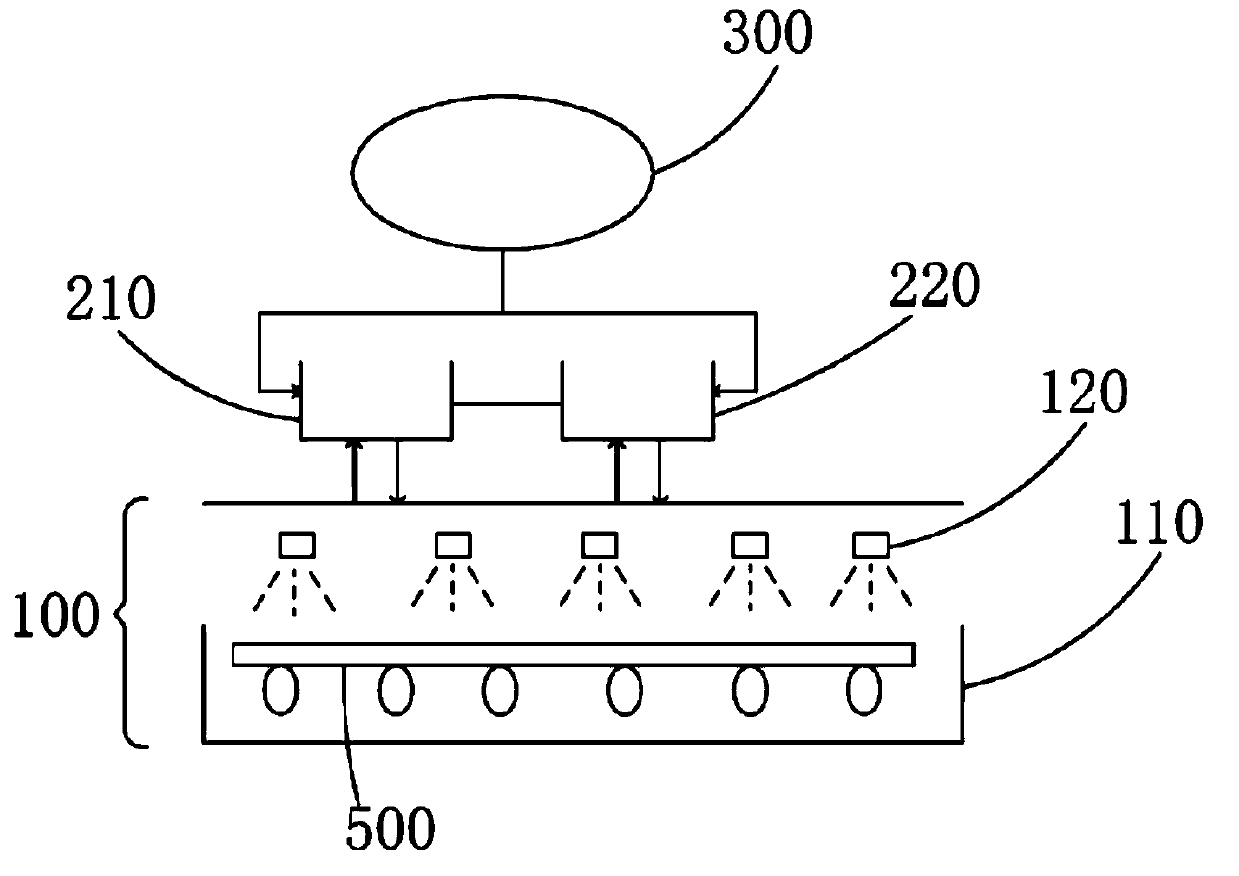

A method for adjusting developer concentration during image development

A developing process and developing solution technology, which can be used in various fluid ratio control, photosensitive material processing and other directions, and can solve the problem of graphics CD deviation from the set range value of the developing solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

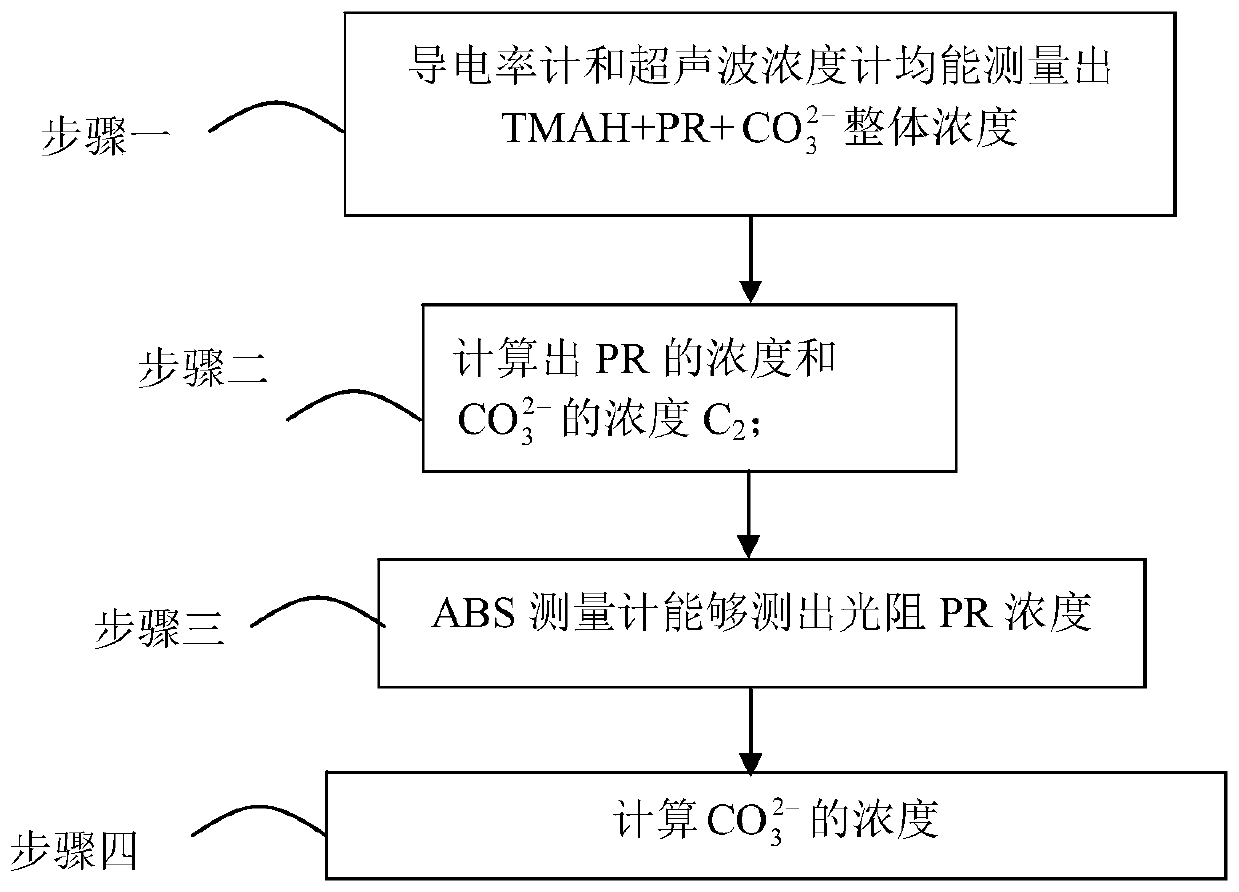

[0042] Specific implementation mode 1: A method for adjusting the developer concentration in the image development process of this embodiment is specifically prepared according to the following steps:

[0043] when in the developer When the concentration exceeds the threshold, adjust the concentration Y of the developer according to the correction relationship;

[0044] According to the concentration Y of the developer and the compensation value of the Offset function, the target concentration M of the developer is calculated; the developer concentration meter in the developer control system (DCS) is measuring the developer There is a certain machine error in the concentration, and the concentration measuring meter will be calibrated in the early stage of equipment debugging, and the offset function will be compensated to eliminate the machine error. The change of the concentration realizes the compensation value of the Offset function, and according to the obtained target...

specific Embodiment approach 2

[0056] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the concentration Y of the developer formulated according to the correction relationship is specifically:

[0057] By measuring developer concentration and measuring post-developer Concentration, according to the critical dimension CD of the pattern after development can be maintained at the set value, the concentration of the developer and the concentration of the developer are obtained. Concentration has an approximate relationship as:

[0058] Y=2.38+2×10 -4 X+8×10 -8 x 2

[0059] Among them, Y is the developer solution concentration wt%, X is the developer solution Concentration ppm;

[0060] 2.38% developer normally used in the process When the concentration is 1500ppm ~ 2000ppm (ie 0.15% ~ 0.20%) after development, the critical dimension CD of the graphics meets the set range value, so the corrected relationship is:

[0061] Y=2.38+2×10 -4 (X-2000)+8×10 -8...

specific Embodiment approach 3

[0065] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: the complementary value of the function is the complementary value K of the Offset function; the calculation method of the complementary value K of the Offset function is:

[0066] M=N+K-(Y-2.38)

[0067] Among them, N is the theoretical developer concentration; M is the developer target concentration; -(Y-2.38) value is The concentration change is updated; the Offset function is a supplementary operation function in excel. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com