Detection circuit, working method of detection circuit, and driving circuit

A detection circuit and driver technology, applied in the field of driving circuits and detection circuits, can solve the problems of high cost, high risk and low technical efficiency, and achieve the effect of improving the efficiency of bad analysis and reducing the cost of bad analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

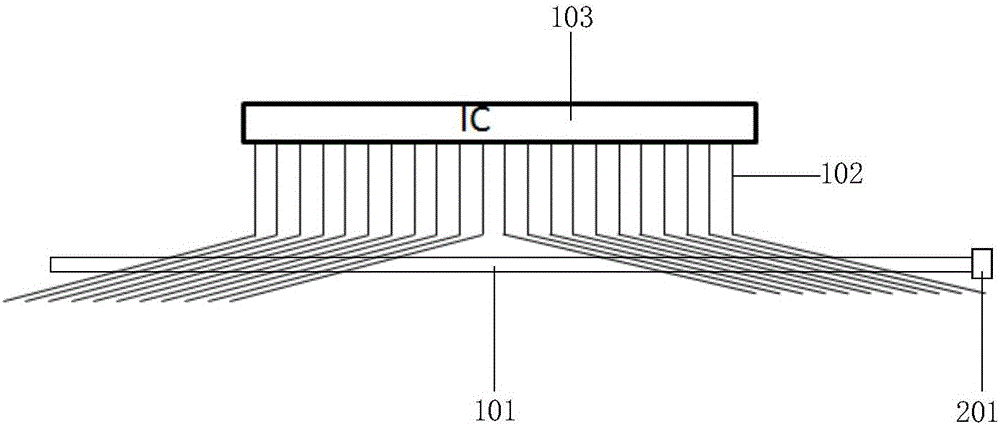

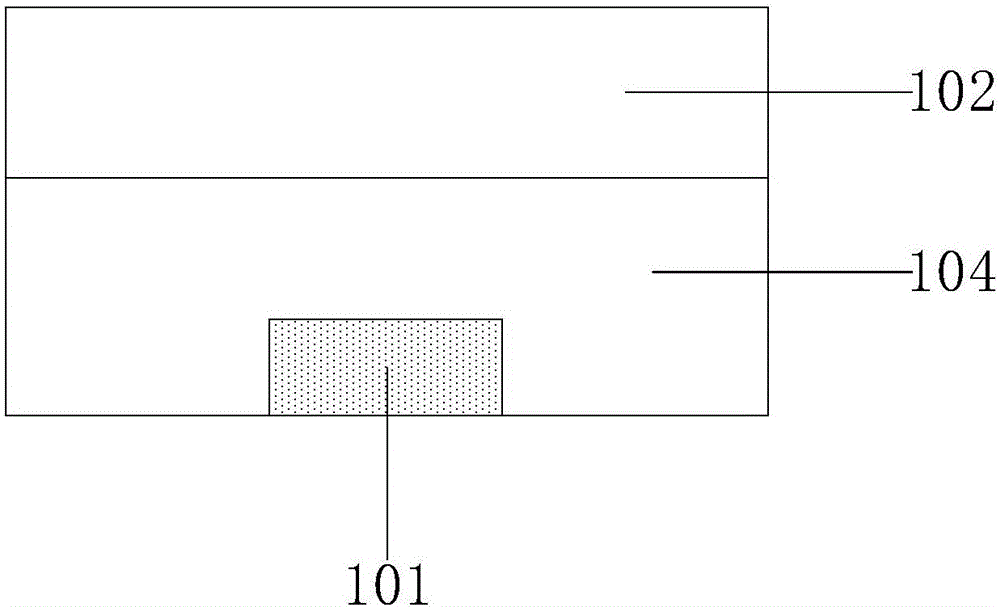

[0032] figure 1 It is a schematic structural diagram of a detection circuit provided in Embodiment 1 of the present invention, figure 2 for figure 1 Cross section of the detection circuit shown. Such as figure 1 and figure 2 As shown, the detection circuit includes a test line 101, a laser unit and a judgment unit, the test line 101 is connected to the judgment unit, and the test line 101 intersects with the projection of the signal line of the driver on the substrate substrate, so An insulating layer 104 is disposed between the test line 101 and the signal line. In this embodiment, the driver is a source driver 103, the signal line is a data line 102, and the test line 101 is routed in the same direction as the gate line.

[0033] In this embodiment, the laser unit is used to perform laser breakdown on the insulating layer 104, so that the test line 101 is connected to the data line 102, and the test line 101 is used to output the standby state of the data line 102. T...

Embodiment 2

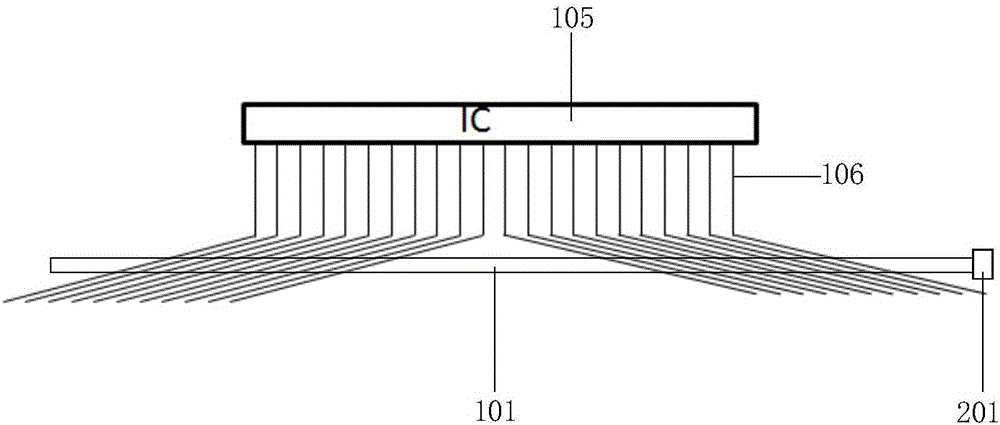

[0037] image 3 It is a schematic structural diagram of a detection circuit provided in Embodiment 2 of the present invention, Figure 4 for image 3 Cross section of the detection circuit shown. Such as image 3 and Figure 4 As shown, the detection circuit includes a test line 101, a laser unit and a judgment unit, the test line 101 is connected to the judgment unit, and the test line 101 intersects with the projection of the signal line of the driver on the substrate substrate, so An insulating layer 104 is disposed between the test line 101 and the signal line. In this embodiment, the driver is a gate driver 105, the signal line is a gate line 106, and the test line 101 is routed in the same direction as the data line.

[0038]In this embodiment, the laser unit is used to perform laser breakdown on the insulating layer 104, so that the test line 101 is connected to the gate line 106, and the test line 101 is used to output the waiting signal of the gate line 106. The...

Embodiment 3

[0042] This embodiment provides a driving circuit, including a driver and the detection circuit provided in Embodiment 1 or Embodiment 2. For specific content, please refer to the description in Embodiment 1 or Embodiment 2 above, which will not be repeated here.

[0043] In the drive circuit provided in this embodiment, the detection circuit includes a test line, a laser unit, and a judgment unit, the test line is connected to the judgment unit, and the test line and the signal line of the driver are connected to each other on the base substrate. The projections intersect, and an insulating layer is provided between the test line and the signal line; the laser unit is used to perform laser breakdown on the insulating layer, so that the test line is connected to the signal line to be tested; the The test line is used to output the signal to be tested of the signal line to be tested; the judging unit is used to judge whether the driving signal of the driver is abnormal according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com