Stripping device for cathode zinc plate

A stripping device and cathode zinc technology, which are applied to the improvement of process efficiency, photography process, instruments, etc., can solve problems such as lack of solutions, and achieve the effect of high stripping efficiency, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

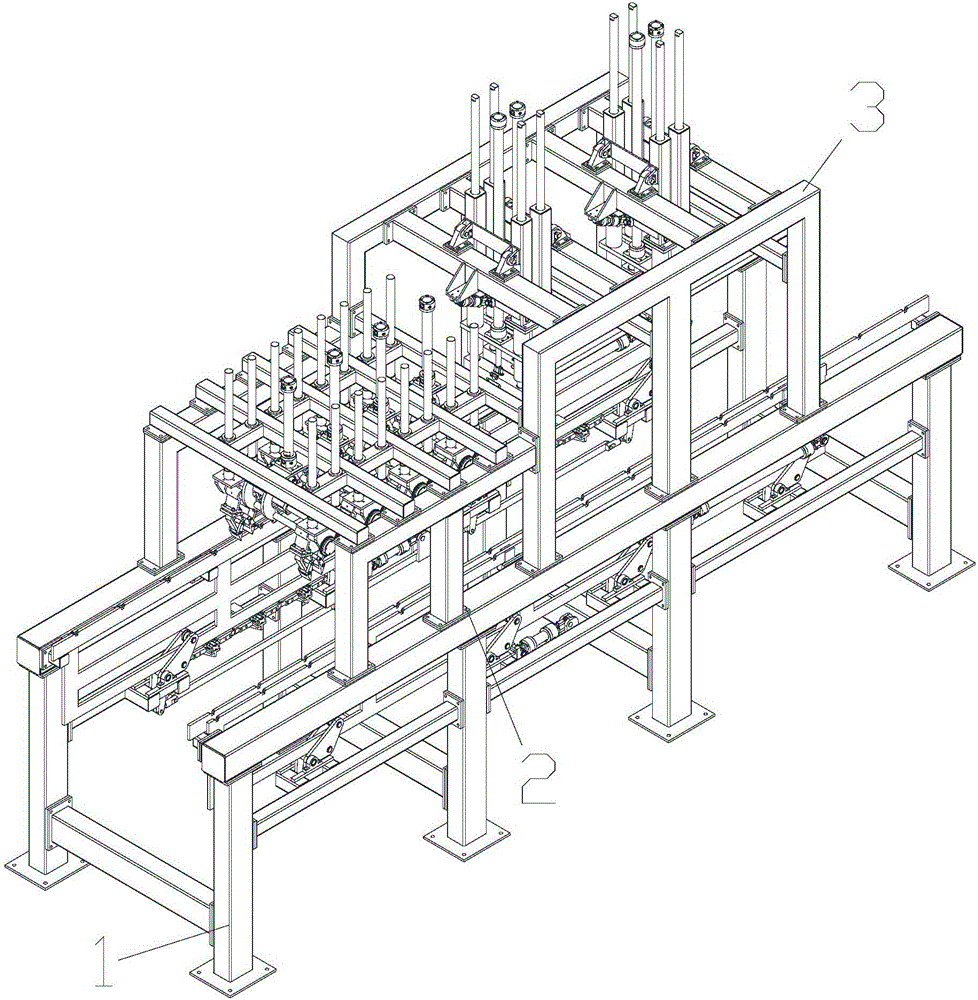

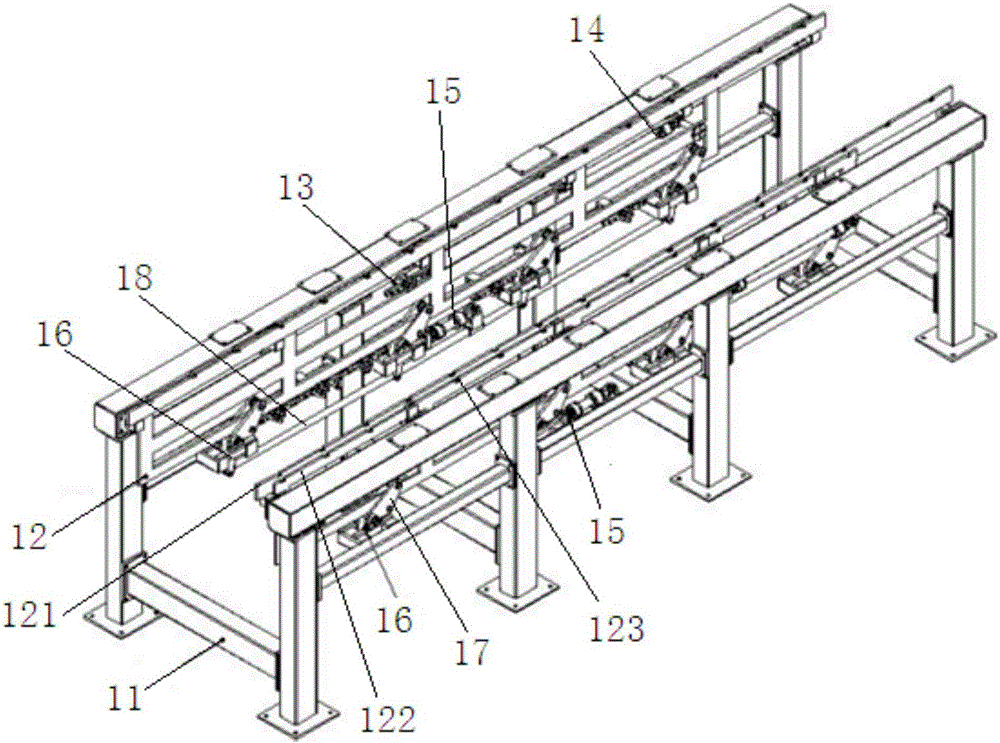

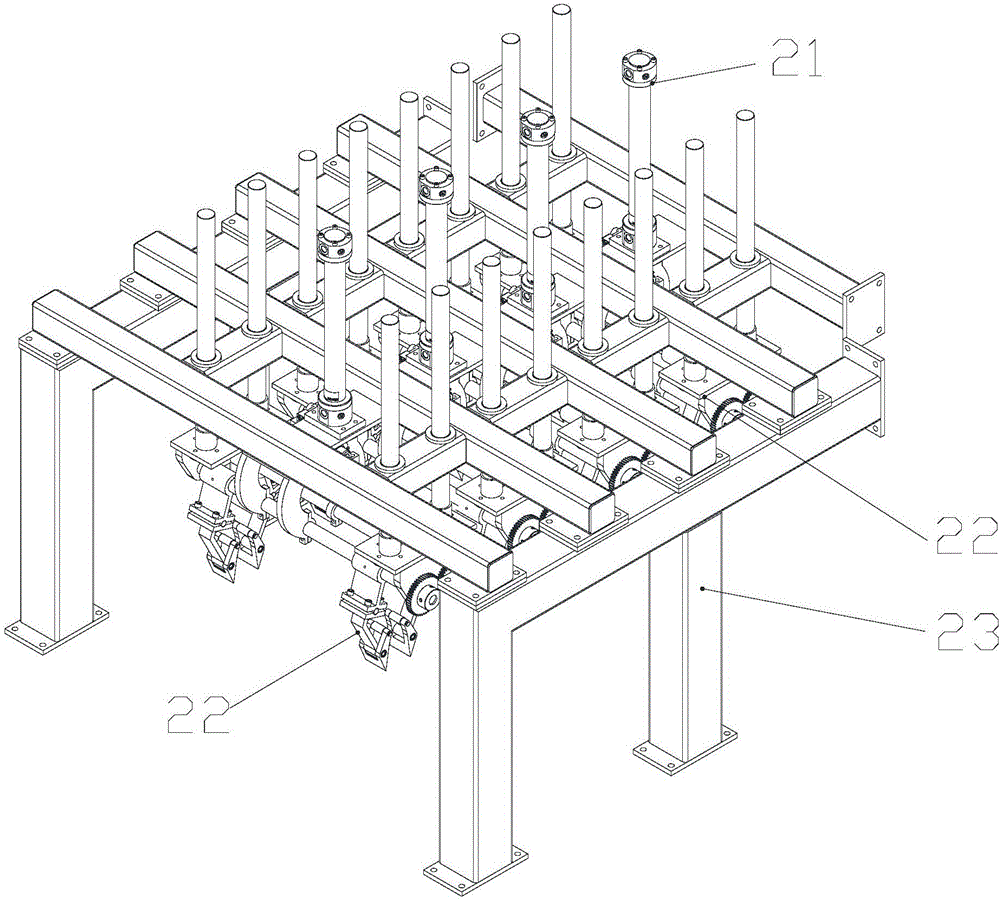

[0016] The present invention will be described in detail below in conjunction with accompanying drawing: Figures 1 to 6 Shown, the present invention is made up of chassis conveyor 1, pre-stripping device 2, stripping device 3, described pre-stripping device 2, stripping device 3 are respectively fixed on the top of chassis conveyor 1, and stripping device 3 is positioned at pre-stripping device After 2; the underframe conveyor 1 is composed of an underframe 11, a transfer mechanism 12, a positioning mechanism 13, a first delivery cylinder 14, a second delivery cylinder 15 and a transfer support seat 16, and the transfer mechanism 12 is located at the bottom respectively. On both sides of the frame 11, the transfer mechanism 12 is composed of a transfer fixed block 121 and a transfer movable block 122. The second conveying cylinder 15 is located below the transfer mechanism 12 and is fixed on the chassis 11. The second conveying cylinder 15 is connected with the transfer suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com