A protective material for radically curing interior wall damp and its preparation method

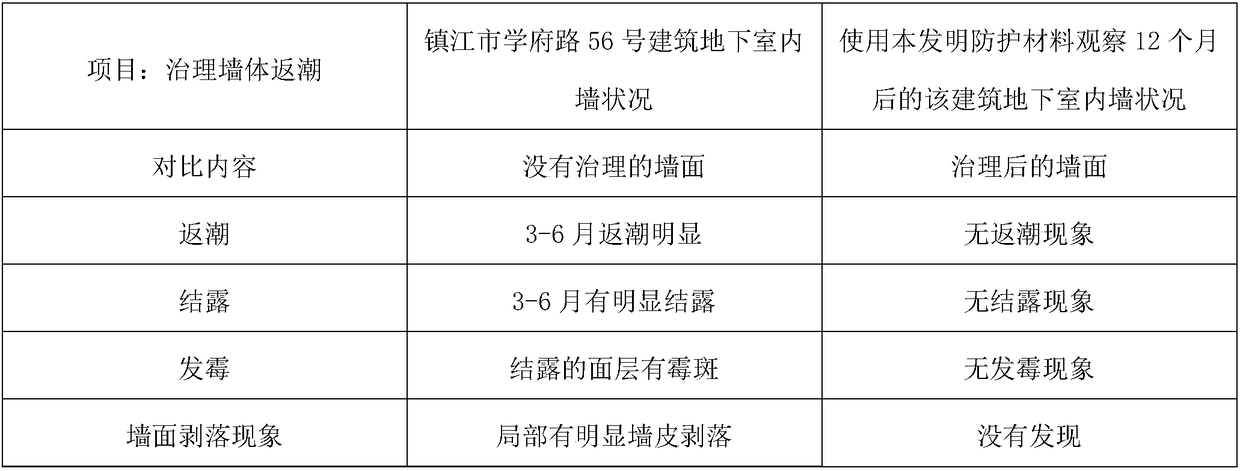

A protective material and moisture-returning technology, applied in applications, ceramic products, household appliances, etc., can solve the problems of easy growth of mold, mildew, and mildew on the surface of the wall, and achieve the effect of preventing moisture-returning condensation and improving thermal insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

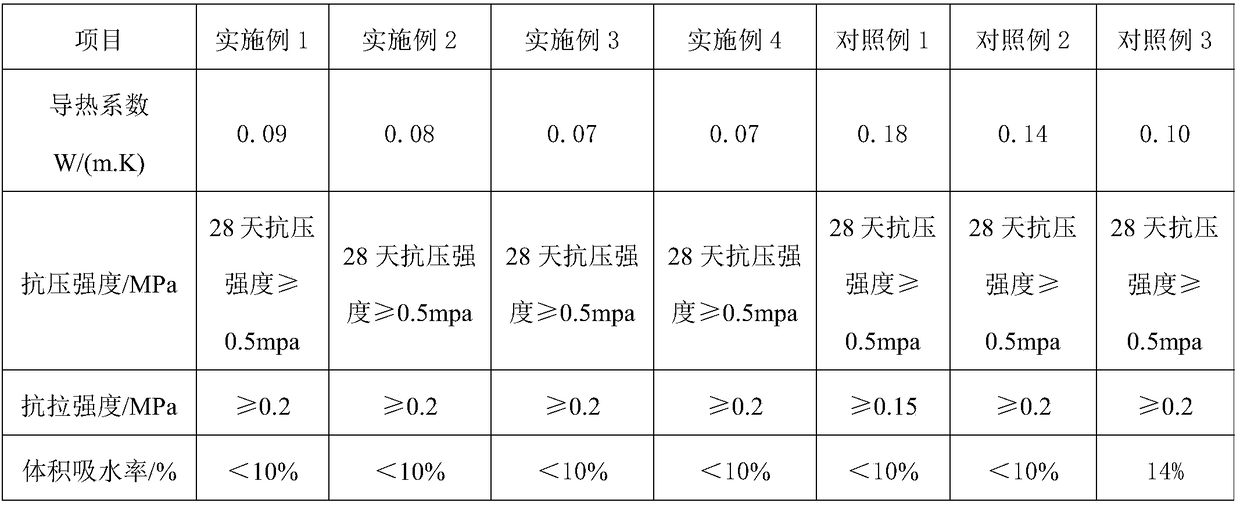

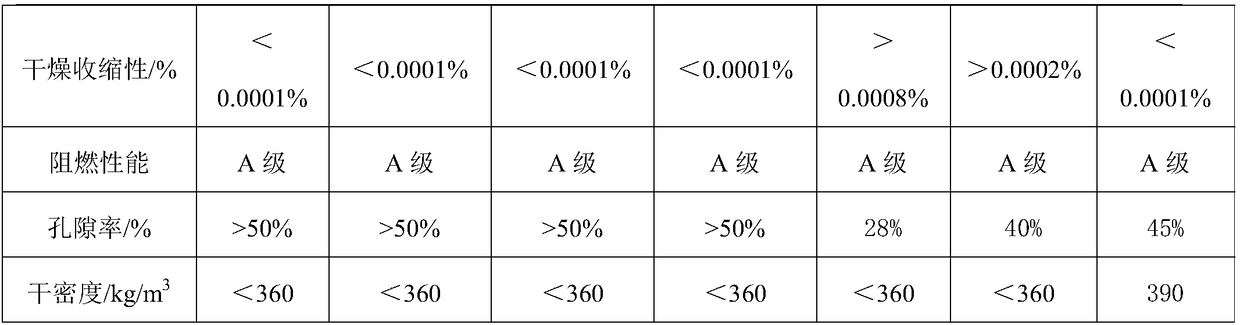

Examples

Embodiment 1

[0019] A kind of protective material used for eradicating moisture in interior walls. The raw materials of the protective material include the following components in parts by weight: 40 parts of cement, 20 parts of fly ash, 15 parts of diatomite, 15 parts of heavy calcium powder, and xanthan gum powder 2 parts, 0.2 parts of air-entraining agent, 0.5 parts of polypropylene anti-crack fiber, 3 parts of EPS particles. Among them, diatomite is calcined diatomite, the fiber length of polypropylene anti-cracking fiber is 1-1.5cm, 30% of the EPS particles have a particle diameter of 1.5-2mm, and 25% have a particle diameter greater than 2mm and less than 3mm. %, particle diameters of 3-5mm account for 45%, and the moisture content of cement, fly ash, diatomaceous earth, heavy calcium powder and xanthan gum powder are all below 5%.

[0020] The preparation method of the protective material for radically curing interior wall moisture, comprises the following steps:

[0021] Step 1, w...

Embodiment 2

[0024] A kind of protective material used for eradicating moisture in interior walls. The raw materials of the protective material include the following components in parts by weight: 55 parts of cement, 28 parts of fly ash, 16 parts of diatomite, 20 parts of heavy calcium powder, and xanthan gum powder 3 parts, 0.3 parts of air-entraining agent, 0.8 parts of polypropylene crack-resistant fiber, and 4 parts of EPS particles. Among them, the diatomite is calcined diatomite, the fiber length of the polypropylene anti-cracking fiber is 1-1.5cm, 35% of the EPS particles have a particle diameter of 1.5-2mm, and 25% have a particle diameter greater than 2mm and less than 3mm. %, particles with a diameter of 3-5mm account for 40%, and the moisture content of cement, fly ash, diatomaceous earth, heavy calcium powder and xanthan gum powder are all below 5%.

[0025] The preparation method of the protective material for radically curing interior wall moisture, comprises the following st...

Embodiment 3

[0029] A kind of protective material used for eradicating moisture in interior walls. The raw materials of the protective material include the following components in parts by weight: 70 parts of cement, 35 parts of fly ash, 18 parts of diatomaceous earth, 23 parts of heavy calcium powder, and xanthan gum powder 5 parts, 0.5 parts of air-entraining agent, 1.2 parts of polypropylene crack-resistant fiber, and 4 parts of EPS particles. Among them, diatomite is calcined diatomite, the fiber length of polypropylene anti-cracking fiber is 1-1.5cm, 32% of the EPS particles have a particle diameter of 1.5-2mm, and 26% have a particle diameter greater than 2mm and less than 3mm. %, particle diameters of 3-5mm account for 42%, and the moisture content of cement, fly ash, diatomaceous earth, heavy calcium powder and xanthan gum powder are all below 5%.

[0030] The preparation method of the protective material for radically curing interior wall moisture, comprises the following steps: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com