A defrosting control method and device

A control method and external motor technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problem of low defrosting accuracy and achieve the effect of improving heating effect and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

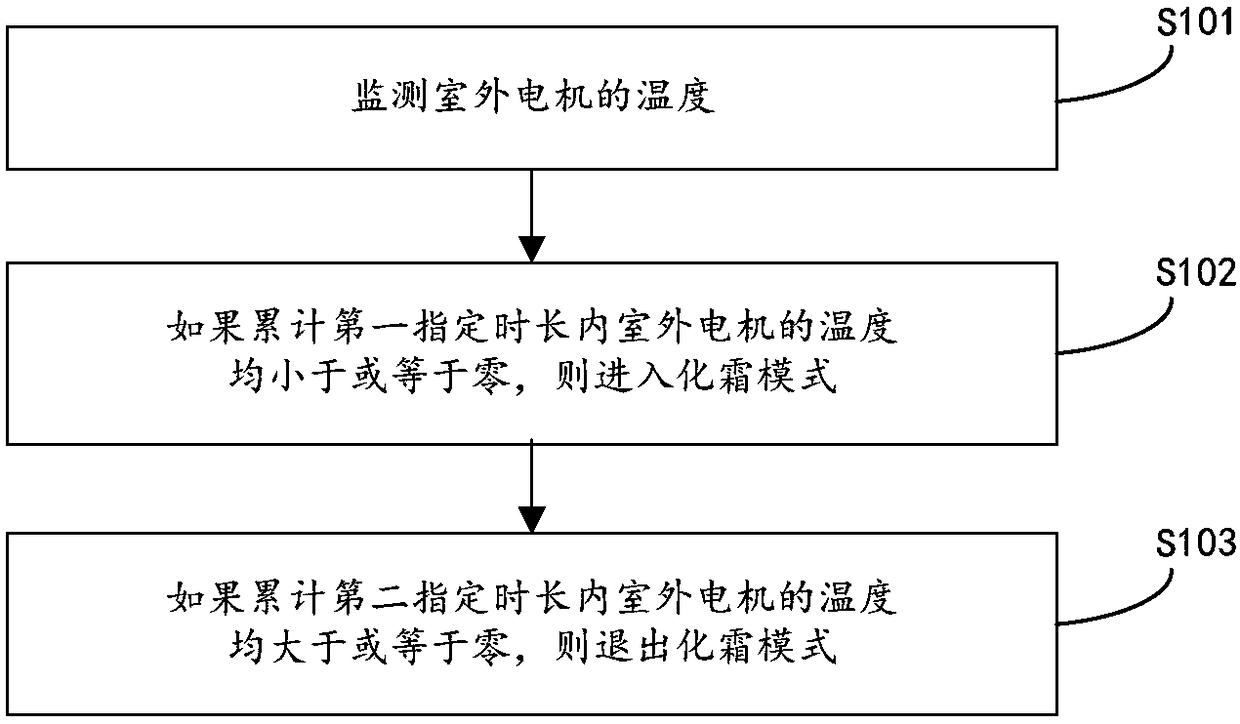

[0018] figure 1 is a flowchart of a defrosting control method according to an embodiment of the present invention, such as figure 1 As shown, the method includes the following steps (step S101-step S103):

[0019] Step S101, monitoring the temperature of the outdoor motor;

[0020] Step S102, if the accumulated temperature of the outdoor motor within the first specified time period is less than or equal to zero, enter the defrosting mode;

[0021] Step S103, if the accumulative temperature of the outdoor motor is greater than or equal to zero within the second specified time period, exit the defrosting mode.

[0022] In this embodiment, the infrared temperature sensor is used to detect the temperature of the outdoor motor, so as to perform defrosting operation and exit the defrosting operation, achieve the purpose of accurate defrosting, and improve the heating effect and reliability of the unit.

[0023] The monitoring of the temperature of the outdoor motor can be realize...

Embodiment 2

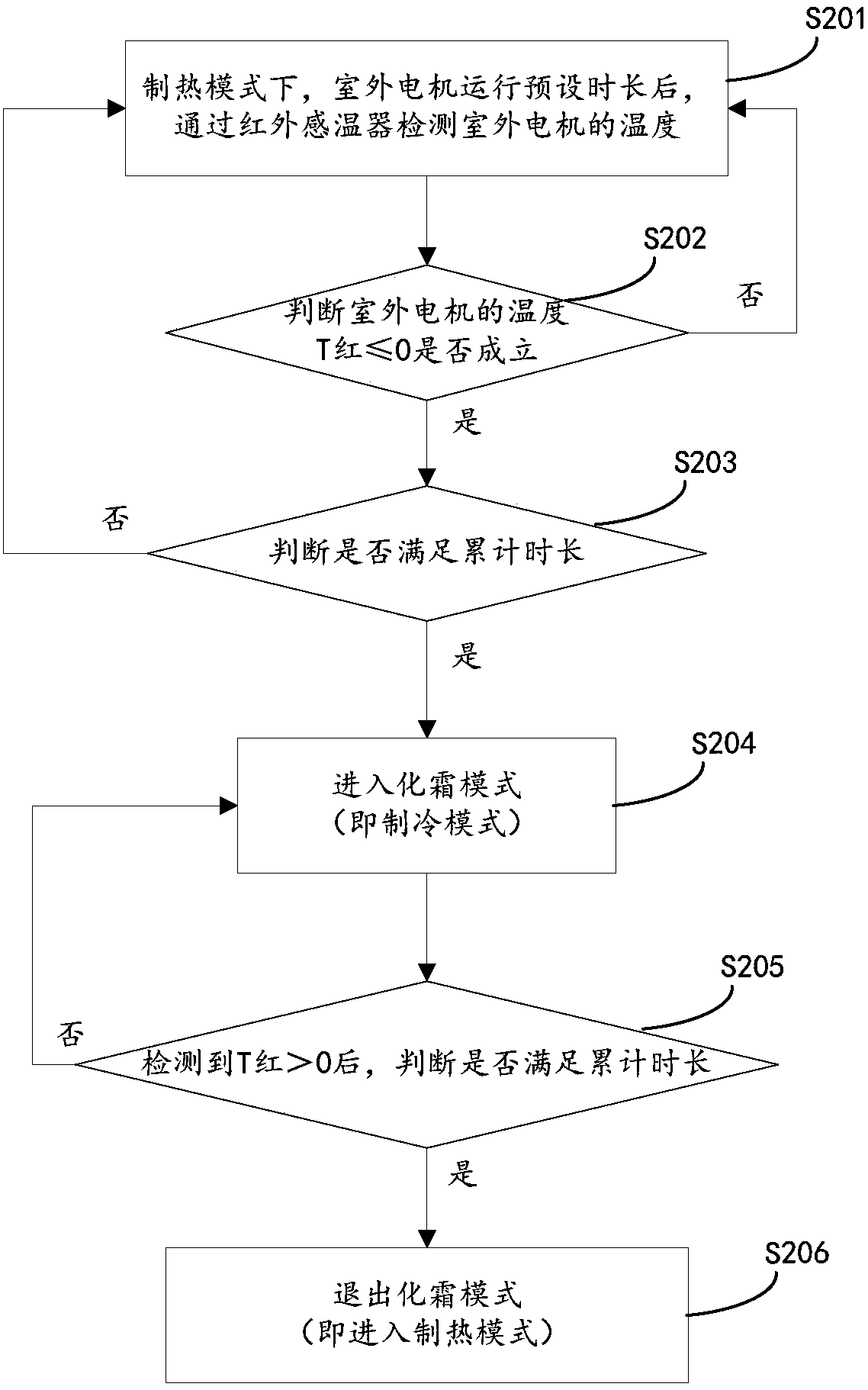

[0030] figure 2 is a flow chart of defrosting in heating mode according to an embodiment of the present invention, such as figure 2 As shown, the process includes the following steps (step S201-step S206):

[0031] Step S201, in the heating mode, after the outdoor motor runs for a preset time, the temperature of the outdoor motor is detected by the infrared temperature sensor.

[0032] Step S202, judging the temperature T of the outdoor motor 红 Whether ≤0 holds; if yes, execute step S203; if not, execute step S201.

[0033] Step S203, judging whether the cumulative duration is satisfied, that is, within the cumulative duration T 红 Whether ≤0 is always established; if yes, execute step S204; if not, execute step S201.

[0034] Step S204, enter the defrosting mode (that is, the cooling mode).

[0035] Step S205, detecting T 红 After >0, it is judged whether the accumulative duration (for example, 20s) is met; if yes, execute step S206; if not, execute step S204.

[0036]...

Embodiment 3

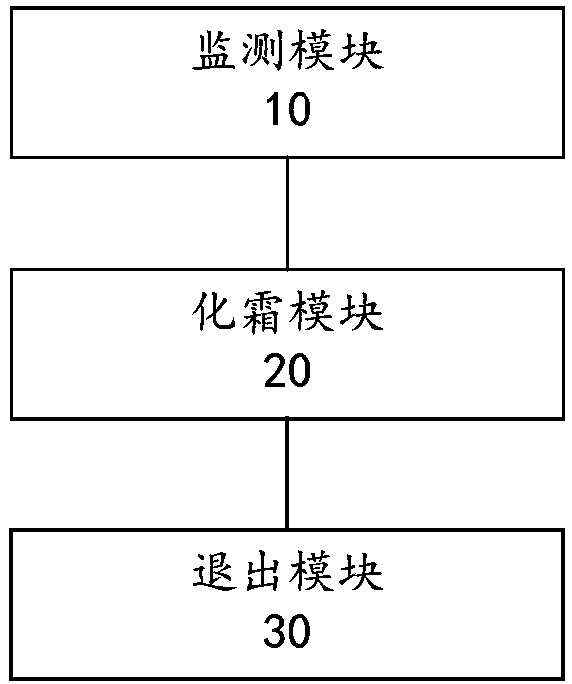

[0039] corresponds to figure 1 The defrosting control method introduced, this embodiment provides a defrosting control device, such as image 3 The structural block diagram of the defrosting control device shown, the device includes:

[0040] The monitoring module 10 is used to monitor the temperature of the outdoor motor;

[0041] The defrosting module 20, connected to the monitoring module 10, is used to enter the defrosting mode when the temperature of the outdoor motor is less than or equal to zero within the accumulated first specified time period;

[0042] The exit module 30 is connected to the defrost module 20, and is used for exiting the defrost mode when the temperature of the outdoor motor is greater than or equal to zero within a second specified period of time.

[0043] In this embodiment, the infrared temperature sensor is used to detect the temperature of the outdoor motor, so as to perform defrosting operation and exit the defrosting operation, achieve the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com