Multi-type vehicle body in white welding main combined fixture

A combined fixture and body-in-white technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of outflow of body-in-white assembly body data, high requirements on site, and unfavorable survival of enterprises. The effect of wide range, high work efficiency and saving money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0198] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

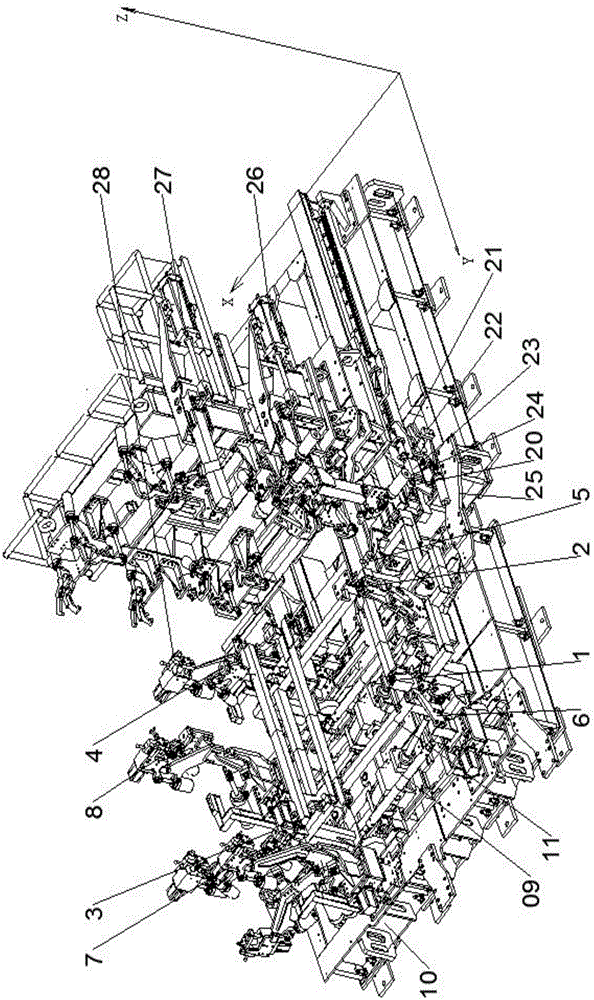

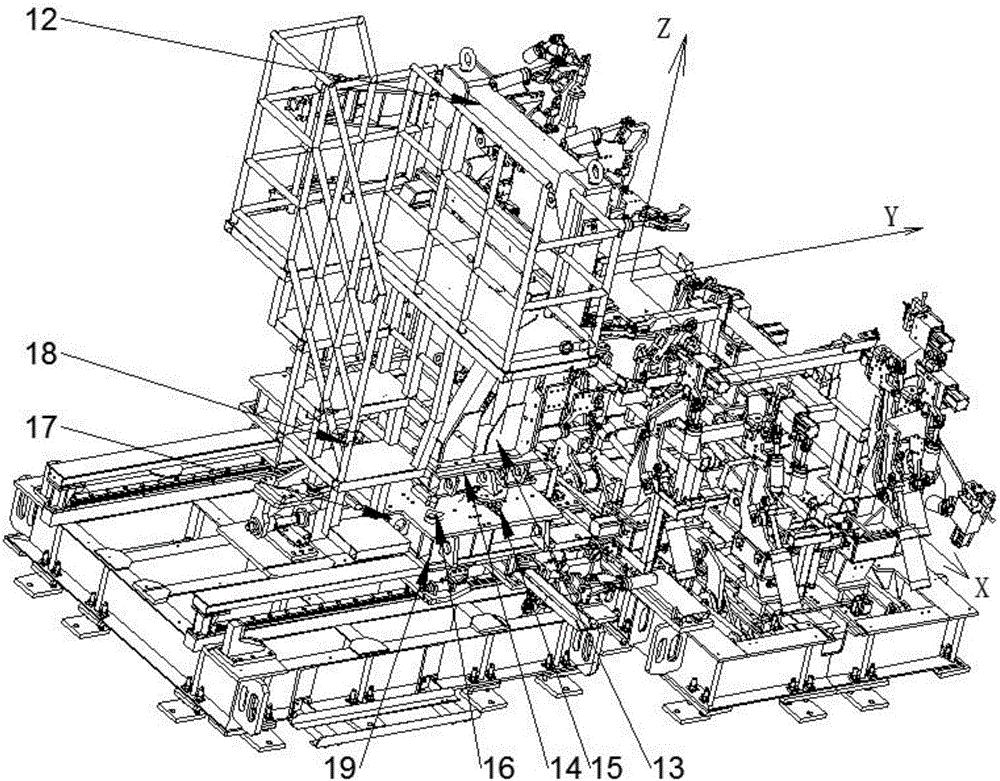

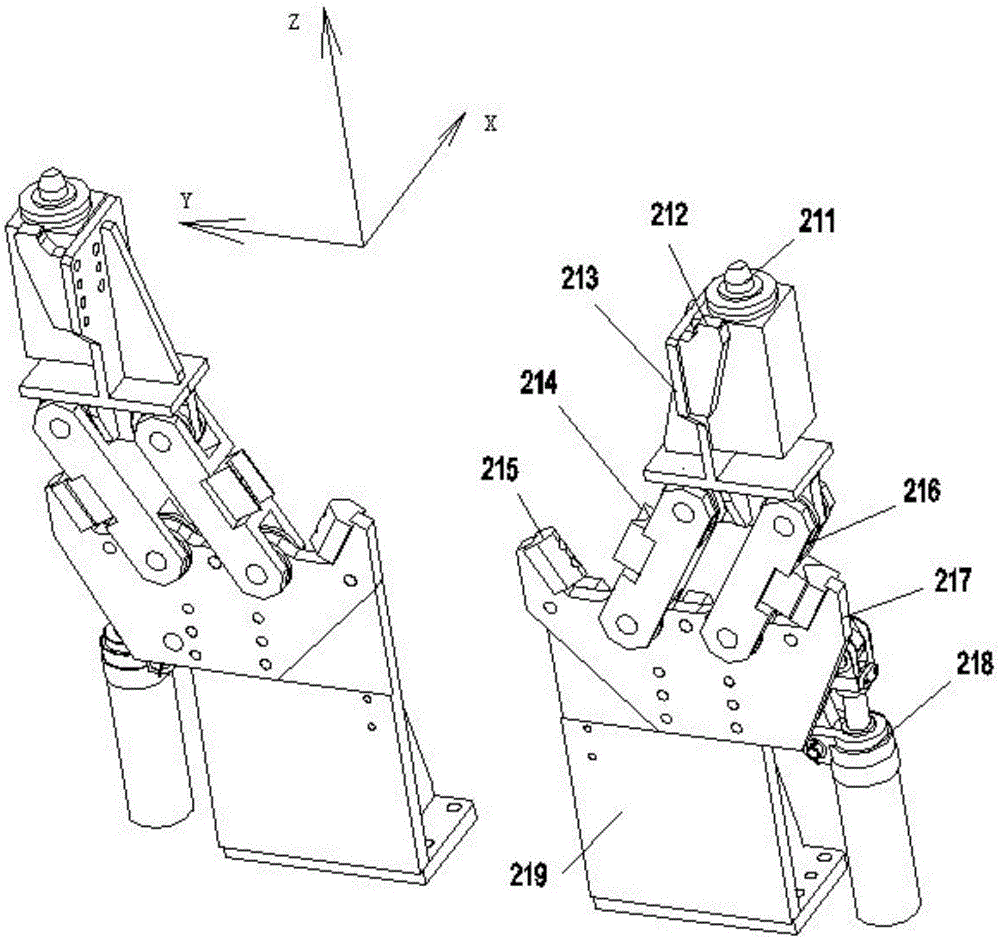

[0199] see Figure 1 to Figure 15 . In order to describe the present invention in detail, the present invention will be described in detail next: the general combination clamp for welding body-in-white of many vehicle types, such as Figure 11 As shown, the bottom panel 10 includes a central bottom panel 101 and two side wall bottom panels 102 located on both sides of the central bottom panel 101 . The middle floor 101 and each side wall floor 102 are connected by two floor connecting plates 25 . The base connecting plate 25 is provided with pin positioning holes 251 and bolt mounting holes 252, and the middle base plate 101 and the side wall base plate 102 are provided with corresponding mounting holes. , to fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com