Control system and method for packaging, filling or dosing

A control system and comparative control technology, applied in the direction of comprehensive factory control, electrical program control, comprehensive factory control, etc., can solve the problems that affect the performance of packaging, filling and ingredient control, the system speed and accuracy have a heavy impact, and affect packaging and filling. Loading and batching control speed and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

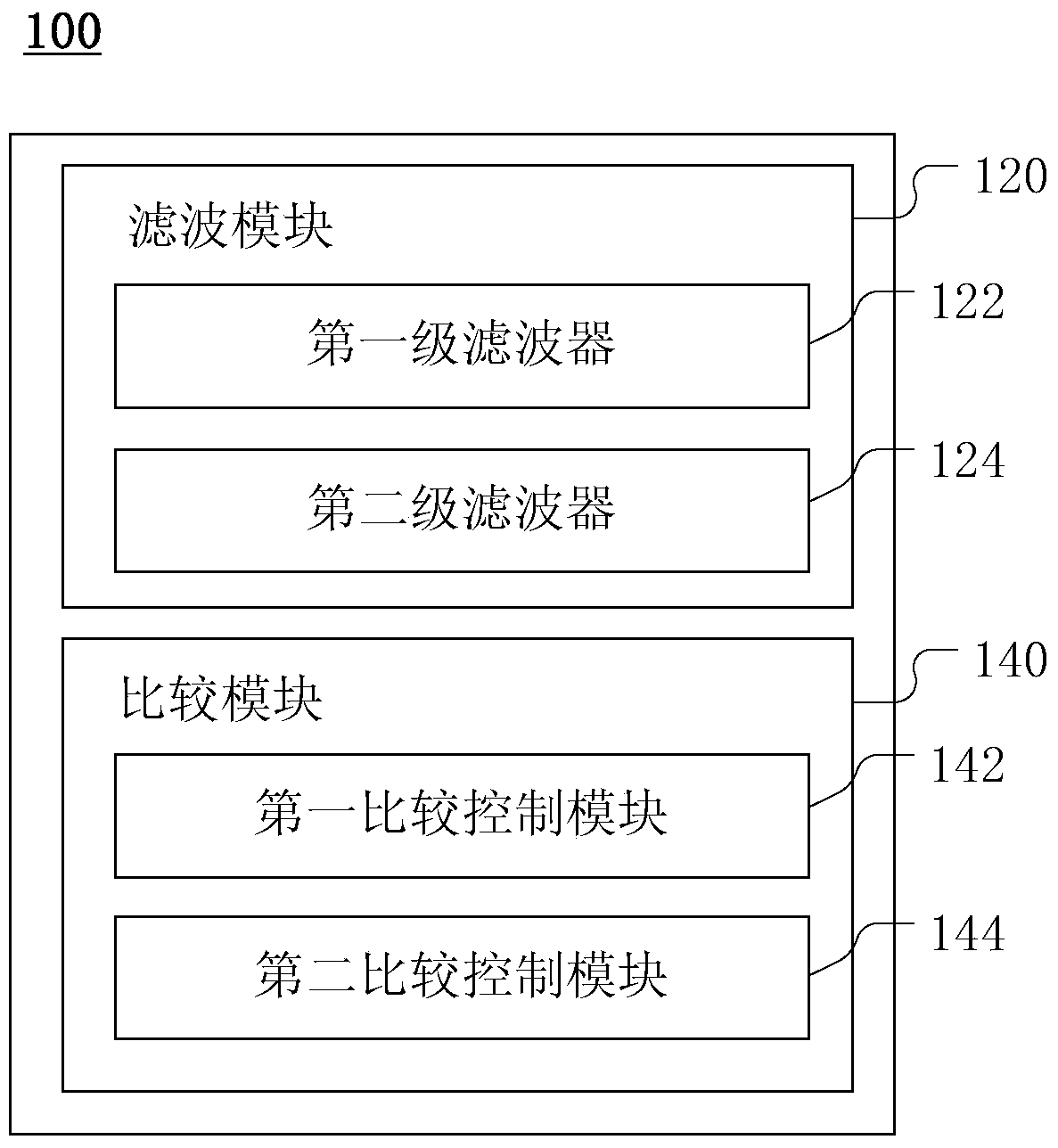

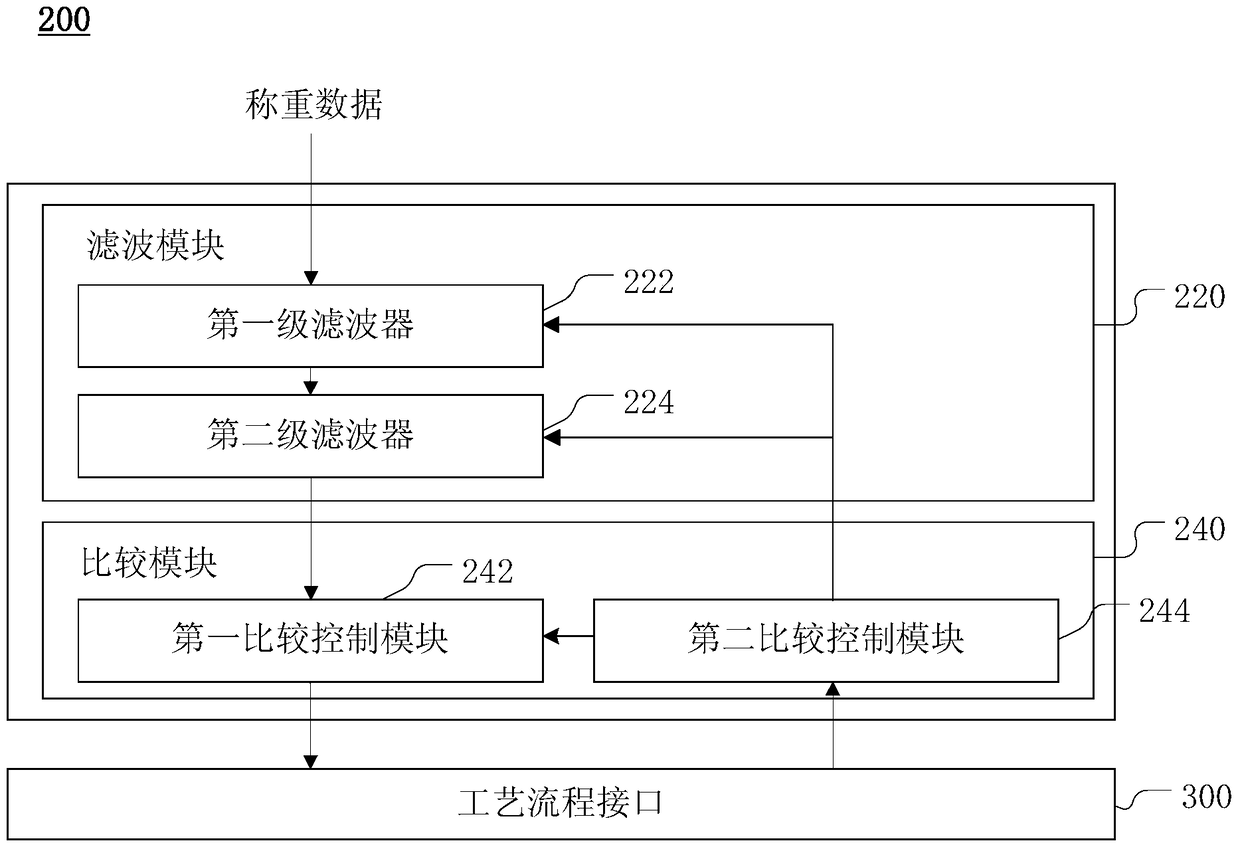

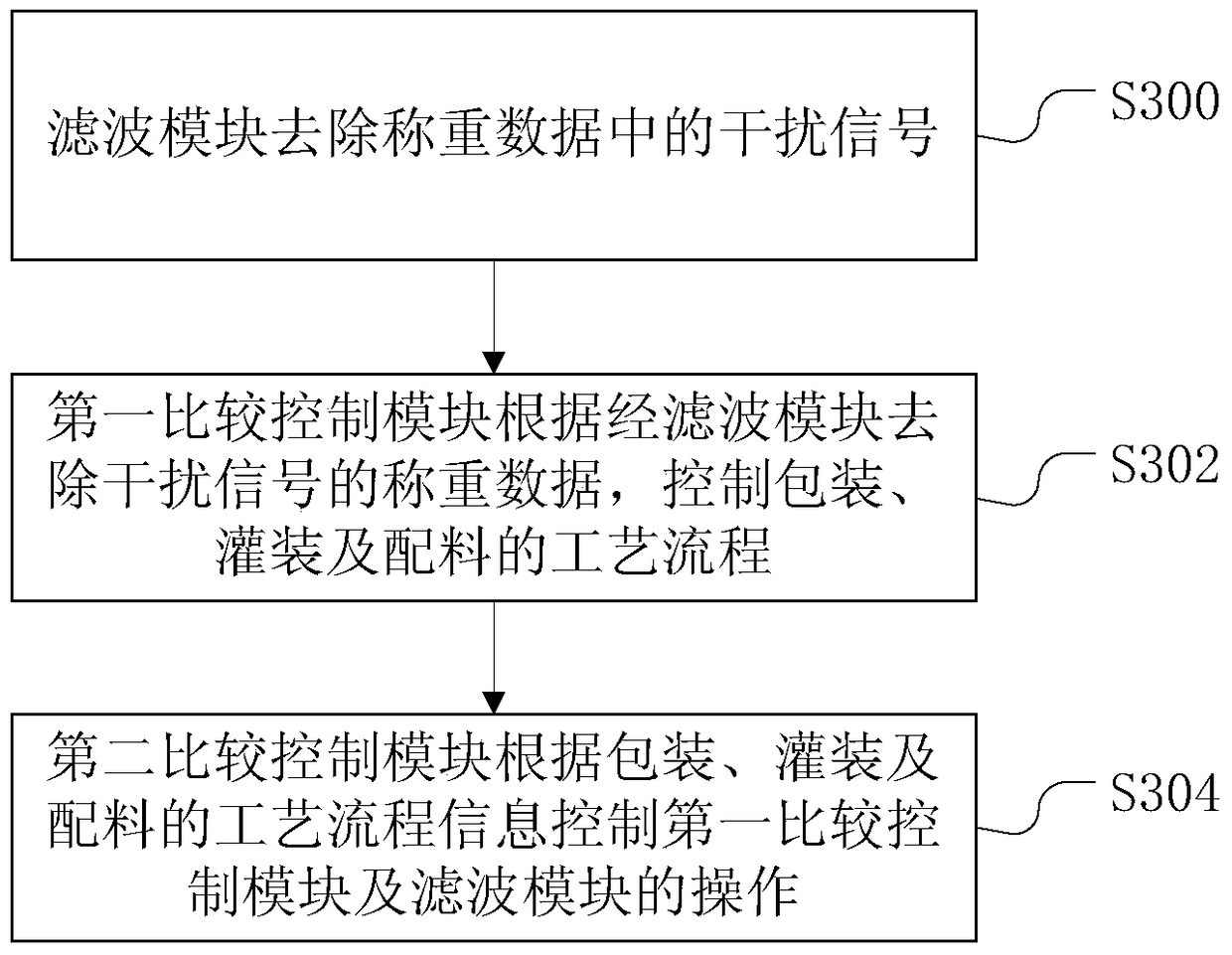

[0030] figure 1 It is a structural diagram of a control system 100 for packaging, filling or batching according to an embodiment of the present invention. The control system 100 for packaging, filling or batching includes a filter module 120 and a comparison module 140 .

[0031] The filtering module 120 is used for removing the interference signal in the weighing data. The filtering module 120 includes a first stage filter 122 and a second stage filter 124 . The first stage filter 122 removes the first interference signal whose frequency of the weighing data is greater than the first threshold. The second stage filter 124 removes the second interference signal whose frequency of the weighing data is less than the second threshold. Specifically, in the application process of packaging, filling or batching, there are mainly two types of interference sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com