Horizontal motion track recorder of rubber support

A track recording device, rubber bearing technology, applied in printing, writing utensils and other directions, can solve problems such as inability to provide deformation information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

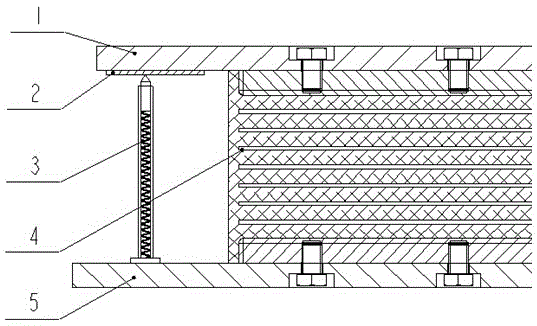

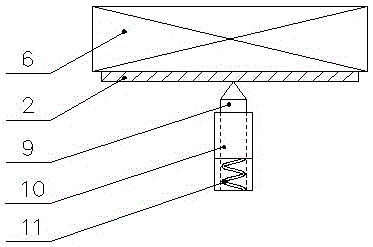

[0019] Such as figure 1 As shown, the present invention relates to a recording device for the horizontal movement track of a rubber bearing, comprising a recording board 2 and a recording pen 3, the recording board 2 is fixedly installed on the upper embedded plate 1 of the rubber bearing, and the recording pen 3 is fixedly installed on the rubber bearing On the lower embedded plate 5 of the support, the nib 9 of the recording pen 3 is elastically contacted with the recording board 2 by a pressure spring, and the recording board 2 materials are selected soft stainless steel plates. The recording pen 3 is a closed cylindrical structure with a built-in pressure spring, including a high-hardness nib 9, a pressure spring 11, and an anti-corrosion sleeve 10; In contact with the trunk of the high-hardness nib 9, the base fixing method of the anti-corrosion sleeve 10 can be threaded. Recording pen 3 high-hardness nib 9 adopts 60 ° sharp angle, and backbone selects cylinder for use. ...

Embodiment 2

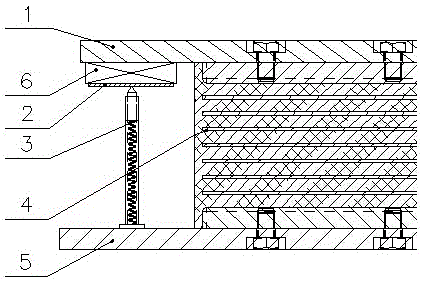

[0023] Such as figure 1 As shown, the present invention relates to a recording device for the horizontal motion track of a rubber bearing, comprising a recording board 2, a recording pen 3 and a recorder 6, the recording board 2 is fixedly installed on the upper embedded plate 1 of the rubber bearing, and the recording pen 3 Fixedly installed on the lower embedded plate 5 of the rubber bearing, the nib of the recording pen 3 is in elastic contact with the recording board 2 through a pressure spring, and the recorder 6 is connected with the recording board 2 to record the track of the pen tip on the recording board 2 . The recording board 2 is made of soft stainless steel. The recorder 6 is sent to the remote receiver through the remote signal transmitting and receiving system. The structure of stylus is identical to embodiment one.

[0024] Under the action of external forces such as earthquakes, the horizontal displacement of the engineering building will cause relative mov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap