A phase change energy storage type oil and gas recovery equipment and recovery method

A technology of phase change energy storage and recovery equipment, which is applied in chemical instruments and methods, separation methods, recovery of liquid hydrocarbon mixtures, etc., can solve the problems of long recovery cost cycle, uneconomical, volume change, etc., and achieve one-time investment cost saving , saving manufacturing cost, and simplifying installation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

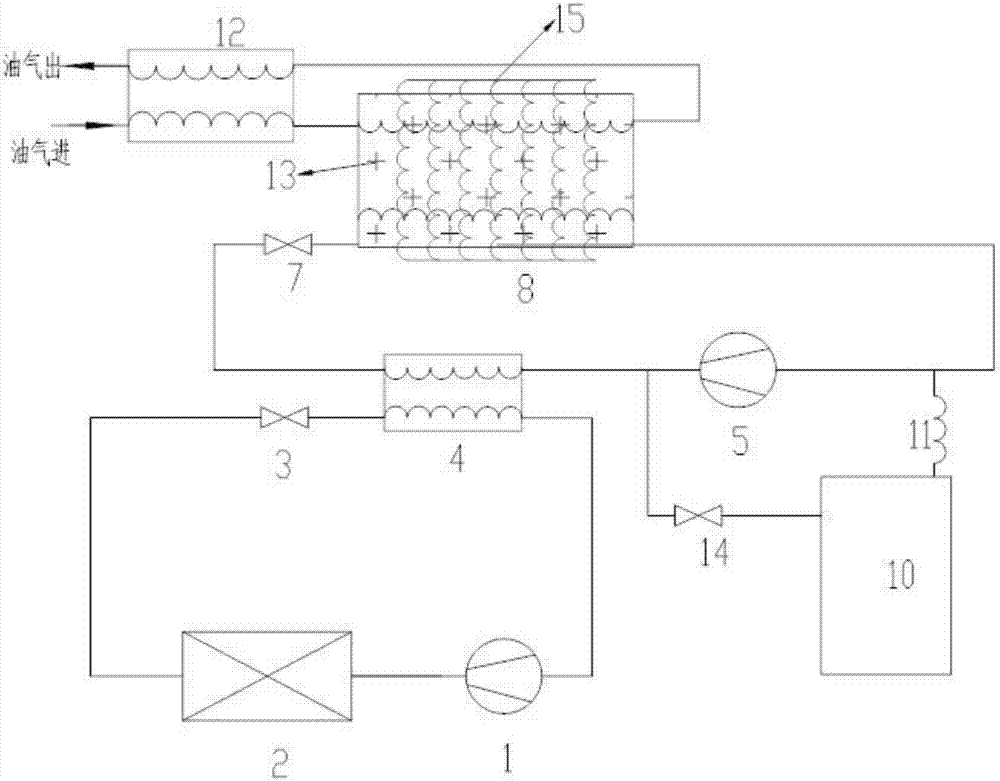

[0091] Such as image 3 As shown, the present invention discloses a phase change energy storage type oil and gas recovery equipment, including an oil and gas recovery device and a refrigeration storage device, wherein:

[0092] The oil and gas recovery device includes a first-stage oil-gas condenser 12 and a second-stage oil-gas condenser 8 connected in sequence, for making oil and gas input from the inlet on one side of the first-stage oil-gas condenser 12, and then condensing through the first-stage oil-gas After the precooling of the device 12 and the secondary oil-gas condenser 8, return to the first-stage oil-gas condenser 12 and output through the outlet on one side of the first-stage oil-gas condenser 12;

[0093]The refrigeration storage device includes a high-temperature compressor 1, an air condenser 2, a high-temperature throttling device 3, an evaporation condenser 4, and a low-temperature throttling device 7, and the high-temperature compressor 1, an air condenser...

Embodiment 2

[0103] like Figure 4 As shown, the present invention additionally discloses a phase change energy storage type oil and gas recovery equipment, including an oil and gas recovery device and a refrigeration and cold storage device, wherein:

[0104] The oil and gas recovery device includes a first-stage oil-gas condenser 12 and a second-stage oil-gas condenser 8 connected in sequence, for making oil and gas input from the inlet on one side of the first-stage oil-gas condenser 12, and then condensing through the first-stage oil-gas After the precooling of the device 12 and the secondary oil-gas condenser 8, return to the first-stage oil-gas condenser 12 and output through the outlet on one side of the first-stage oil-gas condenser 12;

[0105] The refrigeration storage device includes a high-temperature compressor 1, an air condenser 2, a high-temperature throttling device 3, an evaporation condenser 4, and a low-temperature throttling device 7, and the high-temperature compresso...

Embodiment 3

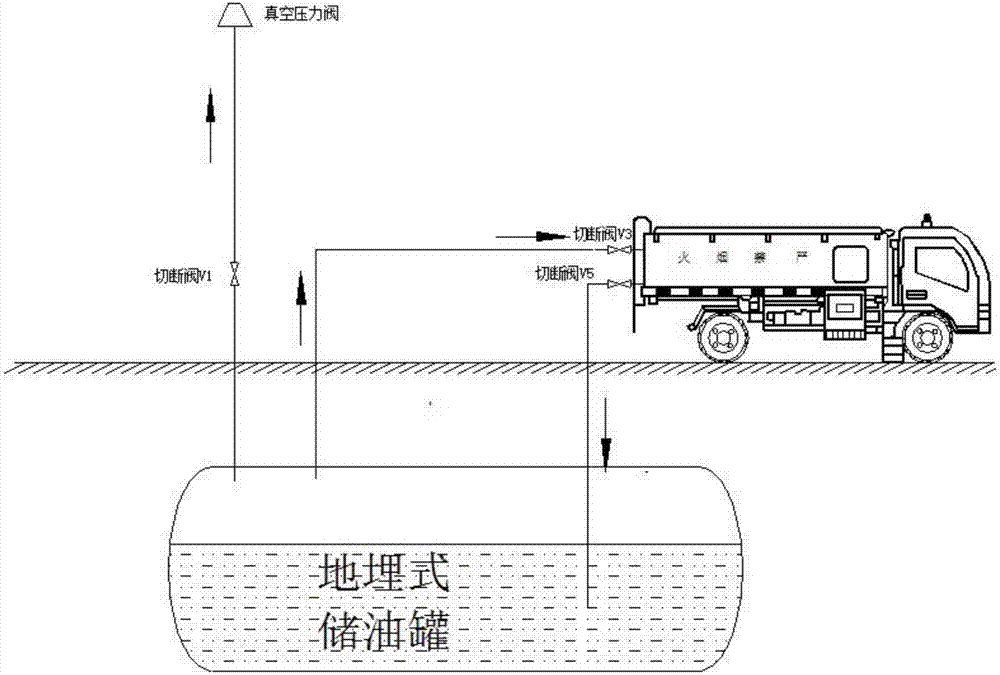

[0115] like Figure 5 As shown, the present invention additionally discloses a phase change energy storage type oil and gas recovery method, comprising the following steps:

[0116] Step A1: The oil and gas generated when the tanker is unloaded is pre-cooled through the primary oil and gas condenser 12, so that the temperature is reduced to between -10° and +10°, and most of the water in the oil and gas is removed at the same time;

[0117] Step A2: The oil and gas pre-cooled by the first-stage oil-gas condenser 12 enters the second-stage oil-gas condenser 8, further reducing the temperature to -40° to -80°, and most of the hydrocarbons in the oil and gas are condensed and recovered. The remaining low-temperature gas returns to the first-stage oil-gas condenser 12, and performs heat exchange with the high-temperature oil-gas entering the first-stage oil-gas condenser 12, and then returns to the tank truck;

[0118] Step A3: The high-temperature and high-pressure refrigerant d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com