A capacitive oil quantity measuring device

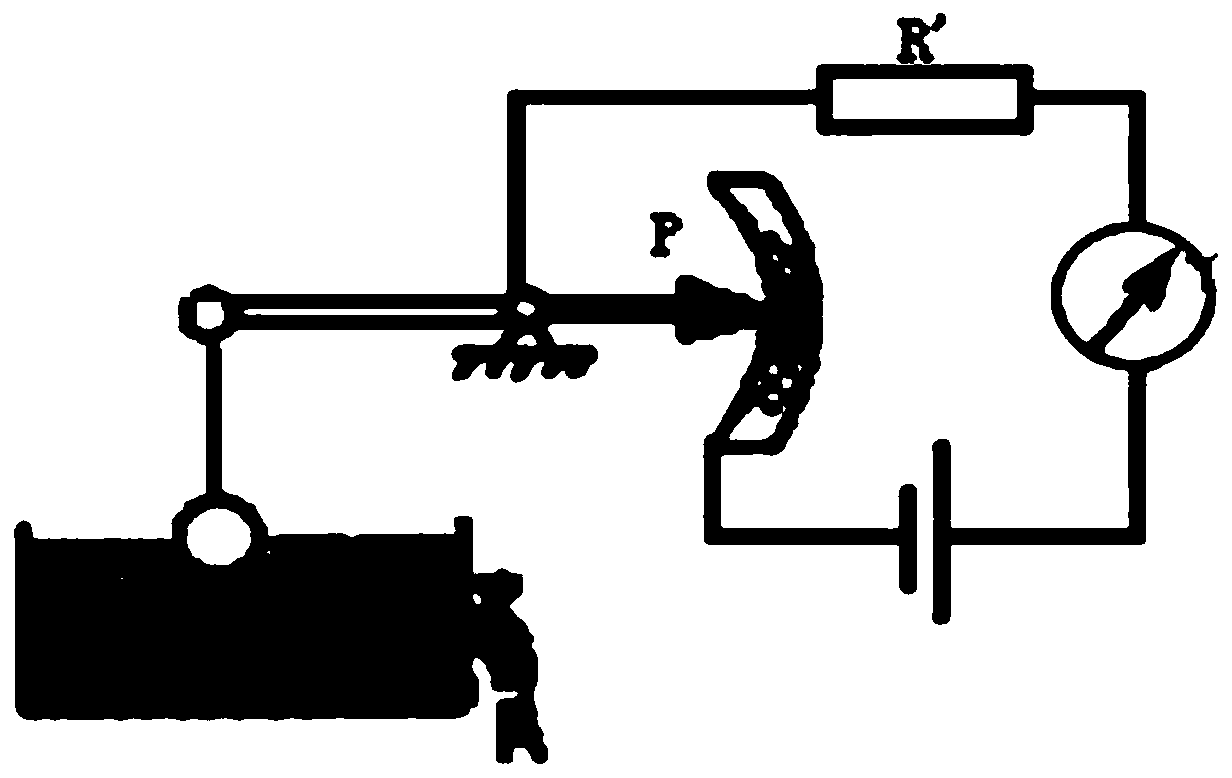

A measuring device, capacitive technology, applied in measuring devices, liquid level indicators for physical variable measurement, liquid/fluid solid measurement, etc., can solve problems such as low sensitivity, inaccurate measurement, and low measurement accuracy of sliding rheostats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

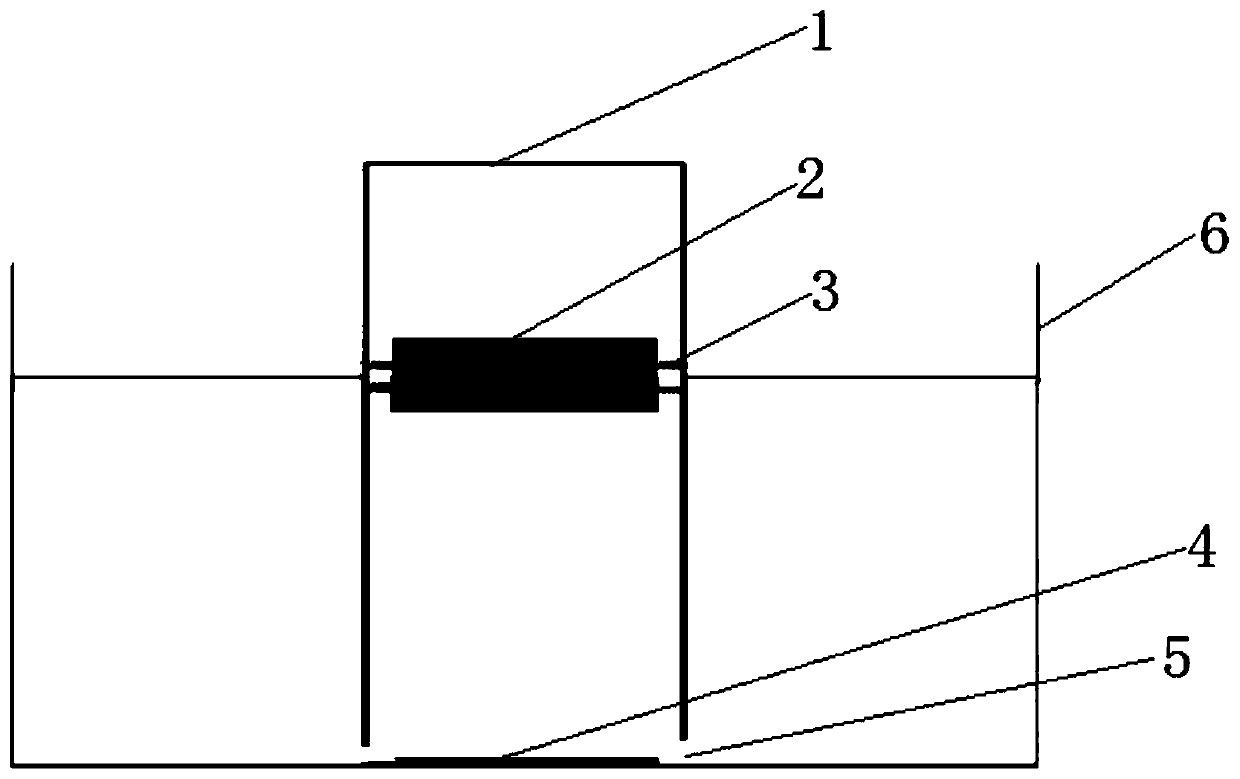

[0018] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The accompanying drawings are only for reference and description, and do not constitute a limitation to the protection scope of the present invention.

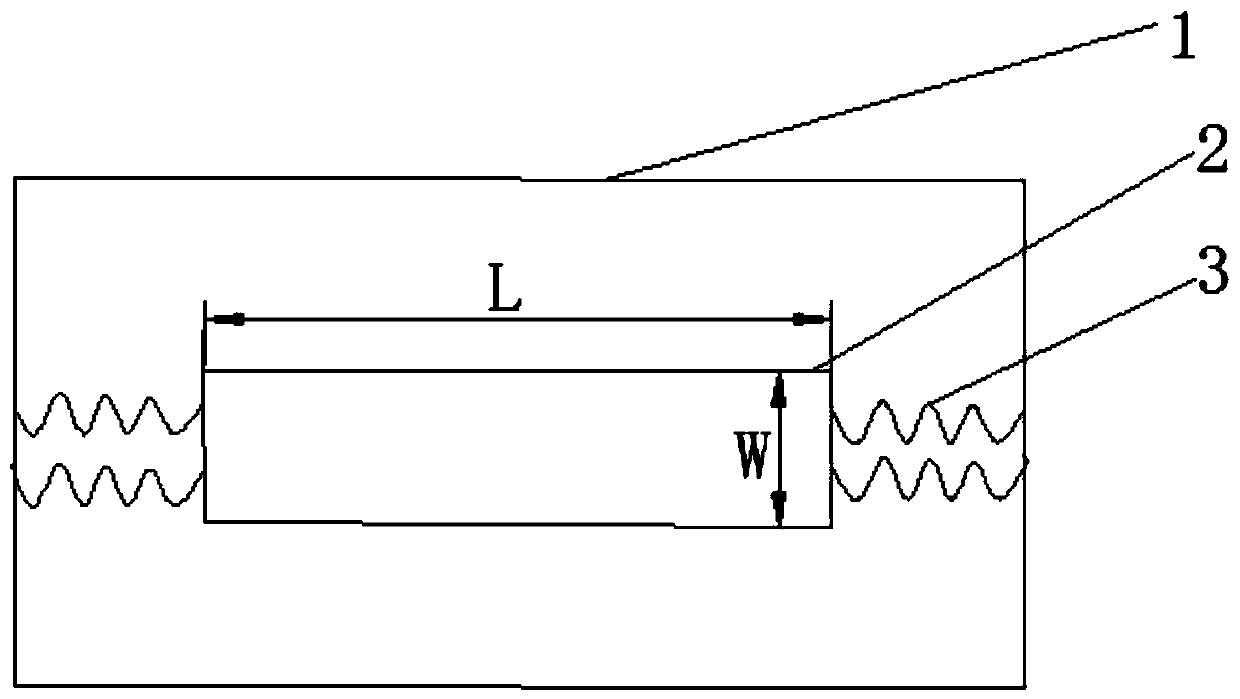

[0019] Such as figure 2 As shown, on the one hand, the present embodiment provides a capacitive oil quantity measuring device, including a capacitive piston structure composed of a cuboid insulating shell 1, a capacitor upper plate 2, a soft spring 3, and a capacitor lower plate 4, and connecting the capacitor. The capacitance measuring unit (not shown) of upper pole plate 2 and electric capacity lower pole plate 4, described soft spring 3 is symmetrically connected with the two sides parallel with automobile driving direction of described electric capacity upper pole plate 2, and described cuboid The two inner walls parallel to the running direction of the automobile of the insulating case 1 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com