Spoke air hole burr extruding and outer diameter finishing device

A technology of air holes and spokes, applied in the field of wheel manufacturing equipment, can solve problems such as low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

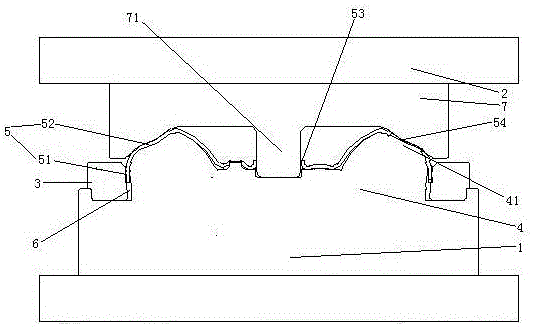

[0030] Embodiment one, see figure 1, a device for extruding burrs and finishing the outer diameter of a spoke air hole, comprising a lower mold base 1 and an upper mold base 2 . The spoke 5 includes a peripheral wall 51 and an end wall 52 connected to one end of the peripheral wall. The peripheral wall 51 is cylindrical. The peripheral wall 51 and the end wall 52 are integrally formed. The end wall 52 is provided with a central hole 53 and an air hole 54 .

[0031] The lower mold base 1 is provided with an extrusion ring 3 and a core 4 . The inner peripheral surface of the extrusion ring 3 is a tapered surface with a large upper end and a smaller lower end. The extrusion ring 3 and the core 4 are arranged coaxially. The outer peripheral surface of the core 4 is a tapered surface with a large upper end and a smaller lower end. The core 4 is provided with an extruding head 41 for extruding the wall of the wind hole. The diameter of the upper end of the core 4 is equal to ...

Embodiment 2

[0033] Embodiment two, the difference with embodiment one is:

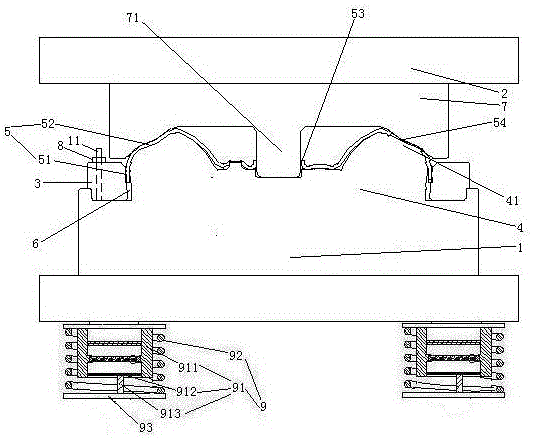

[0034] see figure 2 , The lower mold base 1 is provided with a shock-absorbing structure 9 . The damping structure 9 includes a vertical damping cylinder 91 and a damping spring 92 sleeved on the damping cylinder. The damping oil cylinder 91 includes a damping oil cylinder body 911 . The damping cylinder body 911 is connected with the lower mold base 1. A first piston 912 is disposed inside the damping oil cylinder body 911 . The first piston 912 is connected to the supporting seat 93 through the piston rod 913 . One end of the damping spring 92 is affixed together with the piston rod 913, and the other end is affixed together with the cylinder body 911 of the damping oil cylinder.

[0035] The extrusion ring 3 is detachably connected with the lower die base 1 through bolts 11 and nuts 8 welded on the lower die base 1 .

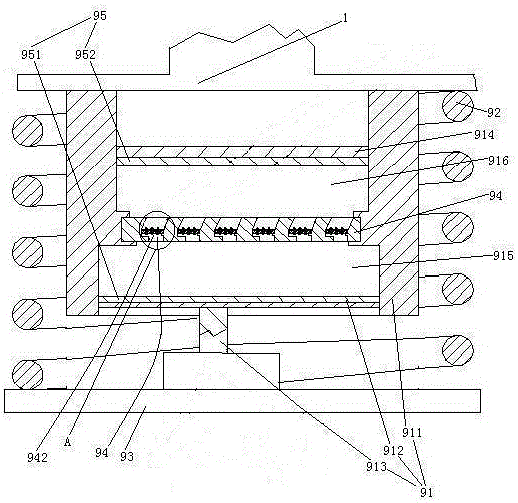

[0036] see image 3 , The second piston 914 and the separation plate 94 are also prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com