Pull rod type composite spring three-dimensional shock isolation support

A technology of composite springs and shock-isolation bearings, which is applied in the direction of springs, shock-proof, protective buildings/shelters, etc., can solve the problems of increasing the complexity of the shock-isolation system, the difficulty of design calculation, and the large degree of correlation, so as to reduce the design Calculation difficulty, transmission route is clear, and the effect of small vertical displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

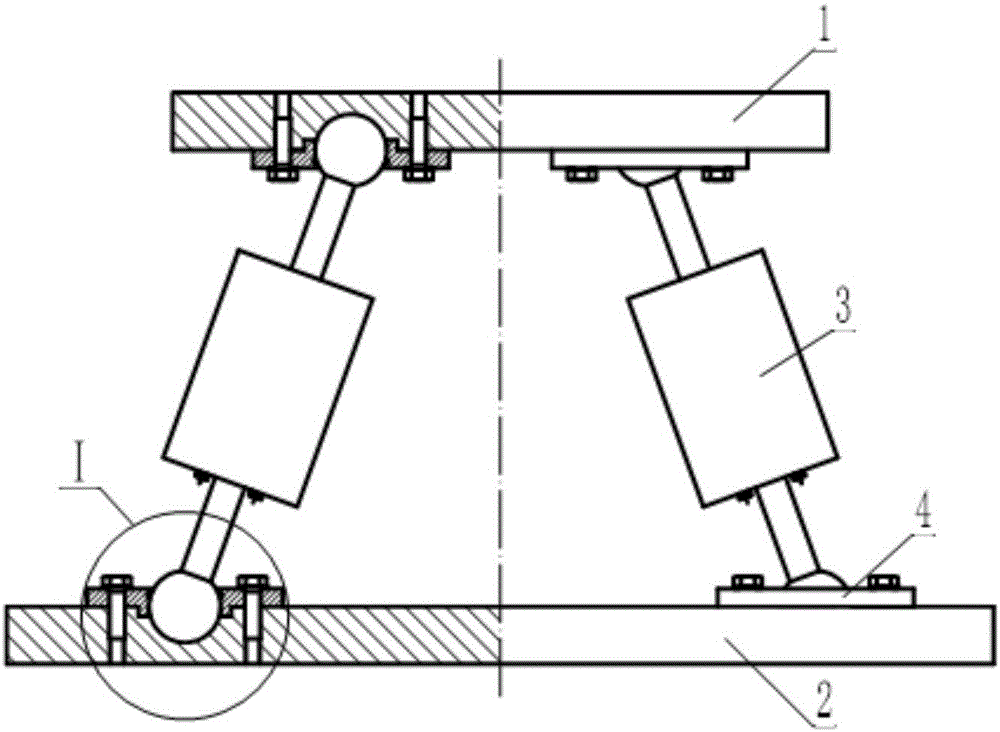

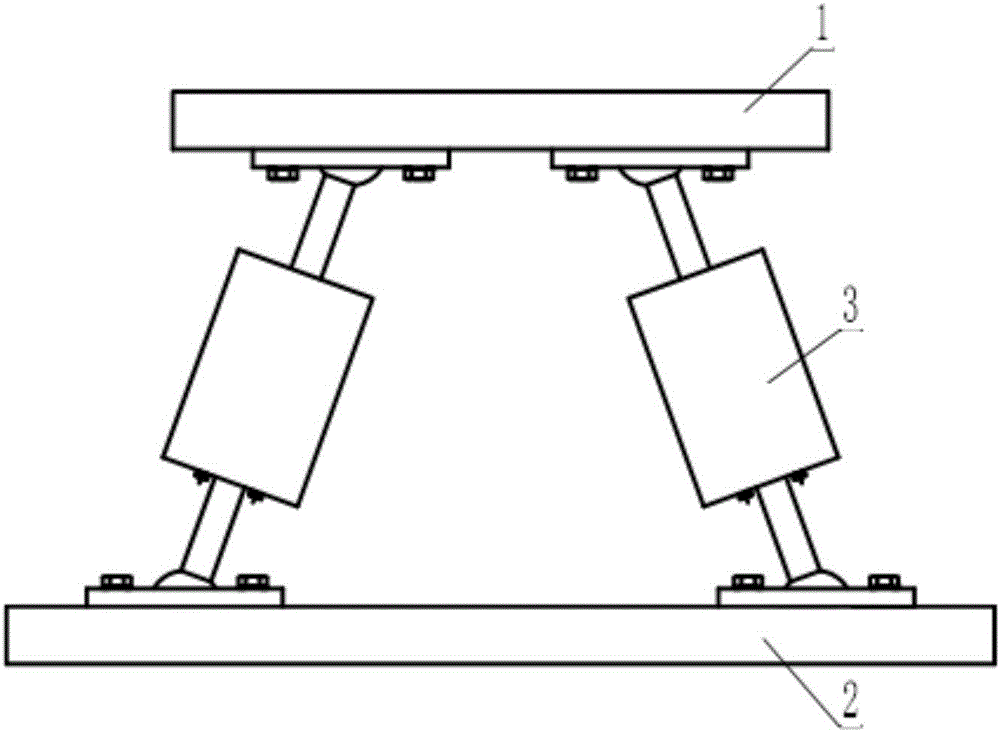

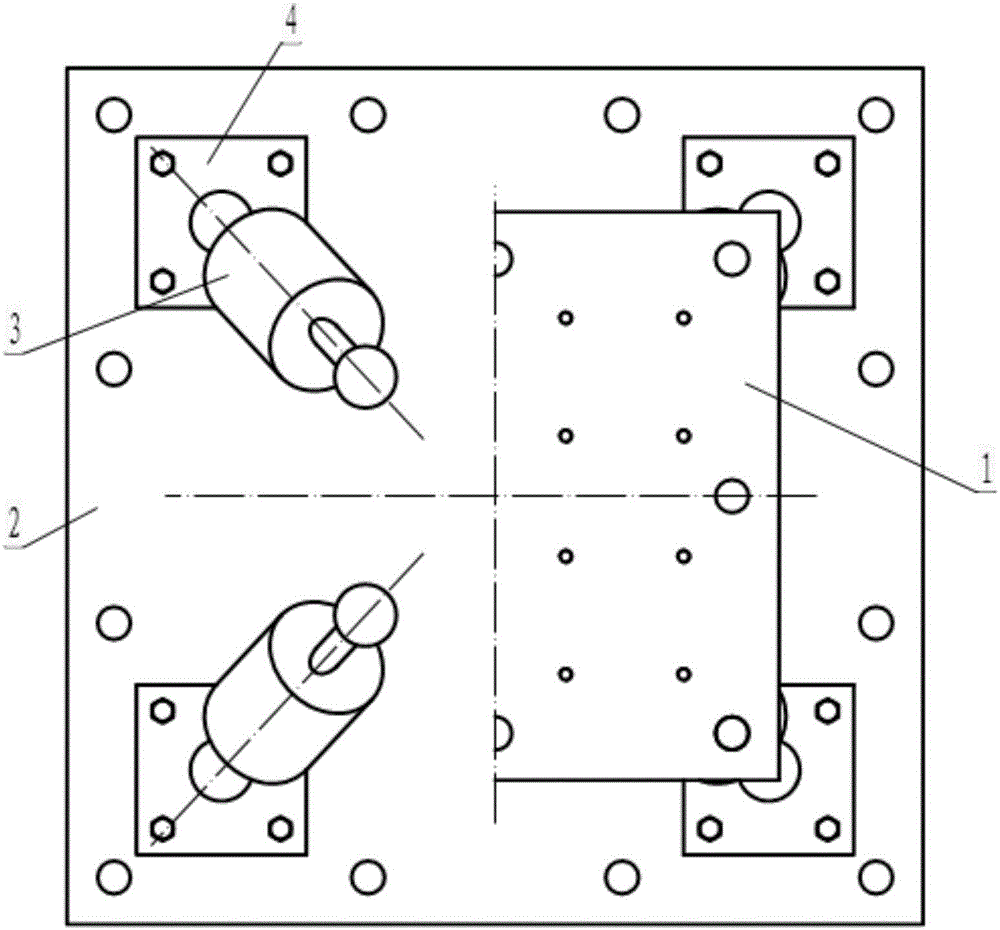

[0023] see Figures 1 to 4 , the three-dimensional isolation bearing in this example includes an upper connecting plate 1, a lower connecting plate 2 that are parallel to each other, and four pull-dry back-pressure composite spring dampers arranged between the upper connecting plate 1 and the lower connecting plate 2 3; The connecting rods 3-1 at both ends of each pull-dry back-pressure composite spring damper 3 and the upper connecting plate 1 and the lower connecting plate 2 are respectively connected by universal ball joints, forming a symmetrical side of one left and right. , The front and rear sides are symmetrical four-sided pyramid structure. The included angle between the pull-dry back-pressure composite spring damper 3 and the lower connecting plate 2 in this example is 70°.

[0024] The connecting rods 3-1 at both ends of the above-mentioned pull-dry back-pressure composite spring damper 3 are the same as the universal ball joint connection structure between the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com