Glue application gun

A glue application and glue gun technology, applied in the field of glue guns, can solve problems such as insufficient glue application, insufficient glue application, overflowing glue, etc., and achieve the effects of easy use, insufficient glue application, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

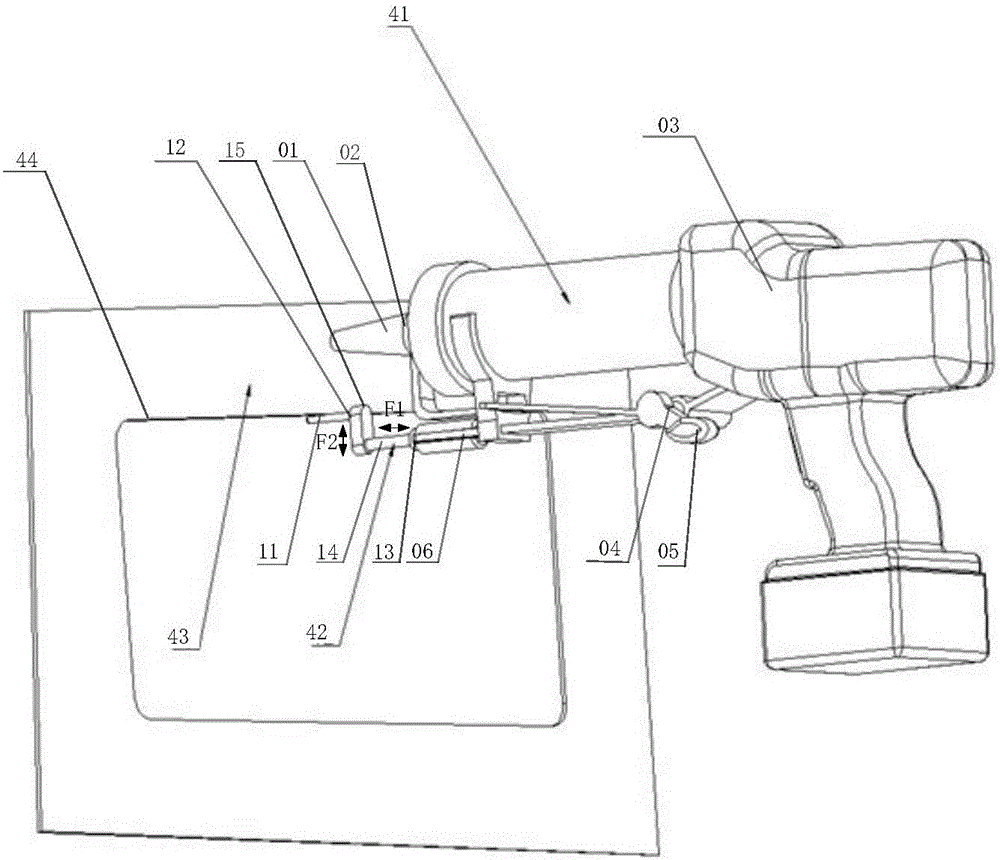

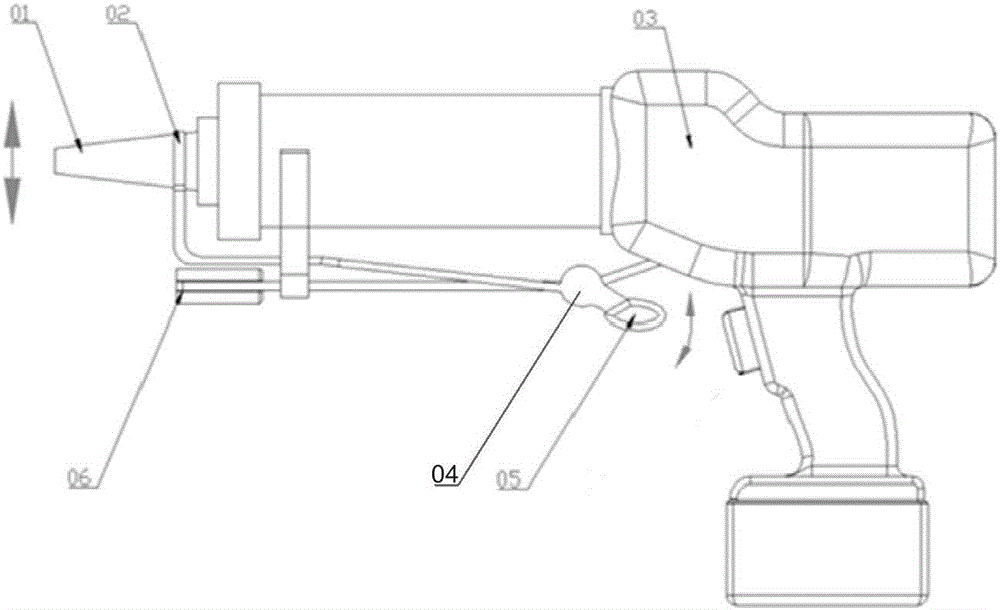

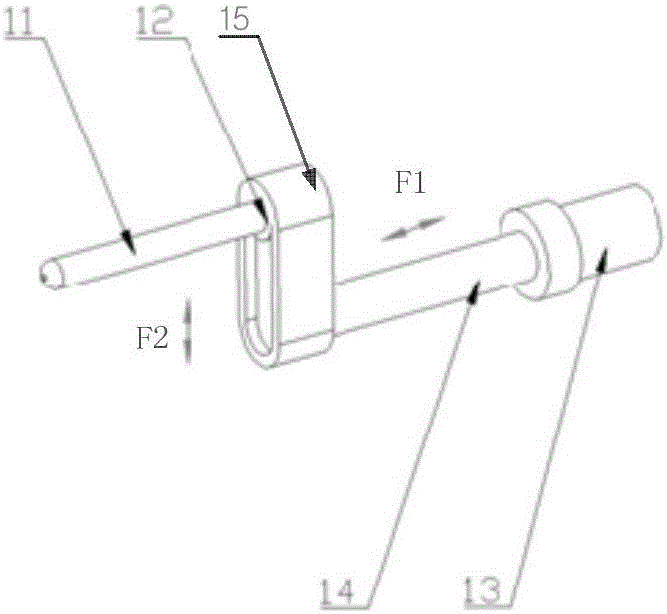

[0084] figure 2 Shown is a schematic structural view of the first embodiment of the glue gun provided by the present invention.

[0085] Such as figure 2 with Figure 5 As shown, the guide head provided in this embodiment is a guide rod structure 11 . The guide head provided in this embodiment adopts the guide rod structure 11 and is suitable for gluing the parts 43 to be glued with an opening structure 44 . Specifically, such as Figure 5 Shown:

[0086] The part to be glued 43 has an opening structure 44, and the predetermined reference position includes the edge of the opening structure 44;

[0087] Wherein, before the gluing operation is performed on the piece 43 to be glued with an opening structure 44, the track tracking mechanism 42 with the guide rod structure 11 is plugged into the track tracking mechanism interface part of the glue gun body 41 through the mounting part 13 06. When carrying out the gluing operation on the part 43 to be glued with an opening s...

Embodiment 2

[0090] image 3 Shown is a schematic structural view of the second embodiment of the glue gun provided by the present invention.

[0091] Such as image 3 with Image 6 As shown, the gluing gun provided in this embodiment adopts the structure of the roller group, which is suitable for gluing the parts 43 to be glued with an edge profile structure. Specifically, such as Image 6 As shown, the part 43 to be glued has an edge profile structure, and the predetermined reference position includes a first reference surface 51 and a second reference surface 52 opposite to the edge profile structure.

[0092] In this example, if image 3 with Image 6 As shown, the guide head of the gluing gun includes a roller set structure capable of contacting a predetermined reference position of the piece to be glued 43 and sliding on the predetermined reference position. The roller set structure includes: two first rollers 21 for clamping the edge contour structure in contact with the oppos...

Embodiment 3

[0097] Figure 4 Shown is a schematic structural view of the third embodiment of the glue gun provided by the present invention.

[0098] Such as Figure 4 with Figure 7 As shown, the gluing gun provided in this embodiment is suitable for gluing the parts to be glued with a flanging profile structure. Specifically, such as Figure 7 Shown:

[0099] The piece to be glued 43 has a flanging profile structure, and the predetermined reference position includes the bent third reference plane 61 and the fourth reference plane 62 of the flanging profile structure.

[0100] The guide head of the glue gun includes a roller set structure capable of contacting a predetermined reference position of the piece to be glued 43 and sliding on the predetermined reference position.

[0101] In this example, if Figure 4 with Figure 7As shown, the structure of the roller set includes: respectively contacting with the opposite third reference surface 61 and the fourth reference surface 62 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com