Partial denture and method for manufacturing same

A manufacturing method and technology of dentures, applied in the fields of medical science, fasteners, dental prosthesis, etc., can solve the problems of reducing the sense of aesthetics, atrophy of the tooth skeleton, not easy to fix the body lining or replace the base, etc., so as to improve the aesthetics Sensitive, easy to maintain, easy to maintain the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. In the process, the thickness of the lines and the size of the structural elements in the drawings may be exaggerated for the convenience of explaining the present invention.

[0036] In addition, the terms described later are defined in consideration of the functions of the present invention and may be different according to user's intention or practice. Therefore, this term is defined based on the entire contents of this specification.

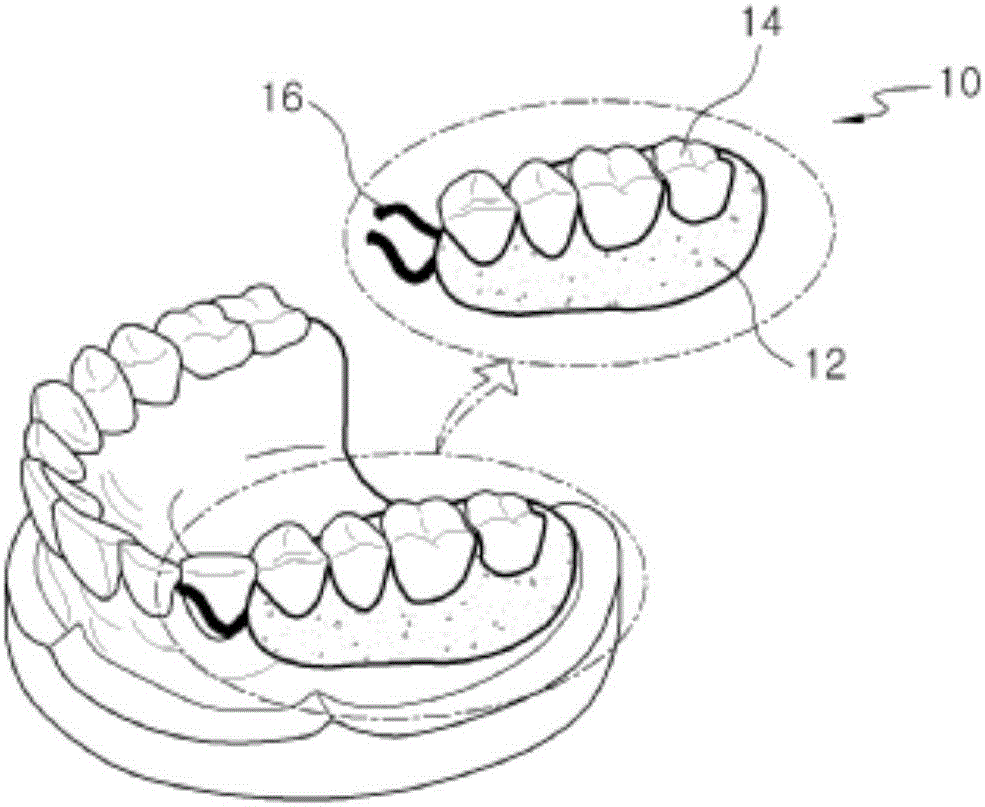

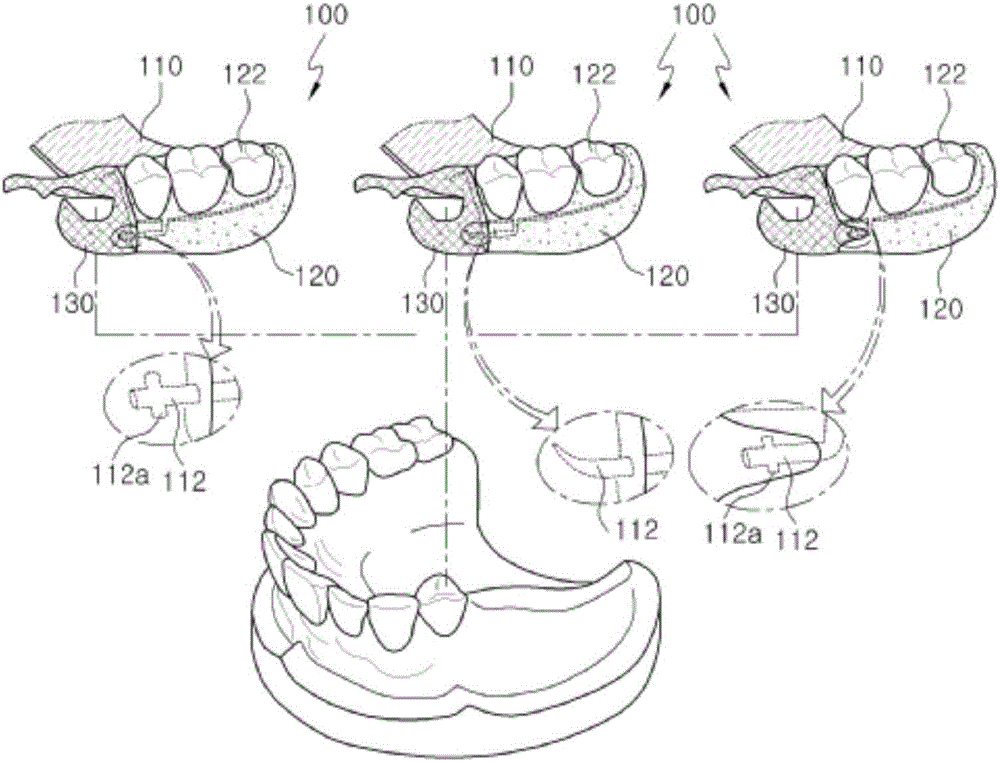

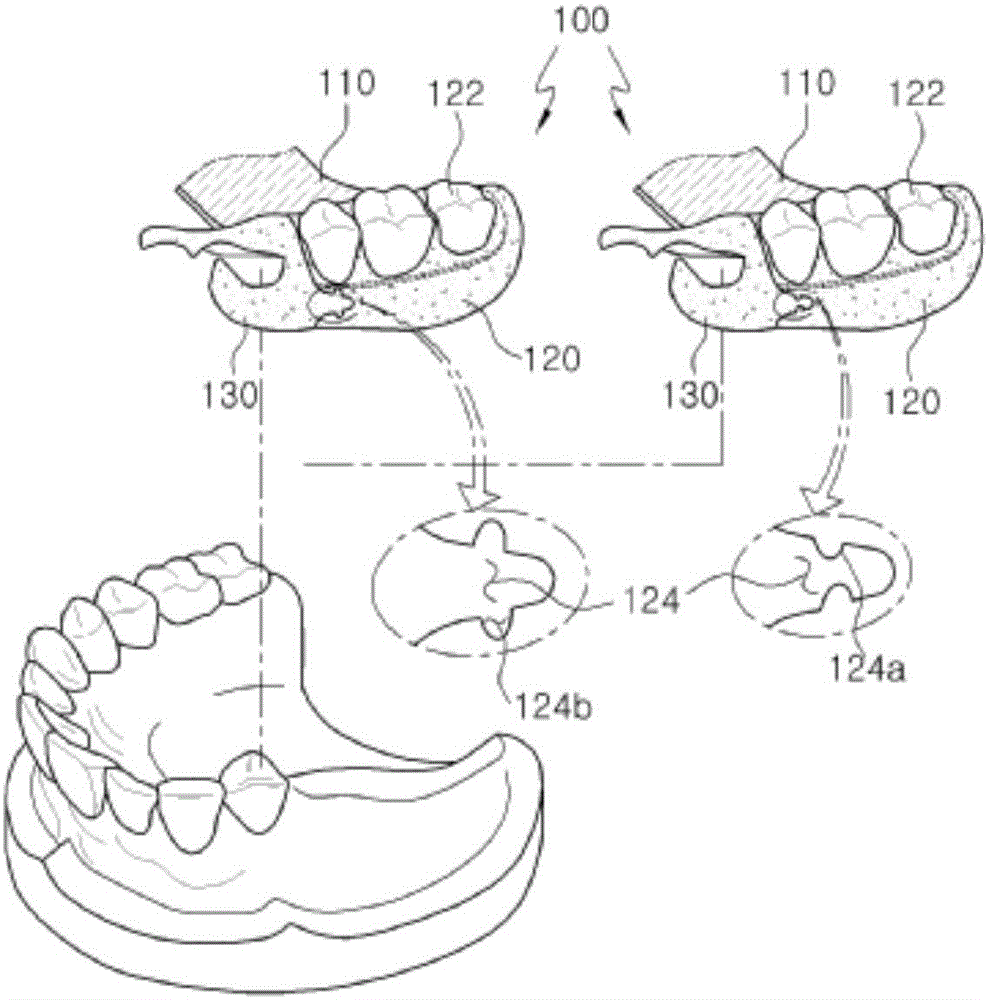

[0037] figure 2 It is an exploded perspective view showing a partial denture according to an embodiment of the present invention.

[0038] refer to figure 2 , The partial denture 100 according to an embodiment of the present invention is composed of a frame 110 , a base 120 , and a clasp 130 .

[0039] The frame 110 is formed in an oral cavity shape, and an indefinite connecting piece 112 is protru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com