Patents

Literature

54results about How to "Improve aesthetic satisfaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

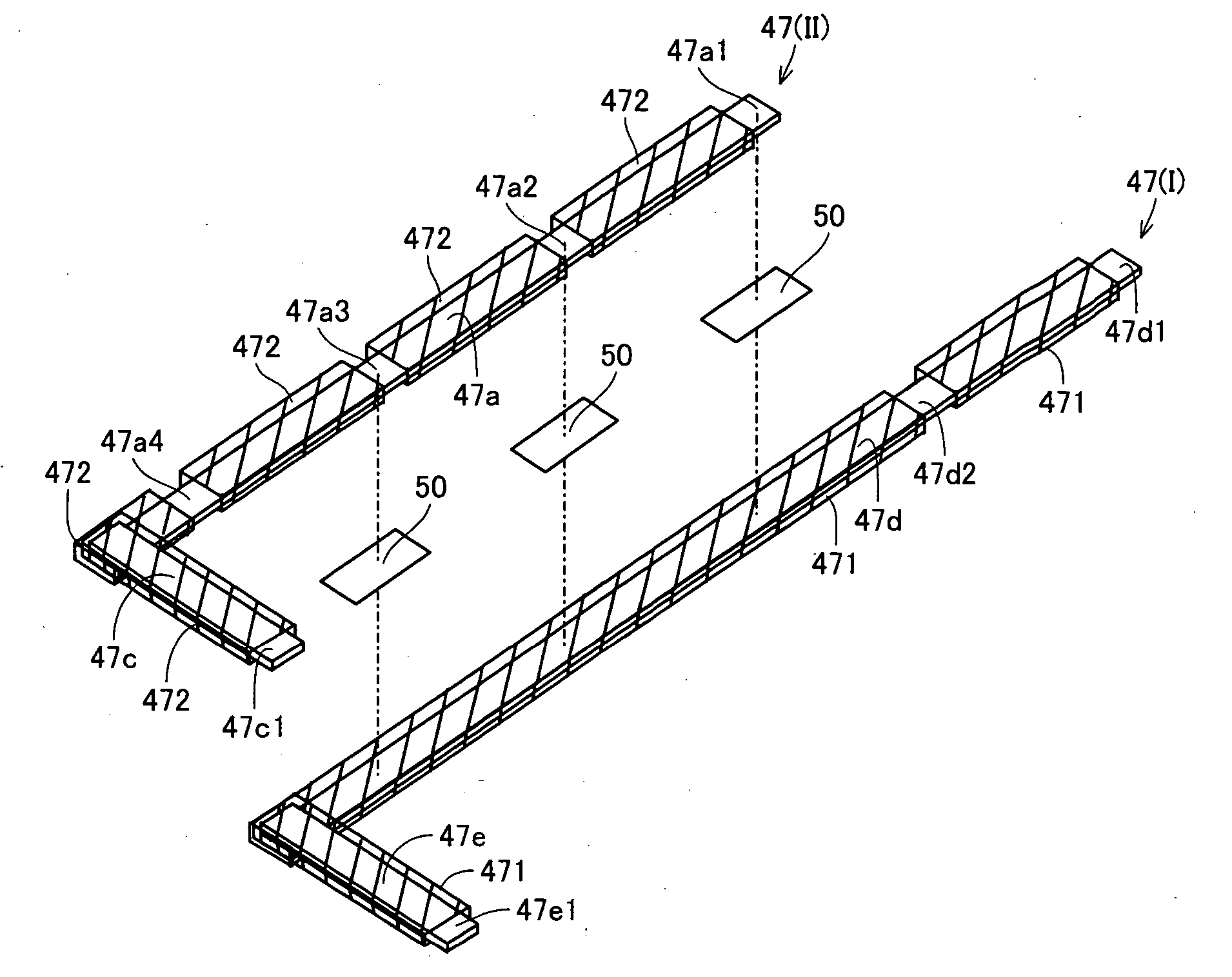

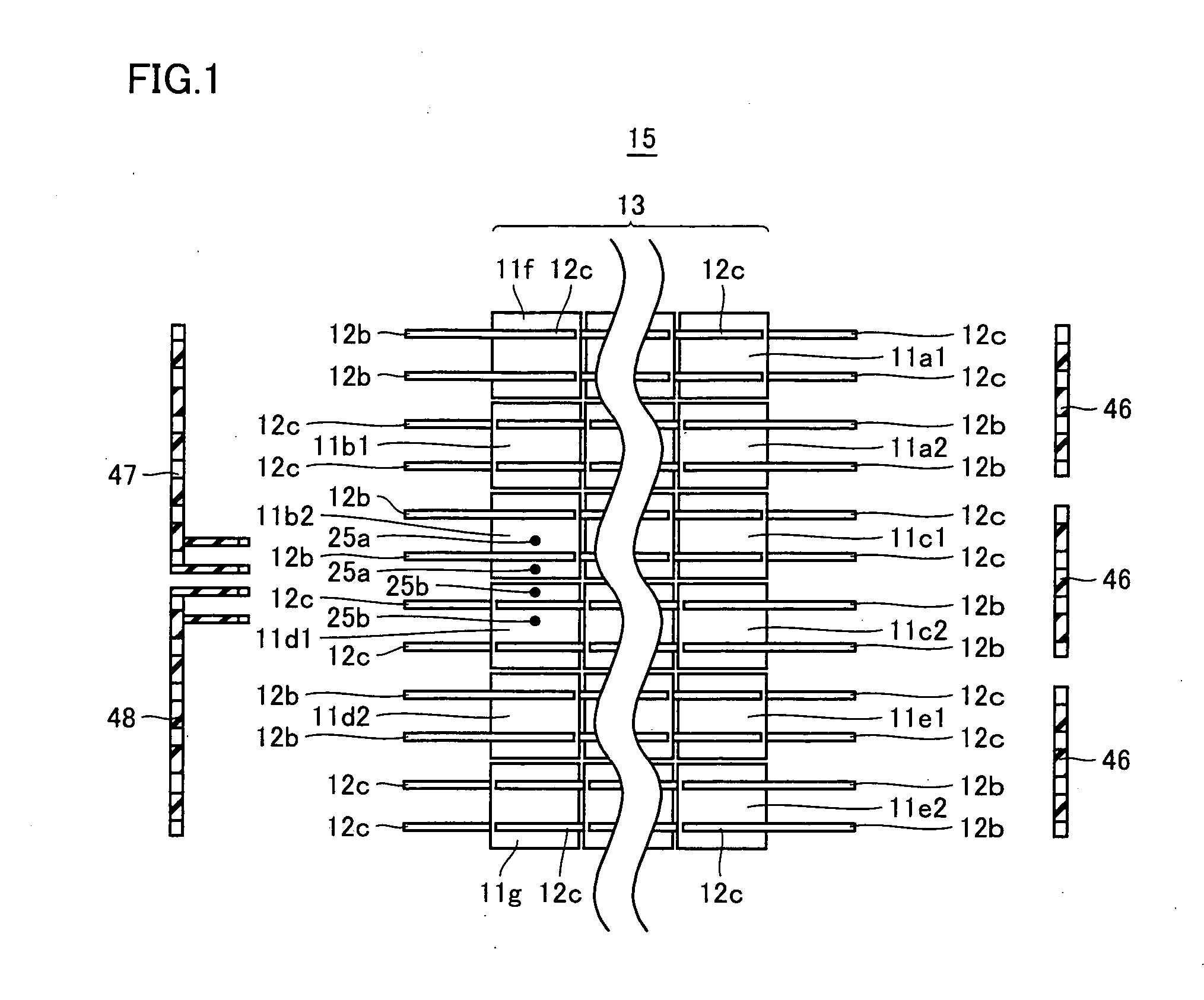

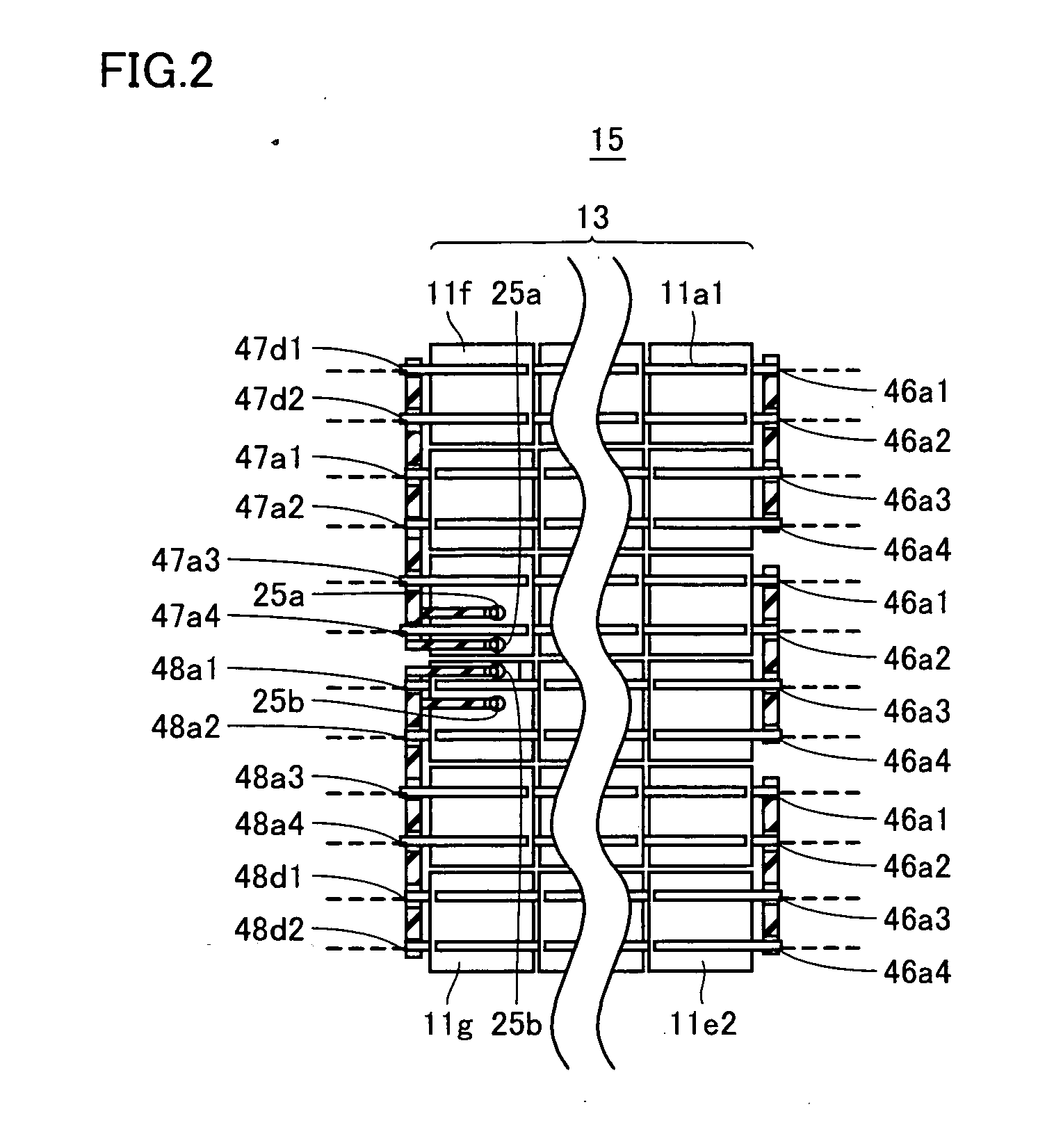

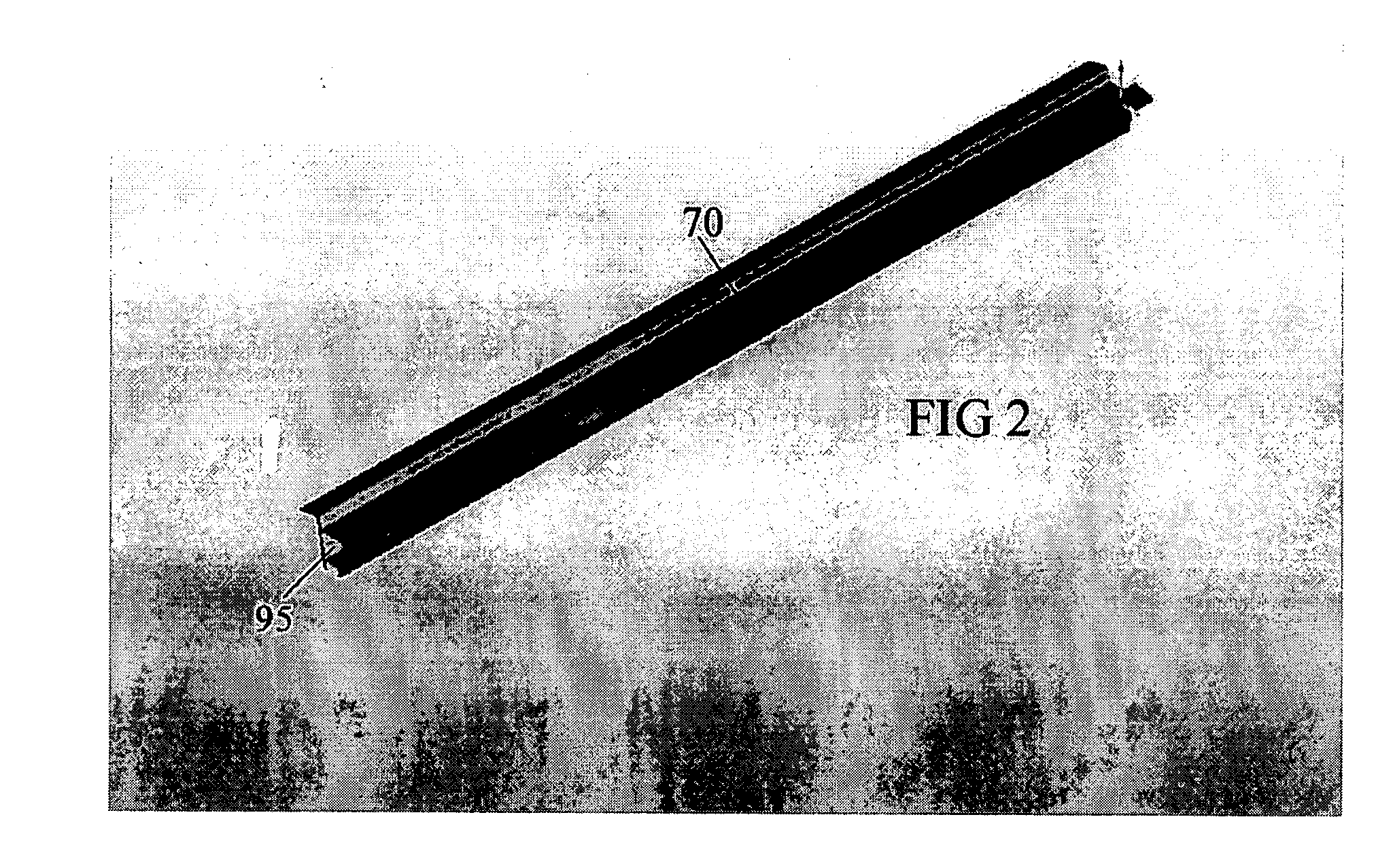

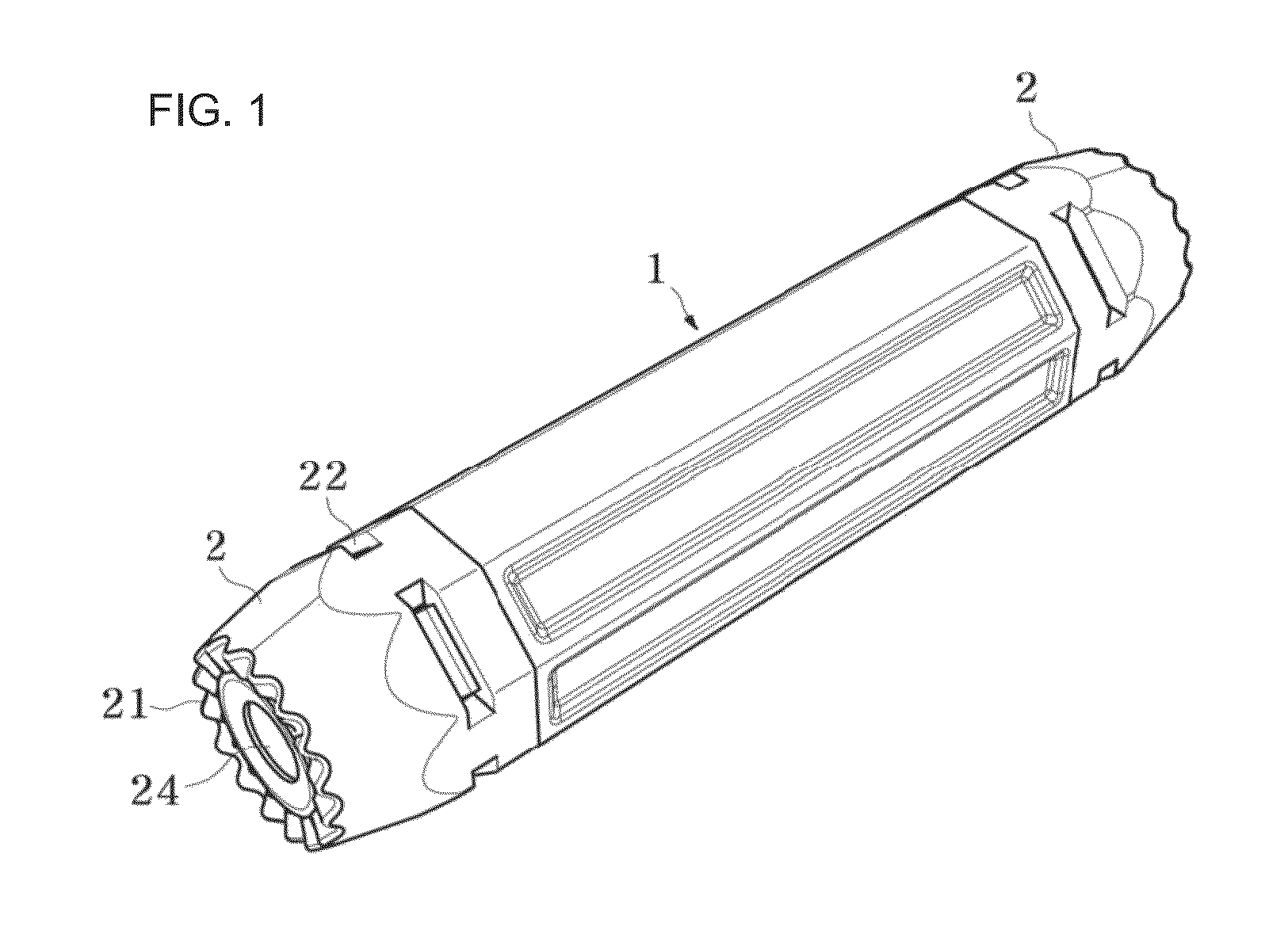

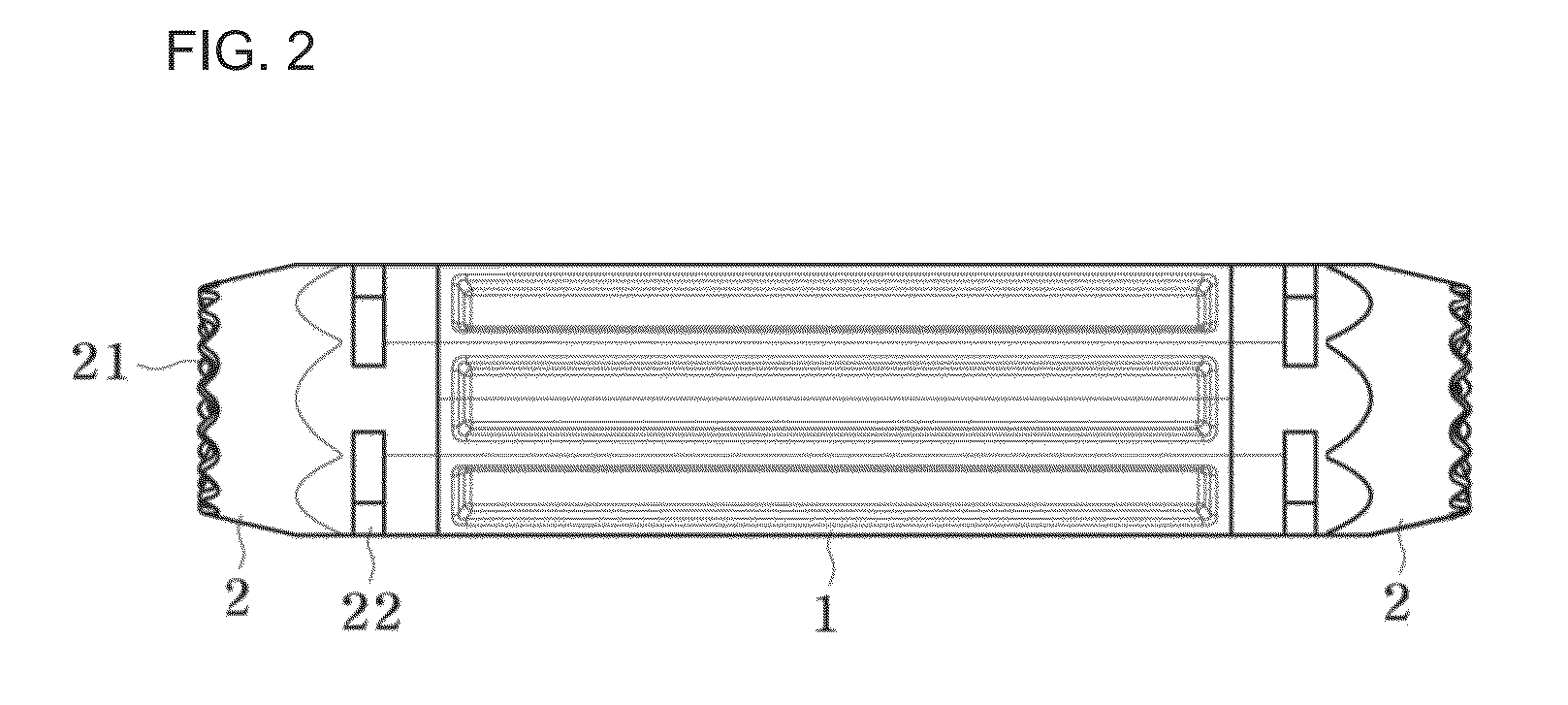

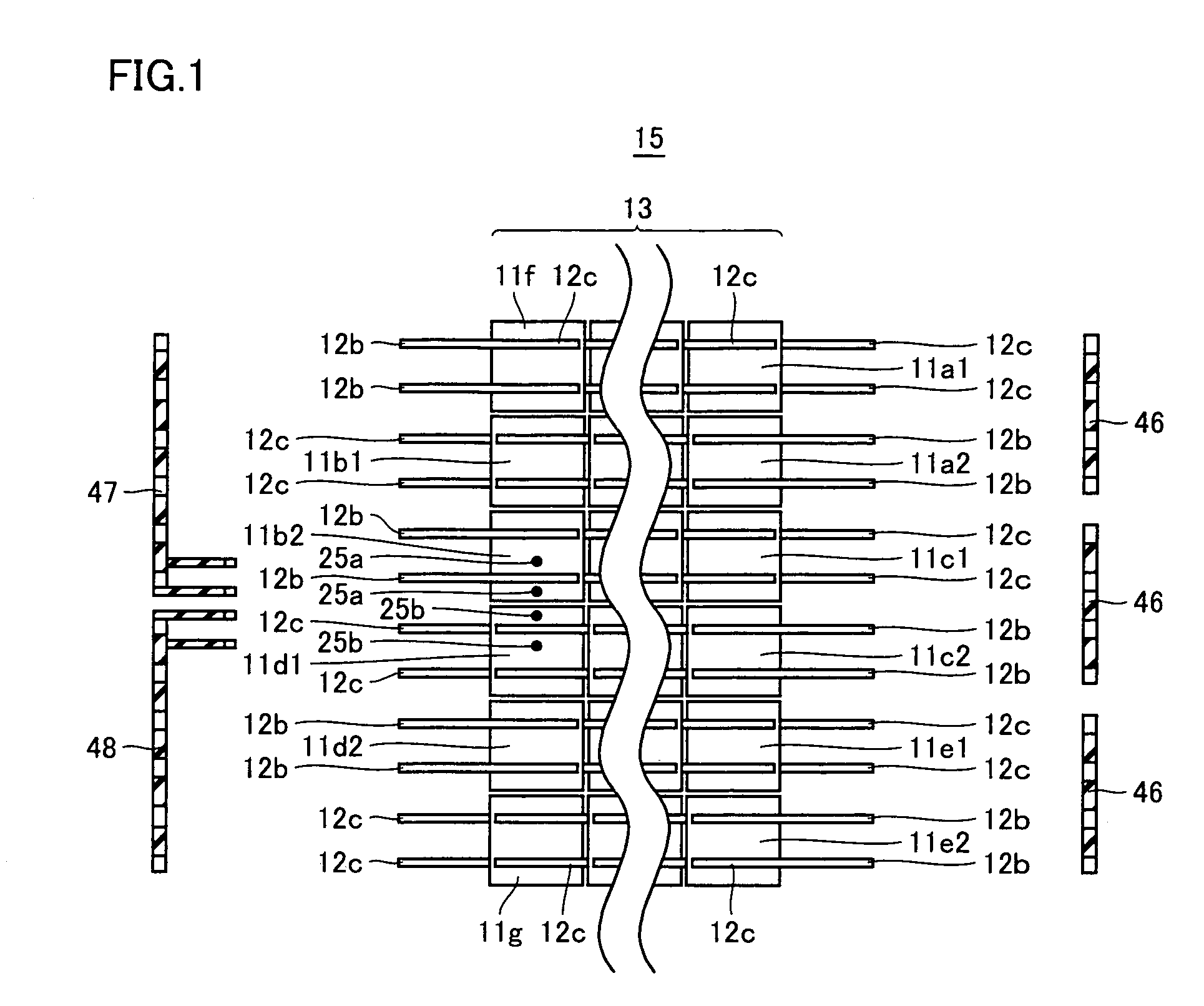

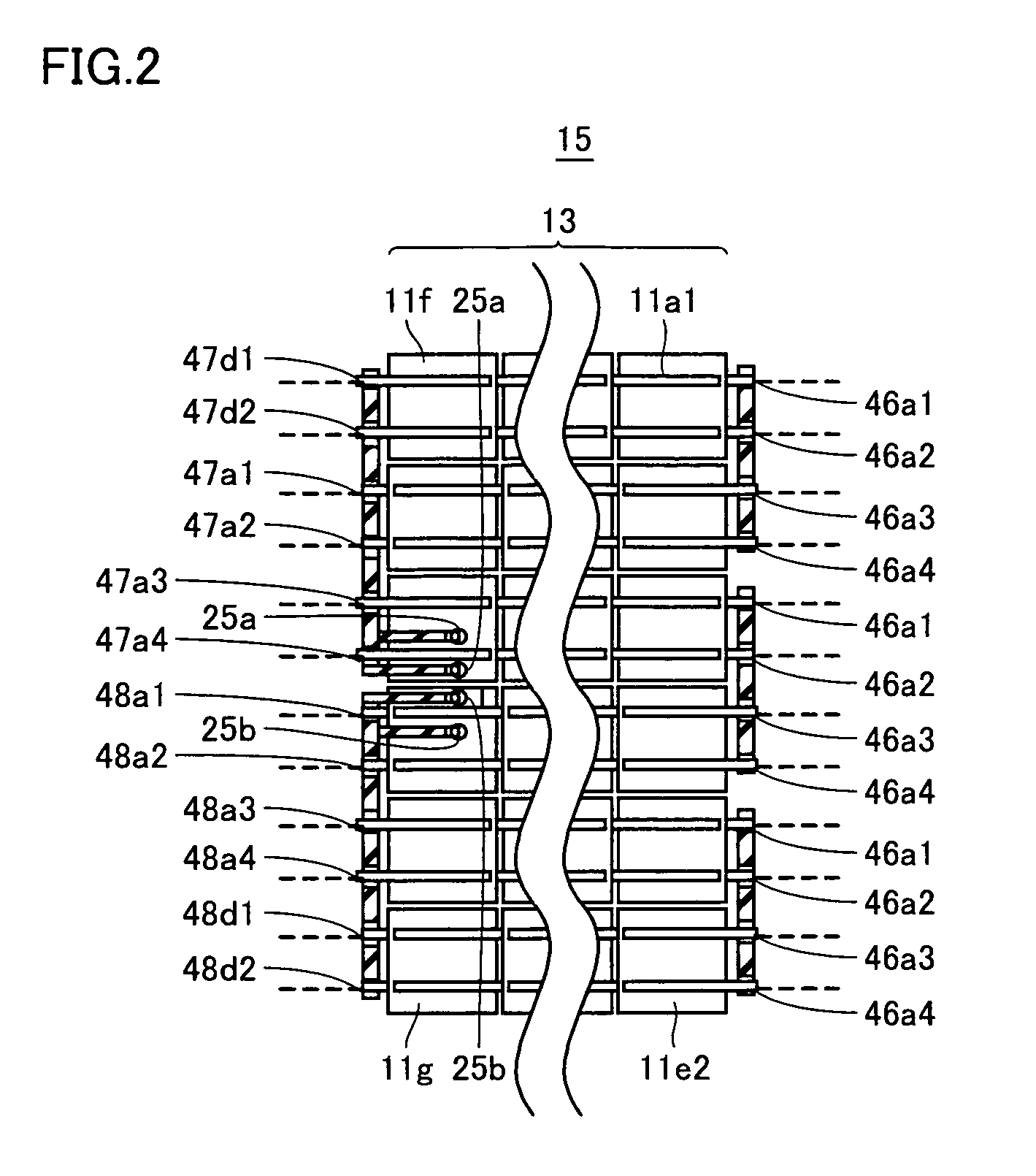

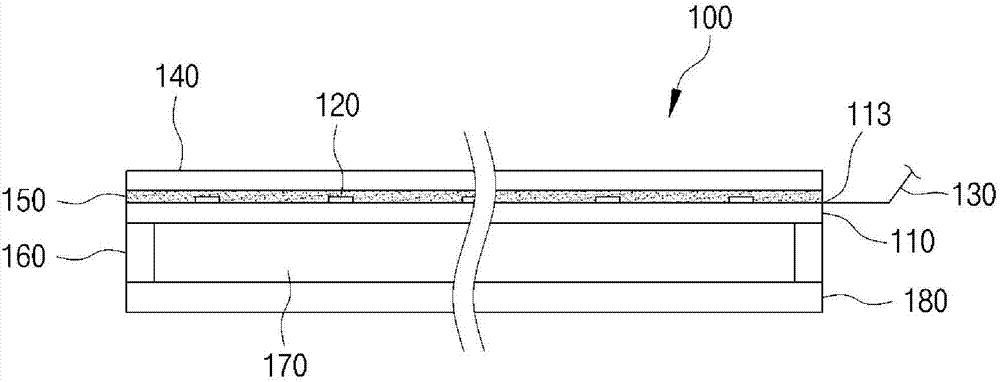

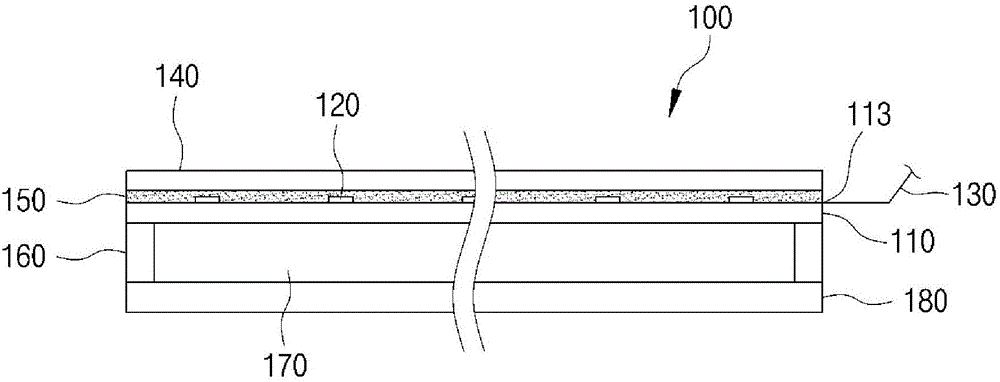

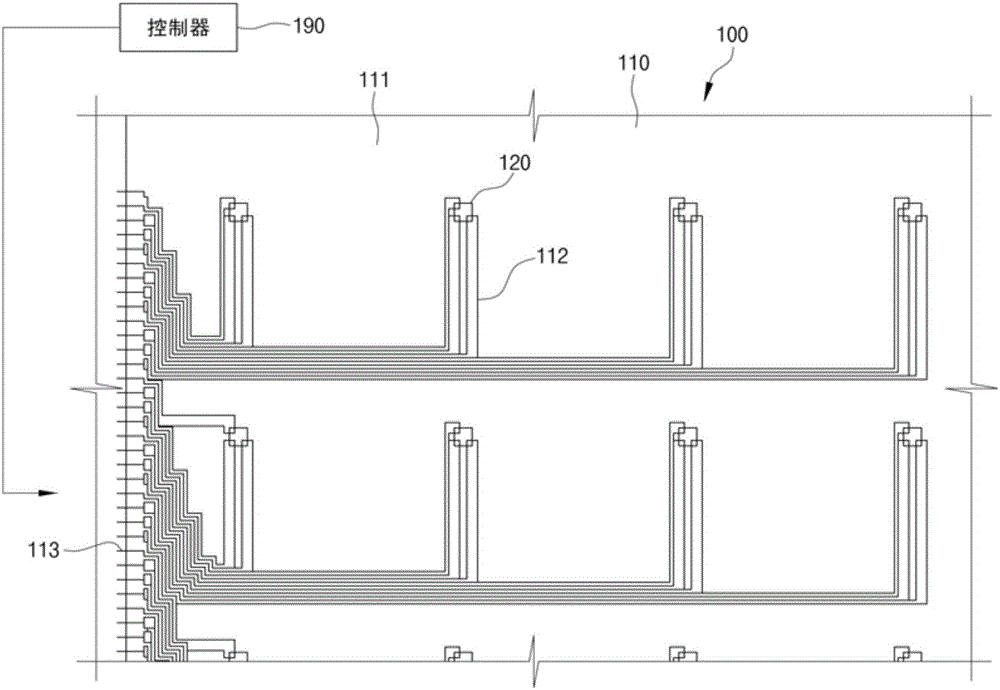

Integrated Wiring Member for Solar Cell Module, Solar Cell Module Using the Same, and Manufacturing Methods Thereof

ActiveUS20080053511A1Reduced external variationImprove aesthetic satisfactionPV power plantsSpecial surfacesSolar cellSolar energy

The present invention provides an integrated wiring member (46, 47, 48) for a solar cell module, including a first wiring member, a second wiring member, and an insulating and protecting film for insulating the first wiring member and the second wiring member from each other. Herein, the first wiring member and the second wiring member are integrated with each other through the insulating and protecting film.

Owner:SHARP KK

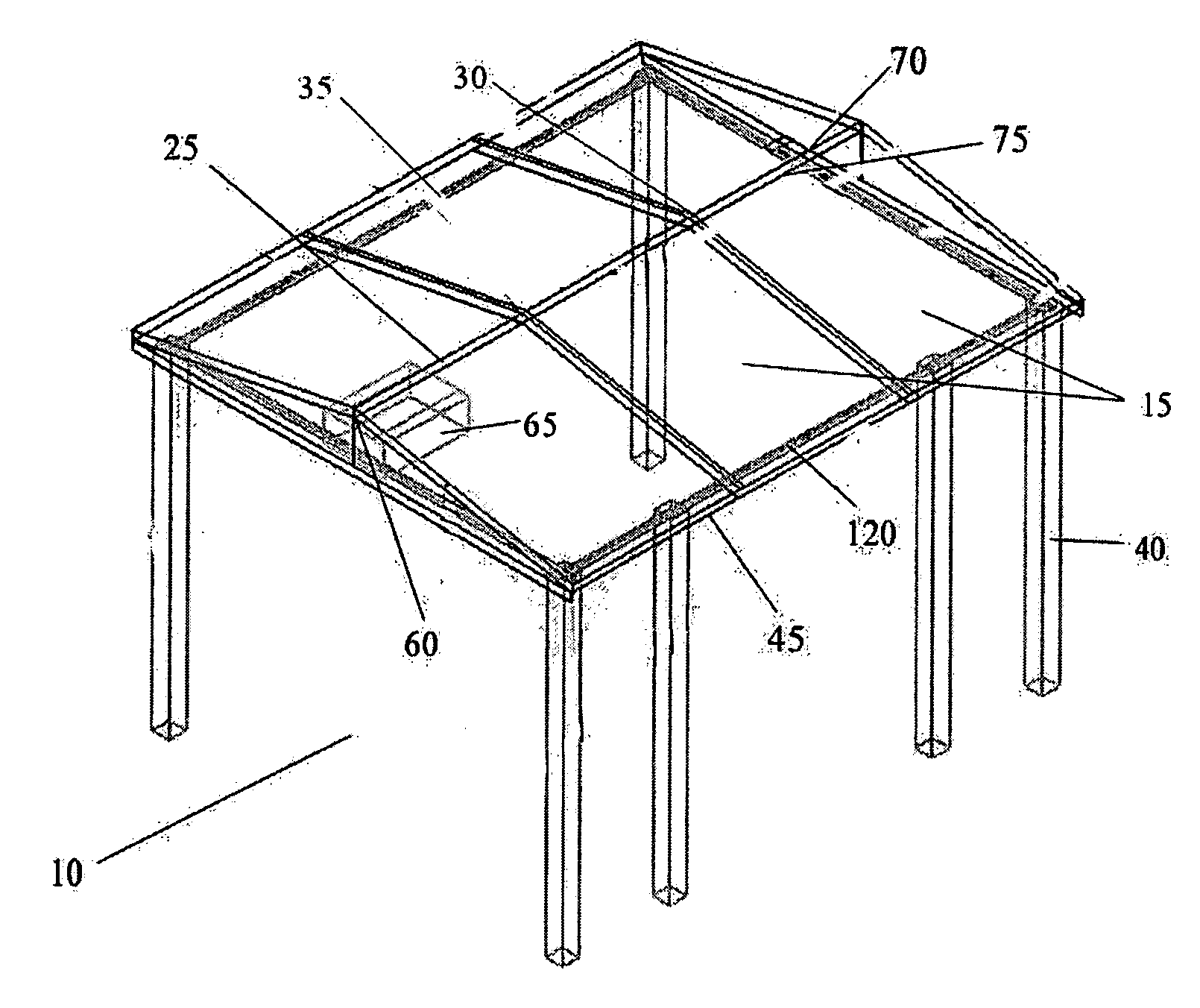

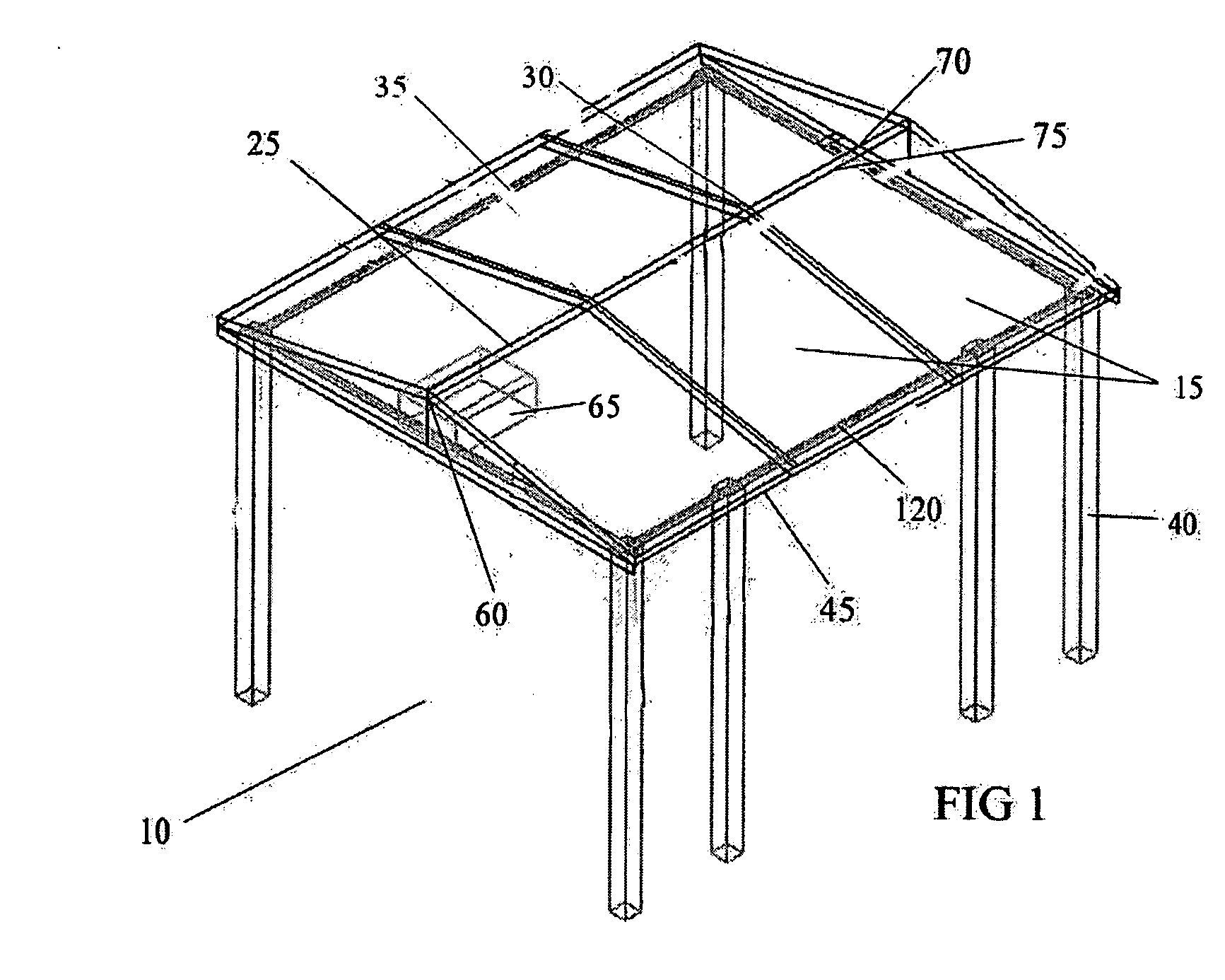

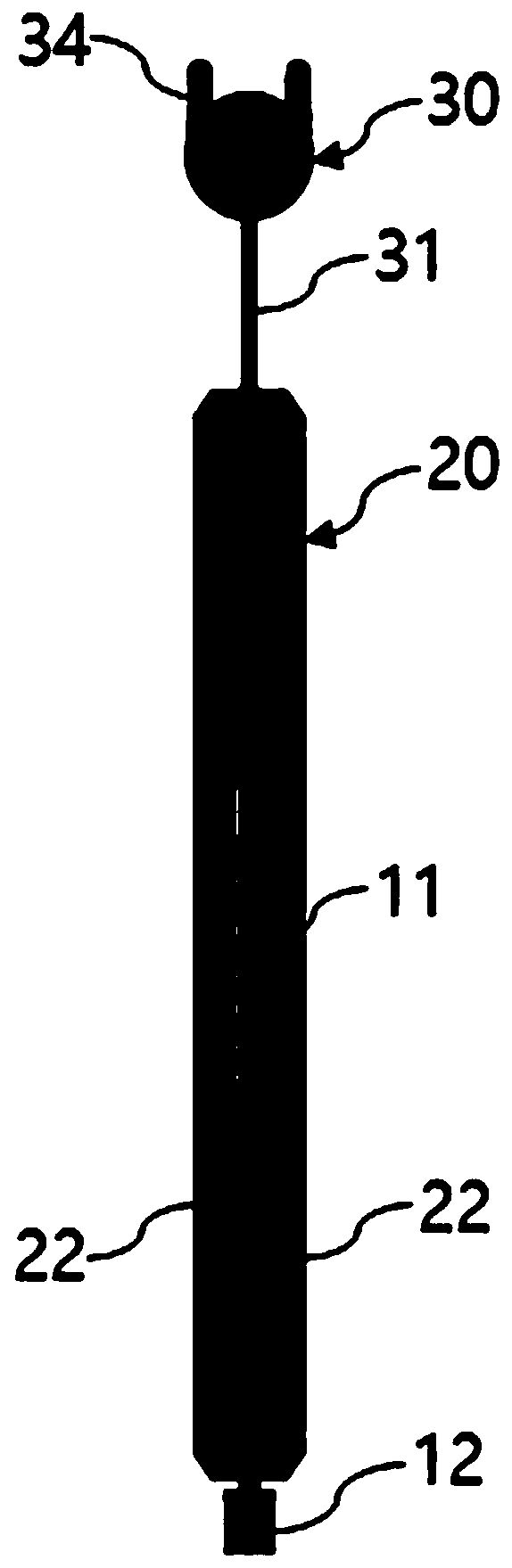

Easy-to-assemble building structure with a mountable frame for supporting solar panels

InactiveUS20050241246A1Improve aesthetic satisfactionEasy to cleanPhotovoltaic supportsSolar heating energyFuel cellsEngineering

The present invention relates generally to an easy-to-assemble building structure with a mountable frame for mounting solar panels, solar water heating panels, fuel cells or any other renewable energy device and more particularly relates to a gazebo or a storage space or an overhang used for purposes of mounting solar panels.

Owner:SINHA SUNIL KUMAR +2

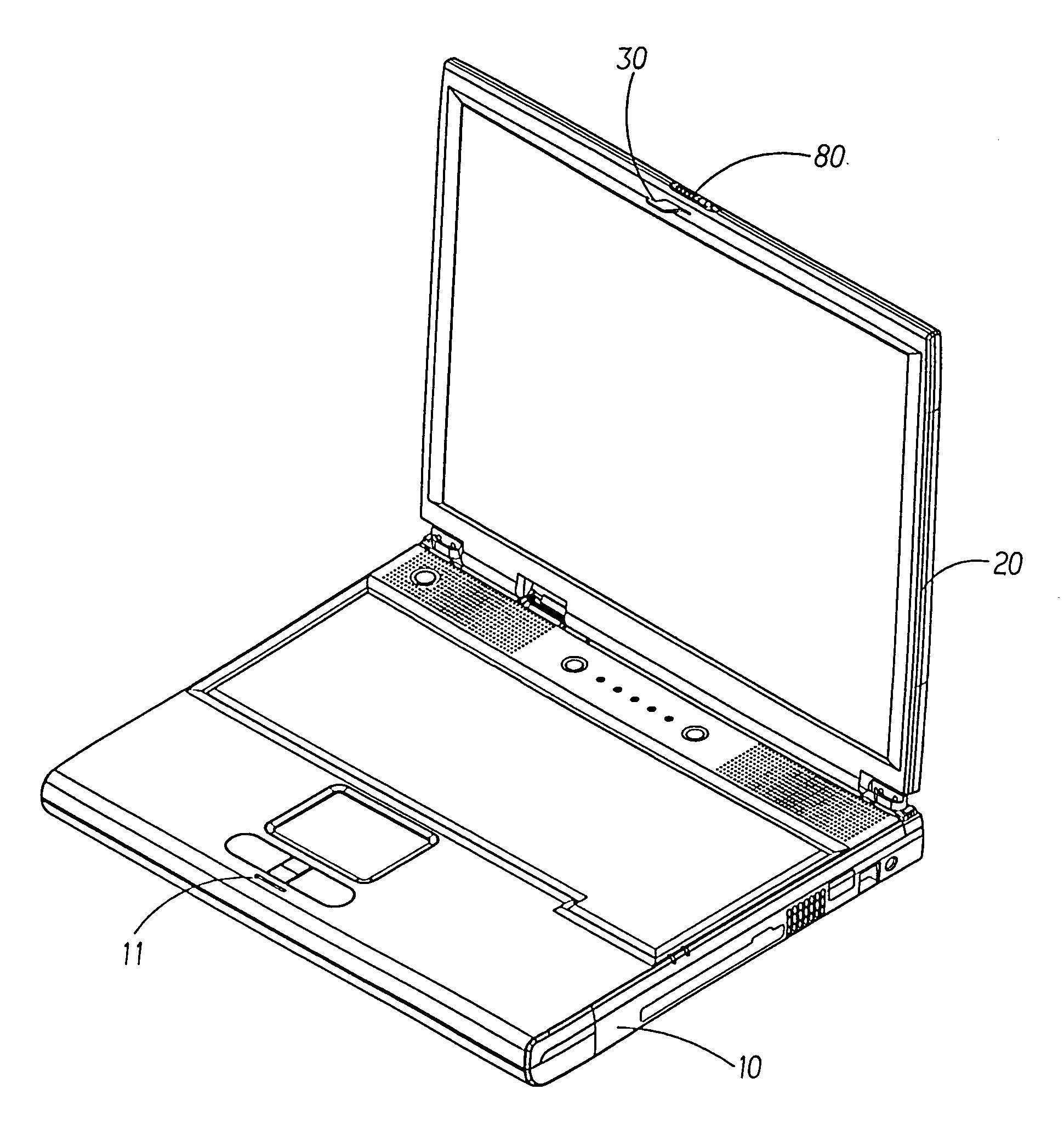

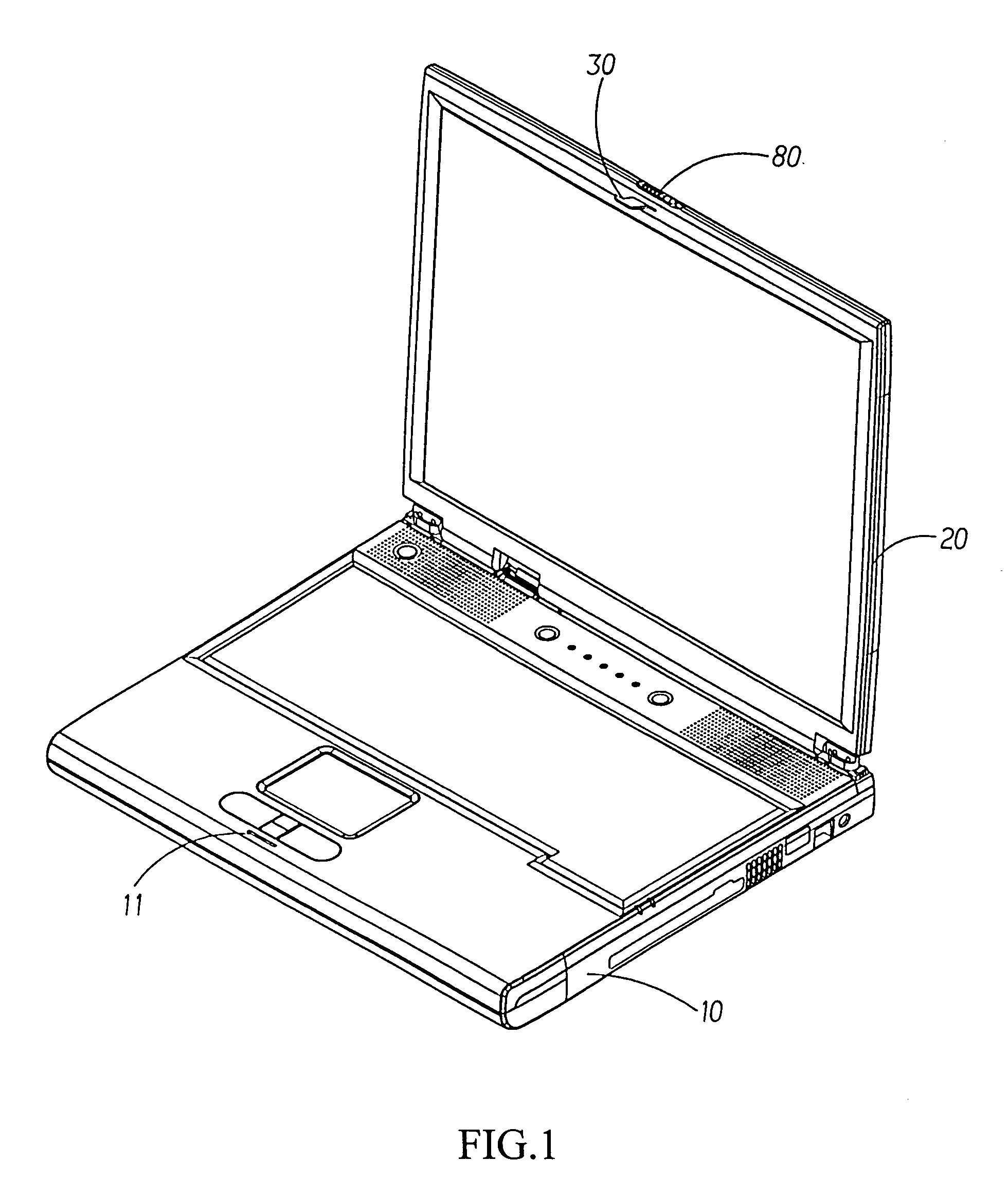

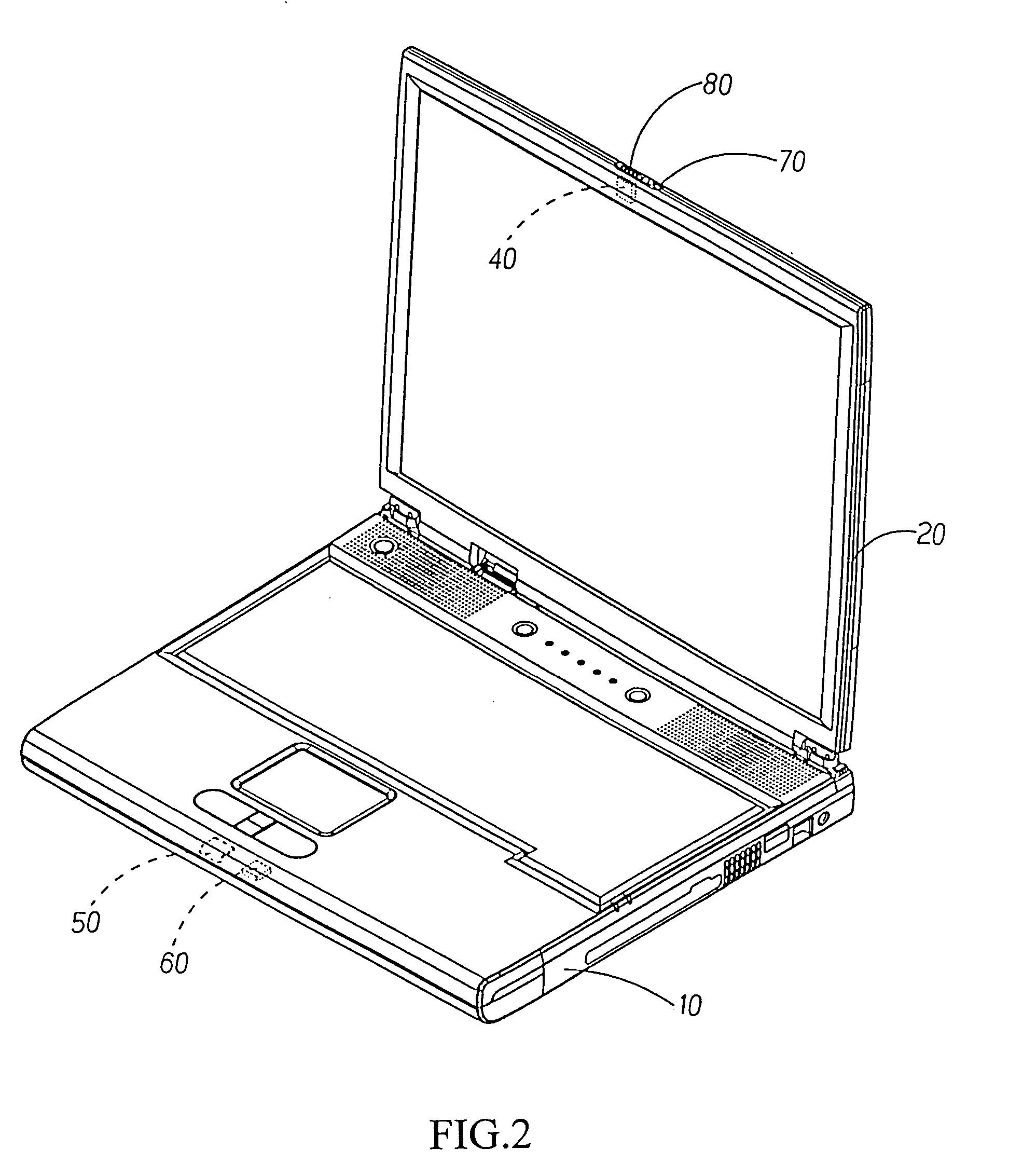

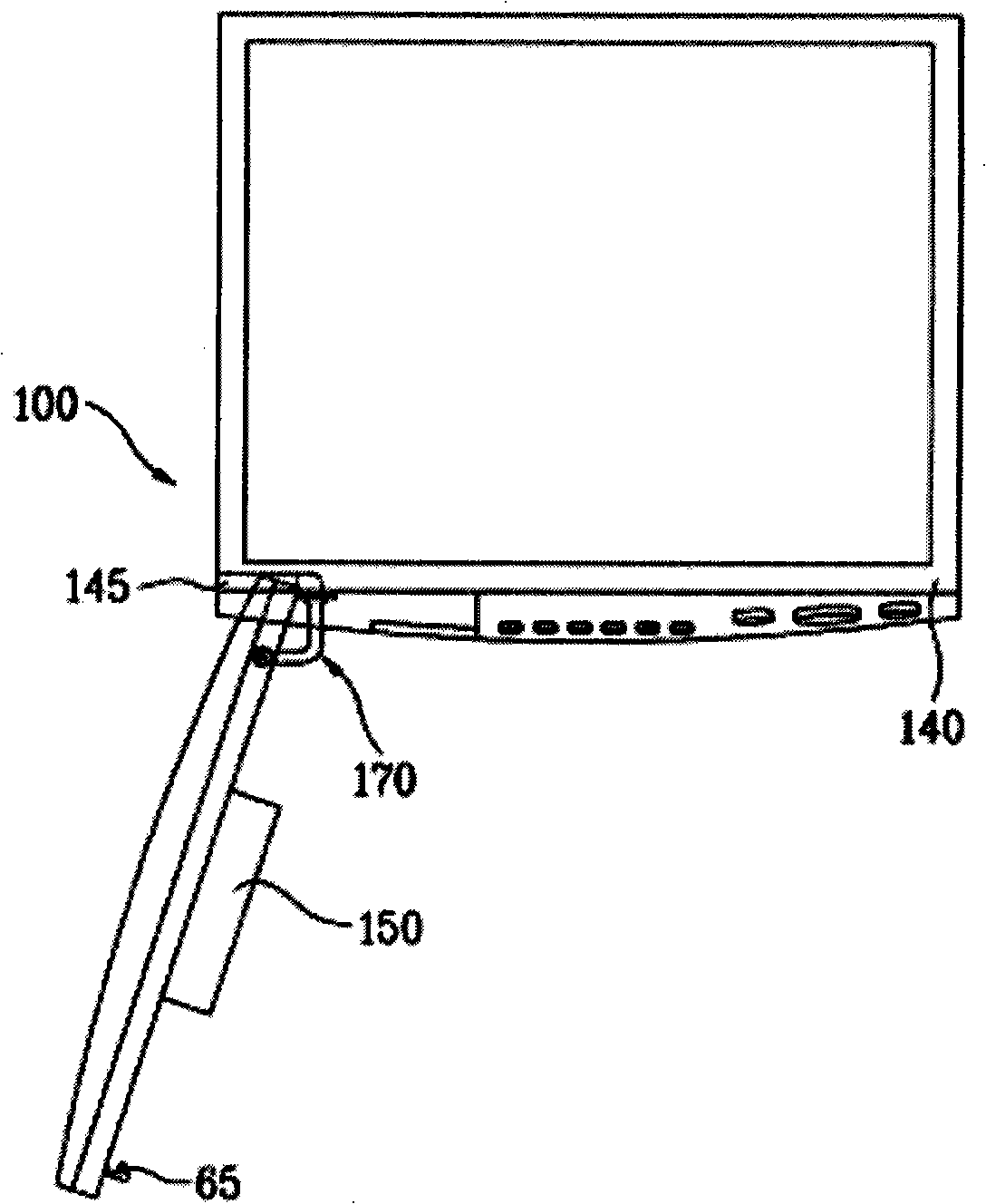

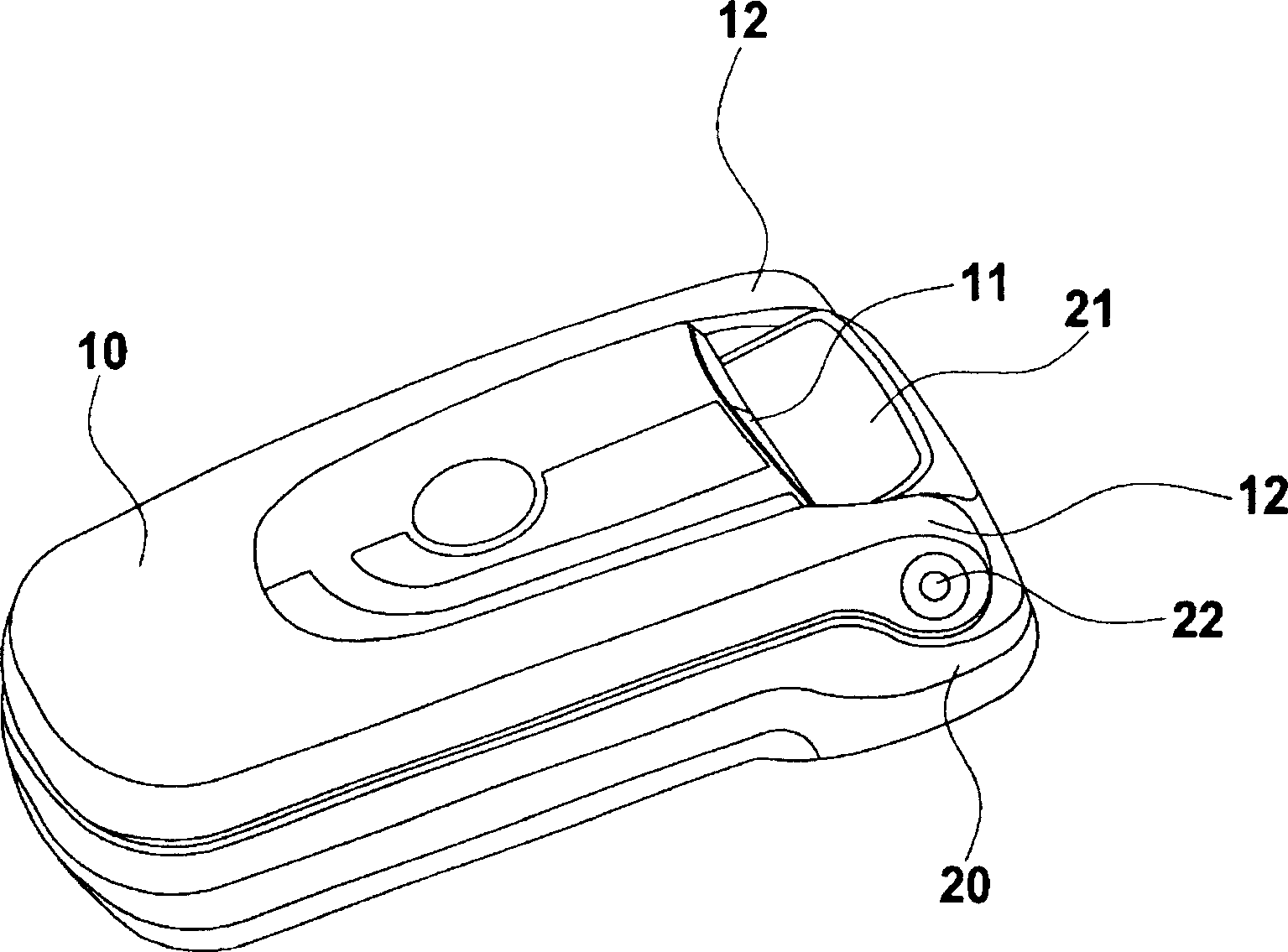

Magnetic open/close structure for electronic device

InactiveUS20050018393A1Avoid hard activationAccurately closedCasings/cabinets/drawers detailsDetails for portable computersElectrical polarityEngineering

A magnetic open / close structure for an electronic device such as a notebook computer is comprised of a primary magnet and an attachment to be attracted respectively provided on one side the lid and fixed at a specific place, a secondary magnet having the same polarity facing to that of the primary magnet being fixed by the side of the attachment; the primary magnet sliding back and forth at where it is overlapped with the attachment or the secondary magnet due to the motion of limited slide from the push key to provide a secure positioning structure for the lid when covering on the case; and the lid being ejected for a certain angle from the case for easy access to open it up by taking advantage of the rejection between the primary and the secondary magnets when the primary magnet is pushed to be overlapped with the secondary magnet.

Owner:UNIWILL COMP

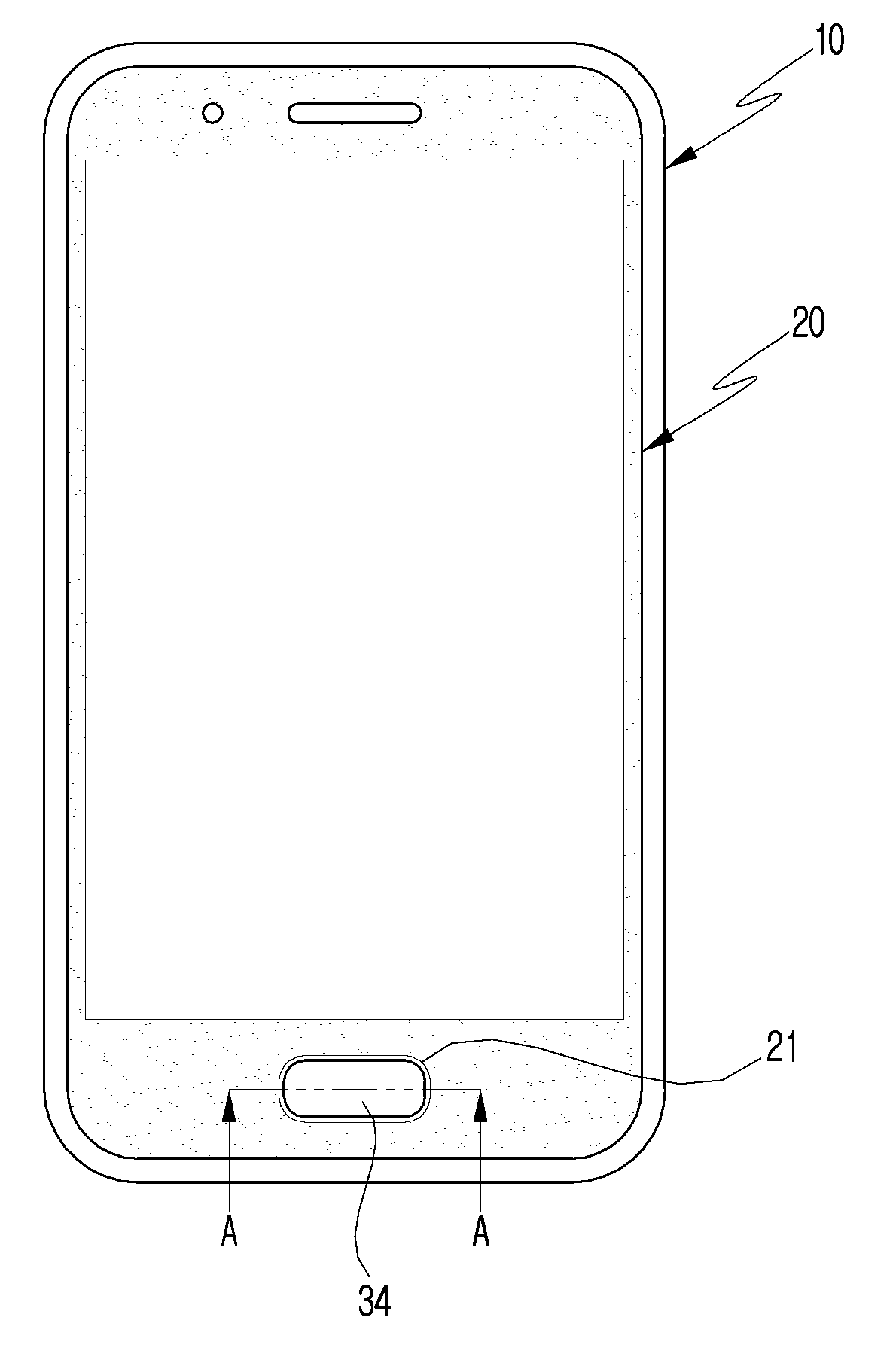

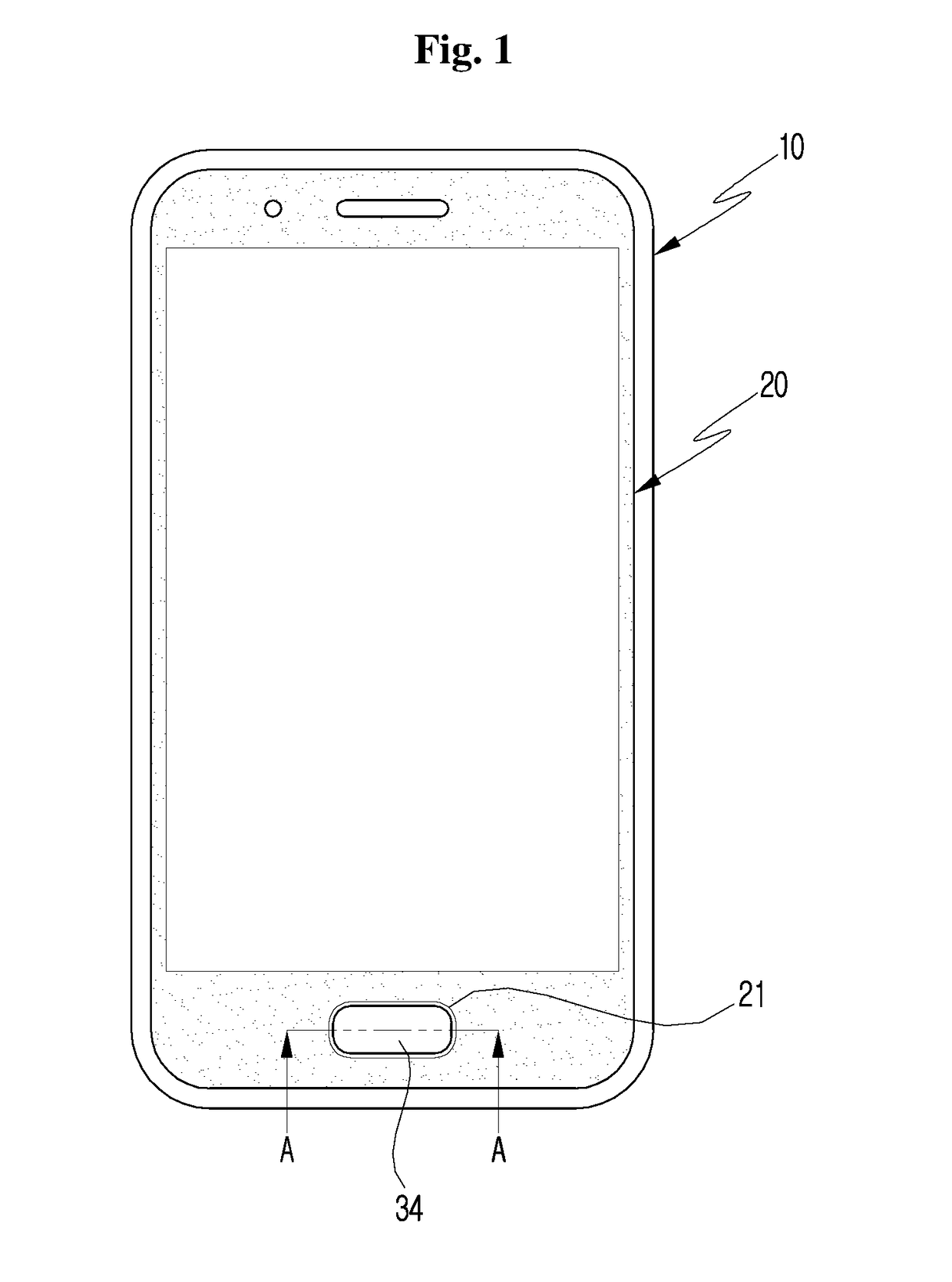

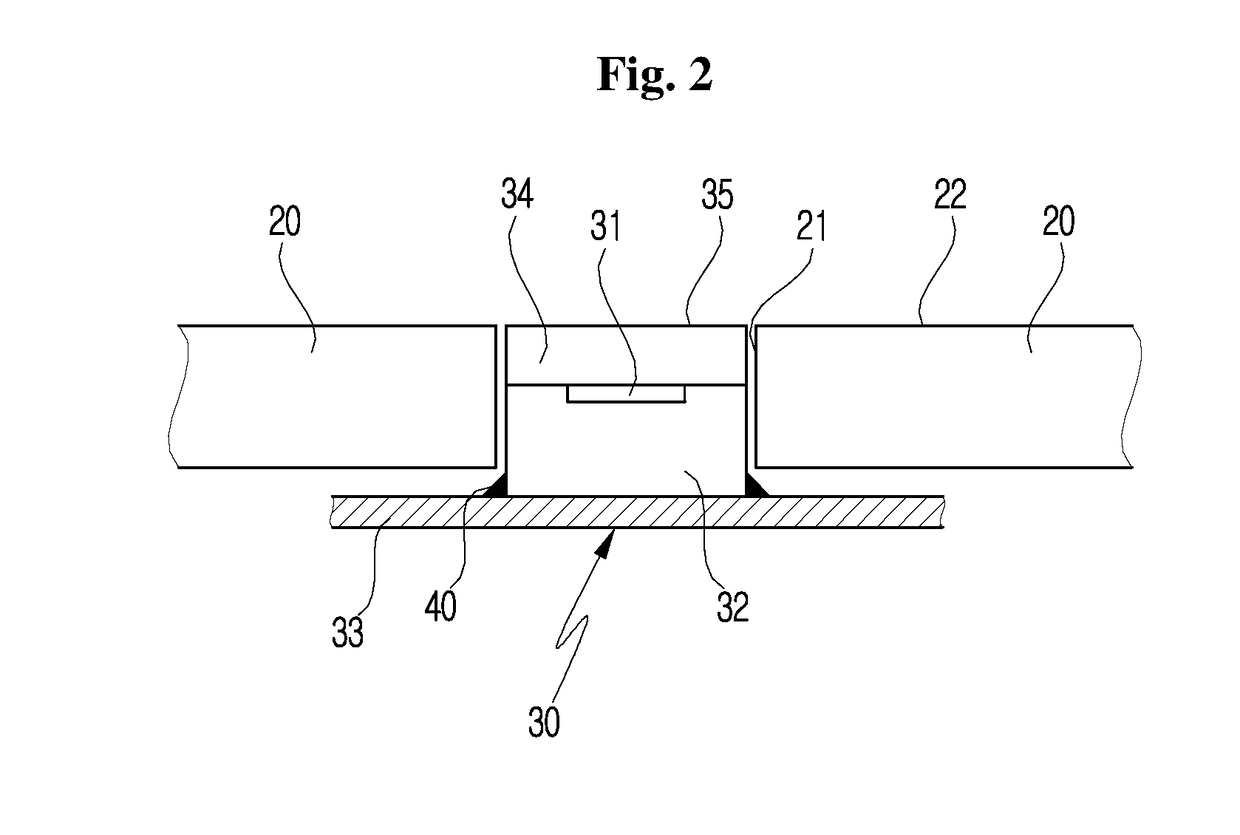

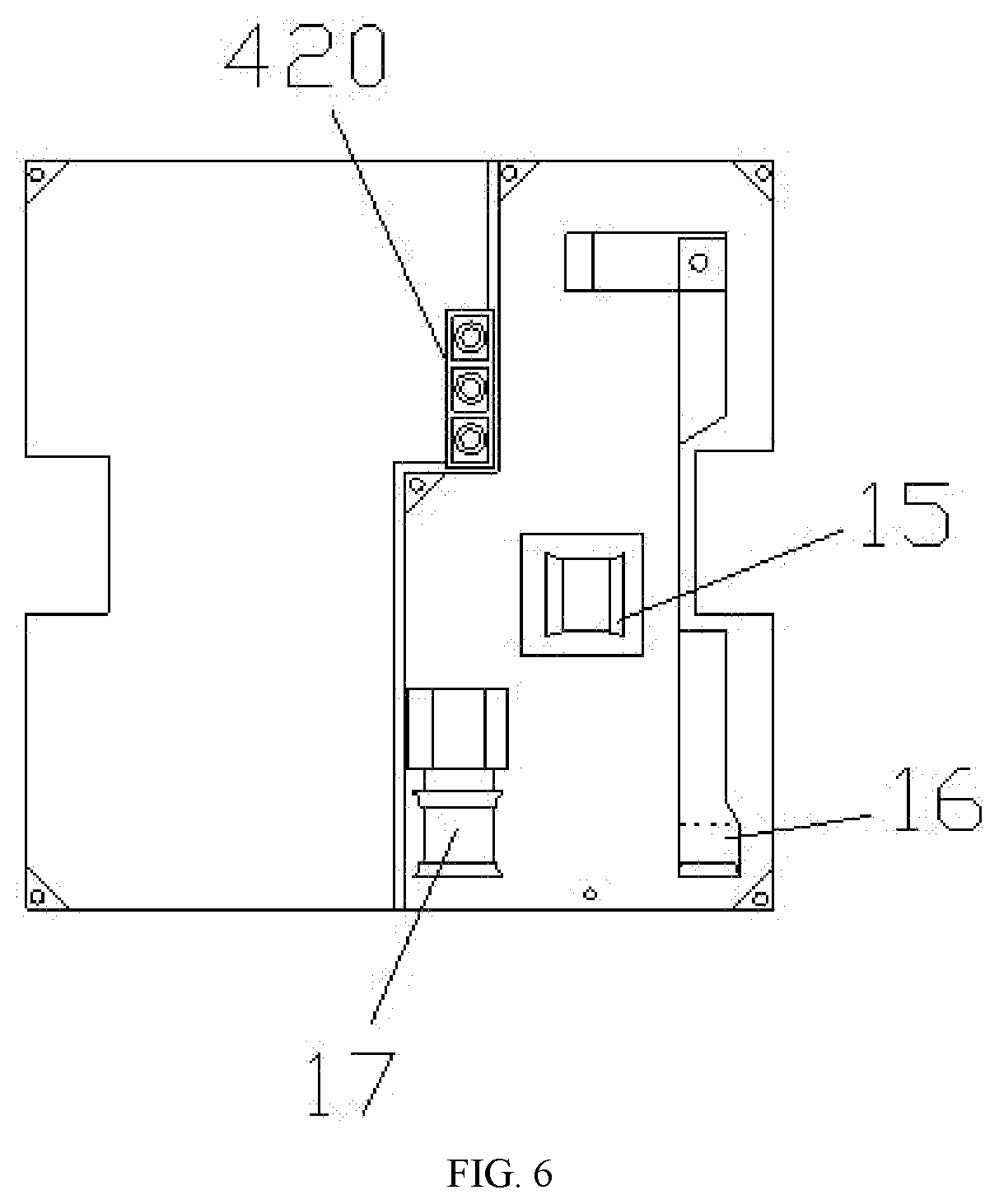

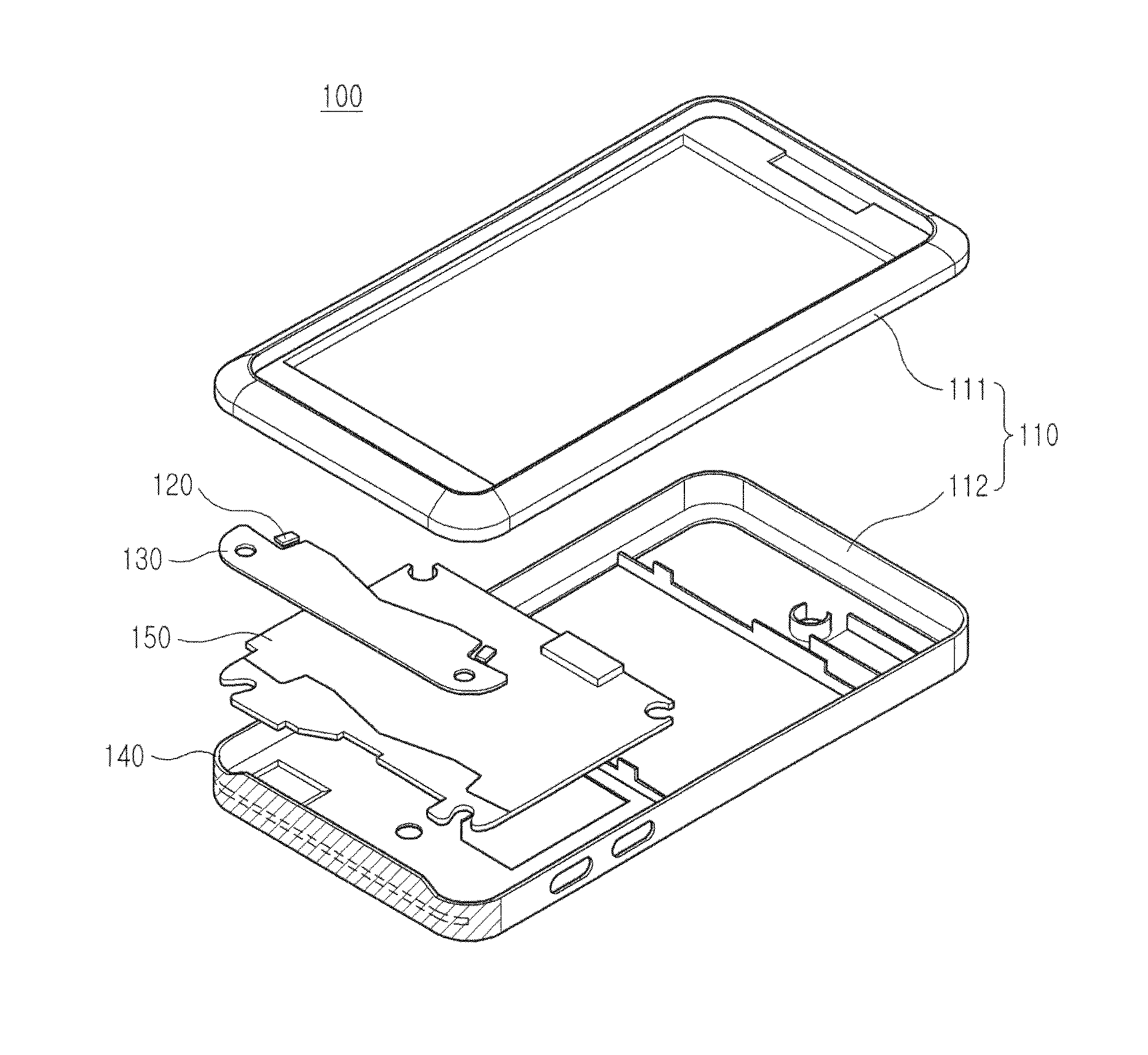

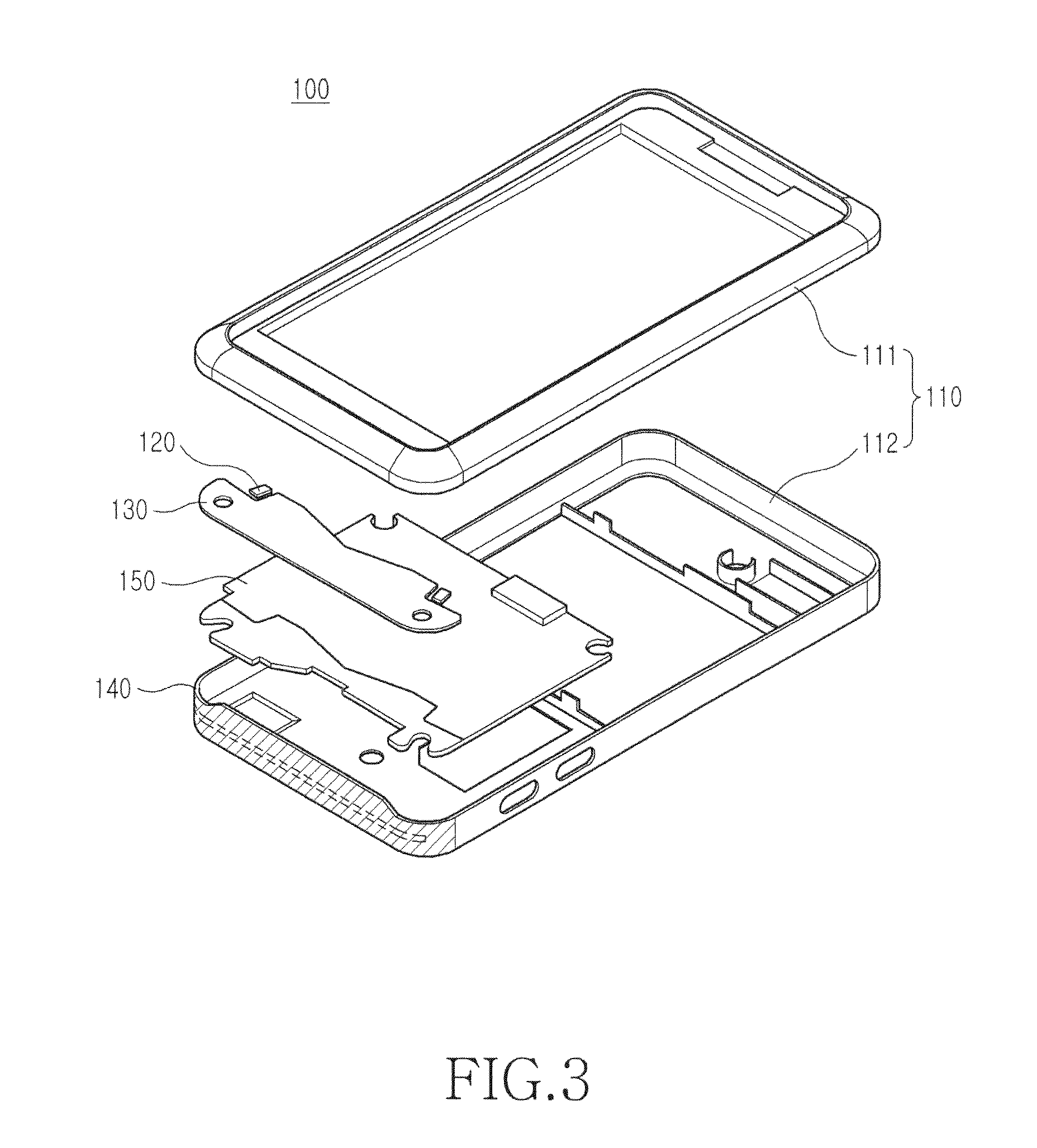

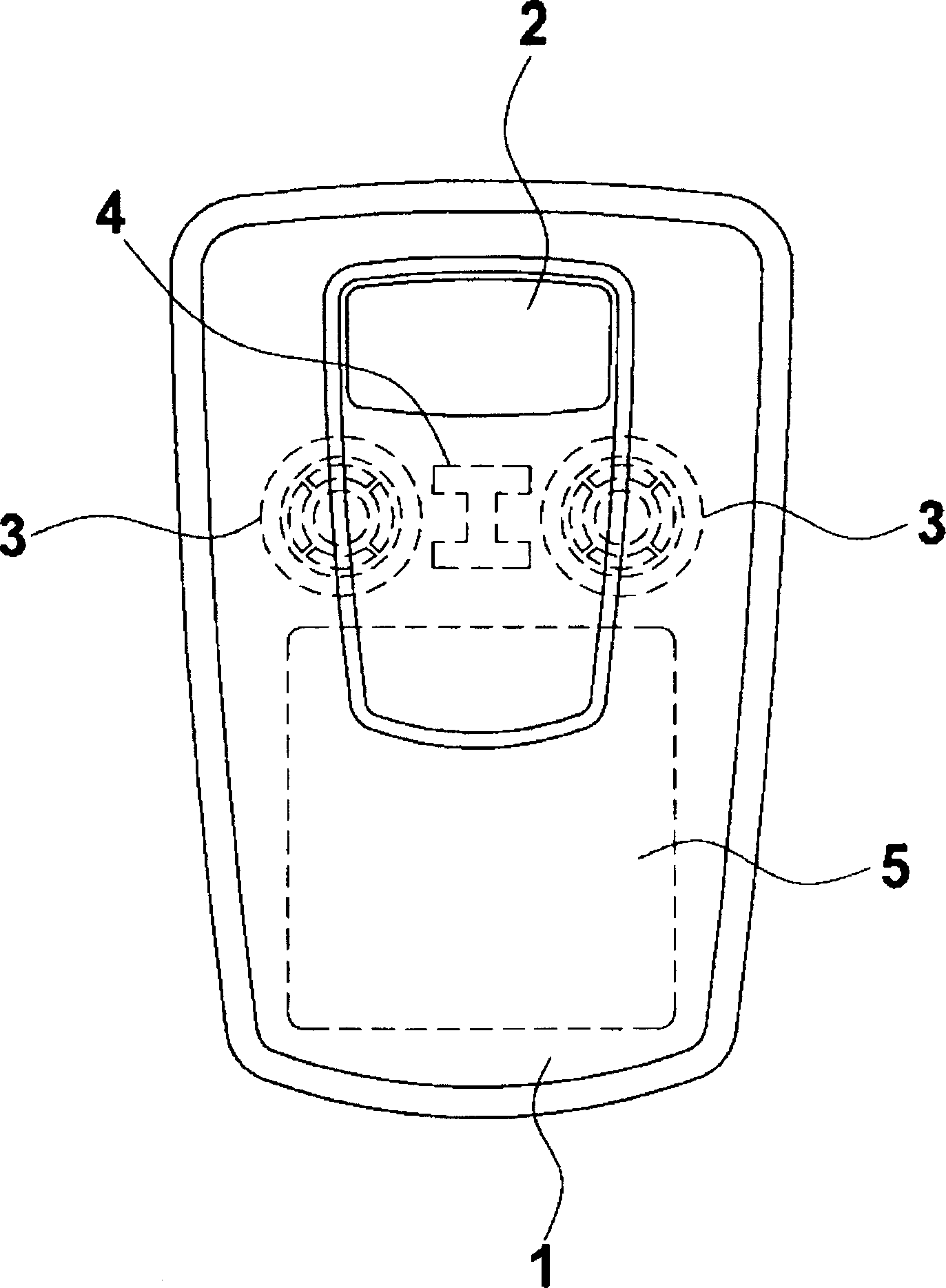

Fingerprint sensor module assembly integrated with cover window for electronic device

InactiveUS20170372123A1Good lookingImprove aesthetic satisfactionPrint image acquisitionMatching and classificationFingerprintEngineering

The present invention provides a fingerprint sensor module assembly integrated with a cover window for an electronic device. The fingerprint sensor module assembly, according to one embodiment of the present invention, comprises: the cover window; a fingerprint sensor module; and an adhesion part. The cover window is disposed on a front surface of the electronic device. An image is generated from a display module and displayed on the cover window. The fingerprint sensor module is coupled to a seating part which is disposed on a lower surface of the cover window. The fingerprint sensor module comprises a fingerprint sensor having a sensing unit for sensing fingerprints; and a substrate electrically connected to the fingerprint sensor. The adhesion part is disposed between the seating part and the fingerprint sensor module and configured to fix the fingerprint sensor module in the seating part.

Owner:CRUCIALTEC

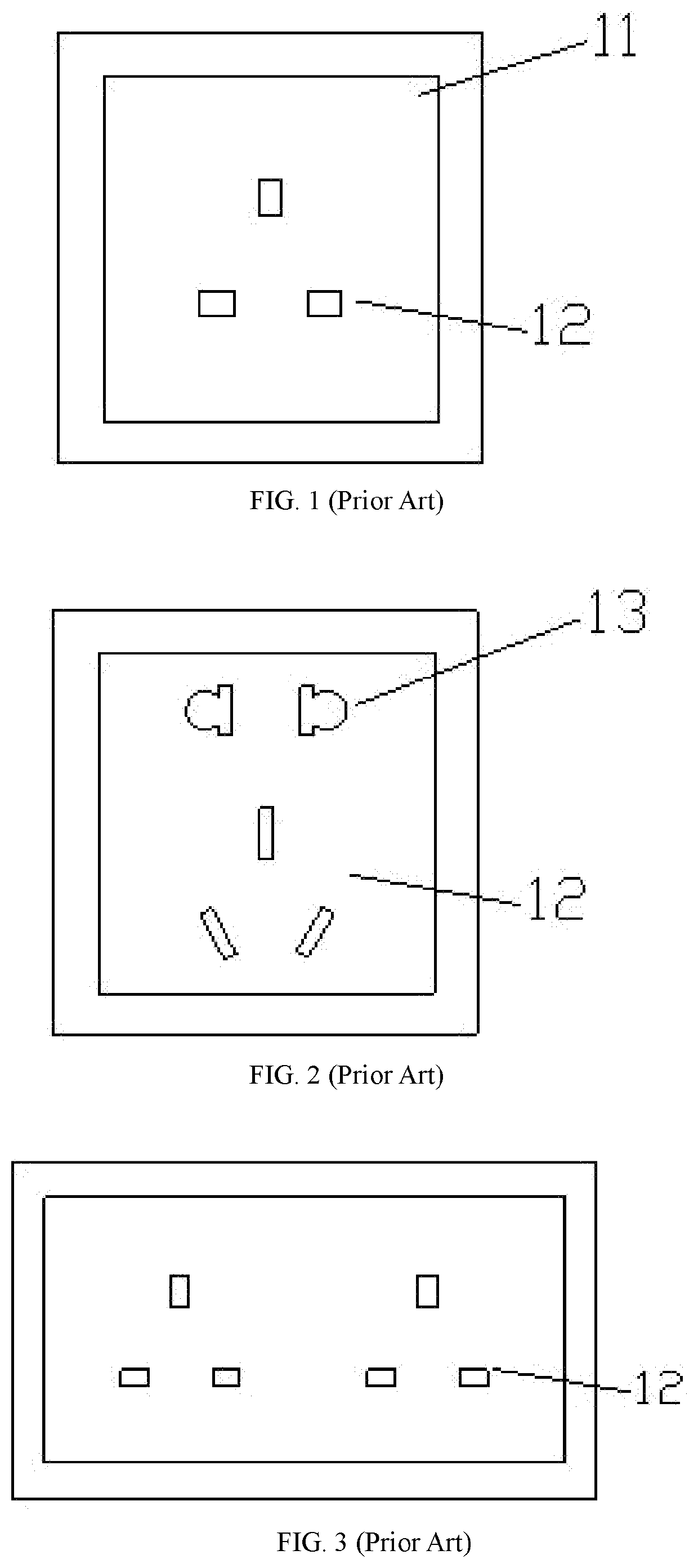

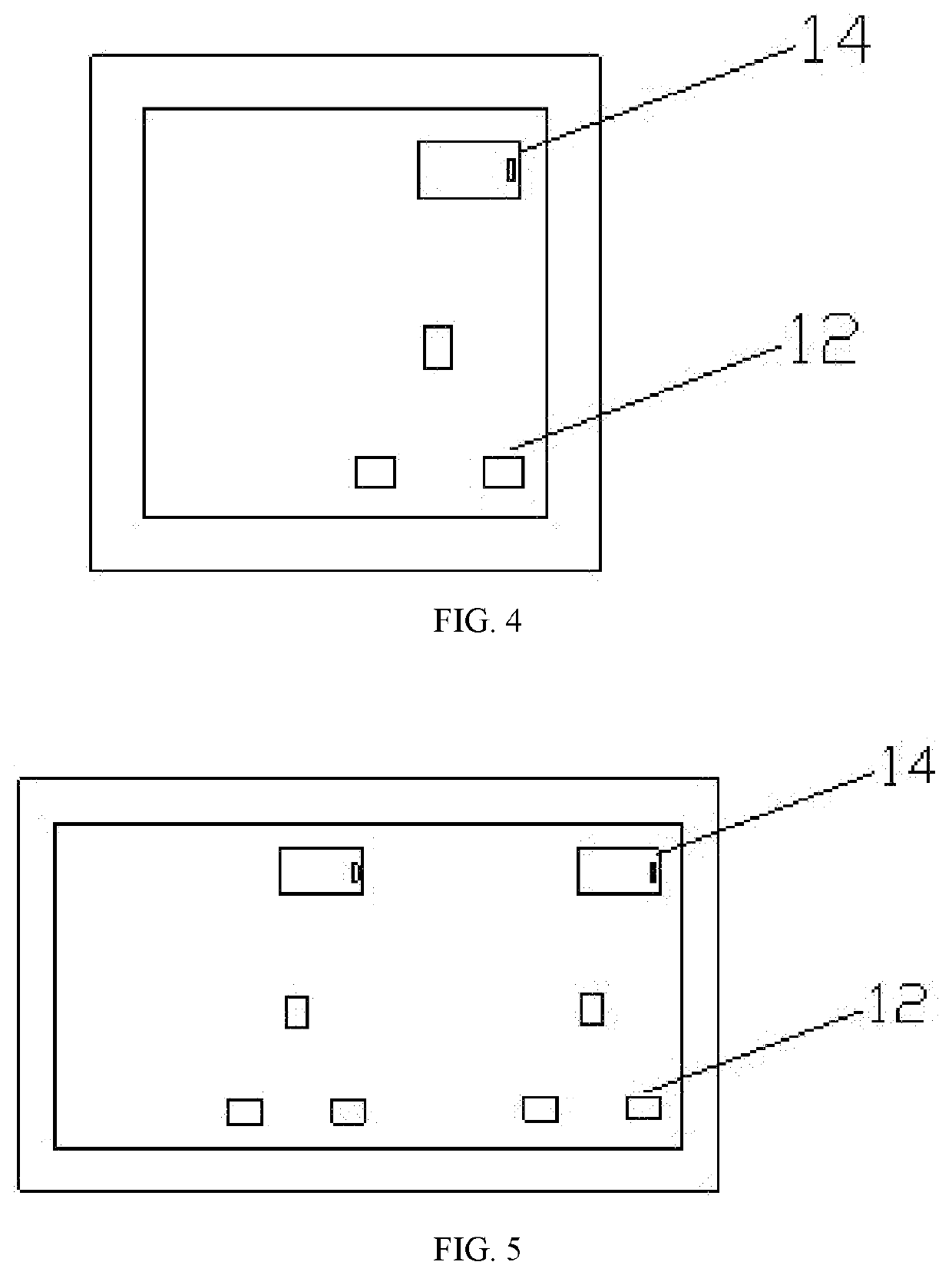

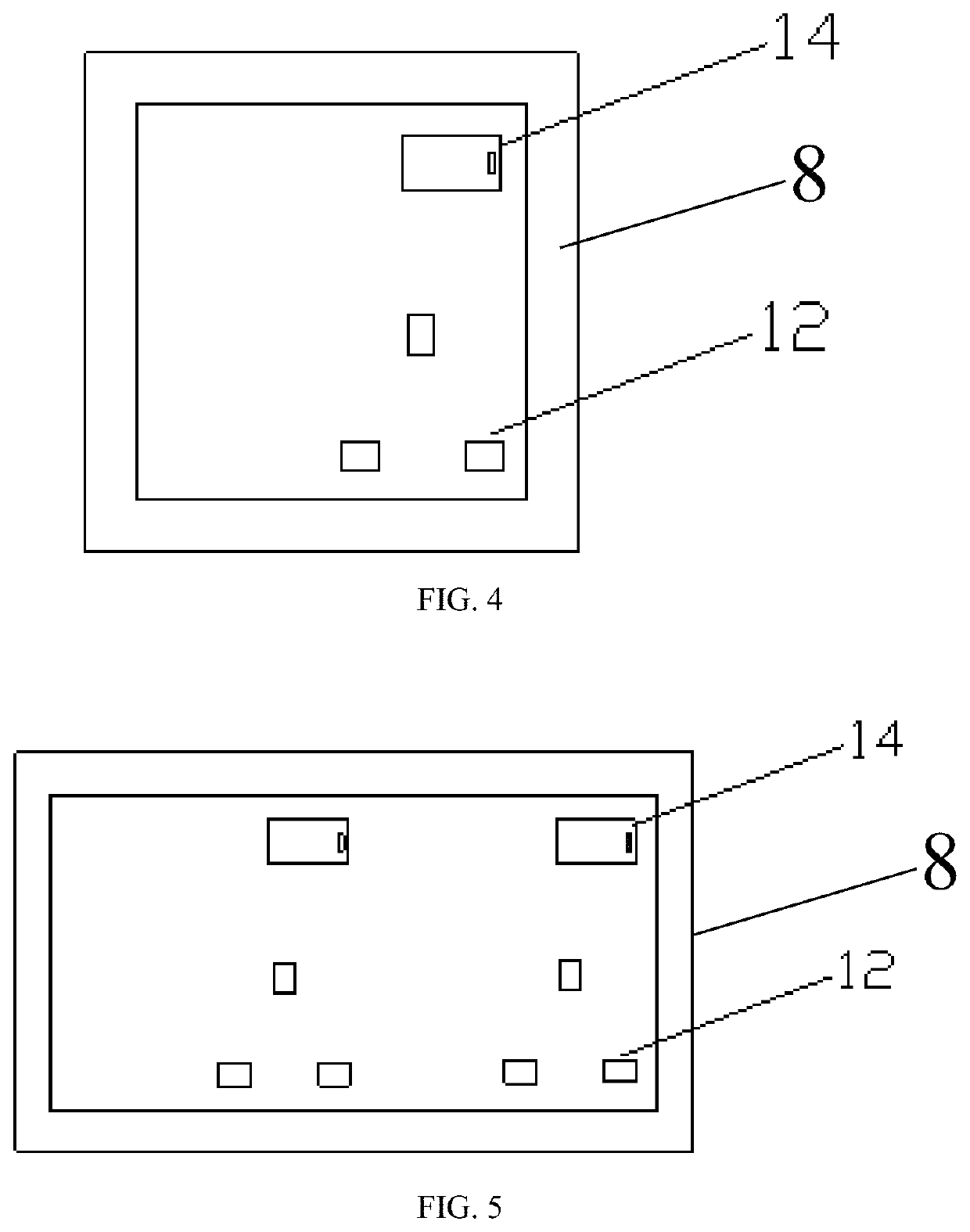

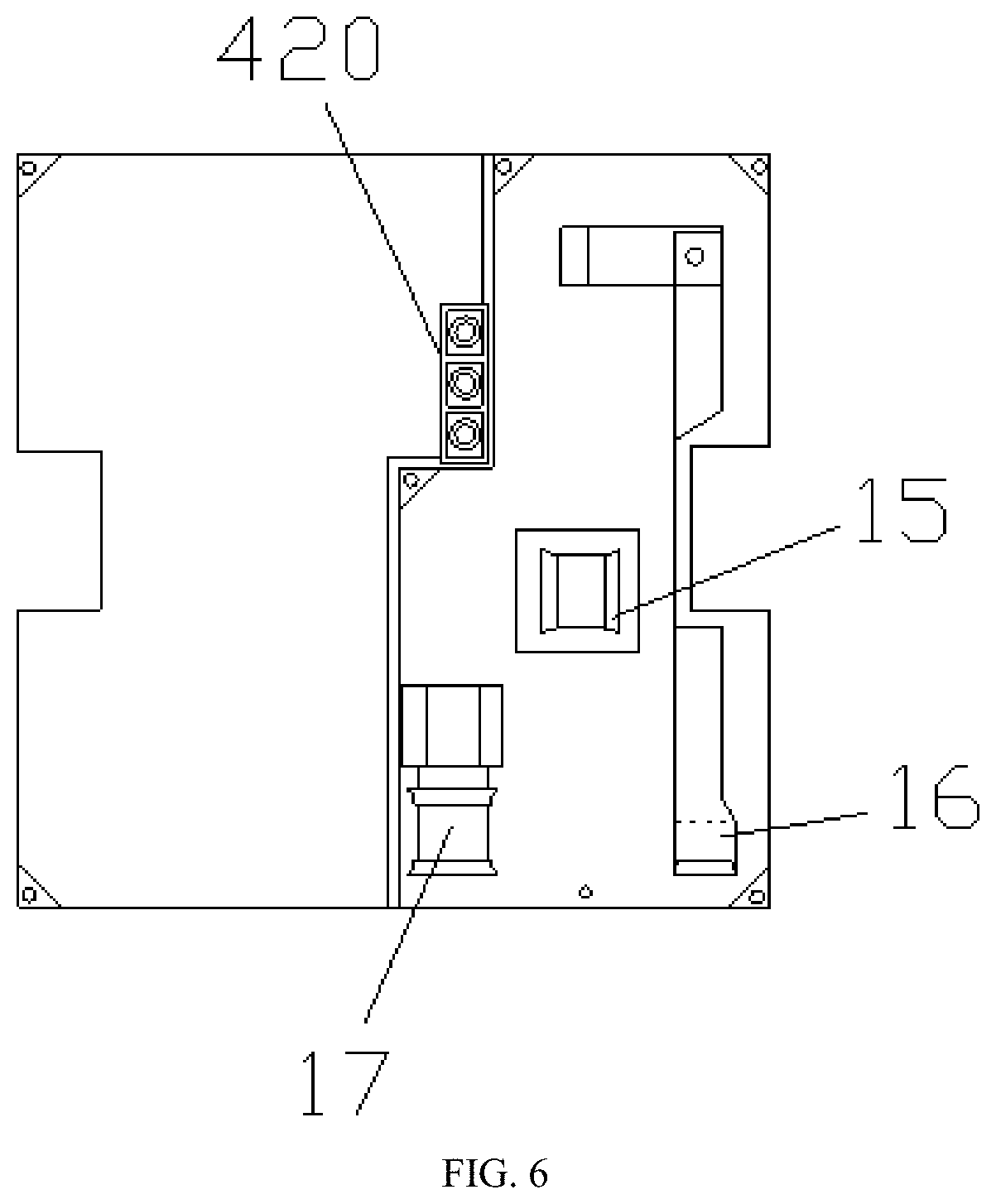

Expandable and upgradeable universal socket

ActiveUS20200006886A1Function increaseReduce in quantityCoupling device detailsTwo-part coupling devicesWire rodTransformer

An expandable and upgradeable universal socket, including a socket body and a function module. The function module is replaceable and upgradeable, and is detachably fixed to the socket body. A power circuit of the function module is separably connected to a power circuit of the socket body to enable the function modules to plug and play. A space is provided in the socket body to accommodate the functional module, and a surface of the socket body is provided with a function area corresponding to the function module. Various expanded function modules can be matched and arranged in the reserved space. Small electronic components can be accommodated in the socket bottom box, and the number of external power transformers are reduced, which saves space, reduces exposed wires and beautifies the appearance. There is no need to replace the entire socket when upgrading the socket, which is environmentally friendly and energy saving.

Owner:CHAN KWOK LEUNG

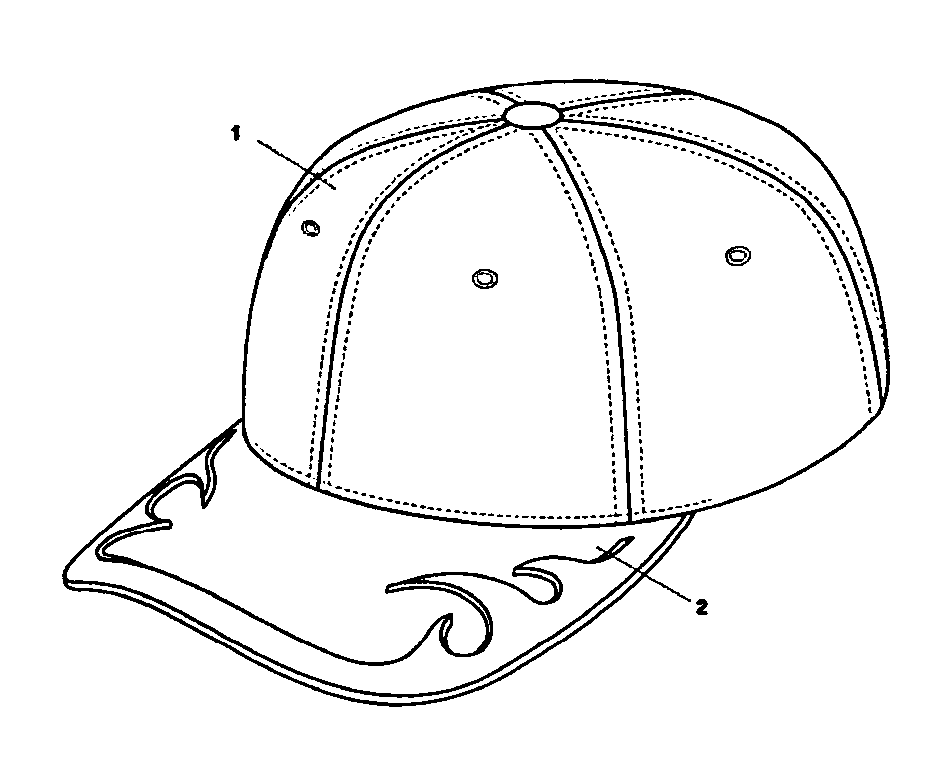

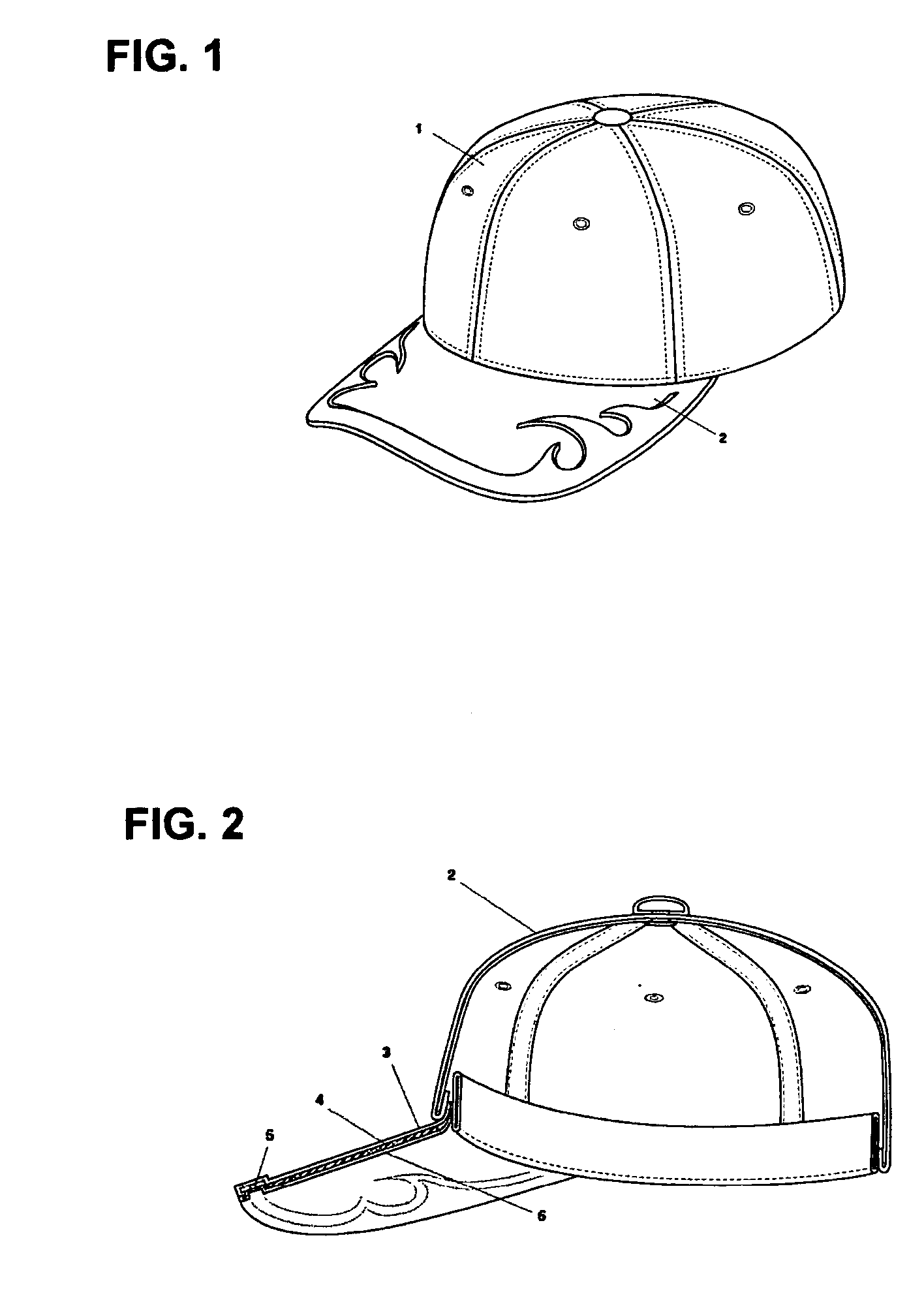

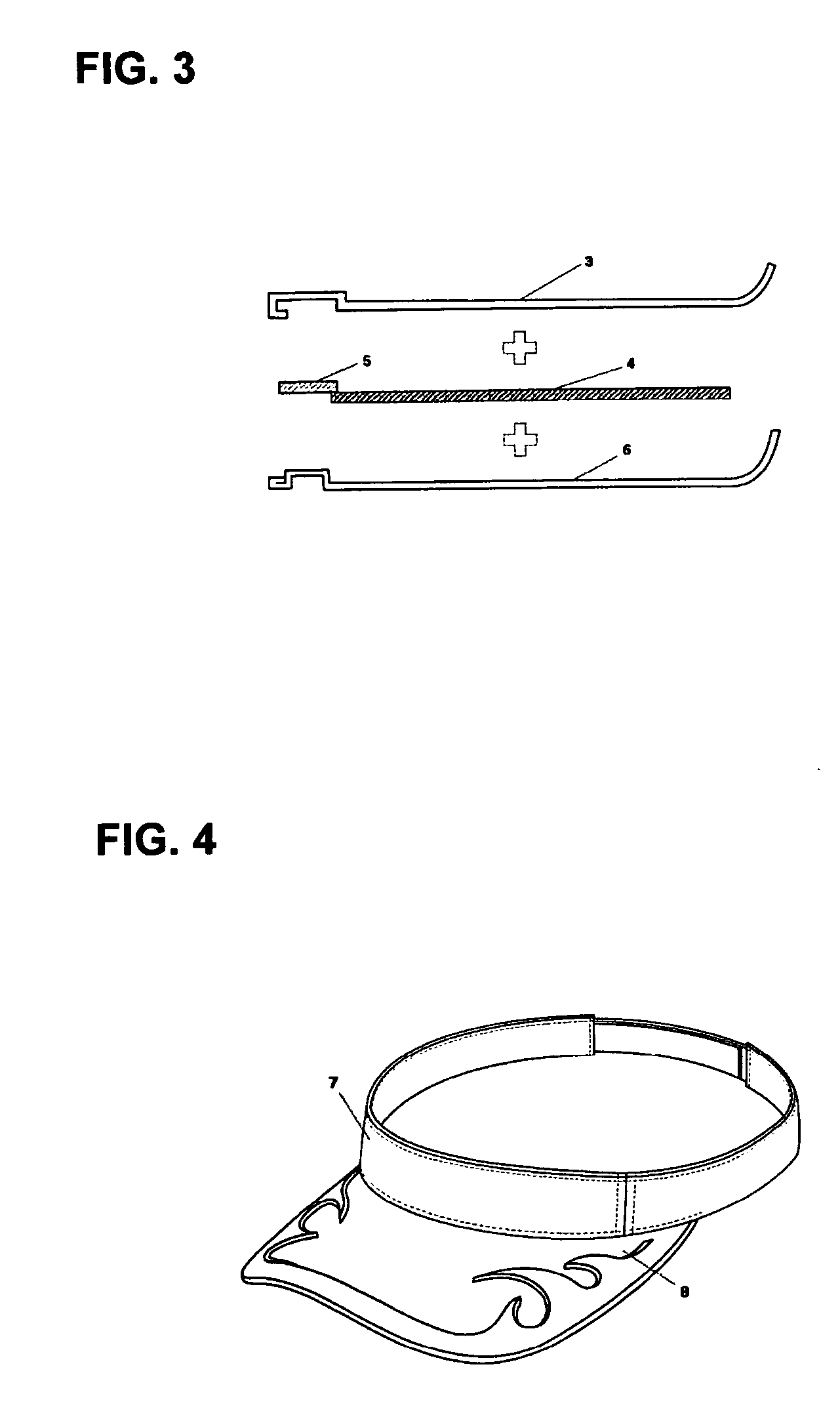

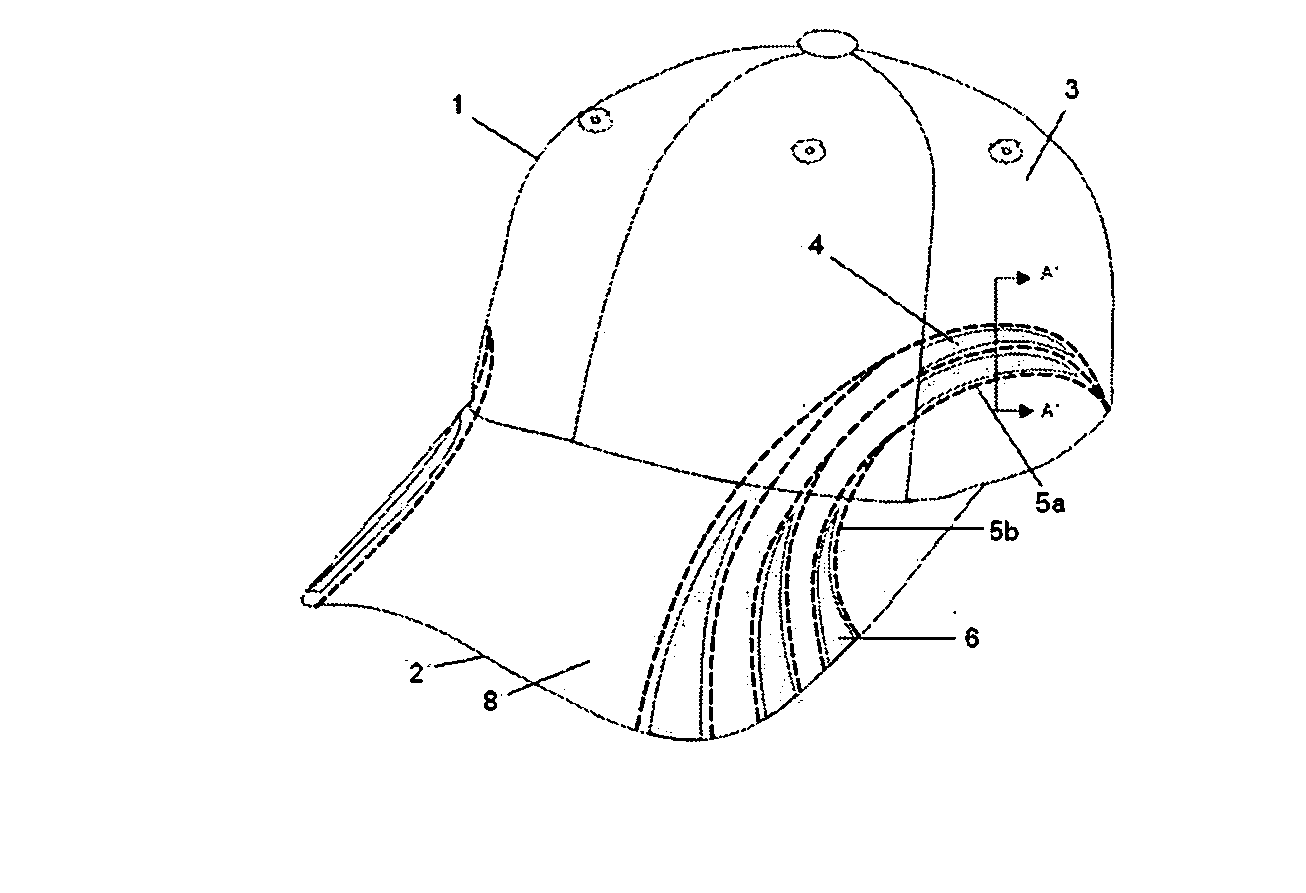

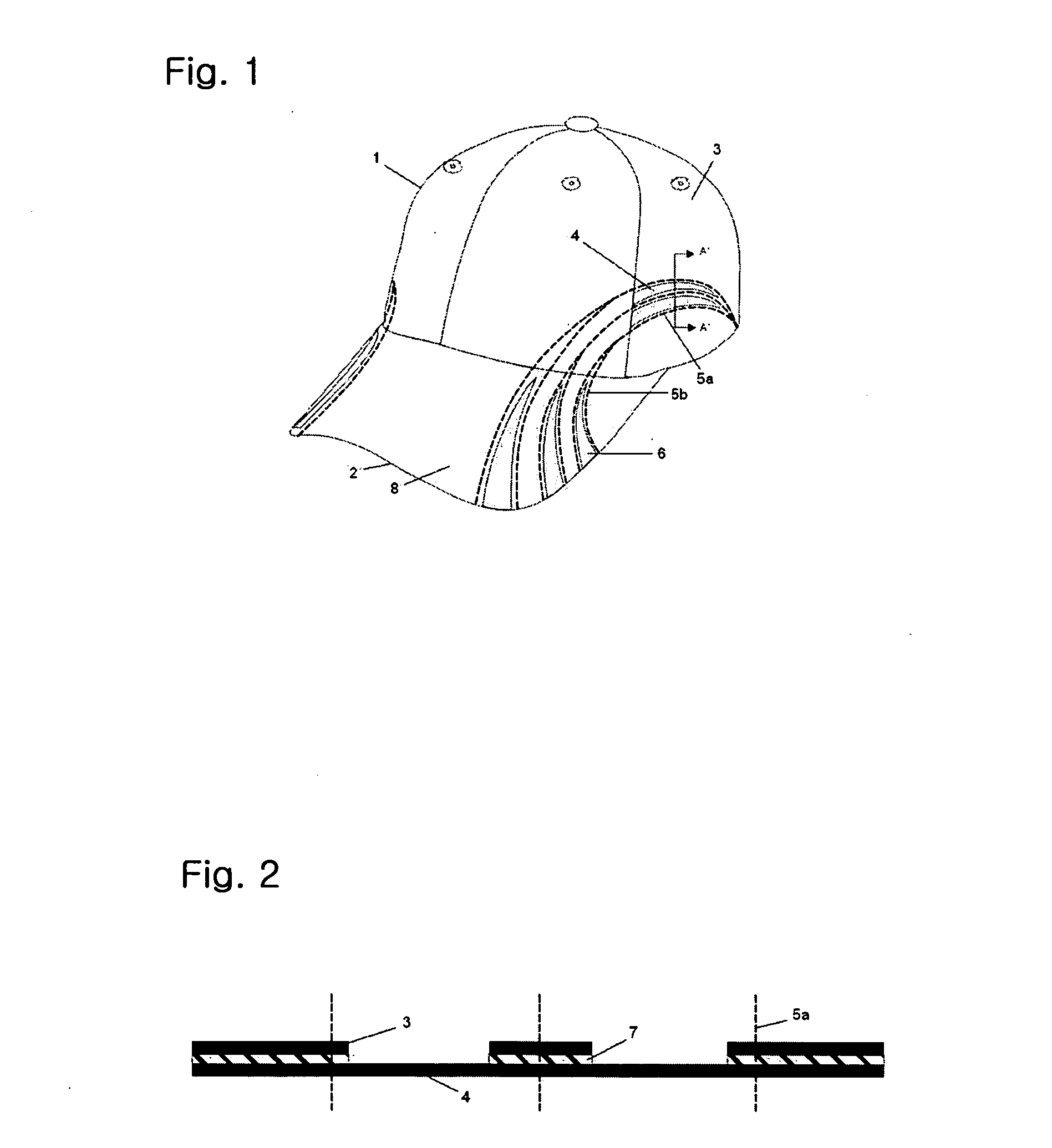

Headwear capable of making all kinds of shapes

InactiveUS20070118969A1Enhance aesthetic senseImprove aesthetic satisfactionHatsHeadwear capsSurface plateEngineering

The present invention relates to a headwear being capable of creating the various shapes, more particular, to a headwear which can create various shapes having a three-dimensional effect without employing additional materials for a visor to provide the user with an aesthetic feeling and enhance remarkably a value of commoditiy of the article. The baseball type headwear according to the present invention comprises a crown section consisting of a plurality of panels and a visor attached to a lower portion of front side of the crown section, won, and the visor cap according to the present invention consists of a frame section surrounding a circumference of the user's head and a visor attached to a front side of the frame, the visor is made of a lower fabric, a visor pad and an upper fabric, a portion of the visor pad is cleaved to form the various shaped visor pad pieces and the cleaved visor pad pieces are overlapped with each other.

Owner:DADA CO LTD

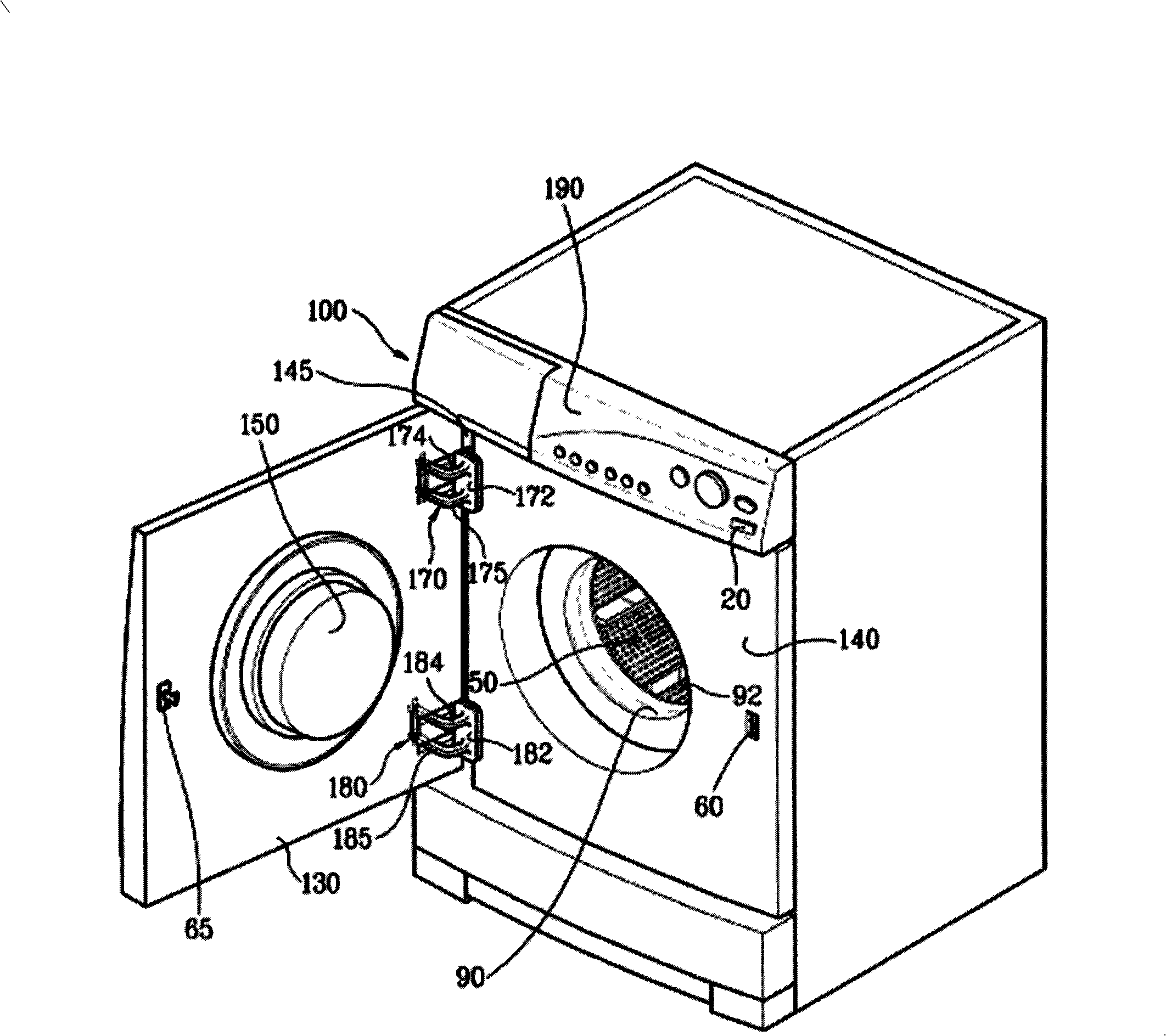

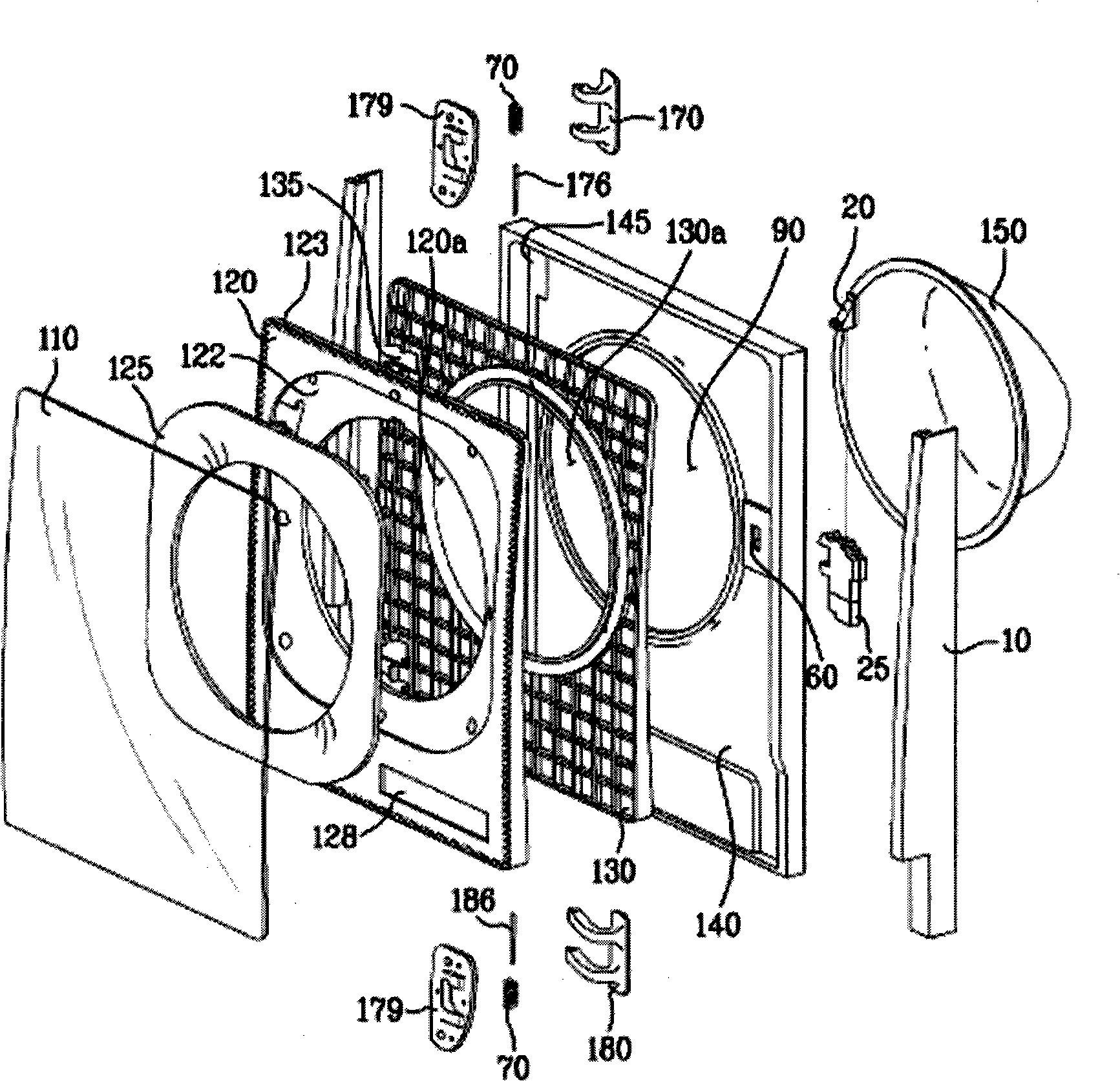

Door of drum washing machine

InactiveCN101333755APrevent saggingAvoid collisionOther washing machinesTextiles and paperEngineeringMechanical engineering

The invention discloses a door of drum-type washing machine combined with one side of a housing with an opening at the front thereof through hinges and rotated left and right to open or close the opening. The door comprises following parts: a first extending part extending and protruding forwards on the upper part of the housing, a first hinge member connected the upper part of the housing with the upper part of the door and rotated the door, a second extending part extending and protruding forwards on the lower part of the housing, and a second hinge member connected the lower part of the housing with the lower part of the door and rotated the door, and extending with the first extending part side by side and the extending length of which is longer than that of the first extending part. The door can be inclined to rotate by the invention and the appearance is beautiful.

Owner:NANJING LG PANDA APPLIANCES

Light-emitting device of portable communication terminal

ActiveUS20100128494A1Clean exterior designImprove aesthetic satisfactionMechanical apparatusMeasurement apparatus componentsLight guideEngineering

A light-emitting device of a portable communication terminal improves exterior decoration by emitting light to the exterior of the portable communication terminal and implements a sense of unity of a design in a non-light emission state by integrating a portion to which the light is transmitted with a main body housing. The light-emitting device includes a housing, a light-emitting element for emitting light, a light guide sheet for guiding the light from the light-emitting element, and a light-transmitting portion integrally formed on the housing for transmitting the light from one end of the light guide sheet to an outer side of the housing. A sense of unity of the main body housing and the light-transmitting portion can be improved by applying a non-conductive vacuum metallizing (NCVM) process to the exterior. An aesthetic sense is improved with the sense of unity of the exterior design.

Owner:SAMSUNG ELECTRONICS CO LTD

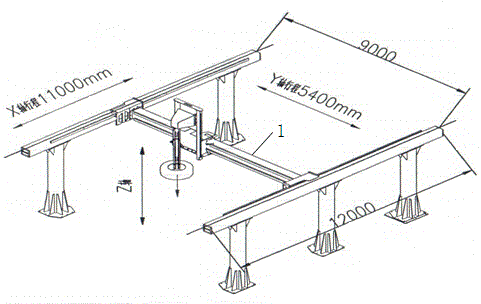

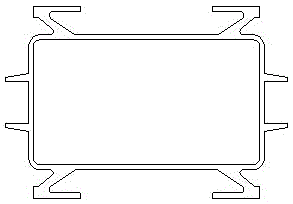

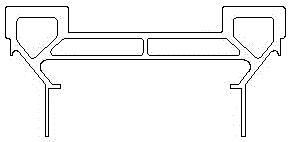

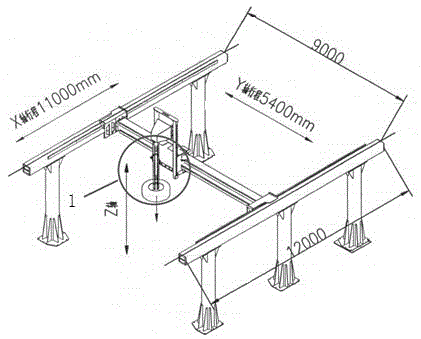

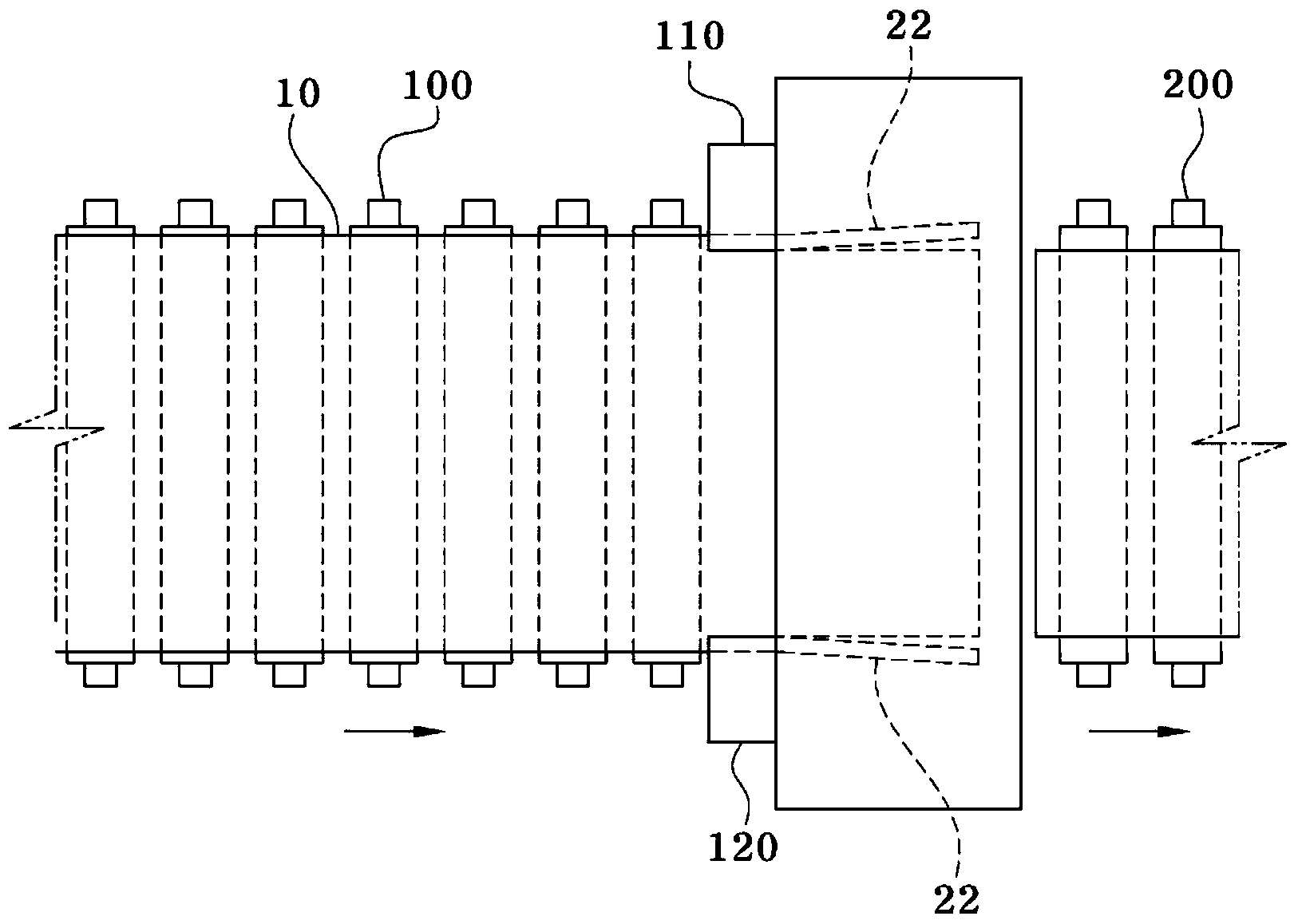

Manufacturing method of aluminum alloy mechanical arm track girder hollow profile

ActiveCN105039805AReduced risk of weakeningMeet the use requirementsUltimate tensile strengthAluminium alloy

The invention belongs to the technical field of aluminum alloy profiles and particularly relates to a manufacturing method for producing an aluminum alloy mechanical arm track girder hollow profile through an aluminum alloy replacing rolled steel. The manufacturing method comprises the steps that firstly, the intensity and the capacity of resistance to deformation of a steel cross beam are evaluated; secondly, the aluminum alloy is selected; thirdly, the structure of the aluminum alloy mechanical arm track girder hollow profile is designed; fourthly, the movement track and deformation of the aluminum alloy mechanical arm track girder hollow profile in a stressed state are simulated through a computer; fifthly, a mould of the aluminum alloy mechanical arm track girder hollow profile is manufactured; sixthly, the aluminum alloy mechanical arm track girder hollow profile is extruded and quenched online; seventhly, the aluminum alloy mechanical arm track girder hollow profile is aged; eighthly, the aluminum alloy mechanical arm track girder hollow profile is sampled; ninthly, the aluminum alloy mechanical arm track girder hollow profile is riveted; and tenthly, the aluminum alloy mechanical arm track girder hollow profile is packaged and delivered, and the aluminum replaces the steel to produce the aluminum alloy mechanical arm track girder hollow profile.

Owner:SHANDONG YUHANG SPECIAL ALLOY EQUIP

Headwear with panels coupled by adhesion and sewing

InactiveUS20090260131A1Avoid wrinklesImprove aesthetic satisfactionHatsHeadwear capsSurface plateEngineering

The present invention relates to a headwear in which some panels of a visor part are adhered and sewed to each other and thus a wrinkle resulted from conventional simple sewing is prevented and an aesthetic sense is more increased.The headwear according to the present invention includes a crown part which is a main body of the headwear and made of a plurality of panels; and a visor part attached to lower front part of the crown part, wherein at least one panel of the panels of the crown part is fabricated so that two panels are overlappedly coupled and an adhesive sheet is inserted between the two overlapped panels to adhere the two panels, and an outer panel of the two panels is cut out in a shape according to user's intention and an inner panel is seen through the cut-out portion, and a sewing line is formed along a periphery of the cut-out portion of the outer panel.

Owner:DADA CO LTD

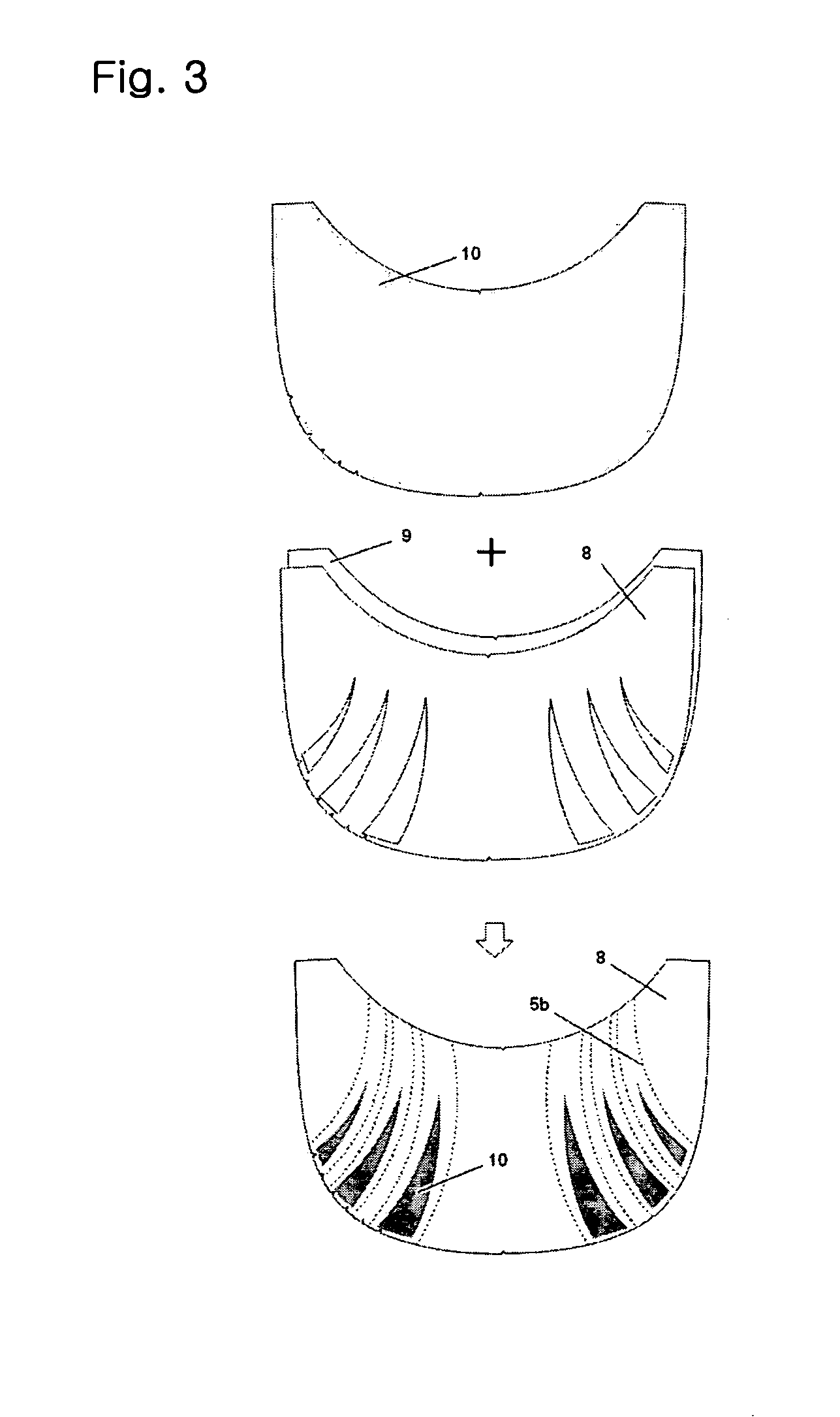

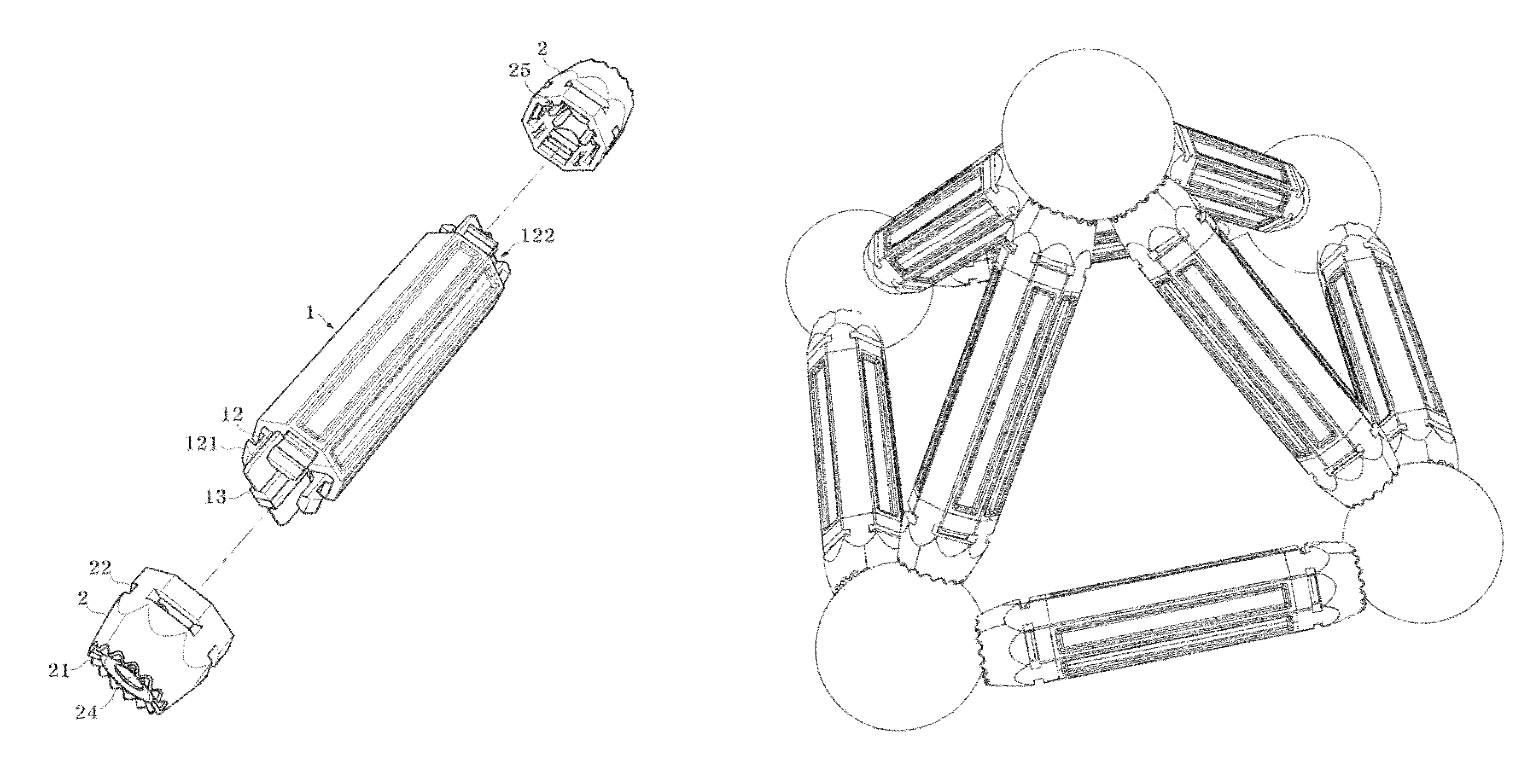

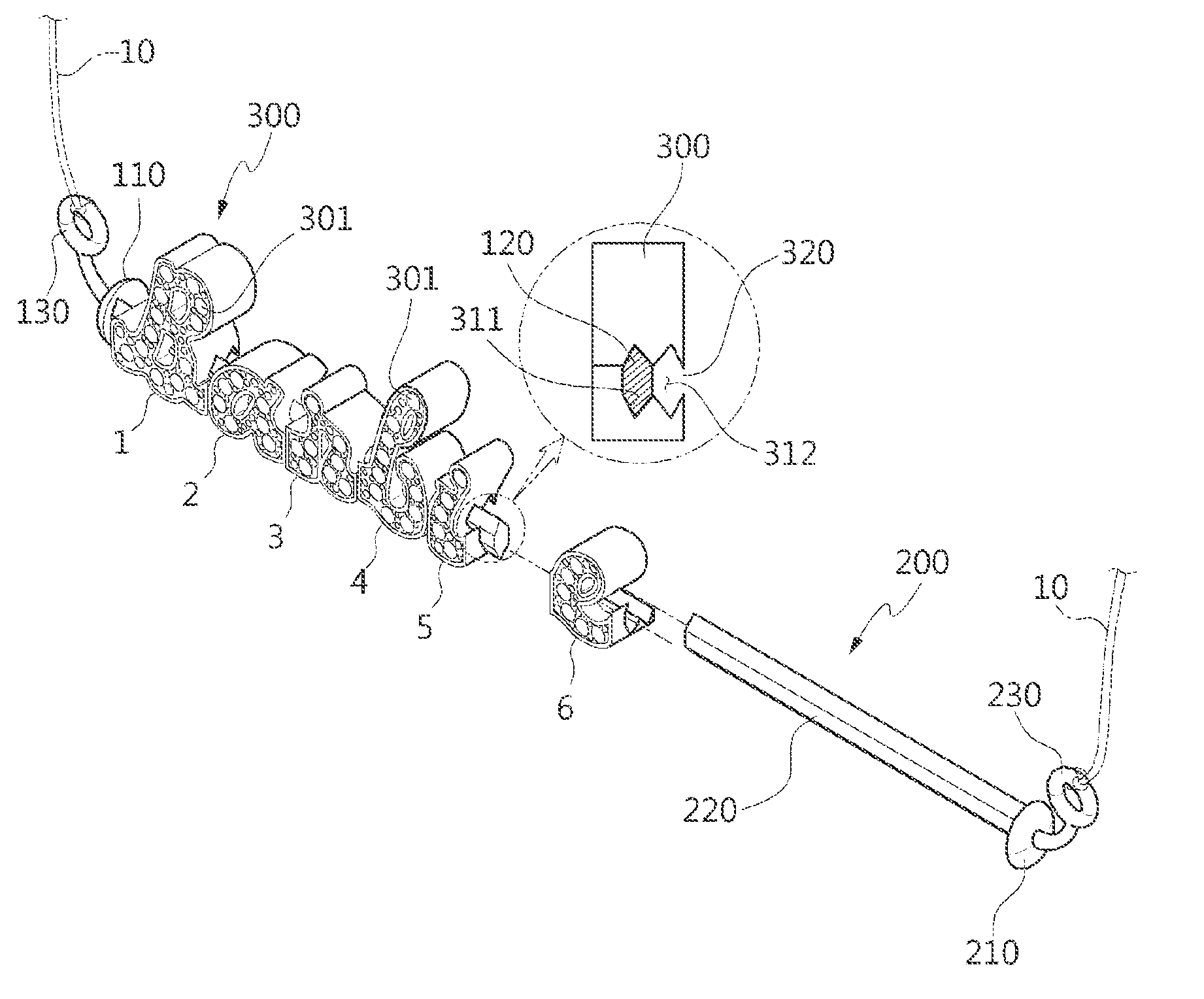

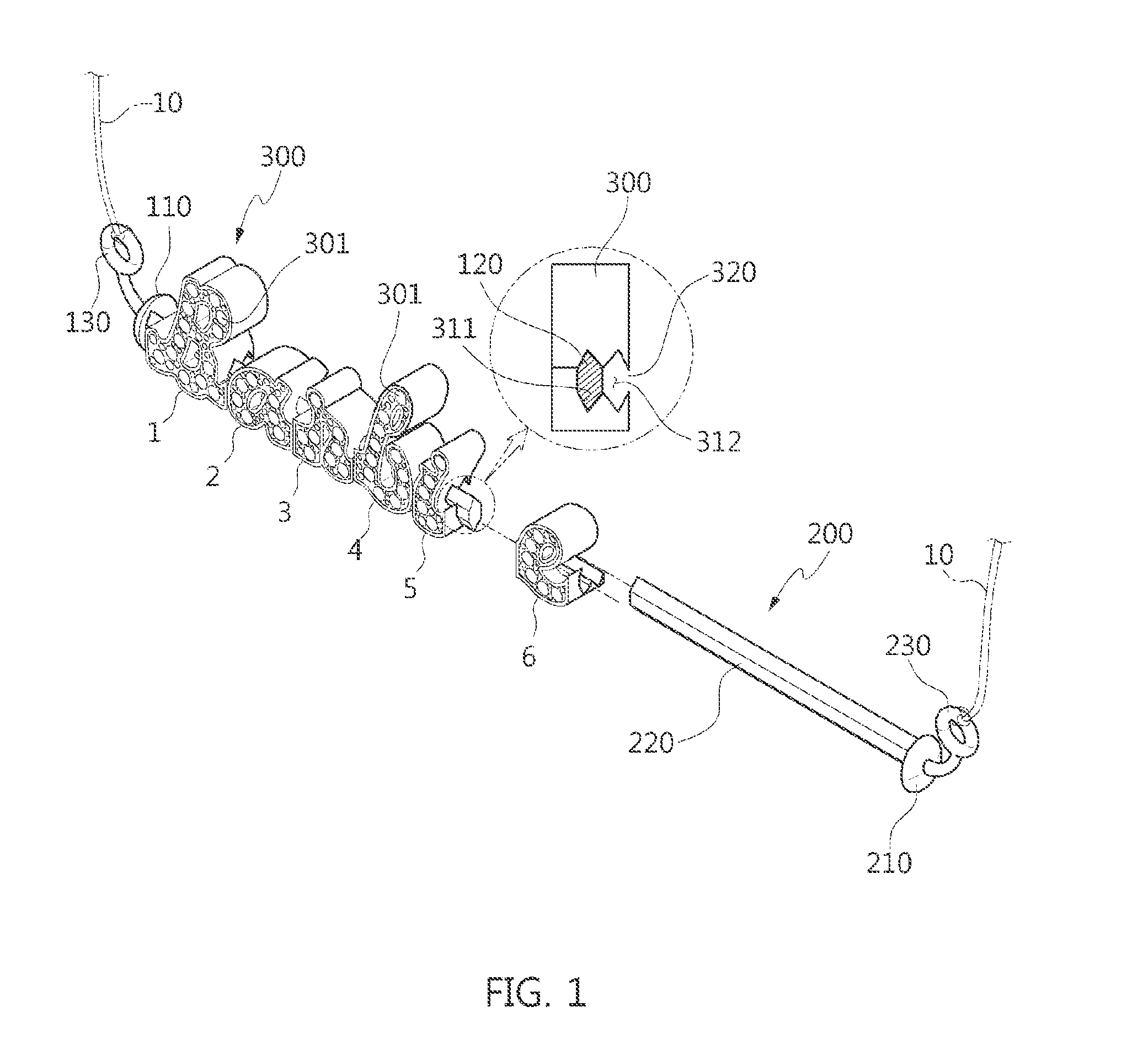

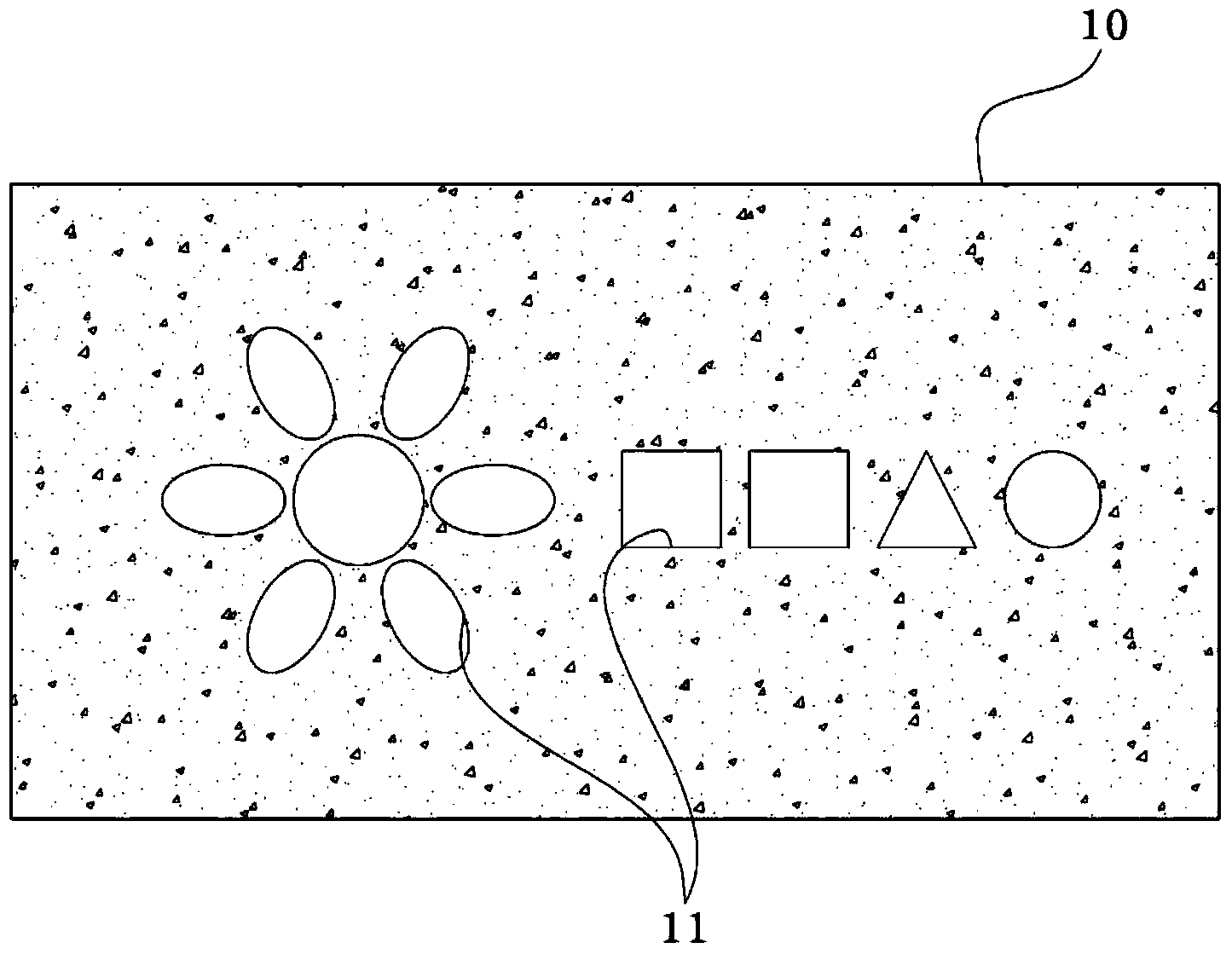

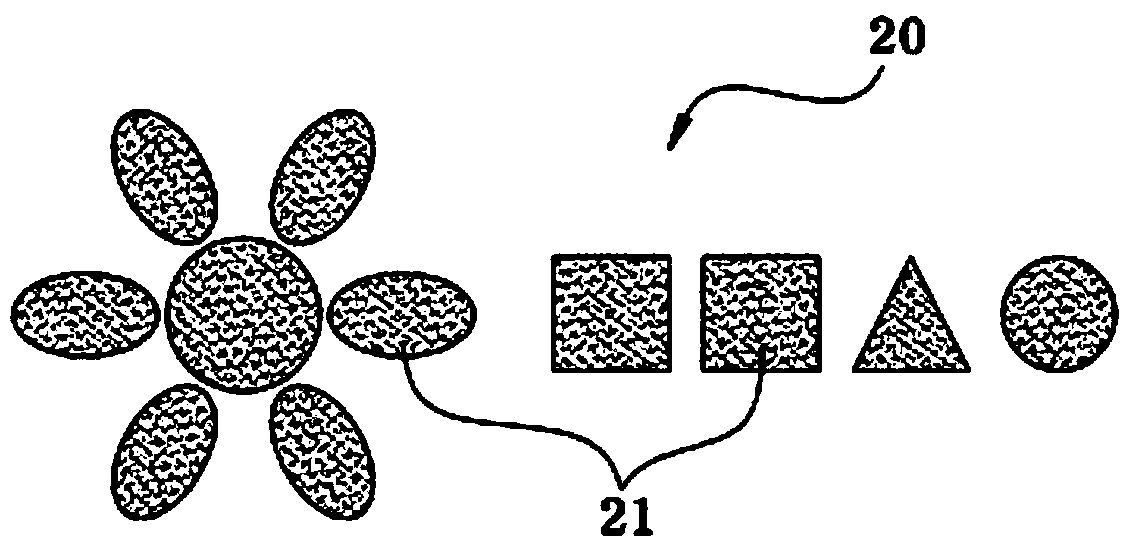

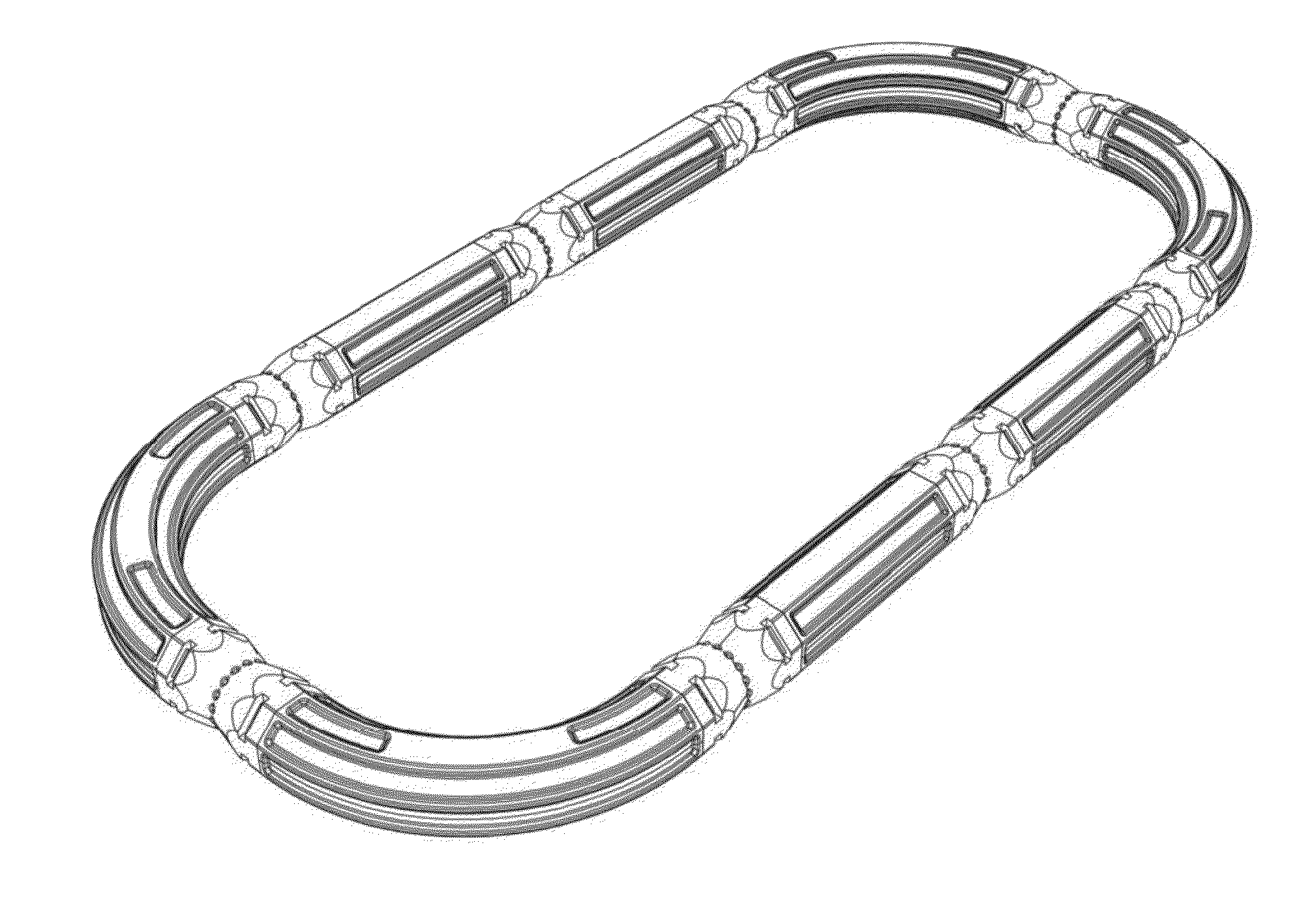

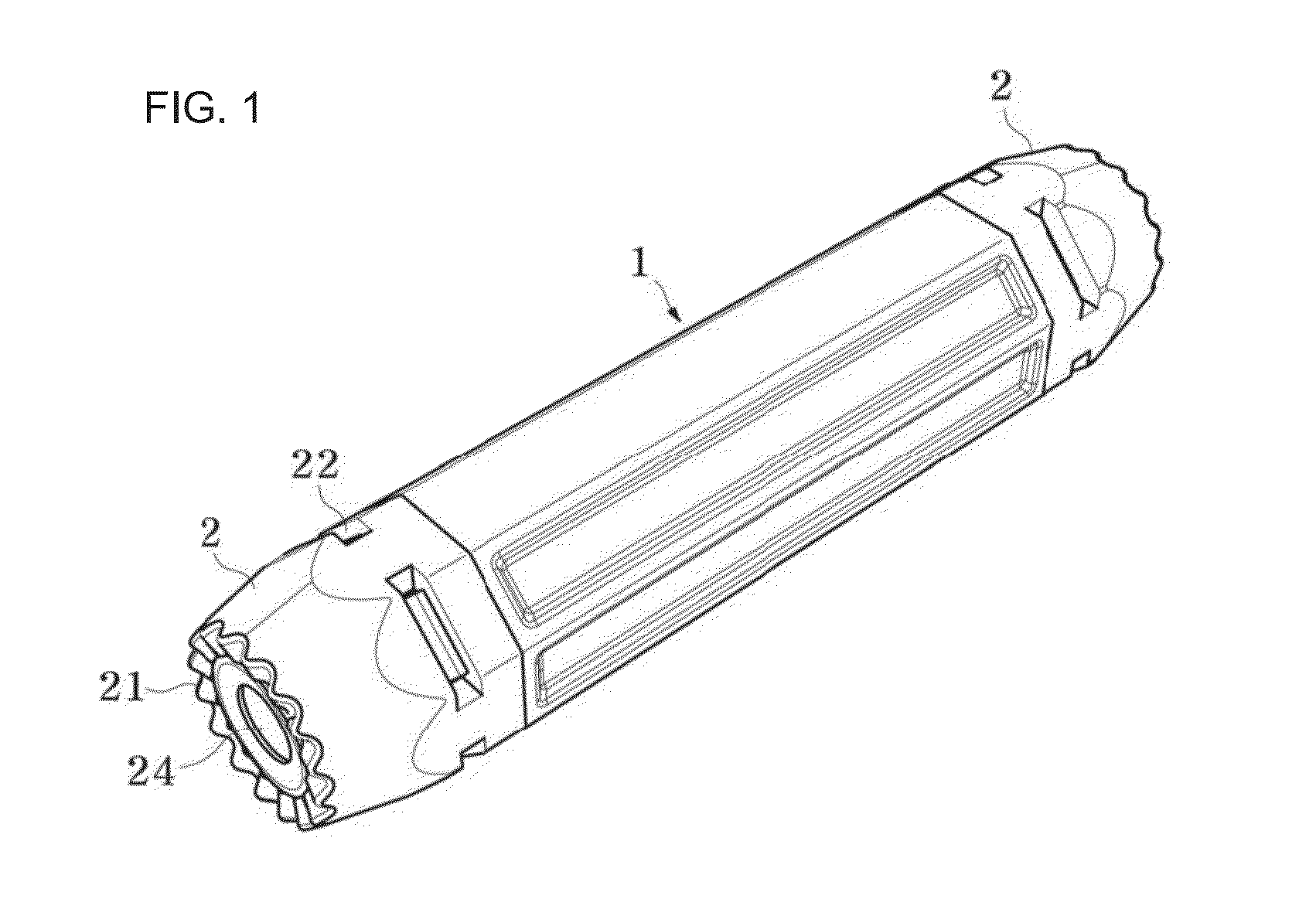

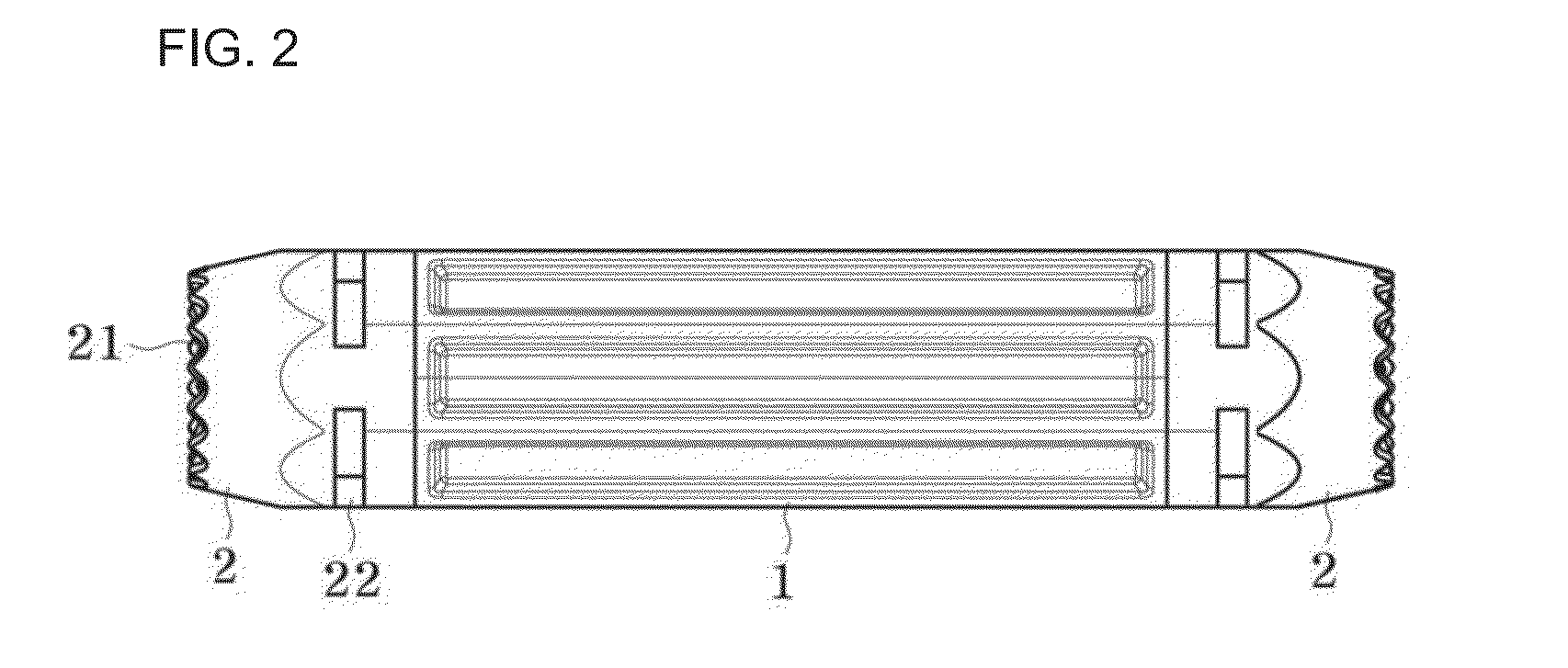

Magnetic block toy

The present invention relates to a magnetic block toy, and more particularly, to a magnetic block toy which makes assembly of blocks firm because caps having serrated coupling parts are combined to both sides of a block body, and which has block bodies and caps of various colors, thereby arousing children's interest and promoting development of intelligence.The magnetic block toy according to the present invention includes: a block body having a pair of brackets each of which has a protrusion and a groove formed on the inner face to correspond to each other and are coupled with each other; caps which are respectively combined to both sides of the block body and each of which has a serrated coupling part formed on the outer surface; and a magnet which is disposed inside the cap to generate a magnetic force.

Owner:CLICK BLOCK

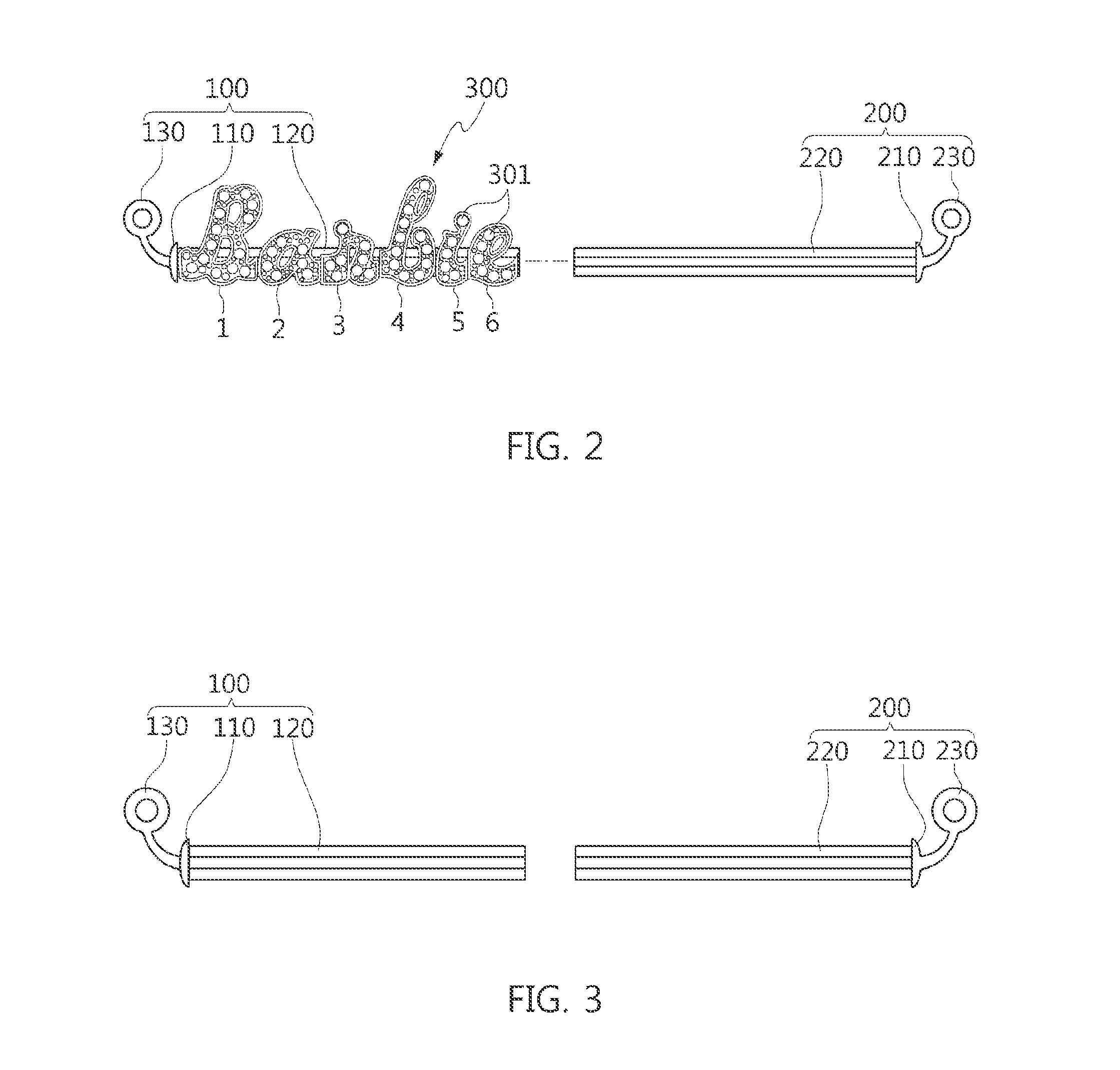

Assembly type accessory

InactiveUS20130239610A1Improve aesthetic satisfactionImproving the esthetic beautyBraceletsWrist-watch strapsMechanical engineeringEngineering

Disclosed herein is an assembly type accessory. The assembly type accessory includes: a plurality of initial blocks each having an insertion hole formed from side to side thereof; and a rail part which is inserted into the insertion hole of each initial block and connects the plurality of initial blocks. The present invention as described above is advantageous because a rail is inserted into the insertion hole formed in the initial blocks so as to adjust the length of a finished product so that there is no concern at all that a space will be generated between the initial blocks.

Owner:LIM DONG YOUN

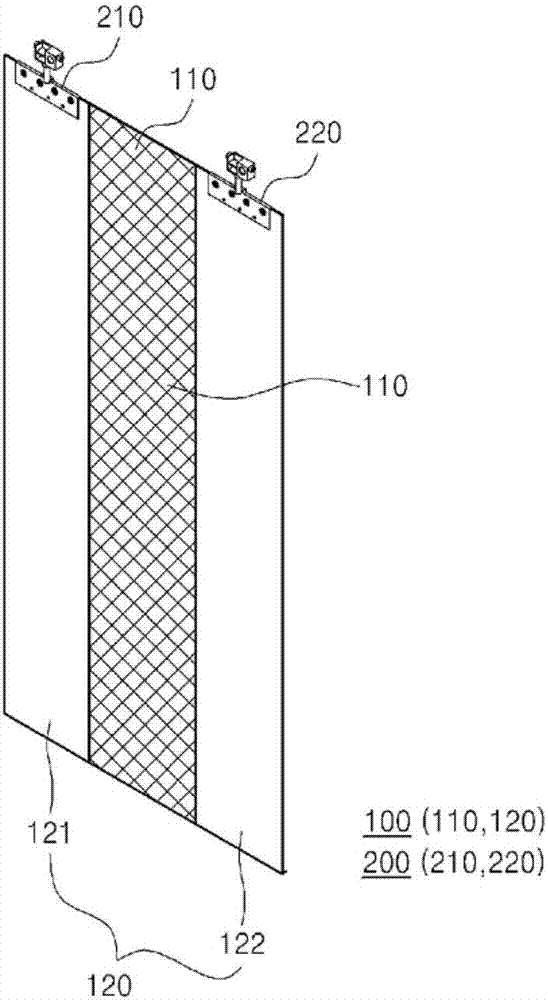

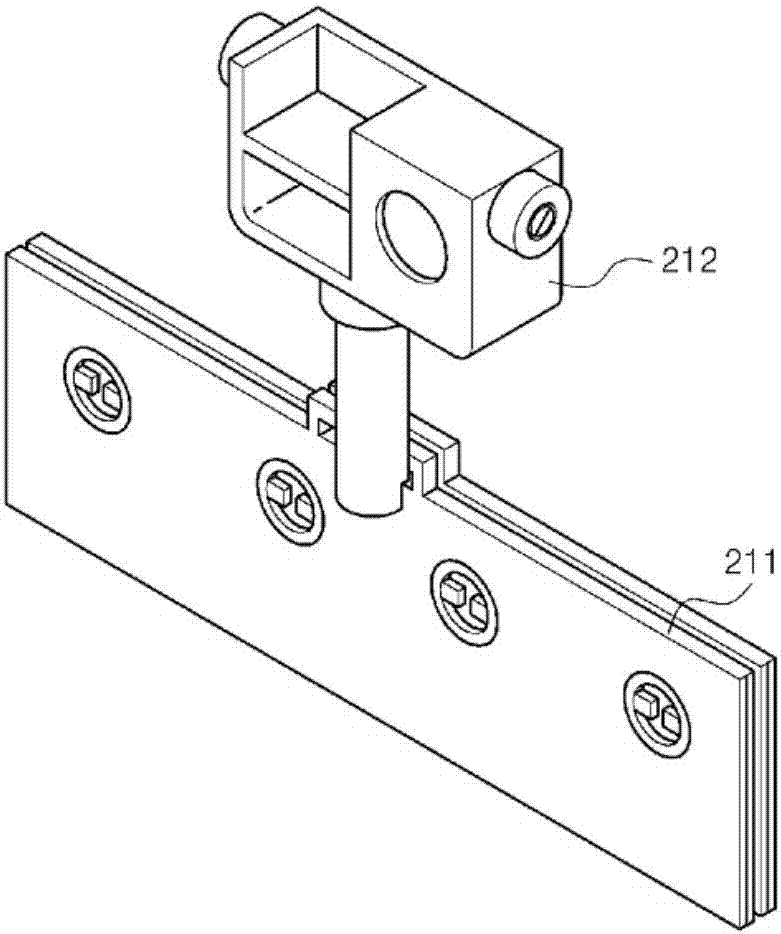

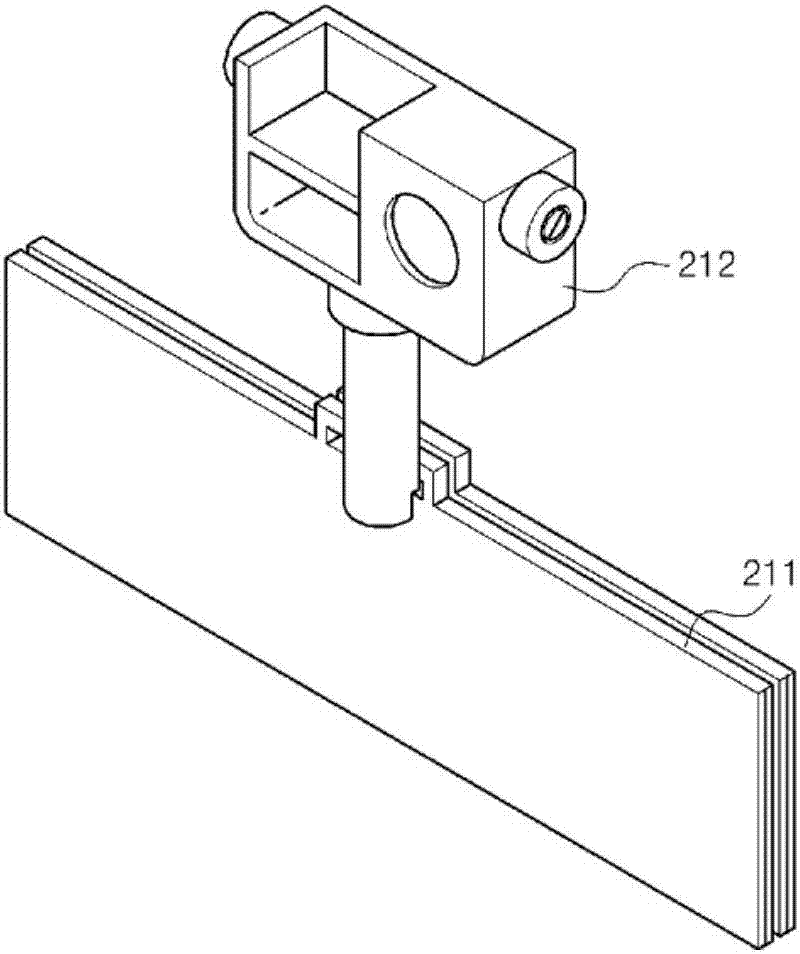

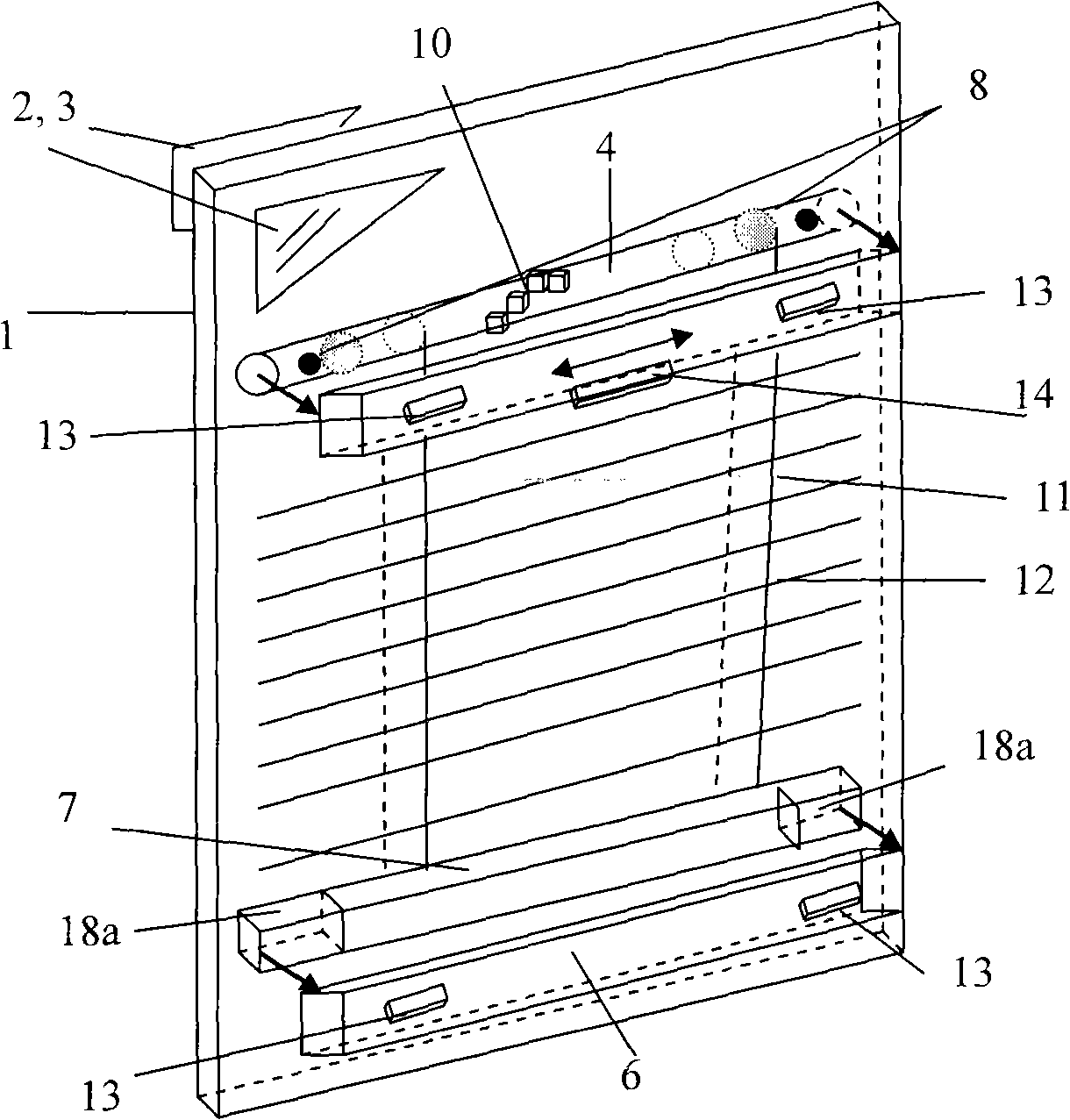

Connector for blind-type curtain and blind-type curtain comprising same

PendingCN107105911AImprove aesthetic satisfactionEasy to washLight protection screensCurtain rodsTransmittanceEngineering

The present invention relates to a blind-type curtain and particularly, to a blind-type curtain capable of allowing curtain blinds to be individually separated and washed or replaced and allowing a light-transmitting state and a blackout state to be easily controlled since a plurality of curtain blinds are connected to each other by a connector, and allowing the curtain blinds to easily form a "U" shape since an extension plate is formed. The present invention can increase aesthetics by fastening adjacent blackout curtain parts through the connector. In addition, the present invention enables light transmittance in the curtain state, and can use a blackout curtain effect by using rotation (the angle control of verticals) when adjacent blackout curtain parts are fastened through a connector. Additionally, the present invention facilitates individual washing and repair due to contamination or damage since a plurality of curtain blinds can be individually separated. Furthermore, the present invention can promote an aesthetic appeal since the curtain blind comprises a weight at the lower end thereof, thereby allowing the curtain blind to be tightly pulled. Moreover, the present invention can promote an aesthetic appeal by allowing the color and the pattern of curtain blinds to be different since a plurality of curtain blinds can be individually separated. The present invention can provide a blind-type curtain having a perfect "U" shape since the extension plate for supporting a light-transmitting curtain part is formed at the connector.

Owner:金成哲

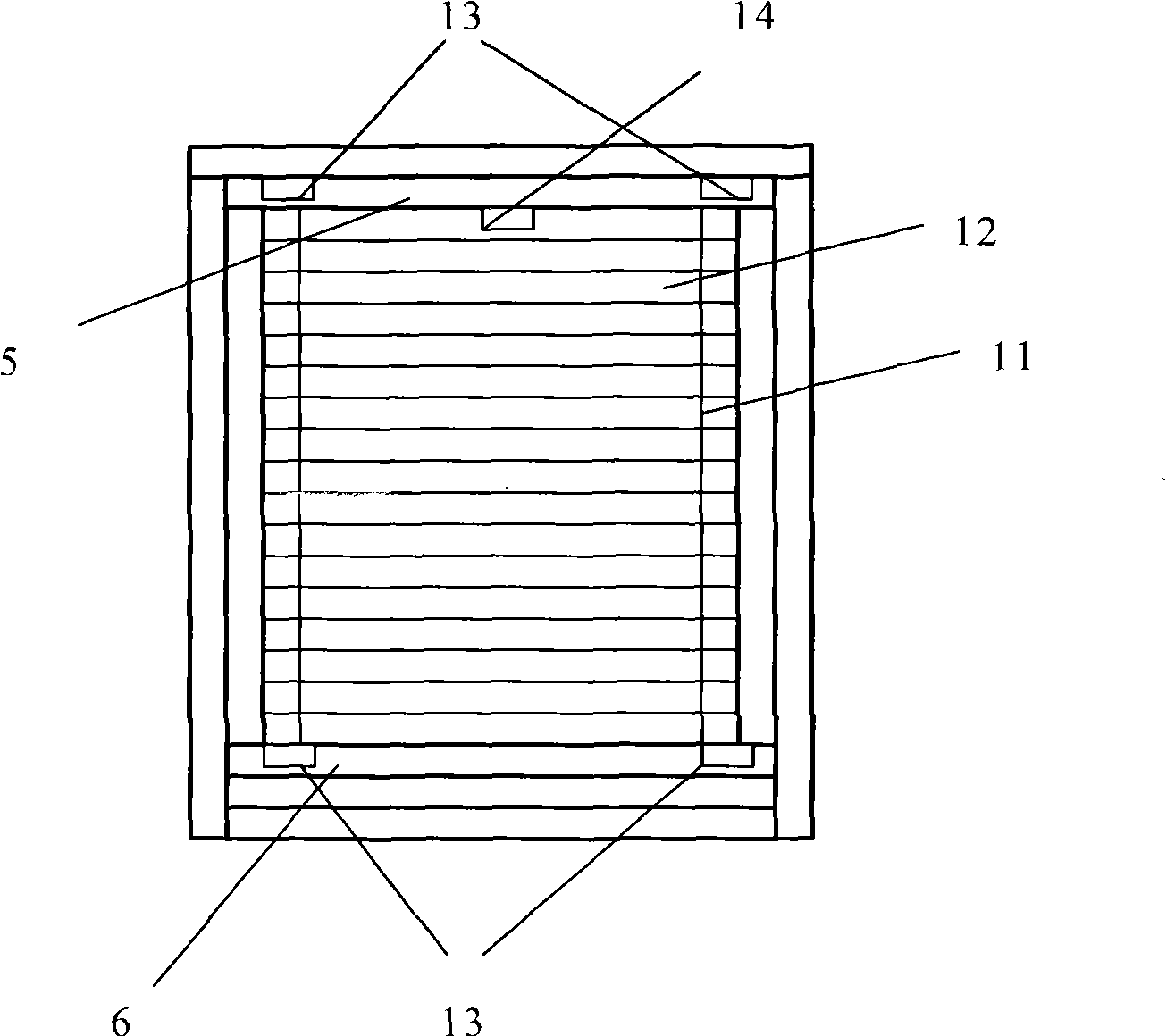

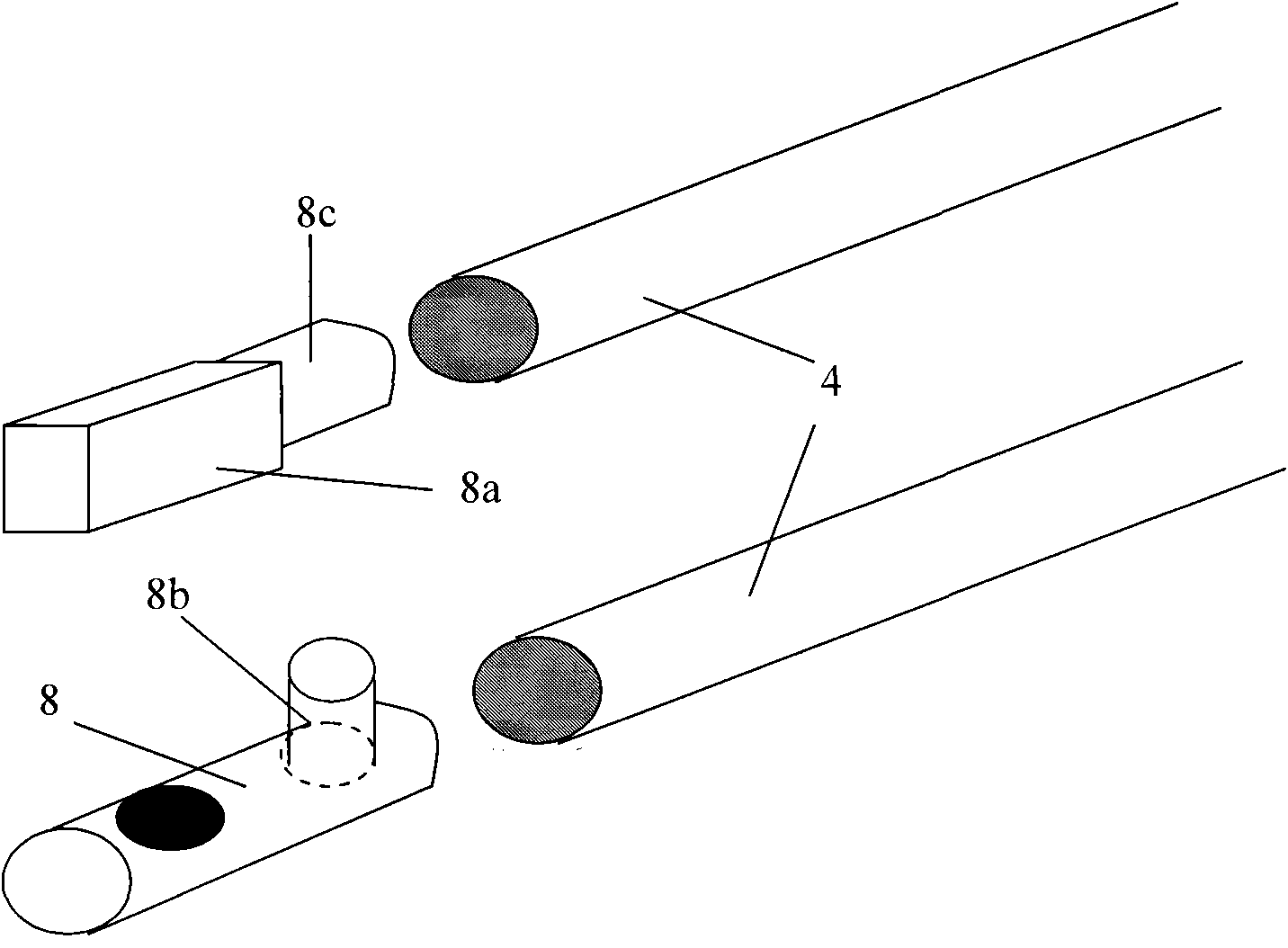

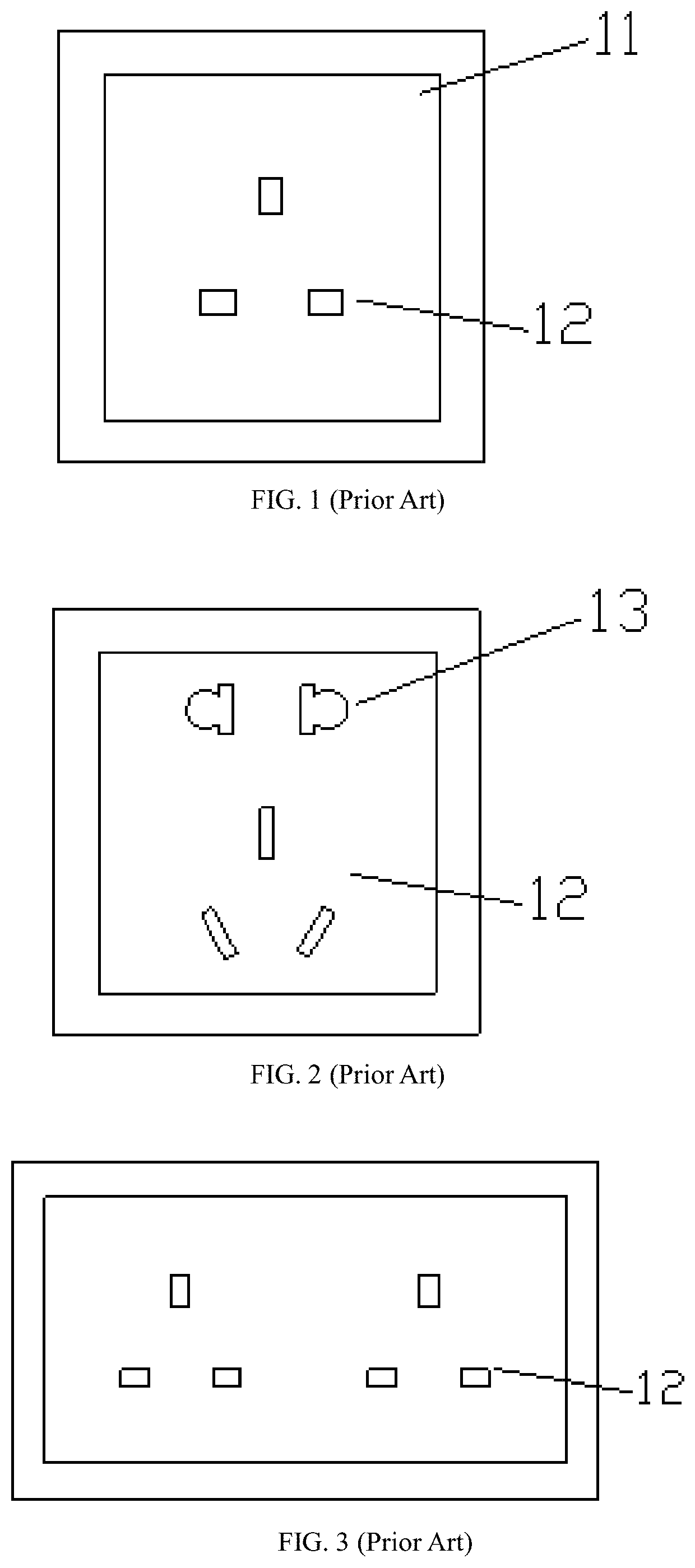

Venetian blinds with magnetic controller for regulation

InactiveCN101550802ANo cleaning requiredEasy to installLight protection screensVenetian blindsRotation control

A Venetian blinds with magnetic controller for regulation consists of strings which form ladder (11) which hold the horizontally fitted slats (12) at the appropriate distance. This structure hangs on the freely rotating bearing hollow pipe (4), and at the bottom it is connected to the inner bottom section (7). Each magnet (8b) in the bearings (8) or the inner top / bottom contact magnets (8a; 18 a) are fitted to be in the opposite magnet pole in relation to the poles of the external top / bottom contact magnets (18; 18b) on the external top and bottom regulating batten (5; 6) Magnets which glide horizontally along the external top regulating batten (5) attract magnets fitted at the edges of the freely rotating bearing hollow pipe (4). The rotation controller (23a; 23b) enables rotation of the slats (12) for 180 DEG . By moving the bottom / top external regulating batten (6; 5) together with the related magnets it is possible to move the Venetian blind up or down, including moving of only one side of the top / bottom regulating batten (6;5). Therefore, interaction of the mentioned elements of the invention it is possible to shade any part of the window, including shading diagonally along the window, which will be described in detail later.

Owner:彭哲彦 +1

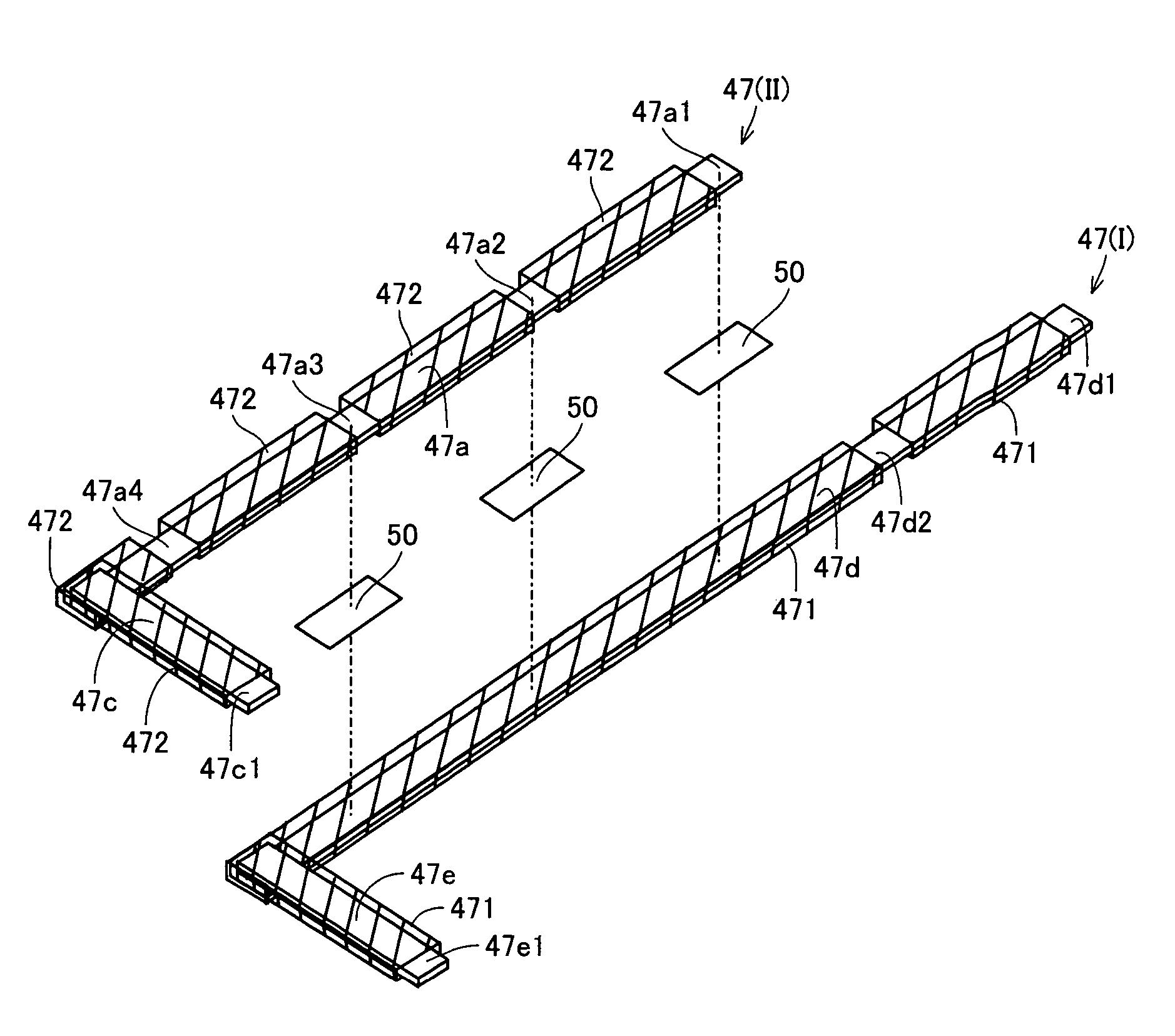

Integrated wiring member for solar cell module, solar cell module using the same, and manufacturing methods thereof

ActiveUS8779279B2Reduced external variationImprove aesthetic satisfactionPV power plantsSpecial surfacesComputer moduleEngineering

Owner:SHARP KK

Manufacturing method for aluminum alloy-made robot arm hollow profile

The invention belong to the technical field of aluminum alloy profile and concretely relates to a manufacturing method for slide rail hollow profile for robot arm movements with aluminum alloy replacing steel. The manufacturing method comprises first, analyzing steel connection member motion and stress conditions, second, selecting aluminum-alloy material, third, designing hollow profile, fourth, simulating aluminum profile connection member motion and stress conditions by a computer to determine whether the hollow profile meets demands, fifth, selecting an extruding machine and designing an aluminum alloy hollow profile connection member via a die, sixth, casting aluminum alloy ingot, seventh, extruding aluminum alloy hollow profile connection member and conducting online quenching, eighth, conducting aluminum alloy hollow profile connection member tension extension and aging treatment, ninth, sampling and checking the aluminum alloy hollow profile connection member, and tenth, hardening and packing the aluminum alloy hollow profile. Motion and stress conditions of the aluminum alloy hollow profile connection member can be simulated by the computer; strength and plasticity meet use requirements; and hollow profile can be manufactured in batches by the use of the method.

Owner:SHANDONG YUHANG SPECIAL ALLOY EQUIP

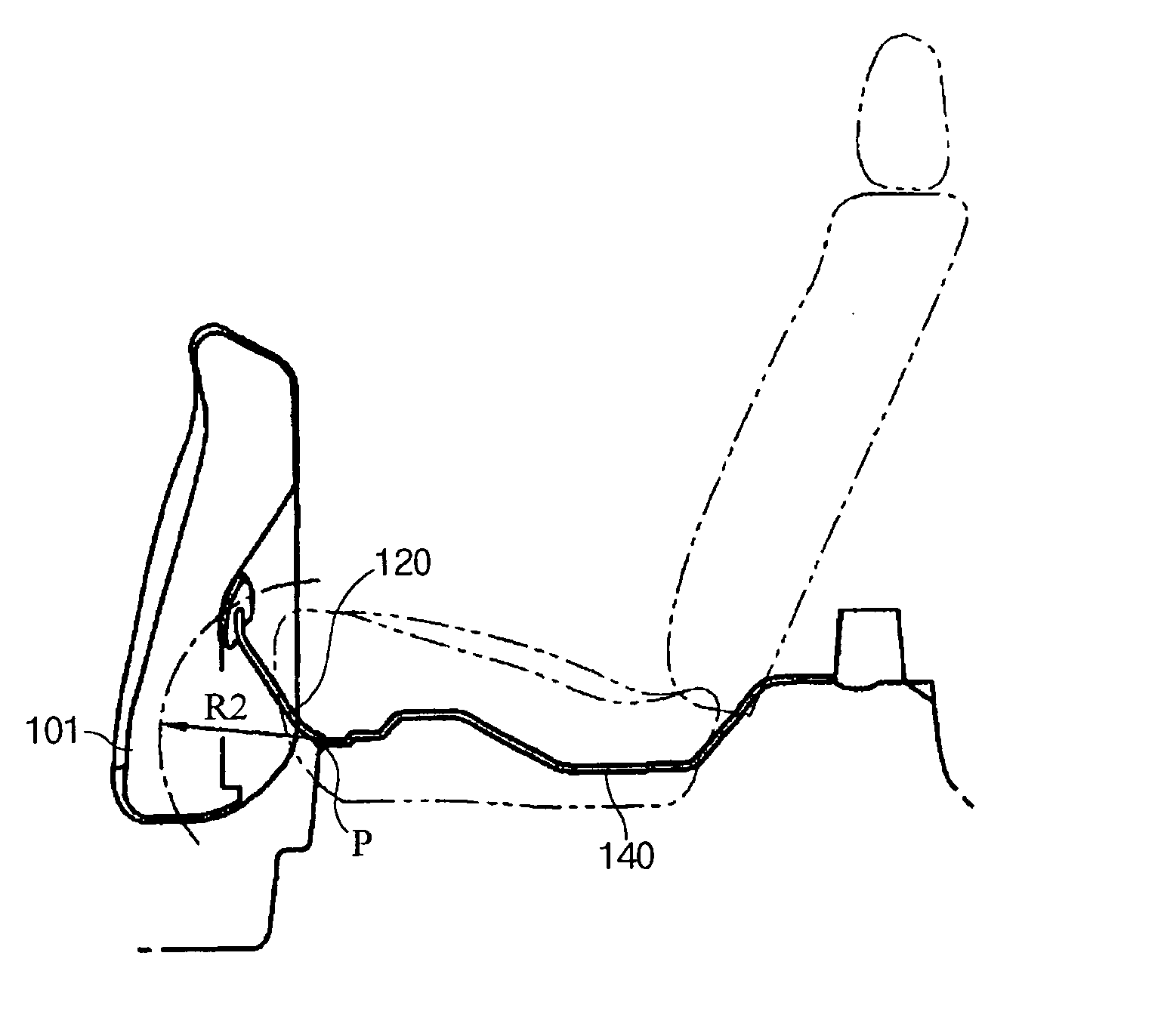

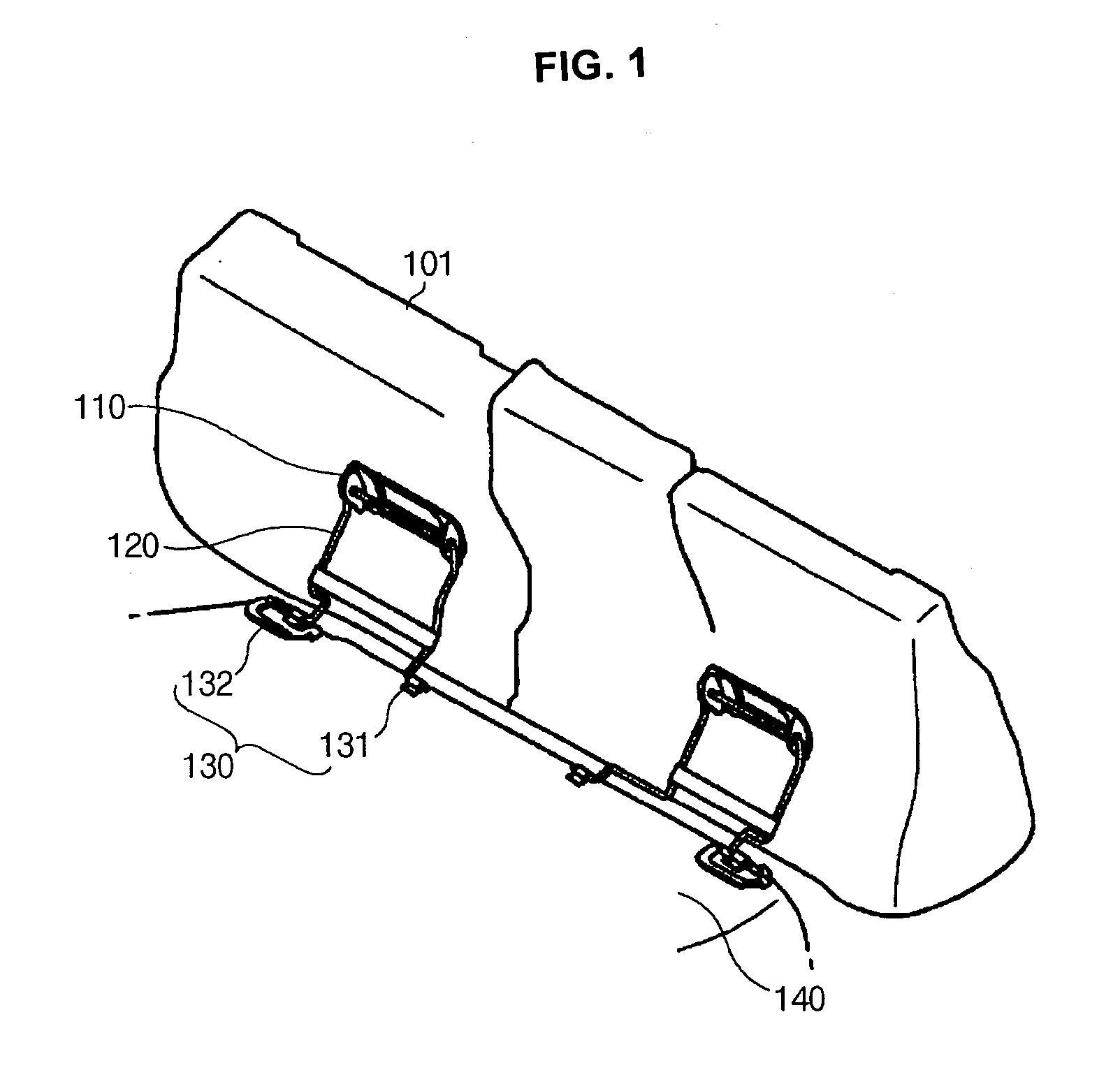

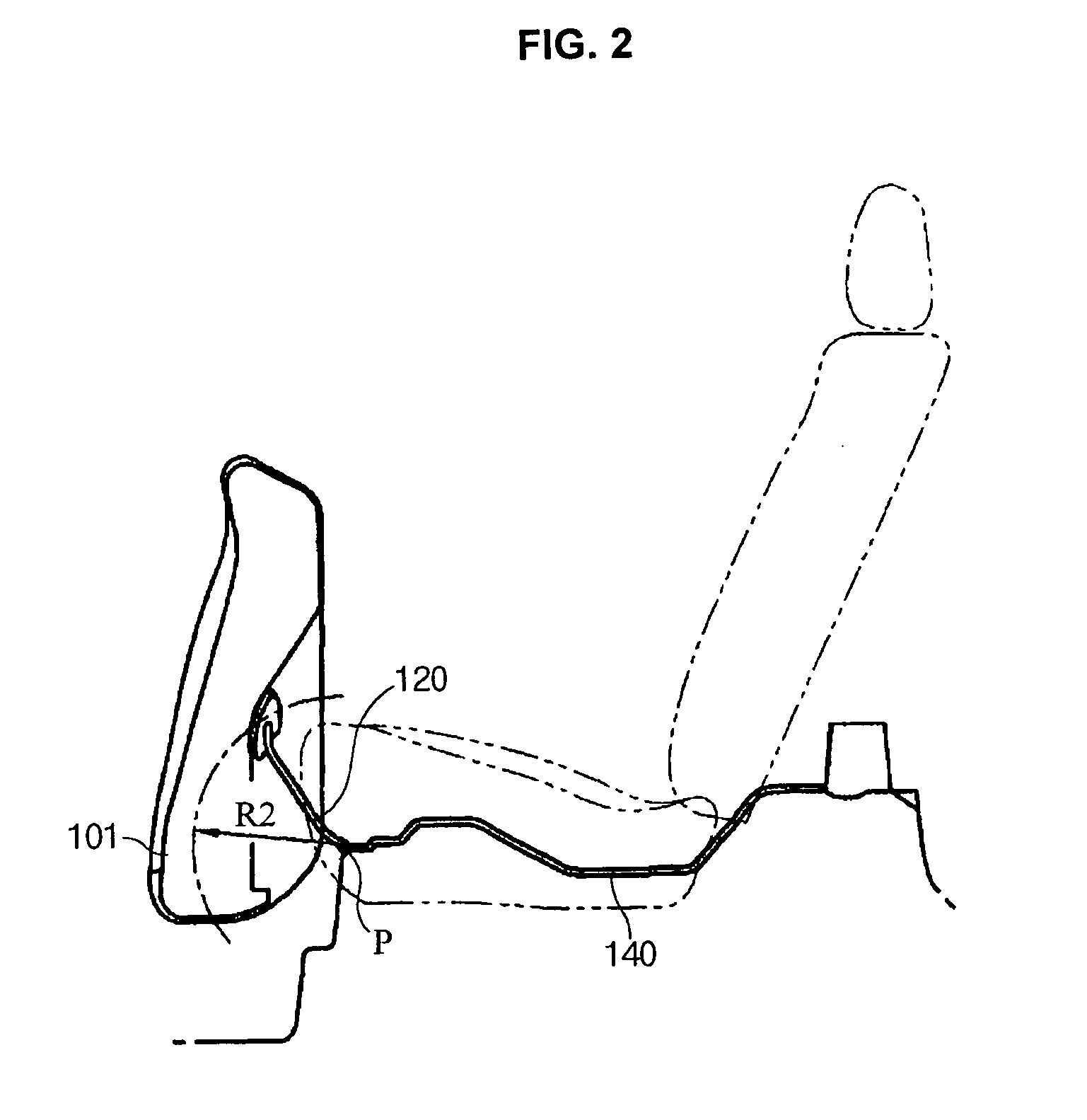

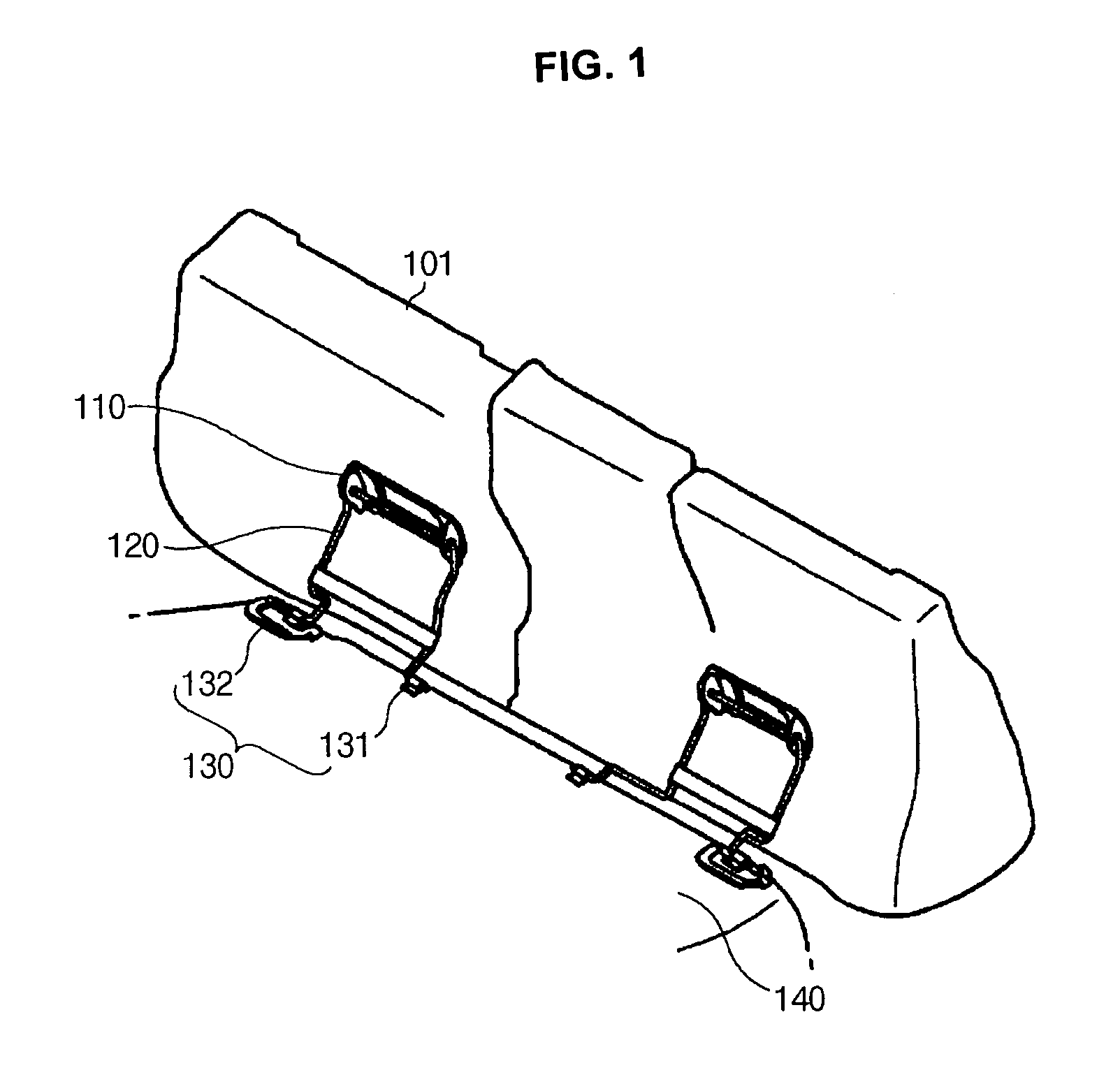

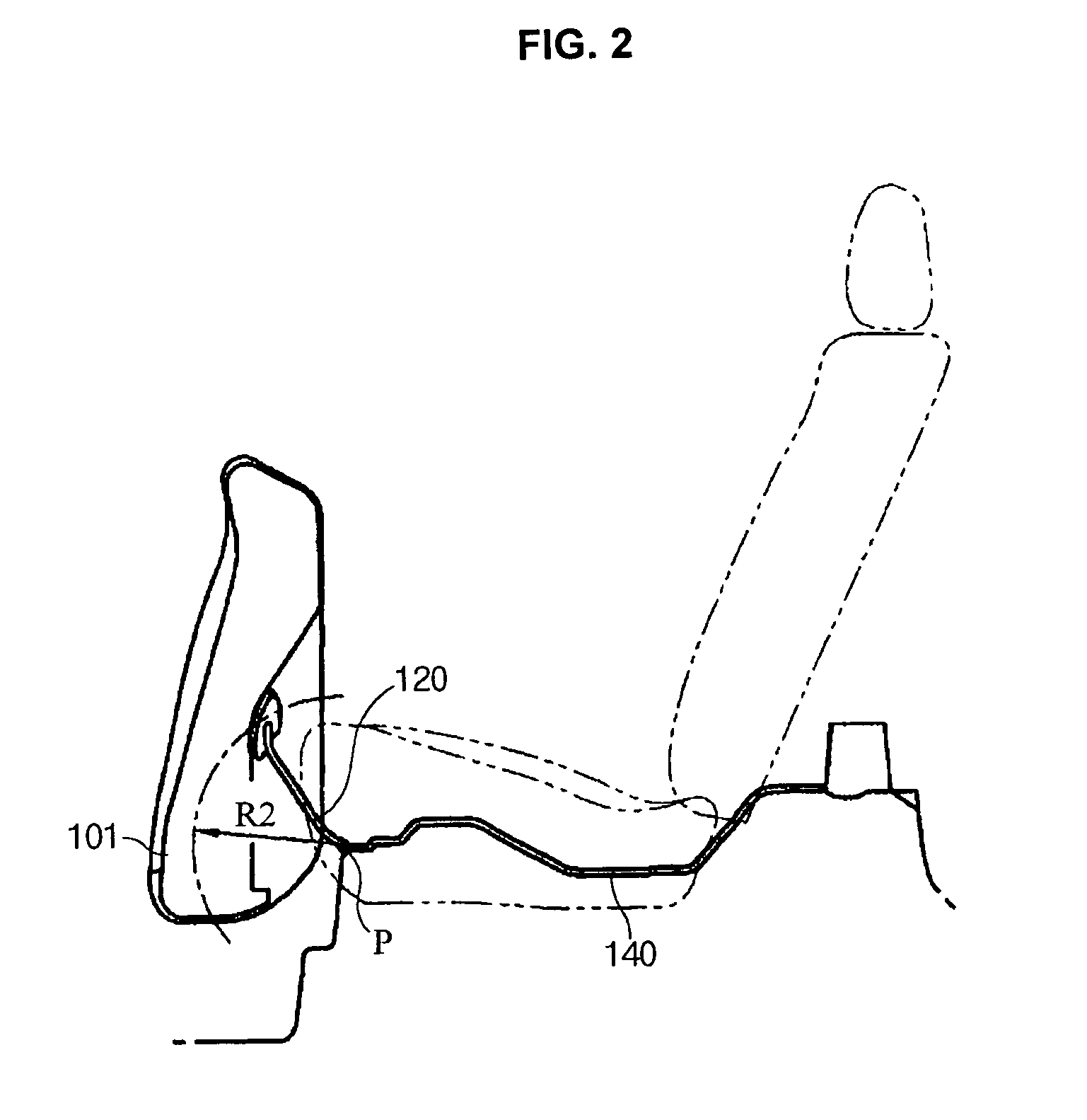

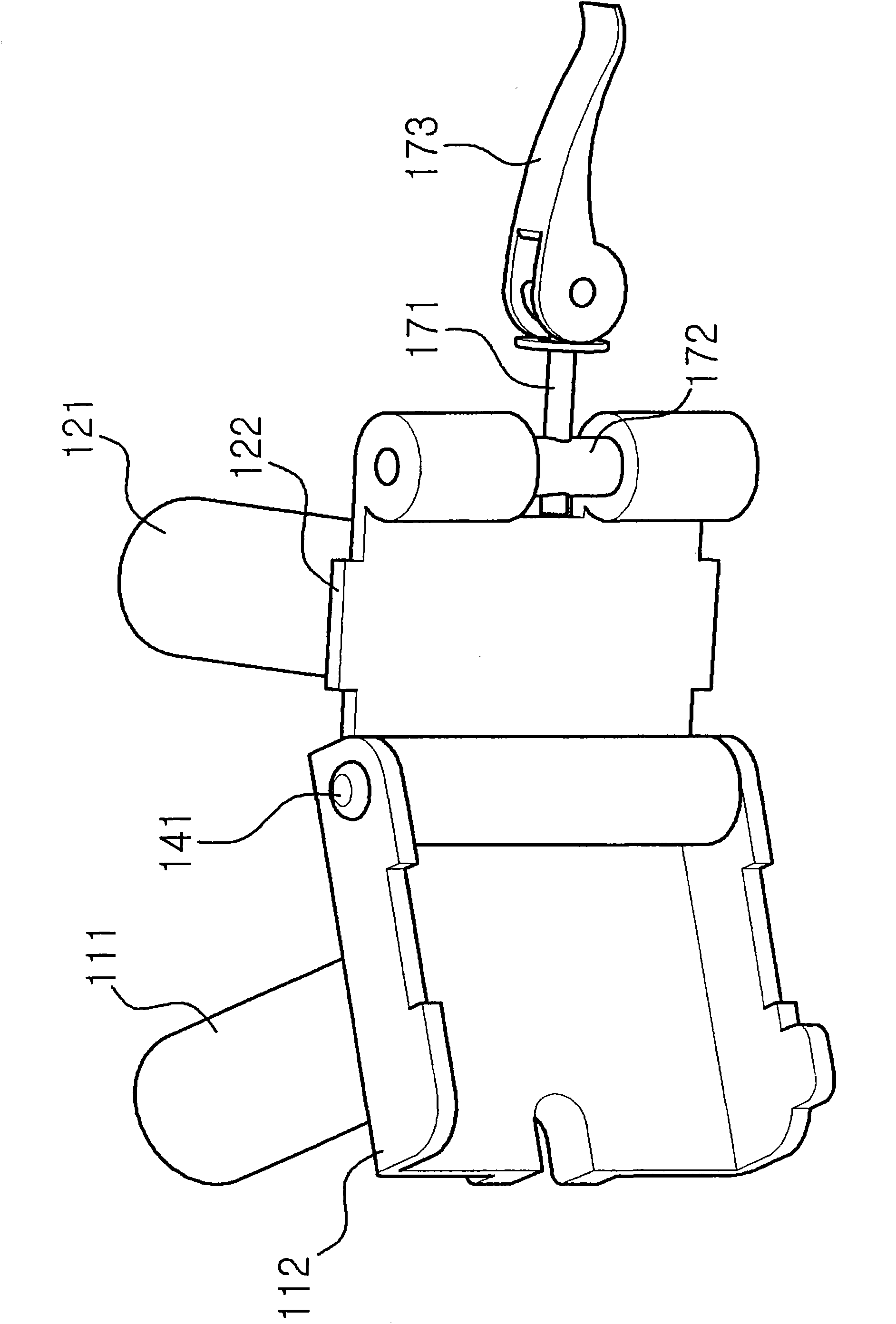

Mounting structure for double-folding seats for vehicles

InactiveUS20050253438A1Improve aesthetic satisfactionSimplify the assembly processOperating chairsBallastwayCushionHinge angle

A mounting structure for a double-folding seat for vehicles in which a seat cushion and a seat back can be double-folded, comprises a cushion hinge bracket, a cushion hinge wire, and a vehicle body hinge bracket. The cushion hinge bracket is connected to a lower portion of the seat cushion. The cushion hinge wire is rotatably connected to the cushion hinge bracket. The vehicle body hinge bracket is provided to an upper surface of a seat mounting part and to which the cushion hinge wire is rotatably connected, so that the seat cushion is foldable with respect to the vehicle body hinge bracket.

Owner:KIA MOTORS CORP

Manufacturing method of 6A02T651 aluminum alloy seam pipe for air separators

The invention belongs to the technical field of aluminum alloy materials for air separators, in particular to a manufacturing method of a 6A02T651 aluminum alloy seam pipe for a low-temperature oxygen / nitrogen air separator, more particularly to a manufacturing method of a 6A02T651 (phi 411*30) aluminum alloy seam pipe. According to the manufacturing method, online quenching production of an ultralarge-diameter and large-wall-thickness seam pipe material for an air separator is realized; under the condition that the standard requirements are met, the labor productivity is raised, the cost is reduced and the ordering requirements of users are met.

Owner:SHANDONG YUHANG SPECIAL ALLOY EQUIP

Artificial marble with formed patterns, and manufacturing method thereof

The invention relates to artificial marble with formed patterns and a manufacturing method thereof. The artificial marble comprises: an artificial marble raw plate, wherein the artificial marble raw plate is cut into the small plate with the predetermined size and the predetermined thickness, grinding is performed, and the pattern portion formed from graphs with a plurality shapes or characters is engraved on the small plate in a negative engraving manner by adopting the processing machine; and a filler, wherein the filler is filled into the pattern portion. With the technical scheme, the texture is remained and the examine aesthetic feeling is high after the artificial marble containing the patterns is produced; and the negative engraving does not form the groove on the pattern portion so as to maintain the smooth surface, such that the artificial marble can further be used as the decoration materials such as the hand washing table upper plate or inscribed tablet, the wall surface material, the flooring material and the like.

Owner:捷美特株式会社

Magnetic block toy

The present invention relates to a magnetic block toy, and more particularly, to a magnetic block toy which makes assembly of blocks firm because caps having serrated coupling parts are combined to both sides of a block body, and which has block bodies and caps of various colors, thereby arousing children's interest and promoting development of intelligence.The magnetic block toy according to the present invention includes: a block body having a pair of brackets each of which has a protrusion and a groove formed on the inner face to correspond to each other and are coupled with each other; caps which are respectively combined to both sides of the block body and each of which has a serrated coupling part formed on the outer surface; and a magnet which is disposed inside the cap to generate a magnetic force.

Owner:CLICK BLOCK

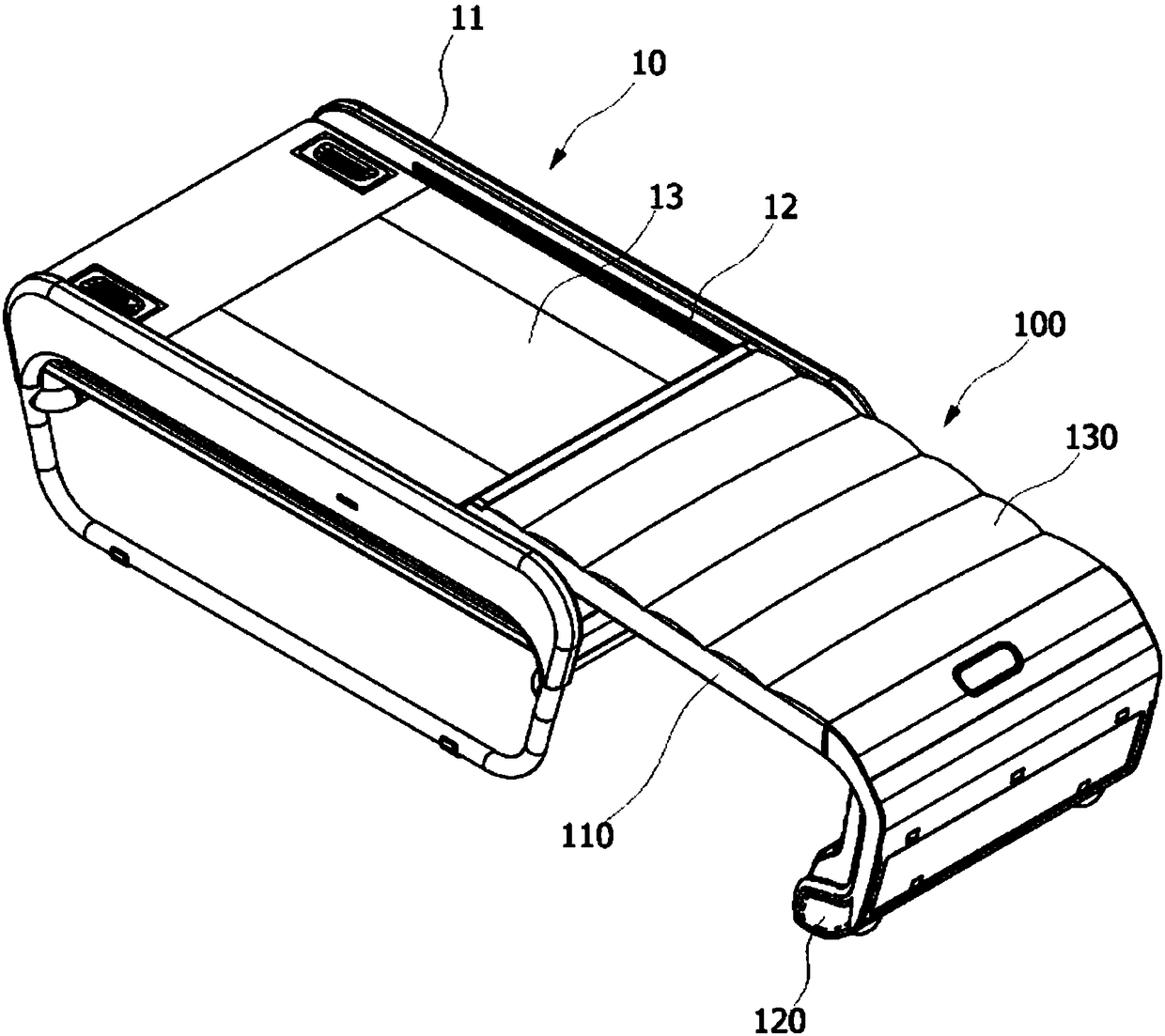

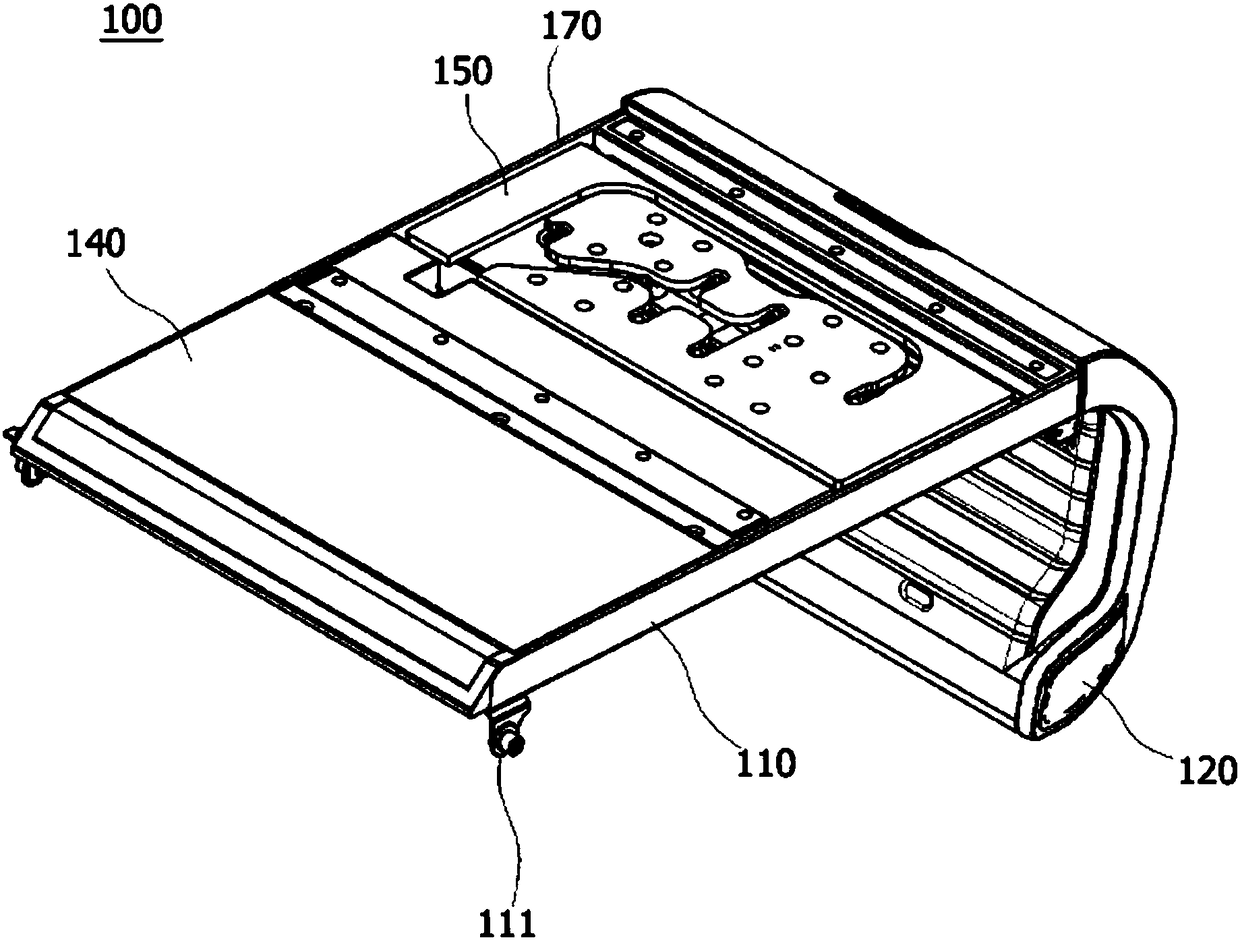

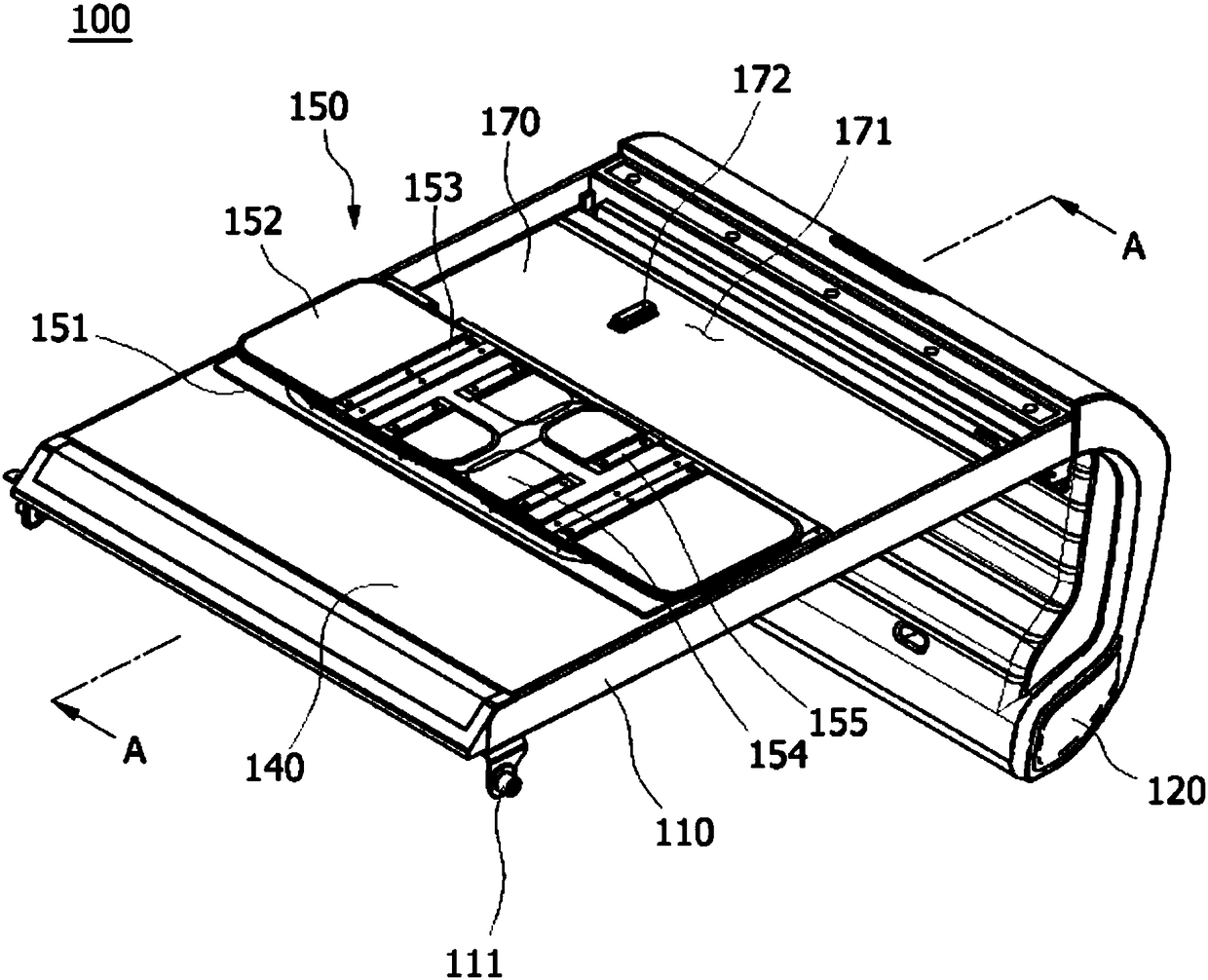

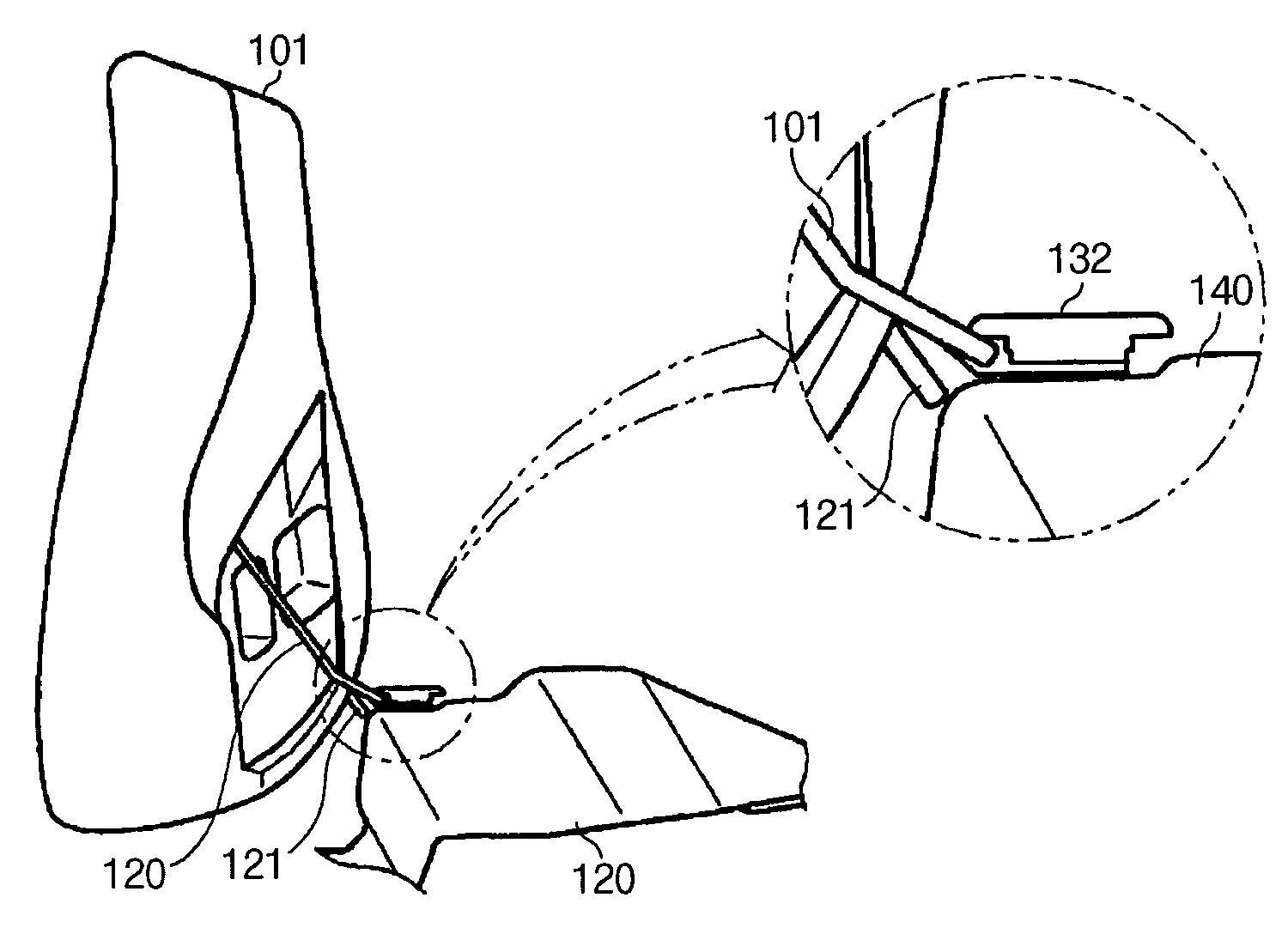

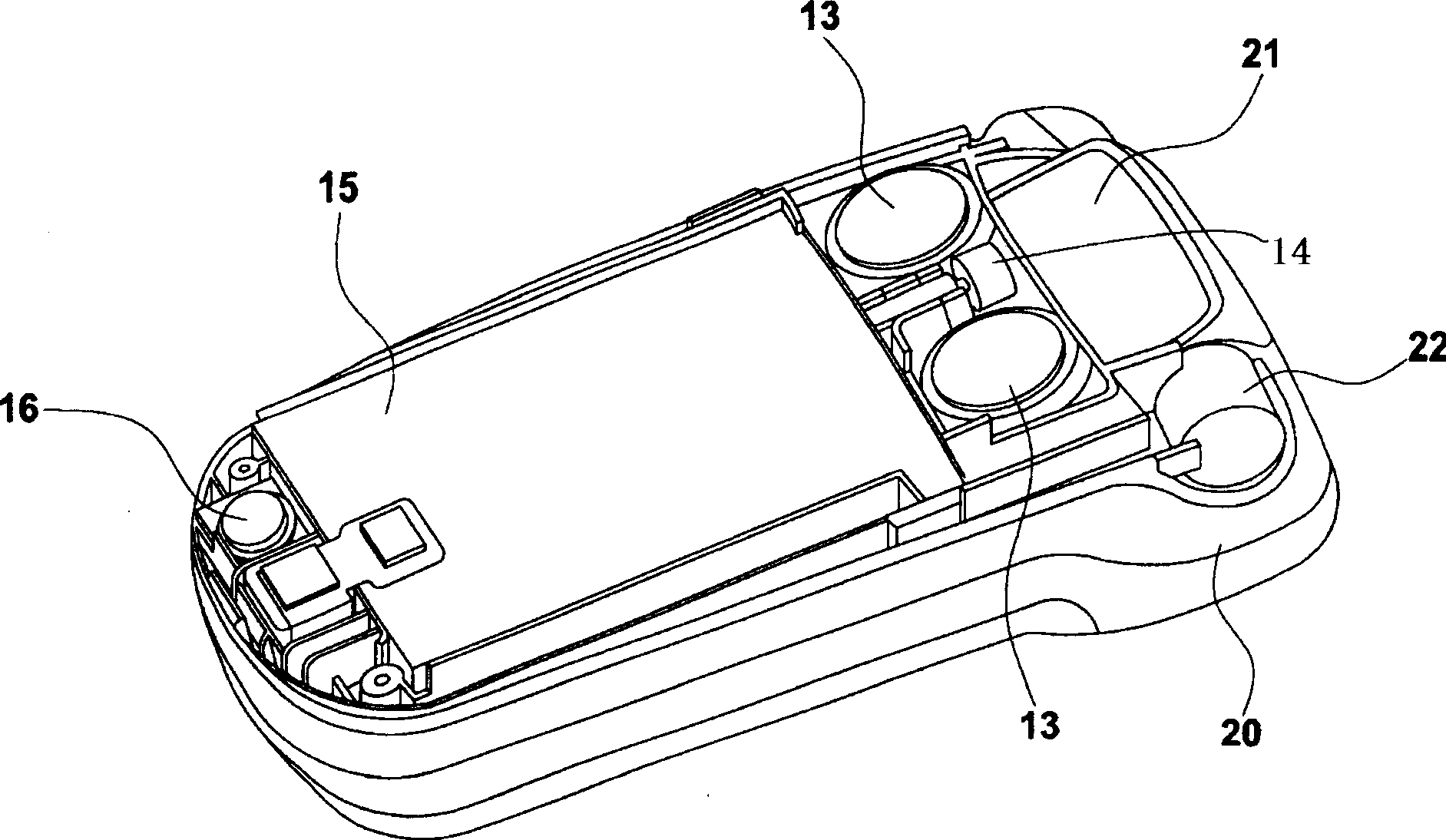

Thermotherapy equipment

ActiveCN108618945AEnsure the effect of placing spaceGood massagePneumatic massageTherapeutic coolingMassageElectrical and Electronics engineering

The present invention relates to thermotherapy equipment and, more particularly, to sliding-type thermotherapy equipment which is used for thermotherapy, and which has an air massage module that can be used and stored easily. The present invention comprises: a body portion having a thermotherapy device installed thereon; an auxiliary portion that slides on the body portion so as to unfold or to overlap with the same, thereby exposing or covering the thermotherapy device; a mat that covers the upper portion of the auxiliary portion; and an air massage module installed on the mat and contained in the auxiliary portion.

Owner:CERAGEM

Mounting structure for double-folding seats for vehicles

InactiveUS7063385B2Improve aesthetic satisfactionSimplify the assembly processOperating chairsBallastwayEngineeringCushion

A mounting structure for a double-folding seat for vehicles in which a seat cushion and a seat back can be double-folded, comprises a cushion hinge bracket, a cushion hinge wire, and a vehicle body hinge bracket. The cushion hinge bracket is connected to a lower portion of the seat cushion. The cushion hinge wire is rotatably connected to the cushion hinge bracket. The vehicle body hinge bracket is provided to an upper surface of a seat mounting part and to which the cushion hinge wire is rotatably connected, so that the seat cushion is foldable with respect to the vehicle body hinge bracket.

Owner:KIA MOTORS CORP

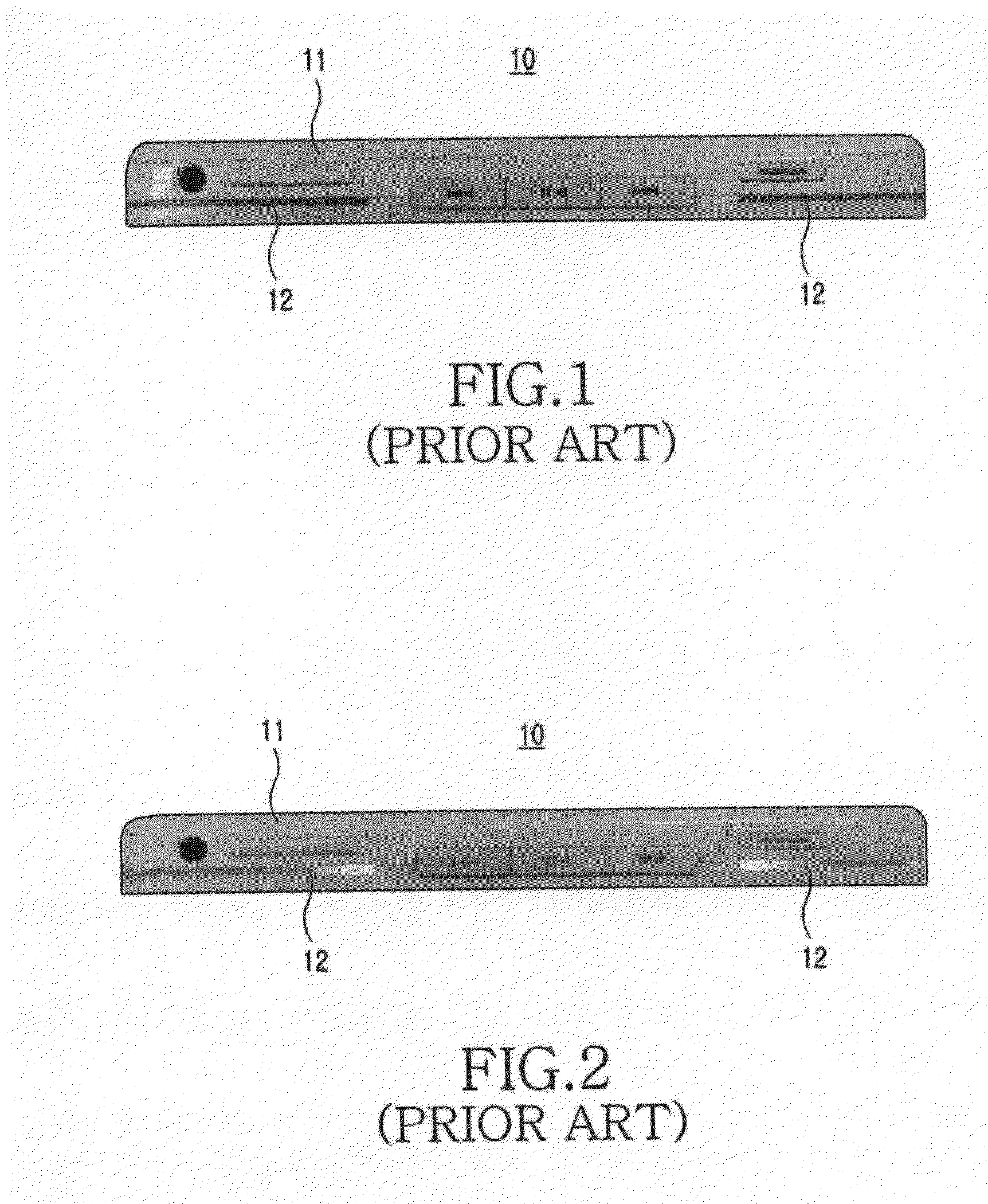

Mobile communication terminal with auxiliary LCD and speaker

InactiveCN1845559AShorten the overall lengthMiniaturizationDevices with multiple display unitsSubstation speech amplifiersLoudspeakerEngineering

The invention relates to a mobile communication terminal auxiliary LCD and loudspeaker, wherein the upper end of machine body has auxiliary LCD; the upper end of cover has concave part for exposing the auxiliary LCD; the lower part of concave part is mounted with loudspeaker; the auxiliary LCD and loudspeaker are inclined to the machine body and the turn cover, to minimize the terminal. And the invention is characterized in that: the upper part of machine body is combined with the turn cover via folding method; the auxiliary LCD is parallel with the loudspeaker, inclined to the plane of cover or machine body.

Owner:LG ELECTRONICS (CHINA) R&D CENT CO LTD

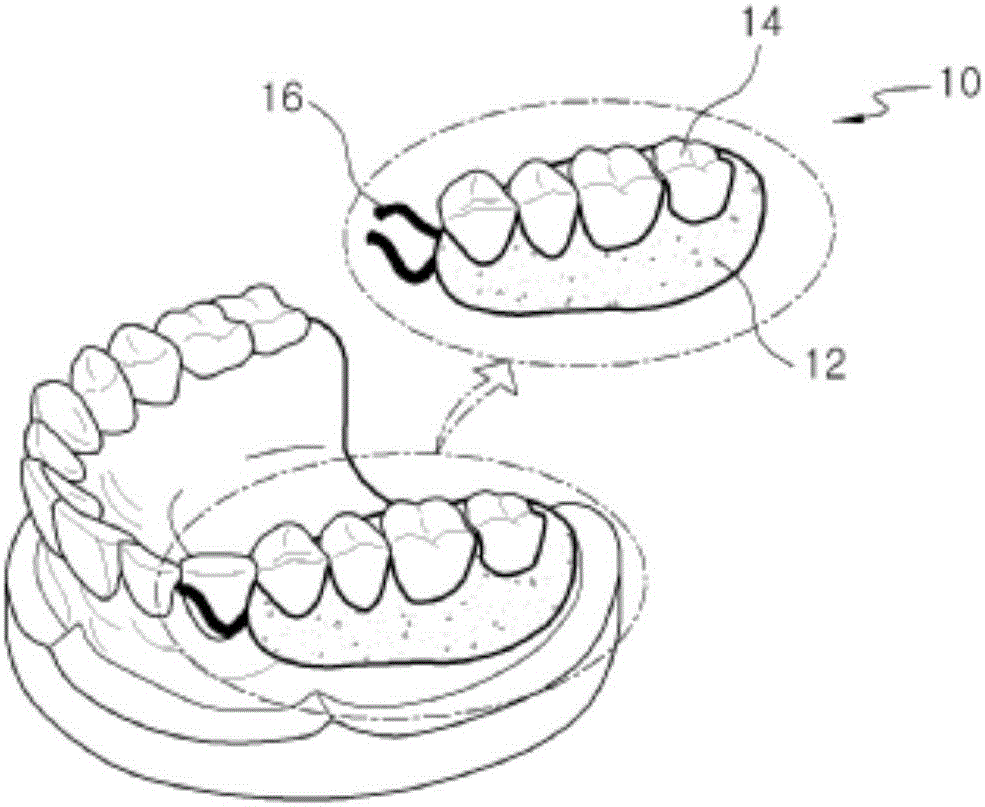

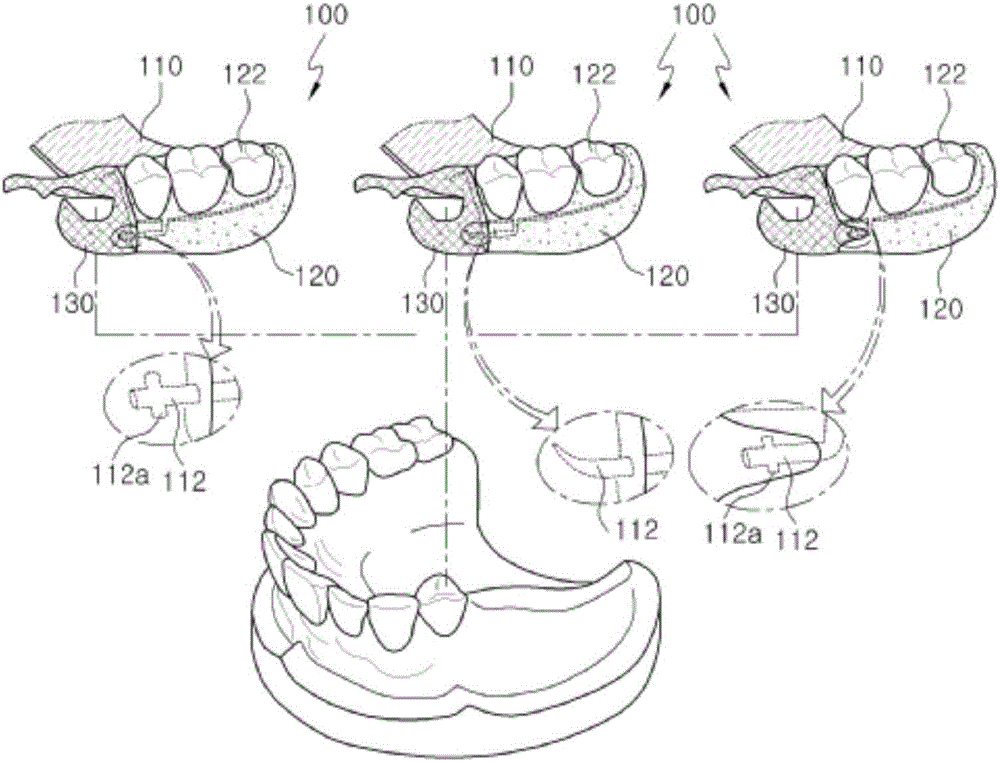

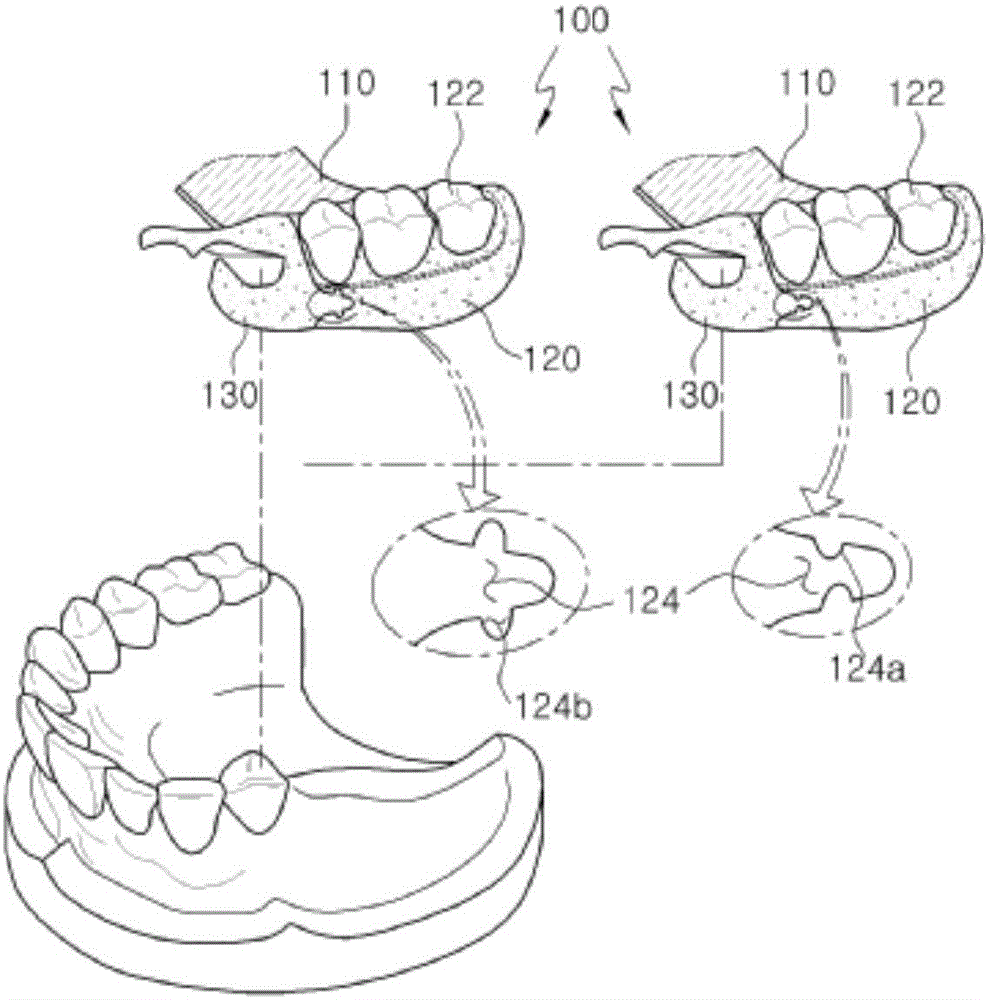

Partial denture and method for manufacturing same

InactiveCN106413627AImprove aesthetic satisfactionFastening prosthesisArtificial teethIndeterminate formPartial upper denture

Owner:赵庸文

Expandable and upgradeable universal socket

ActiveUS10892583B2Function increaseReduce in quantityCoupling device detailsTwo-part coupling devicesTransformerHemt circuits

An expandable and upgradeable universal socket, including a socket body and a function module. The function module is replaceable and upgradeable, and is detachably fixed to the socket body. A power circuit of the function module is separably connected to a power circuit of the socket body to enable the function modules to plug and play. A space is provided in the socket body to accommodate the functional module, and a surface of the socket body is provided with a function area corresponding to the function module. Various expanded function modules can be matched and arranged in the reserved space. Small electronic components can be accommodated in the socket bottom box, and the number of external power transformers are reduced, which saves space, reduces exposed wires and beautifies the appearance. There is no need to replace the entire socket when upgrading the socket, which is environmentally friendly and energy saving.

Owner:CHAN KWOK LEUNG

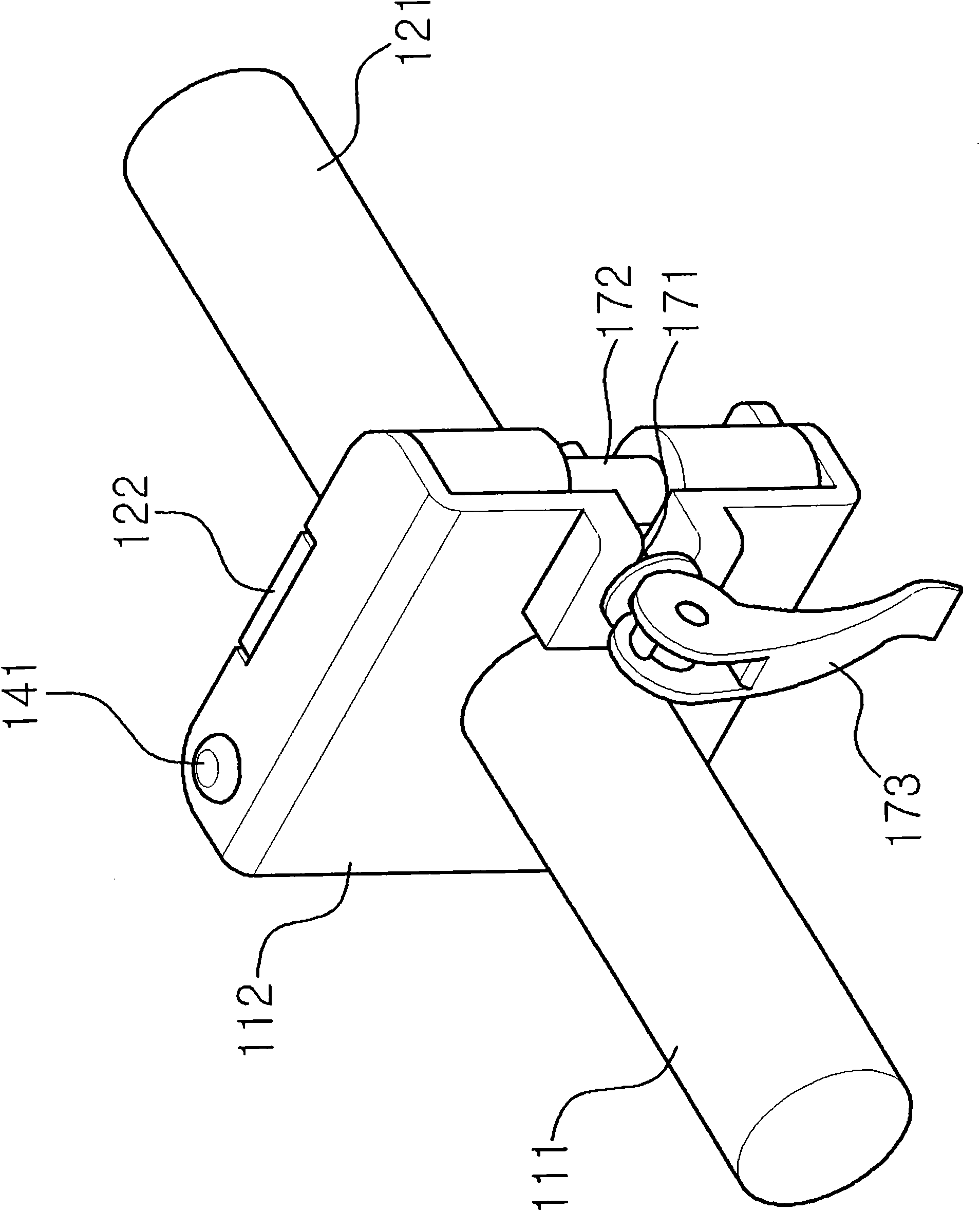

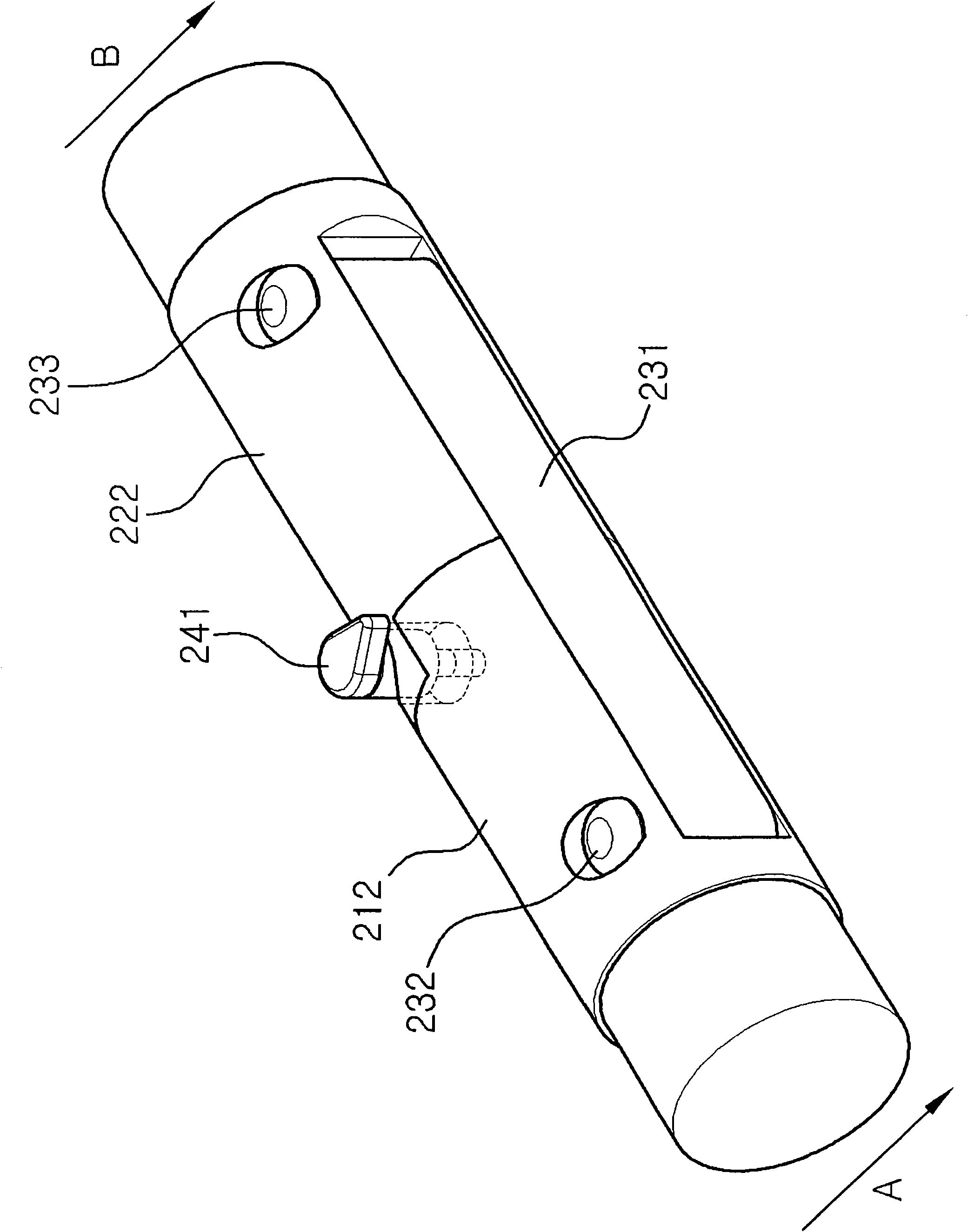

Bicycle folding device having a two-pivot hinge structure

InactiveCN102039970AImprove aesthetic satisfactionMiniaturizationSecuring devicesFoldable cyclesEngineeringMechanical engineering

Owner:SS AUTOMOTIVE ENG

A method of manufacturing 6082t6 aluminum alloy large-scale rods for power equipment

The invention belongs to the technical field of aluminum alloy materials for electric power equipment and particularly relates to a method for manufacturing large-sized aluminum alloy bars with high strength and high electrical conductivity. The large-sized 6082 bars with high strength and high electrical conductivity, especially 6082T6 aluminum alloy bars with diameter from 150mm above to 300mm, are utilized for processing large-sized electrical elements with high strength and high electrical conductivity in the electric power equipment. An aluminum alloy ingot used in the method contains the following elements in percentage by mass: 1.0%-1.05% of Si, no more than 0.12% of Fe, no more than 0.10% of Cu, 0.55%-0.65% of Mn, 0.9%-0.95% of Mg, no more than 0.10% of Cr, no more than 0.10% of Zn, no more than 0.05% of Ti, no more than 0.05% of isolated impurity, no more than 0.15% of total impurities, and the balance being Al. According to the method, mass production and delivery can be achieved, the strength and the electrical conductivity of the large-sized aluminum alloy bars are enhanced, and processing and use are facilitated; the mechanical property and the electrical conductivity of the large-sized aluminum alloy bars obtained by the method are stable; in repeated operation, the bars can satisfy the Chinese standard of bars with diameter smaller than 150mm, the Chinese standard of bars with diameter from 150mm above to 300 mm can be supplemented or perfected and each performance index can be introduced into the Chinese standard.

Owner:SHANDONG YUHANG SPECIAL ALLOY EQUIP

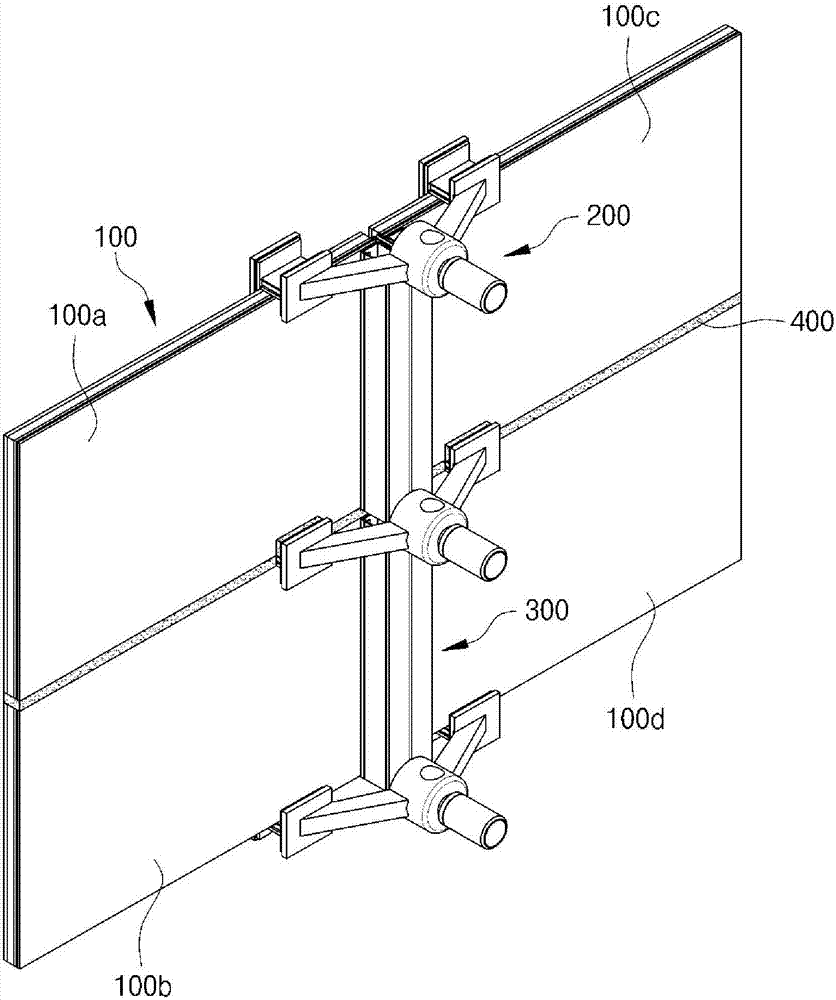

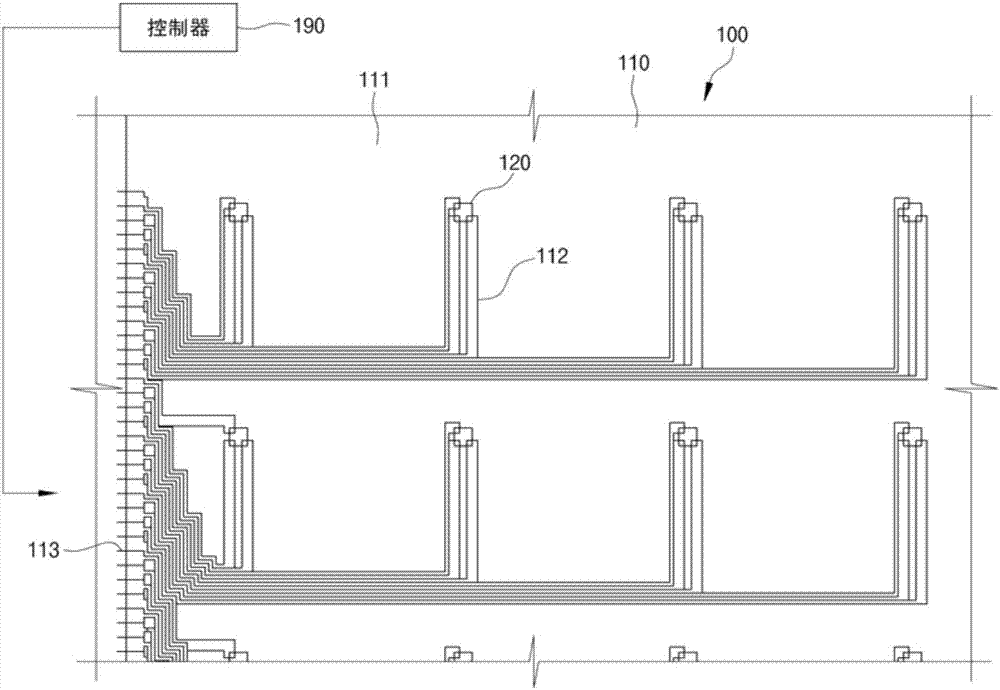

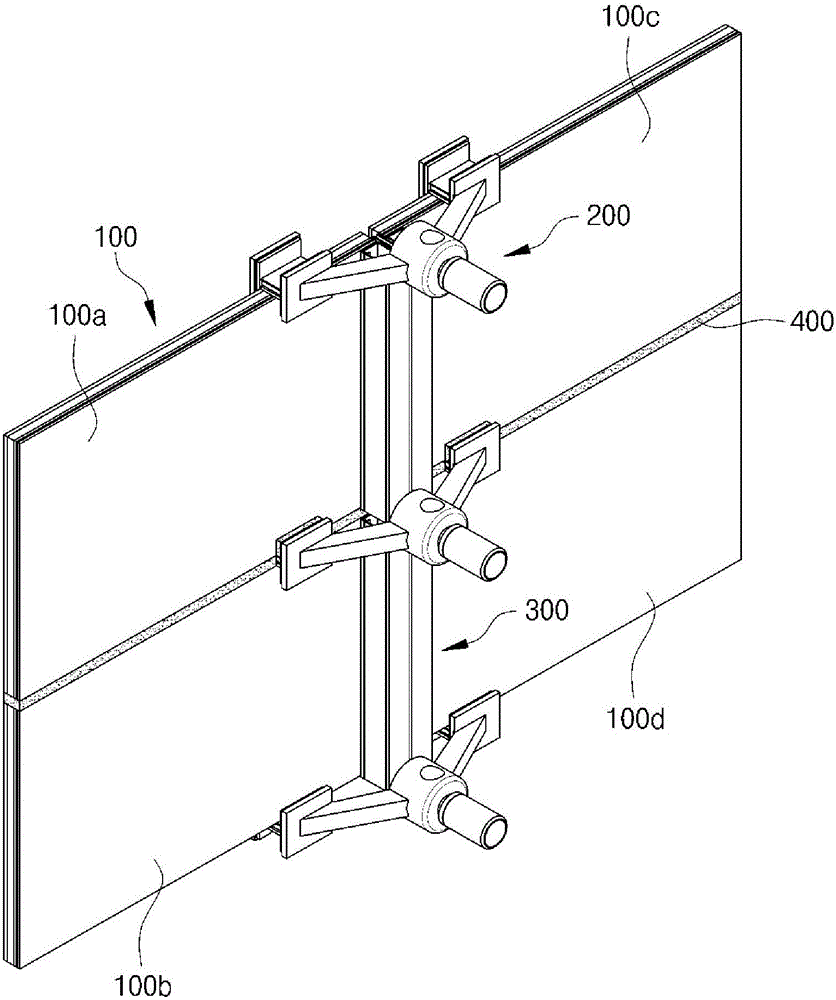

Curtain wall system utilizing transparent displays

InactiveCN106023817BImprove aesthetic satisfactionHold steadyWallsIdentification meansEngineeringElectric signal

The invention provides a curtain wall system using a transparent display board. The curtain wall system comprises a building outer wall made of transparent display screens, a power supply transmission device, a frame and a fixing clamp. The building outer wall is used to display various visual effects and safely accommodate a device for controlling the transparent display screens. Multiple transparent display screens are connected together to form a wall. The power supply transmission device transmits the electric signals that control the transparent display screens. The frame is used to accommodate the controller that is connected to the power supply transmission device and is adhered on the terminal part of the transparent display screens. The fixing clamp supports the transparent display screens in a dot type connection mode (DPG: dot point glazing system).

Owner:TIANJIN CECEP BRILLSHOW

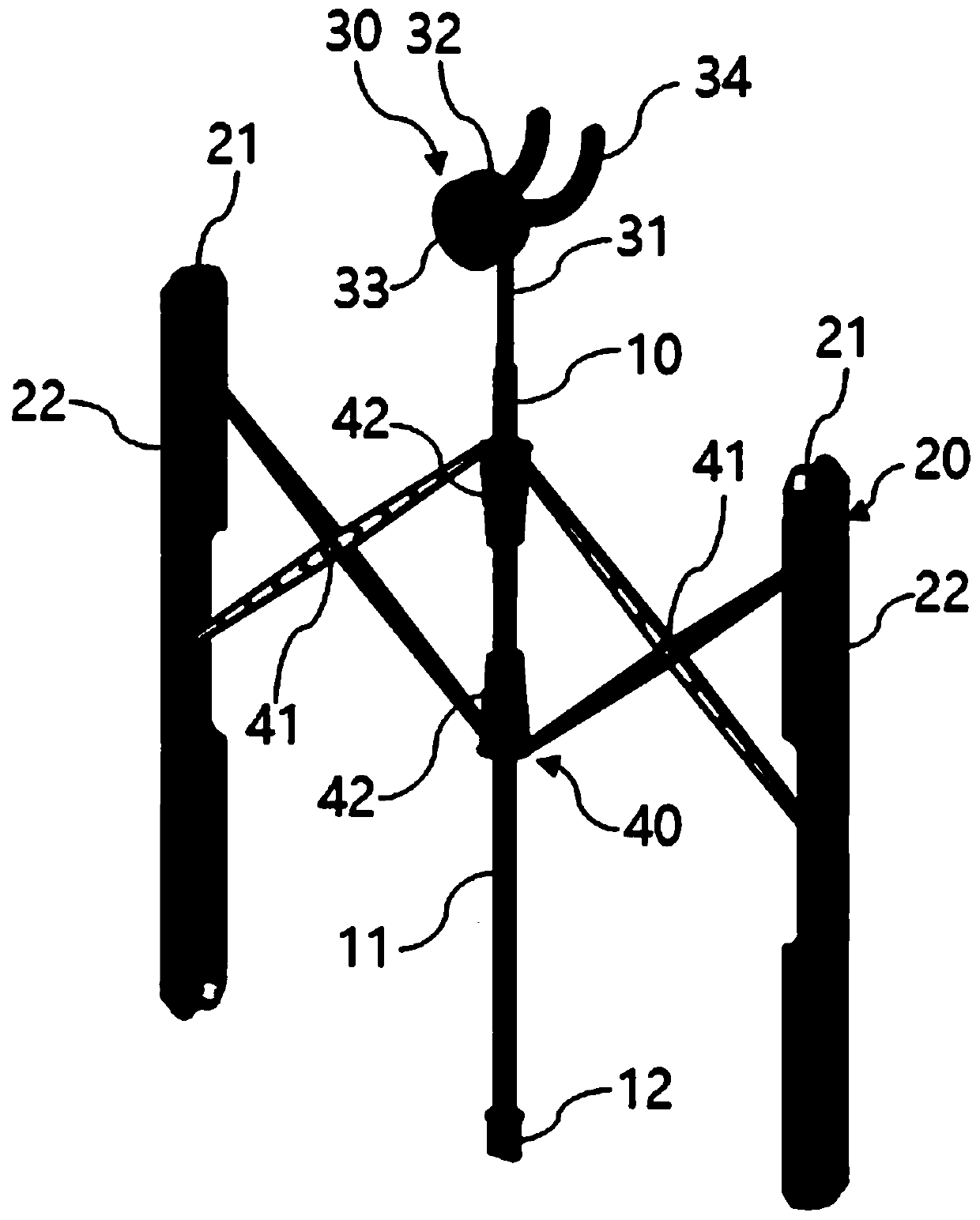

Hanger for ironing

ActiveCN111411498AIroning is easy and simpleEasy to keepIroning apparatusTextiles and paperStructural engineeringMechanical engineering

The present invention relates to a hanger for ironing, and more particularly, to a hanger for ironing comprising: a frame formed in a lengthwise direction; a clothes extending part provided to be extended in opposite directions with respect to the frame and configured to unfold clothes; a hanger holding part provided on one side of an upper portion of the frame to hold a hanger, on which the clothes are hung; and a feeding part formed to surround an outer peripheral surface of the frame and configured to extend or fix the clothes extending part, wherein the frame comprises an uneven part thatis formed in a lengthwise direction thereof and in which a groove is continuously formed, the feeding part comprises a fixing part configured to selectively fix the clothes extending part, the fixingpart has a bent wire shape, the bent portion of the fixing part is inserted into the groove of the uneven part such that the clothes extending part is fixed, and the bent portion of the fixing part deviates from the groove of the uneven part when an external force by a user is applied such that the clothes extending part is unfolded or folded.

Owner:博得生活株式会社

Curtain wall system using transparent display board

InactiveCN106023817AImprove aesthetic senseImprove aesthetic satisfactionWallsIdentification meansElectric signalTransparent display

The invention provides a curtain wall system using a transparent display board. The curtain wall system comprises a building outer wall made of transparent display screens, a power supply transmission device, a frame and a fixing clamp. The building outer wall is used to display various visual effects and safely accommodate a device for controlling the transparent display screens. Multiple transparent display screens are connected together to form a wall. The power supply transmission device transmits the electric signals that control the transparent display screens. The frame is used to accommodate the controller that is connected to the power supply transmission device and is adhered on the terminal part of the transparent display screens. The fixing clamp supports the transparent display screens in a dot type connection mode (DPG: dot point glazing system).

Owner:TIANJIN CECEP BRILLSHOW

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com