Device and method for manufacturing prefabricated parts

A technology of prefabricated parts and adjustment devices, which can be applied to household components, applications, household appliances, etc., and can solve the problem of small net income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

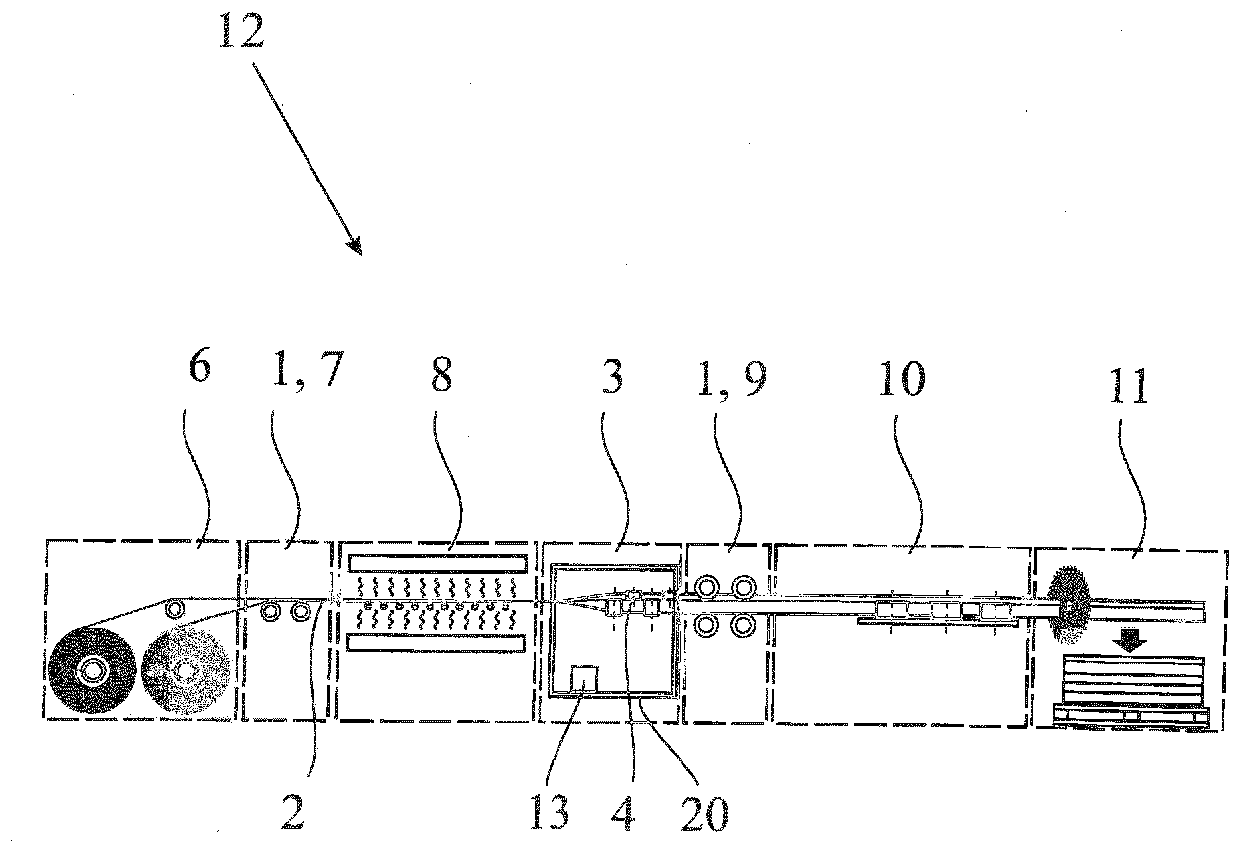

[0021] figure 1 An exemplary embodiment of a device according to the proposal for producing fiber-reinforced synthetic materials is shown. The proposed device has a conveying mechanism 1 for the continuous conveying of fiber webs 2 . The fiber fabric 2 is presently a thermoplastic powder-bonded fiber material and thus a fiber matrix semi-finished product, which is also referred to as a prepreg.

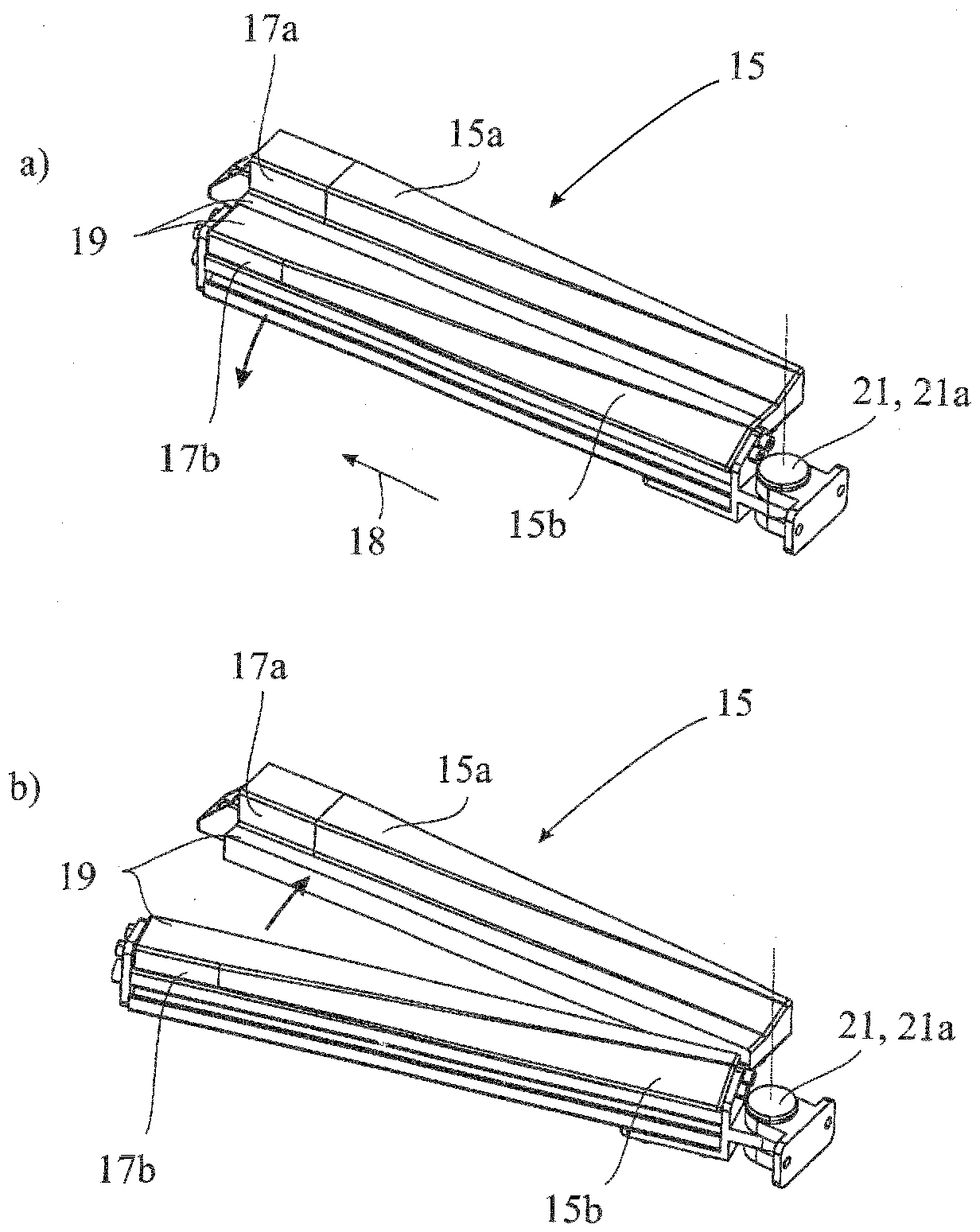

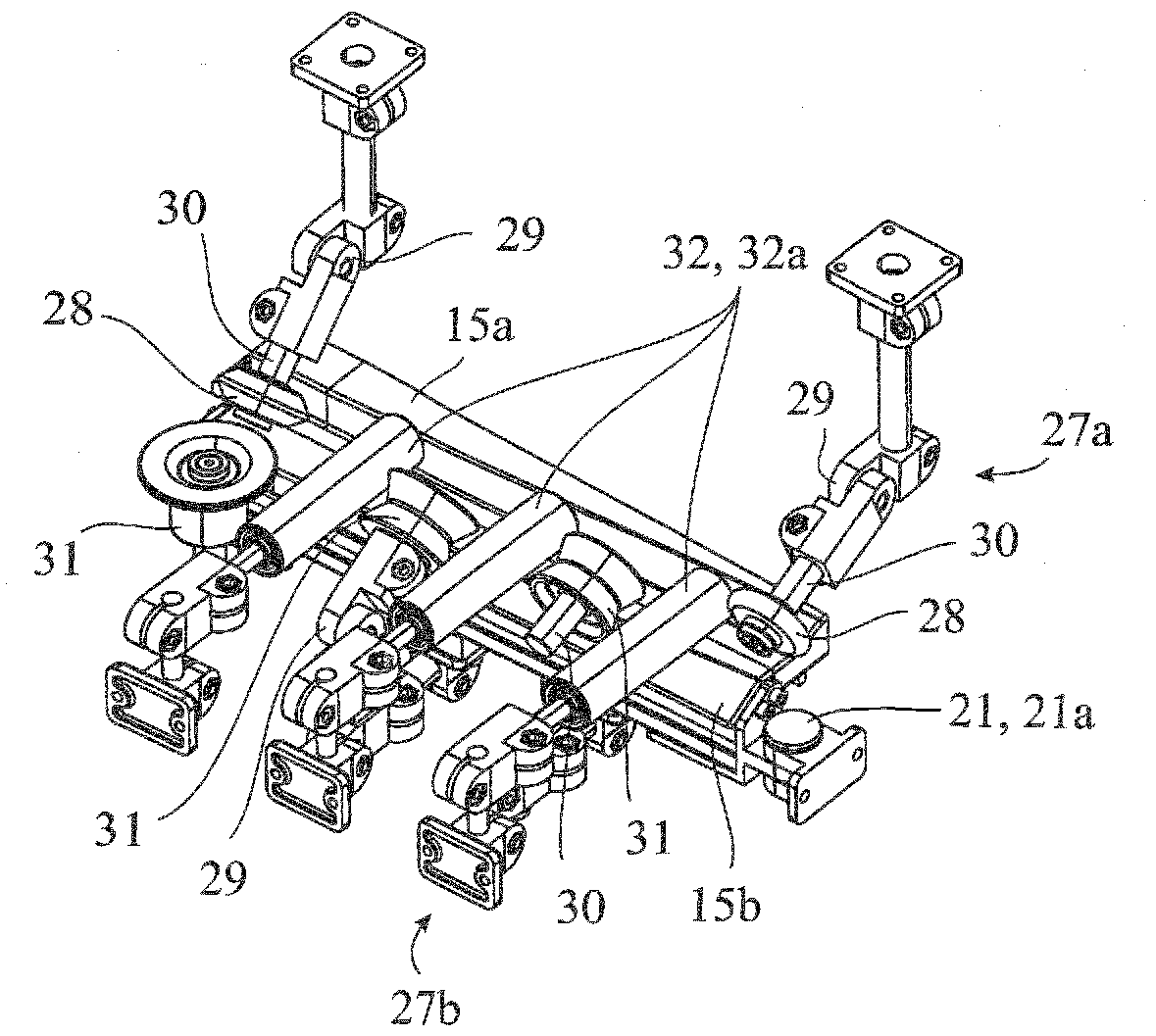

[0022] The proposed device likewise has a transverse deformation mechanism 3 with an adjustment device 4 for deforming the conveyed fiber web 2 into a predetermined theoretical profile 5 . Two such theoretical profiles 5 with respectively different cross-sections in Figure 5 shown in a and b. In addition, further processing steps can be carried out in the transverse deformation mechanism 3 .

[0023] The device according to the proposal is then characterized in that the adjusting device 4 can be adjusted for changing the cross-section of the theoretical profile 5 . This adjustab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com