Design system and method of pipe supports and hangers

A design method and design system technology, applied in computer-aided design, calculation, instruments, etc., can solve problems such as construction delays, lagging pipeline 3D models, readjustment and increased workload of designers, etc., to reduce rework design and calculation, The effect of avoiding repeated input and reducing the probability of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

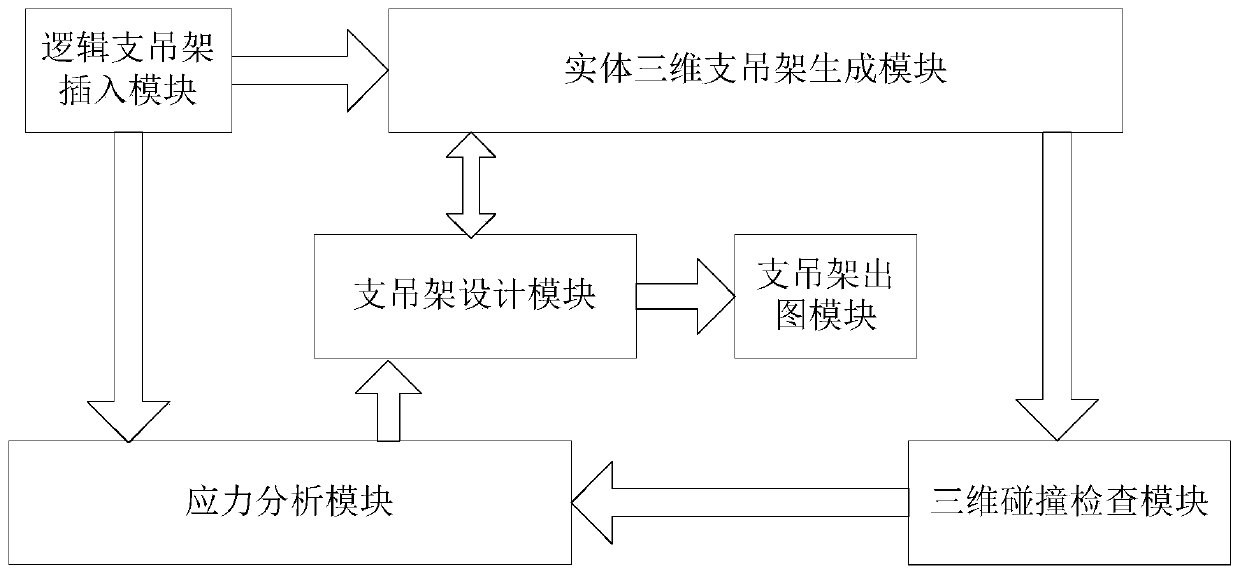

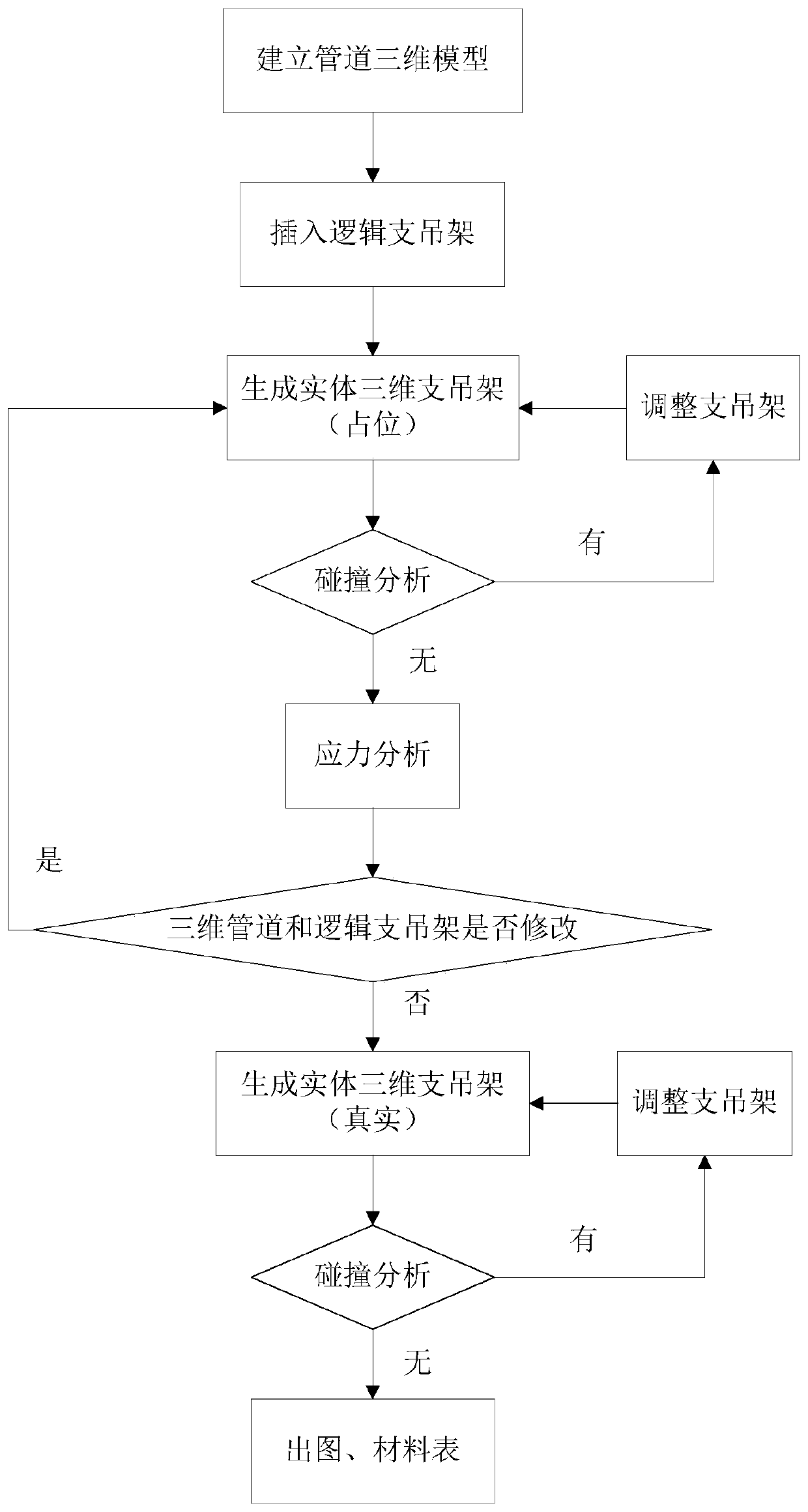

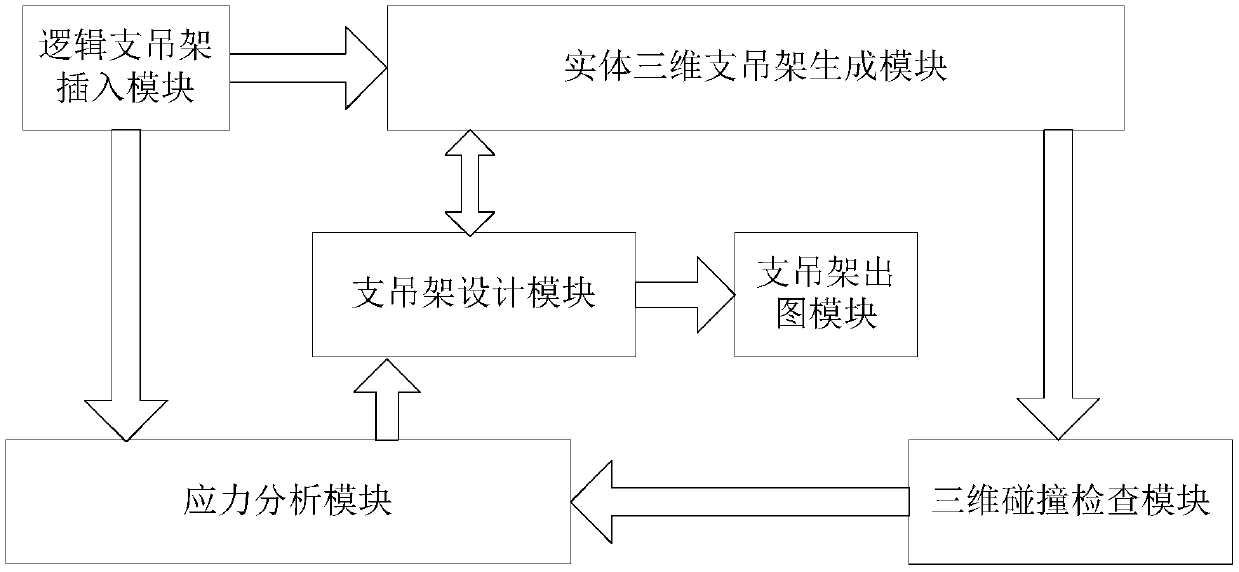

[0030] Such as figure 1 The design system of the shown pipeline support and hanger of the present invention includes:

[0031] Logical support and hanger insertion module: used to insert logical support and hanger into the pipeline system after preliminary layout, mainly including spring support and hanger, rigid support and hanger to bear the weight of the pipeline, fixed support and hanger, limit support and hanger Frames, etc. are used to limit the displacement of the pipeline. Designers can enter the logical support and hanger insertion module in the PDMS 3D factory design software, view the automatically inserted logical support and hanger, and adjust the type and position of the logical support and hanger.

[0032] Entity three-dimensional support and hanger generation module: receive the pipeline parameters of the logical support and hanger insertion module, the type of logical support and hanger, and the beam and column position relationship with the civil structure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com