Gas diffusion layer, electrochemical cell having such a gas diffusion layer, and electrolyzer

A gas diffusion layer, electrochemical technology, applied in the direction of electrochemical generators, battery electrodes, electrolytic components, etc., can solve the problems of high manufacturing cost, difficult warping temperature, etc., and achieve the effect of easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

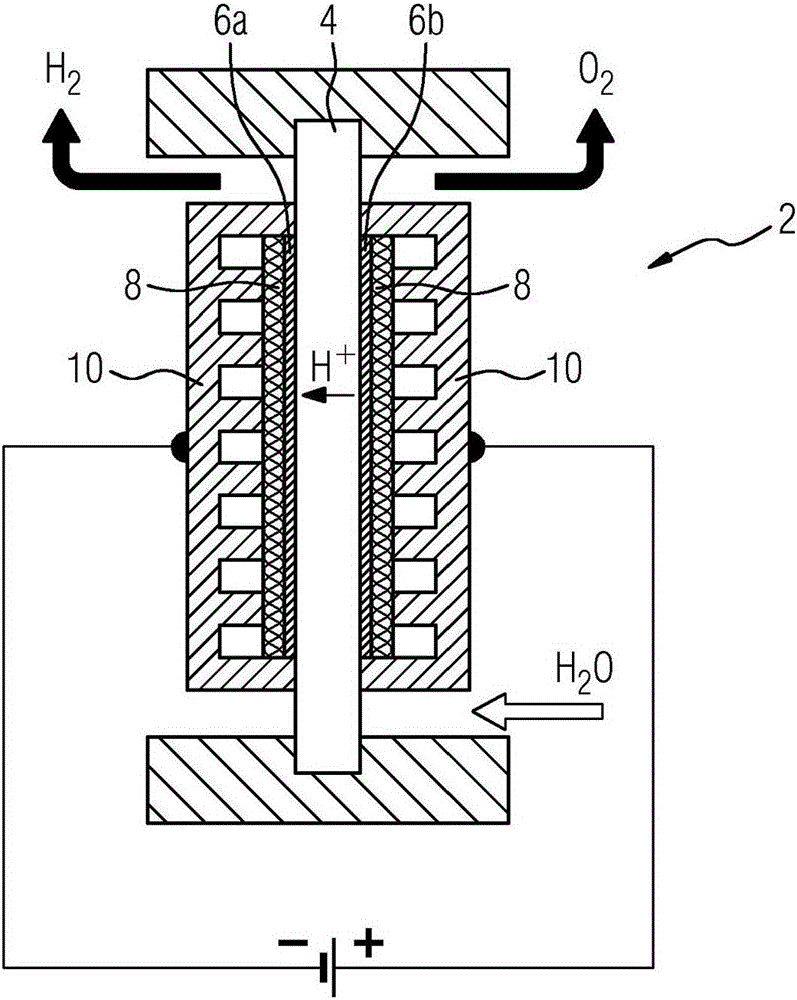

[0044] exist figure 1 The structure of the electrochemical cell 2 is schematically shown in , the electrochemical cell being formed as a PEM electrolysis cell. The electrochemical cell 2 is part of an electrolyzer, not shown in detail here, for splitting water by means of an electric current into the products hydrogen and oxygen.

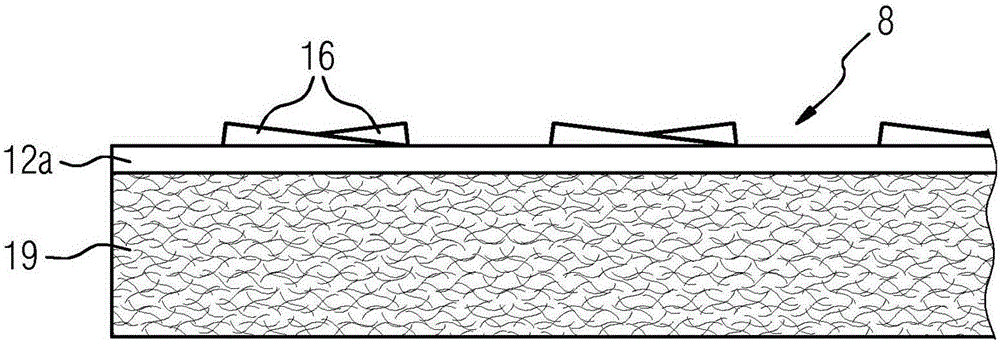

[0045] The electrochemical cell 2 comprises an electrolyte consisting of a proton-conducting membrane 4 (proton exchange membrane, PEM), on which electrodes 6a, 6b are located on both sides. A unit consisting of a membrane and an electrode is called a membrane electrode unit (MEA). Here, the cathode is denoted by 6a, and the anode is denoted by 6b. The gas diffusion layer 8 is placed against the electrodes 6a, 6b, respectively. The gas diffusion layers 8 are contacted by so-called bipolar plates 10 , which are separated from one another in the assembled state of an electrolytic stack composed of a plurality of individual electrolytic cells 2 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com