Extrusion device for cotton stalk skin-core separator

A technology of extrusion device and separator, which is applied in mechanical equipment, mechanical processing of plant materials, raw material pretreatment, etc., can solve the problem of weakening contact force, poor effect of cotton stalk extrusion, and difficulty in separating cotton stalk core and cotton stalk skin. and other problems, to achieve the effect of convenient separation and reduced connection force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

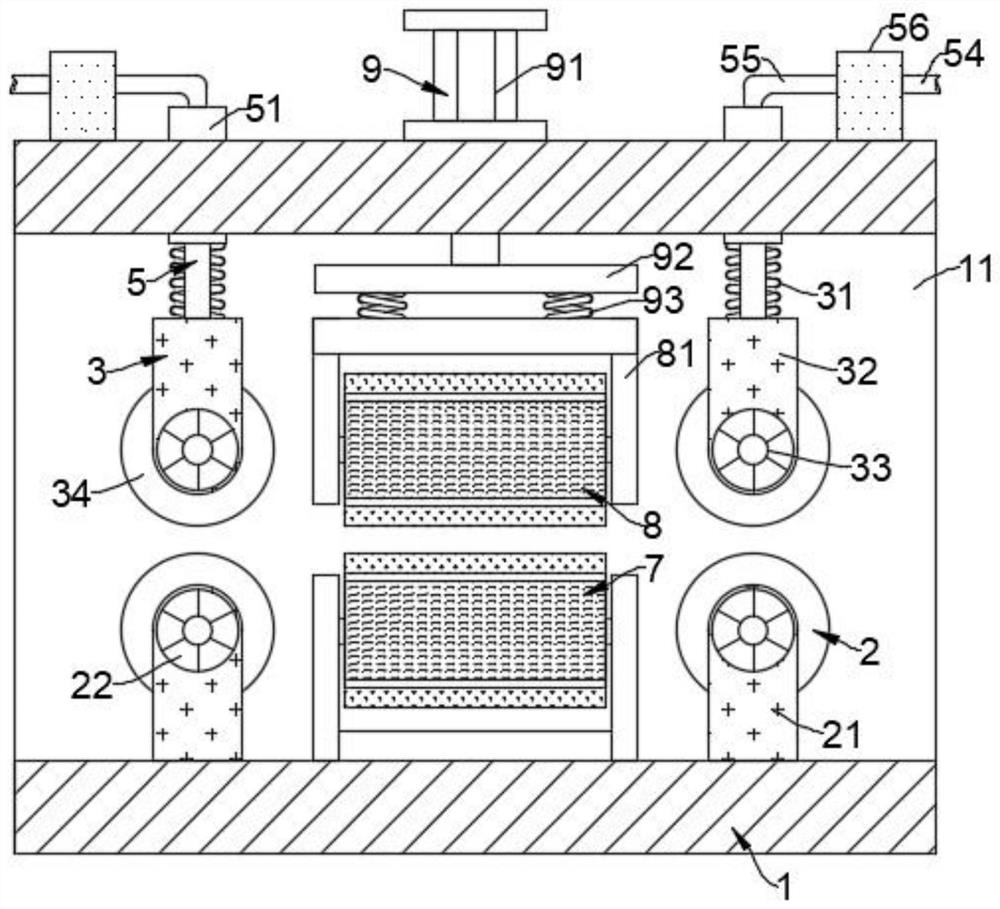

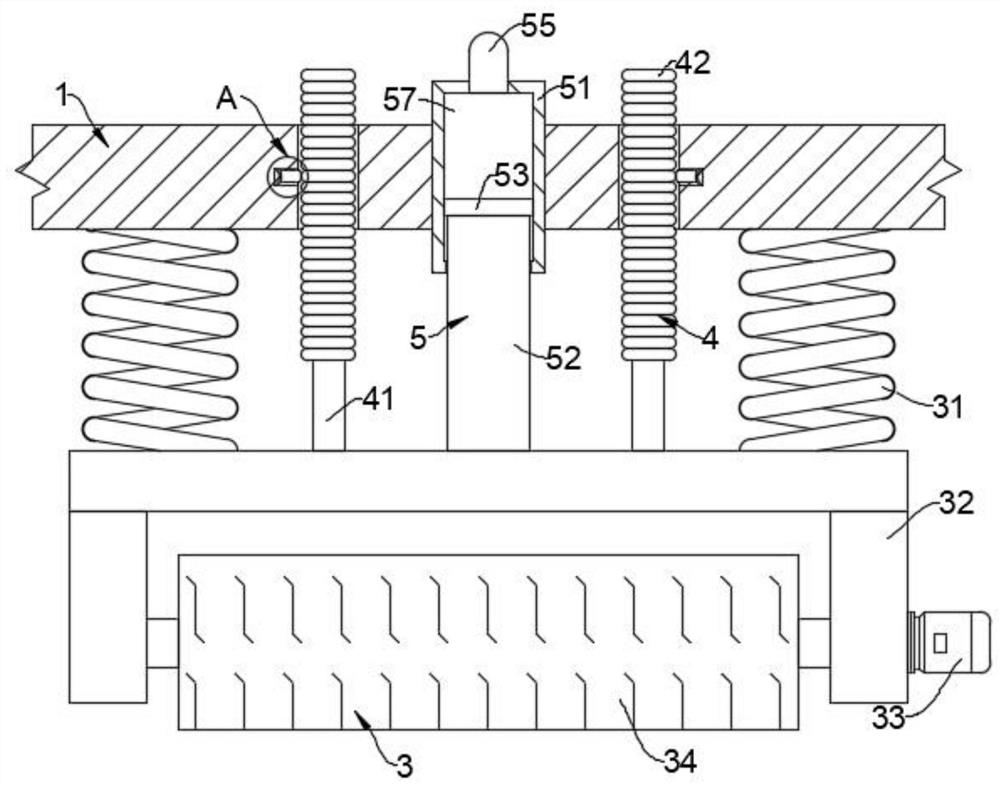

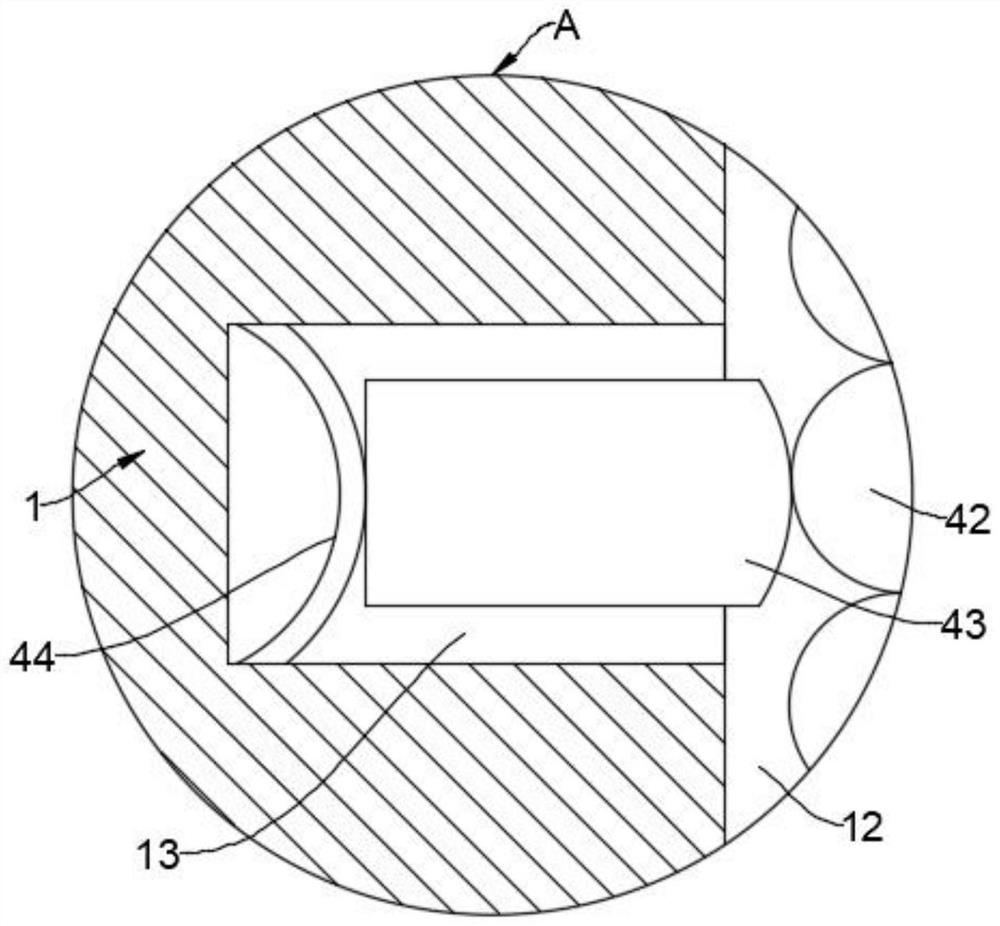

[0022] Such as Figure 1-5 As shown, an extrusion device used on a cotton stalk sheath-core separator includes an extrusion housing 1 with an extrusion chamber 11 inside, and two sets of rotating rollers 2 are arranged in the extrusion chamber 11, and two rotating rollers 2 The sides are rotatably connected with a fixed plate 21 , the bottom of the fixed plate 21 is fixedly connected with the bottom wall of the extrusion chamber 11 , the fixed plate 21 is fixedly connected with a first motor 22 , and the output end of the first motor 22 is fixedly connected with the rotating roller 2 .

[0023] A pressing member 3 is arranged above the rotating roller 2, and the pressing member 3 is composed of a connecting member 32, a second motor 33 and a pressing roller 34. The connecting member 32 has a U-shaped structure, and the pressing roller 34 is rotatably con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com