A kind of optical lens automatic discharging mechanism

A technology of automatic discharge and optical lens, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of management confusion, manual search, trouble, etc., and achieve the effect of convenient replenishment, convenient management, and convenient access.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

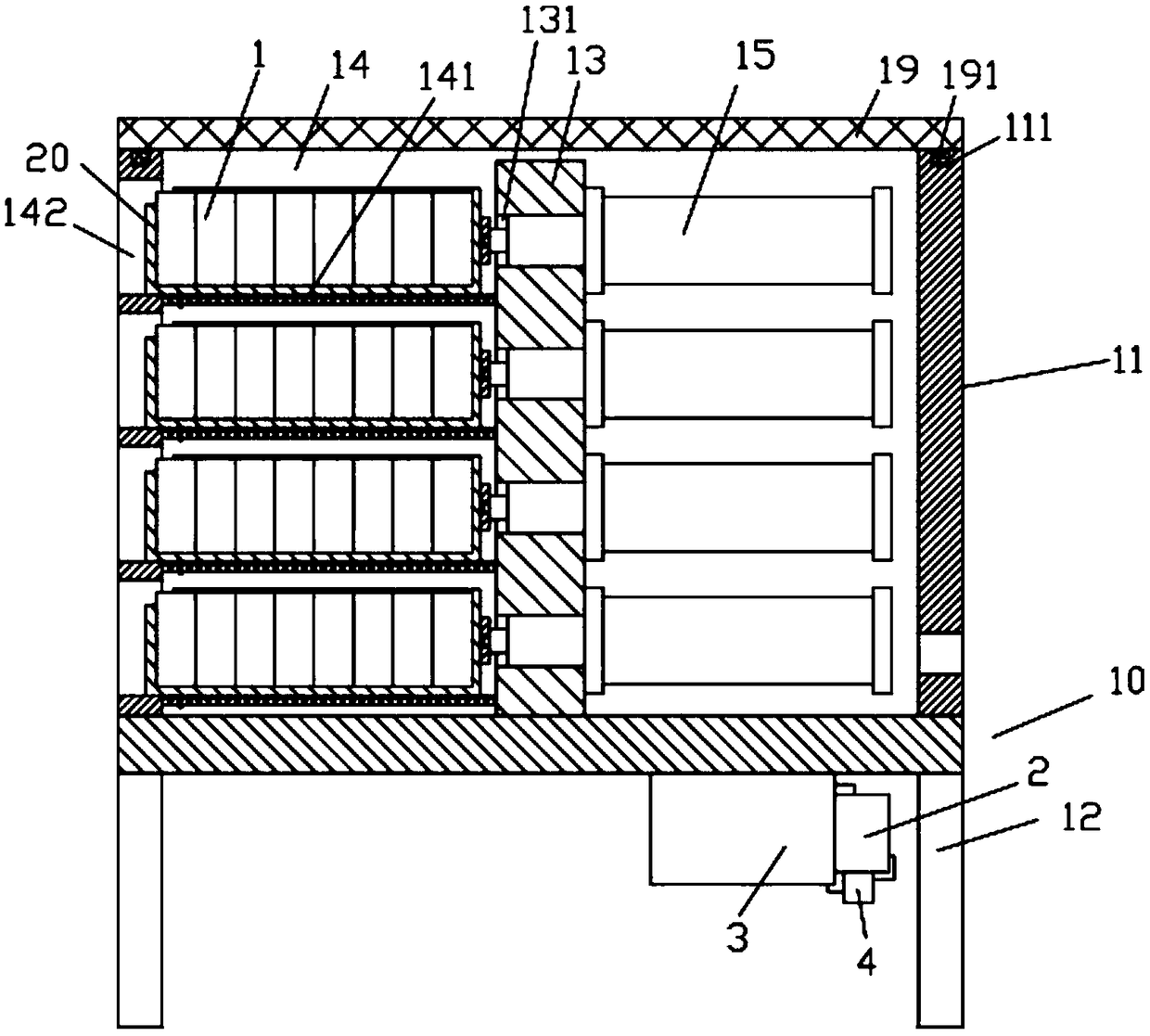

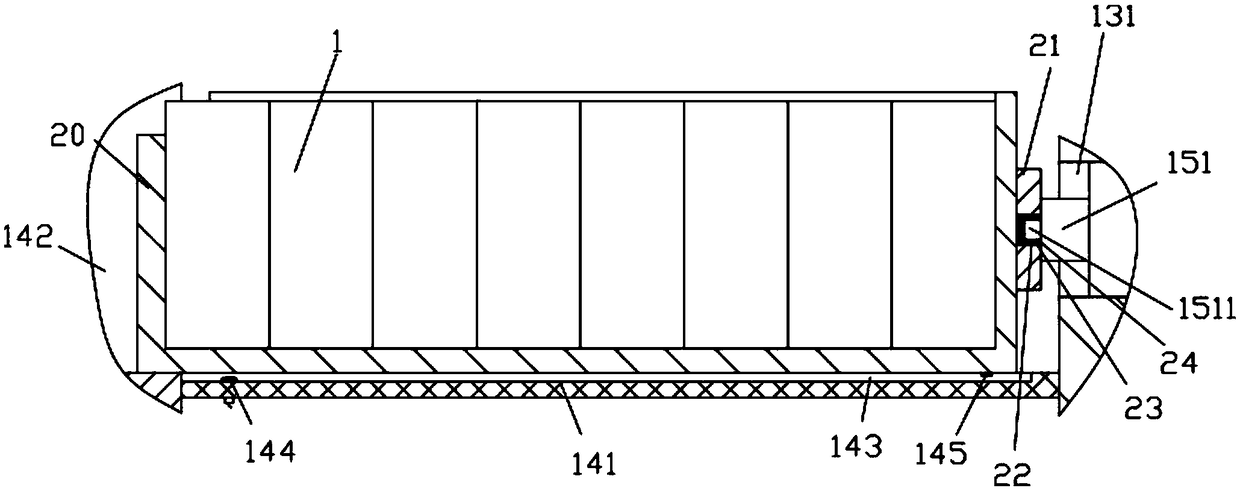

[0017] Examples, see e.g. Figure 1 to Figure 2 As shown, an automatic optical lens discharge mechanism includes a frame 10, the upper part of the frame 10 is a box body 11, and the bottom surface of the box body 11 is fixed with a leg 12;

[0018] The middle part in described box body part 11 is provided with middle partition 13, and the bottom surface of middle partition 13 is fixed on the top surface of the bottom plate of box body part 11, and the front and back side walls of middle partition 13 are fixed on box body part 11. On the front and rear inner side walls of the middle partition 13, the left side of the middle partition 13 is a discharge cavity 14, and a plurality of pushing cylinders 15 are fixed on the right side of the middle partition 13;

[0019] The discharge cavity 14 is provided with a plurality of parallel horizontal support plates 141, one end of the horizontal support plate 141 is fixed on the intermediate partition 13, and the other end of the horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com