A Bidirectional Installable Hidden Door Closer

A technology of door closers and rotating arms, applied in the field of hidden door closers, which can solve the problems of poor running stability, stagnation, and increased production costs of door closers, and achieve the effects of reducing production costs and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

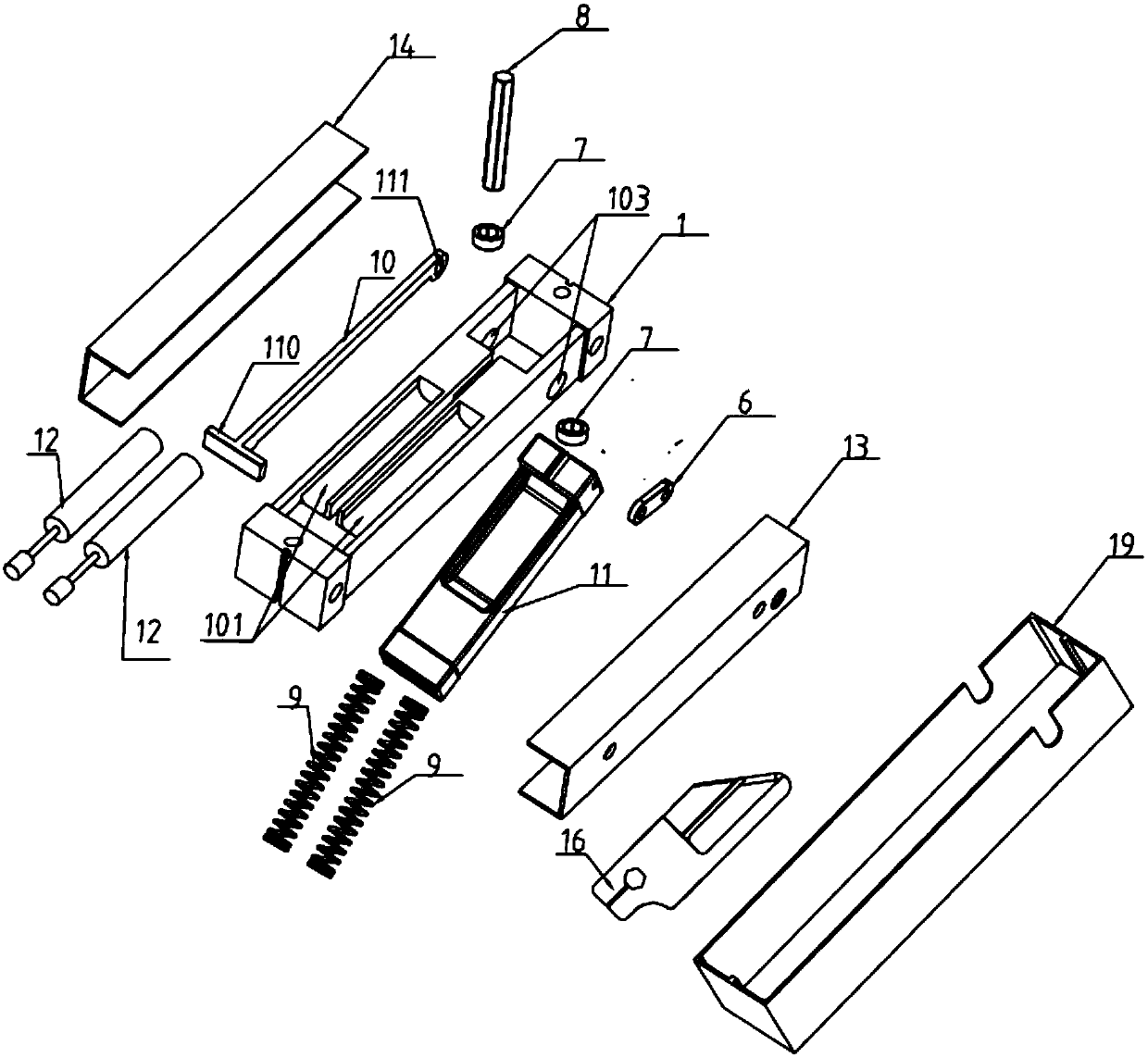

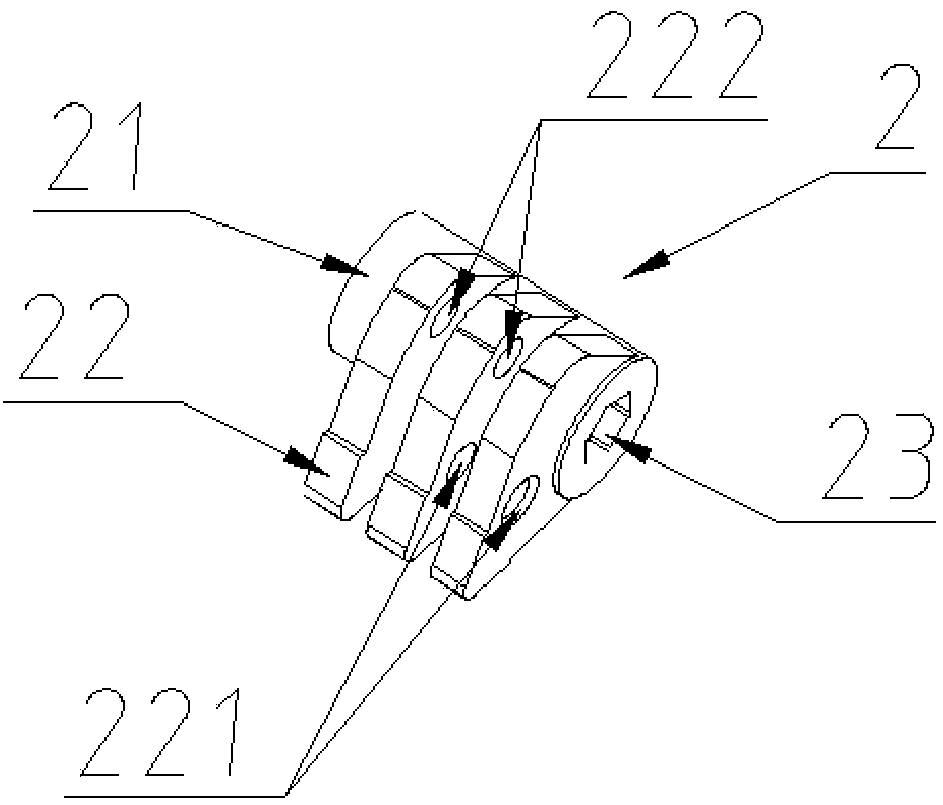

[0032] Such as Figure 1-6 The shown door closer includes a main body 1, two oil cylinder grooves 101 are arranged on one side of the main body 1, and an oil cylinder 12 is respectively placed in each oil cylinder groove 101, and the cylinder barrel of the oil cylinder 12 abuts against At the bottom of the cylinder tank 101. Inside the main body 1 and on the back of the oil cylinder groove 101, a slider 11 that slides back and forth along the length direction of the main body 1 is provided. The sliding direction of the slider 11 is parallel to the moving direction of the oil cylinder 12. A rotating member 2 is provided at the same end as the oil cylinder 12 , and the rotating member 2 is rotatably mounted on the main body 1 through a rotating rod 8 . The slider 11 is connected to the rotating member 2, and the slider 11 is provided with a spring 9 at an end far away from the rotating member 2, and one end of the spring 9 abuts against the slider 11, and the other end abuts ag...

Embodiment 2

[0044] The difference between the second embodiment and the first embodiment lies in the rotating arm and the positioning block, and the rest of the structures are exactly the same. The rotating arm 116 in this embodiment is a bent rod, and when no external force is applied, the end of the rotating arm 116 away from the rotating rod 8 protrudes to the front of the door panel and extends in the width direction of the door panel. Similarly, when the installation directions are inconsistent, the rotating arm 116 needs to be replaced, and the structures of the rotating arm 116 in the two cases are mirror images of each other.

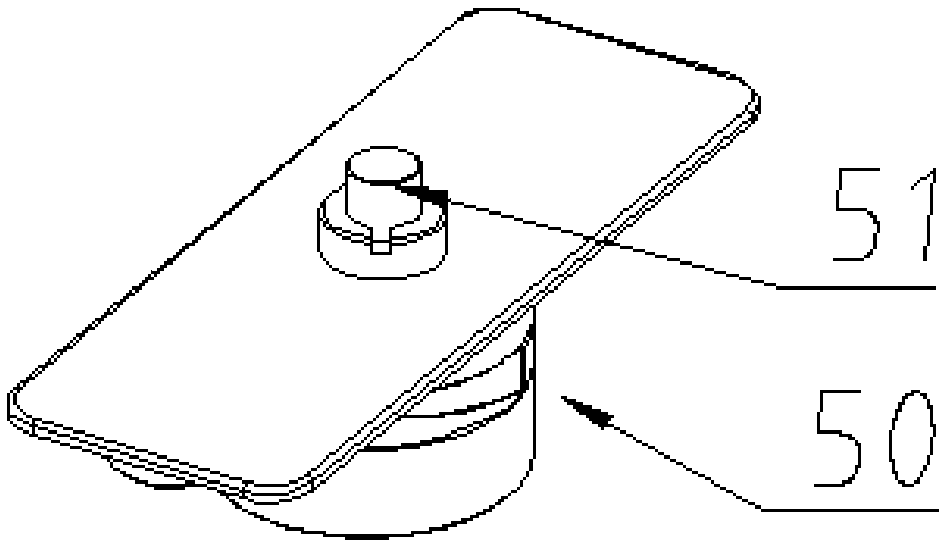

[0045] Such as Figure 12-15 As shown, the positioning block 150 of this embodiment includes a housing 151, a core 152 and a fixed plate 153, a gap 1511 is provided in the middle of the housing 151, and a movable moving plate is provided on the core 152 1521, such as Figure 14 with 15 As shown, the notch 1511 cooperates with the moving plate 1521 to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com