Electric kettle capable of automatically closing kettle cover

An automatic shut-off, electric kettle technology, which is applied to water-boiling appliances, heating devices, cooking utensils, etc., can solve the problems of causing fire, non-self-resetting, and short-circuit burnout of the electric kettle's circuit board, preventing noise, The effect of improving the environment and increasing the lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

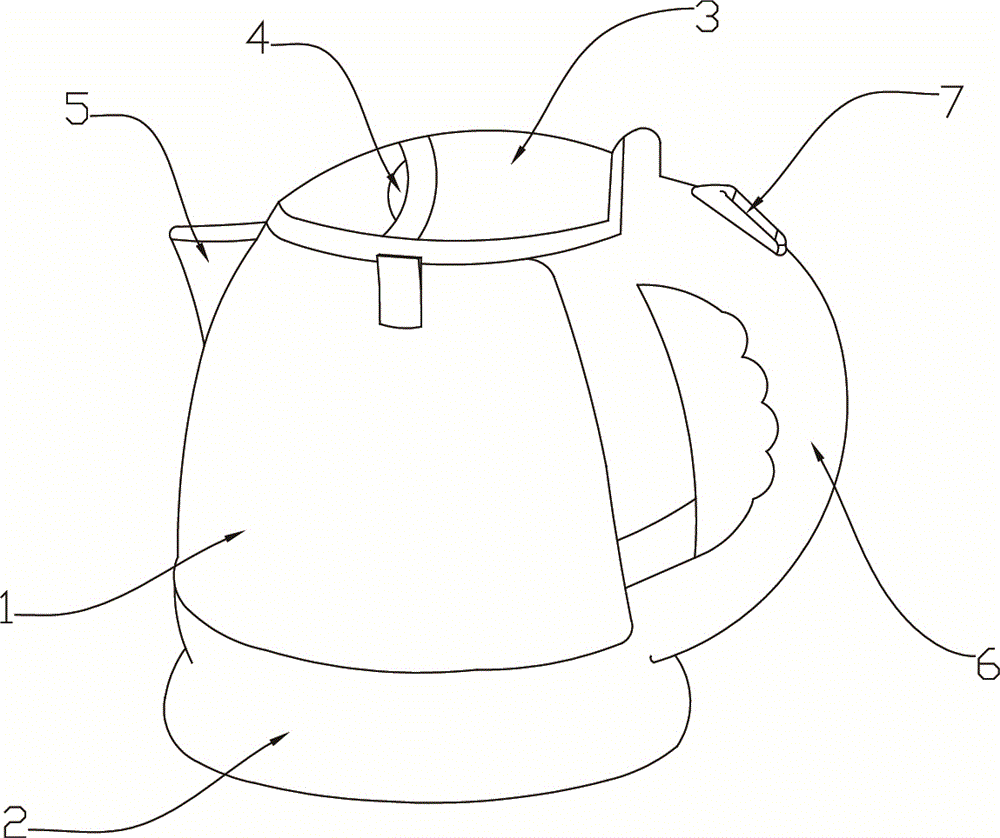

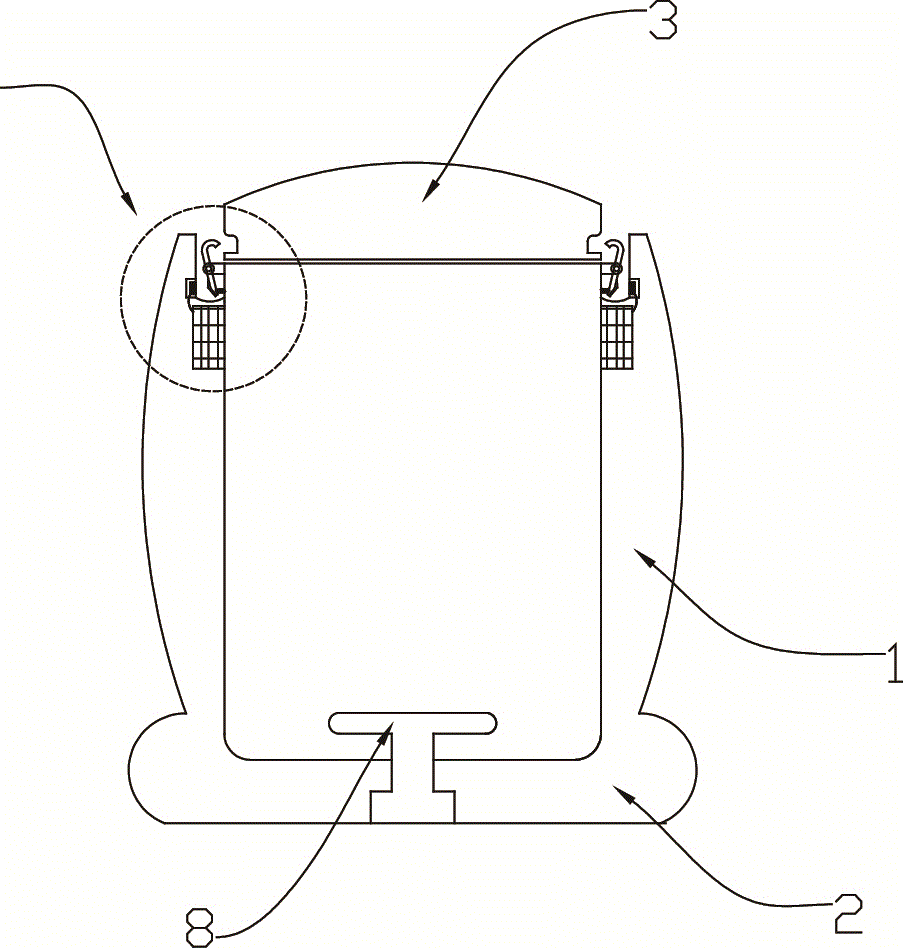

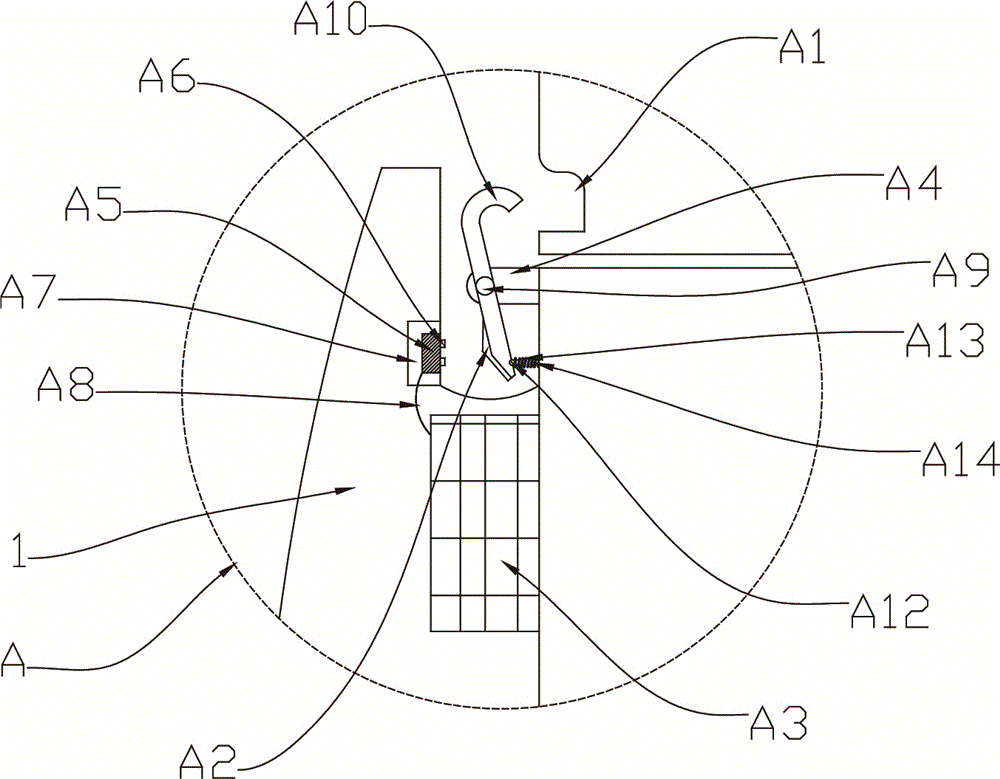

[0014] See Figure 1 to Figure 4 , an electric kettle capable of automatically closing the lid, comprising a kettle body 1, a lid 3, a lid switch 4, a spout 5, a handle 6, a kettle base 2, a switch 7, a heating device 8, the lid 3 Set above the pot body 1, the pot base 2 is set under the pot body 1, the pot body 1 is also provided with a spout 5 and a pot handle 6, the switch 7 is set on the pot handle 6, the heating The device 8 is arranged on the pot base 2, and also includes an automatic closing device A, which includes a pot lid groove A1, a protruding block A4, an iron sheet A2, a thermoelectric power generation device A3, an electromagnet A5, a rotation pressing Rod A10, rotating shaft A9, electric wire A8, a groove is provided between the kettle body 1 and the lid 3, the protruding piece A4 is arranged in the groove and connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com