High-temperature high-pressure brake valve

A high temperature and high pressure, gate valve technology, applied in the direction of sliding valve, valve details, valve device, etc., can solve problems such as failure to open, gate valve failure, enterprise loss, etc., to achieve the effect of solving the phenomenon of boiler effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

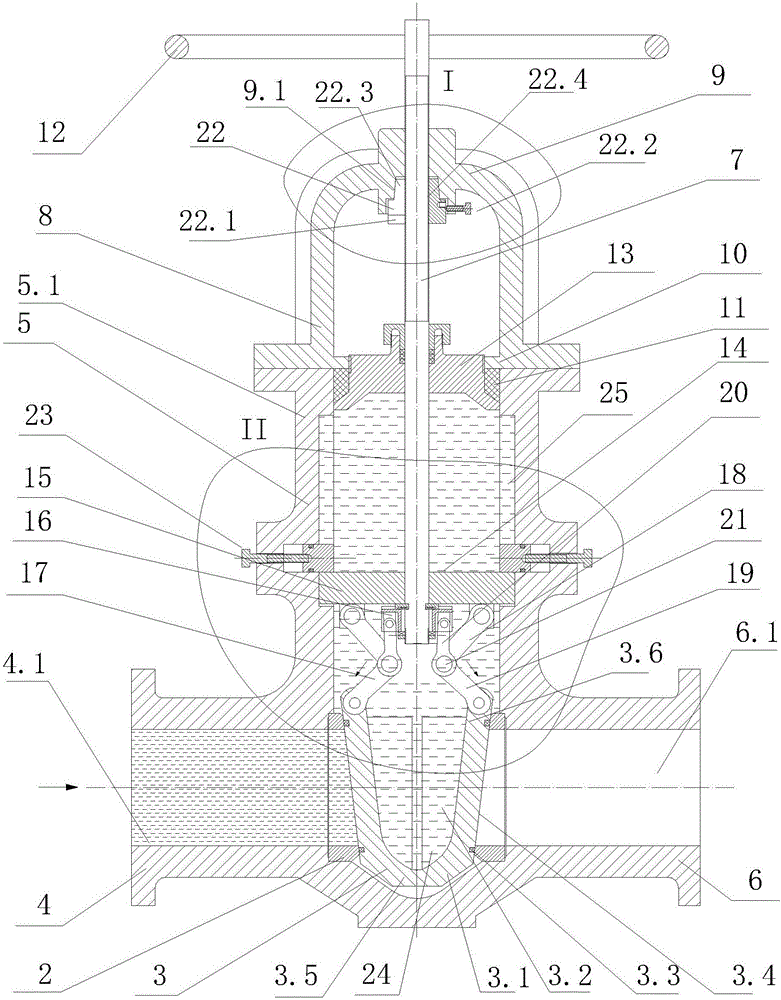

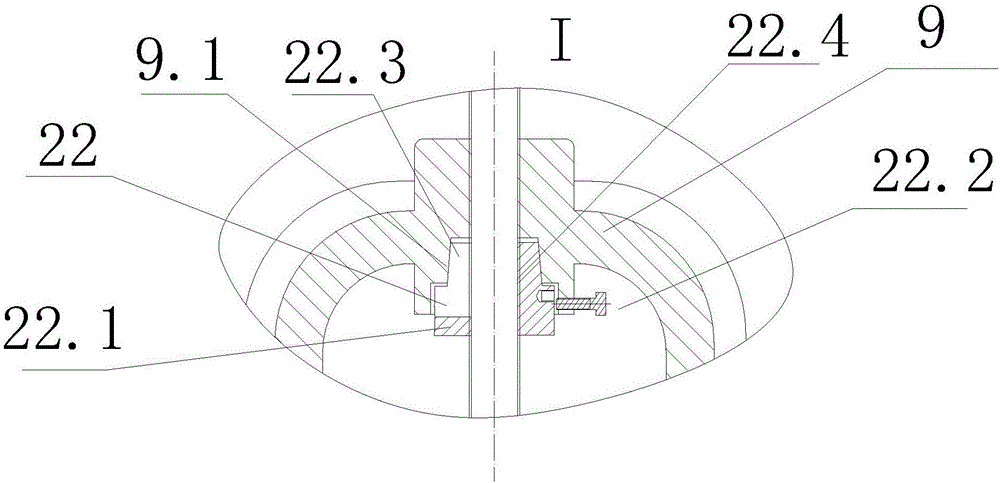

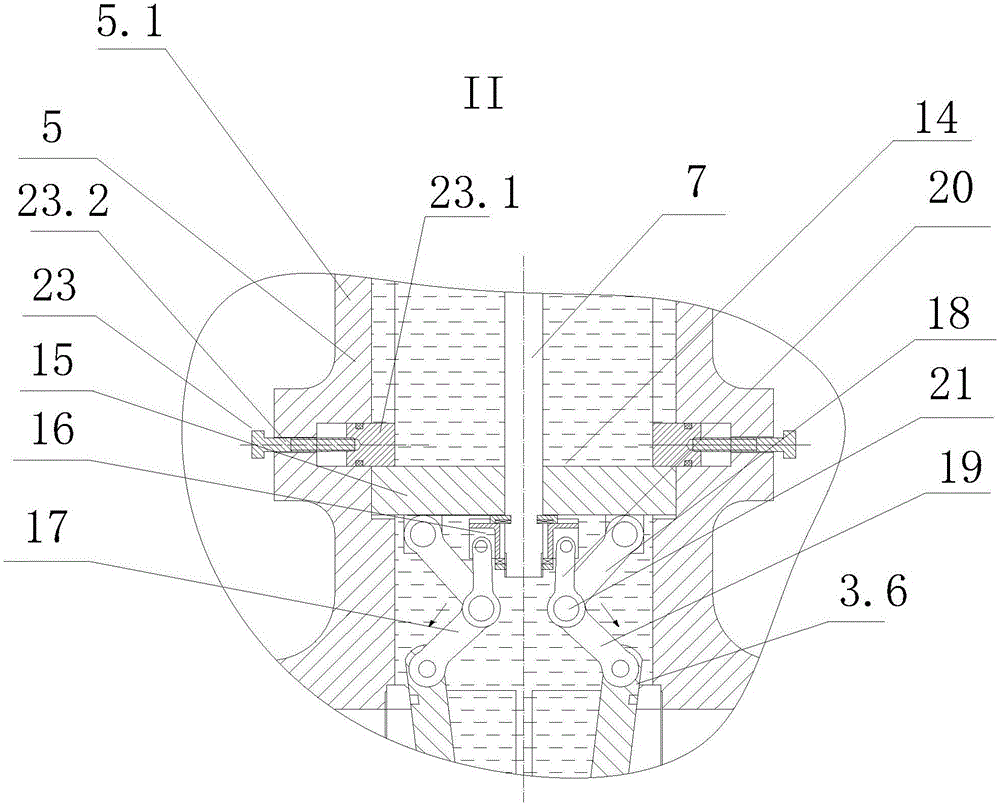

[0041] As shown in the figure, a high-temperature and high-pressure gate valve includes a valve body 1, a valve seat 2, and a valve plate 3. The valve body 1 has an inlet portion 4, a valve chamber 5, and an outlet portion 6. The inlet portion 4 is provided with a first through hole 4.1 , the first through hole 4.1 communicates with the valve chamber 5, the outlet portion 6 is provided with a second through hole 6.1, and the second through hole 6.1 communicates with the valve chamber 5; the valve chamber 5 has an upper neck 5.1. The upper neck 5.1 is fixed with a supporting part 8, the top of the supporting part 8 is provided with a supporting top ring 9, the base of the supporting part 8 is provided with an inner flange 10, and the inner flange 10 is rotatably installed with a bonnet 13, the bonnet 13 and the upper neck A sealing cone ring 11 is provided between the inner walls of the part 5.1.

[0042] The valve stem 7 is set in the upper neck 5.1 and the lower end of the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com