A self-locking channel steel rail clamp

A technology of channel steel track and rail clamp, which is applied in the direction of load hanging components, building material processing, construction, etc., can solve the problems of insufficient smoothness of the sliding process, increase of engineering construction amount, jumping of rail clamp, etc., and achieve the goal of purchasing Convenience, short working cycle, small clamping surface slope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

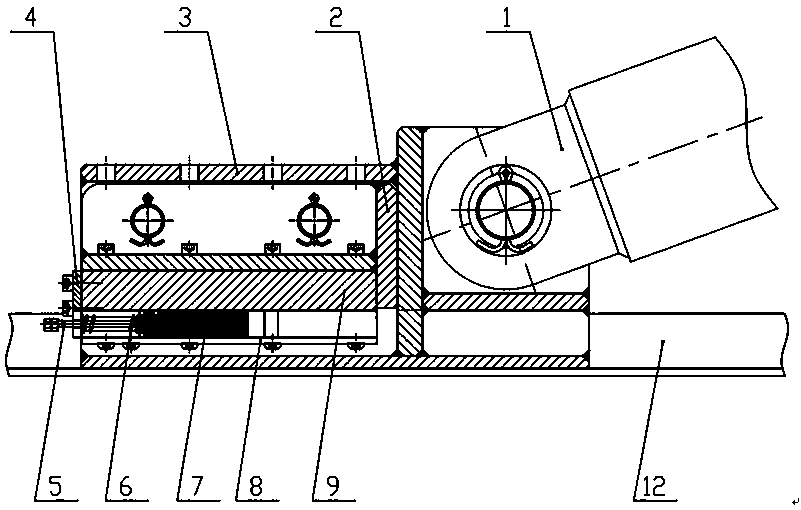

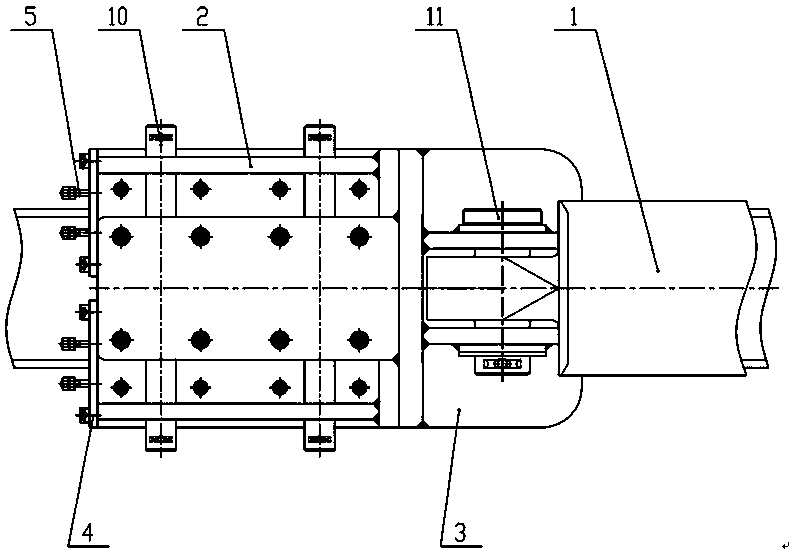

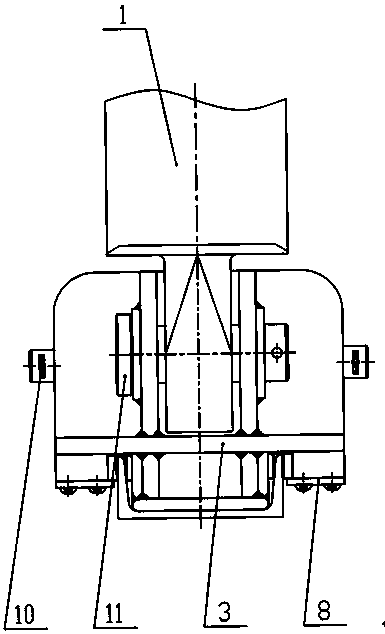

[0027] like figure 1 — image 3 As shown, the device consists of a push cylinder 1, a reaction frame 2, a push seat 3, a tail seal plate 4, a fixing bolt 5, a compression spring 6, a wedge block 7, a wedge support plate 8, a wedge seat 9, Long pin 10, bearing pin 11 and channel steel track 12 form.

[0028] Among them, a reaction force frame 2 is respectively placed on both sides of the push seat 3, and is connected with the reaction force frame 2 by two long pins 10; The wedge block 7 is embedded in the dovetail groove at the bottom of the wedge block seat 9; the friction surface of the wedge block 7 is designed to be serrated and can slide along the edge of the dovetail groove; the fixing bolt 5 passes through the tail sealing plate 4 and the wedge block 7 Carry out fastening connection, be provided with stage clip 6 between the two; Wedge supporting plate 8 and the bottom end of wedge seat 9 carry out fastening connection by hexagon socket head cap screw, be used to suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com