Single discharging amount regulating mechanism of feeding machine

A technology for adjusting the mechanism and output volume, which is applied in animal feeding devices, applications, poultry industry, etc. It can solve the problems of increasing equipment costs, inability to match a variety of poultry and livestock, and fixed single output volume, etc., to achieve saving The effect of equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

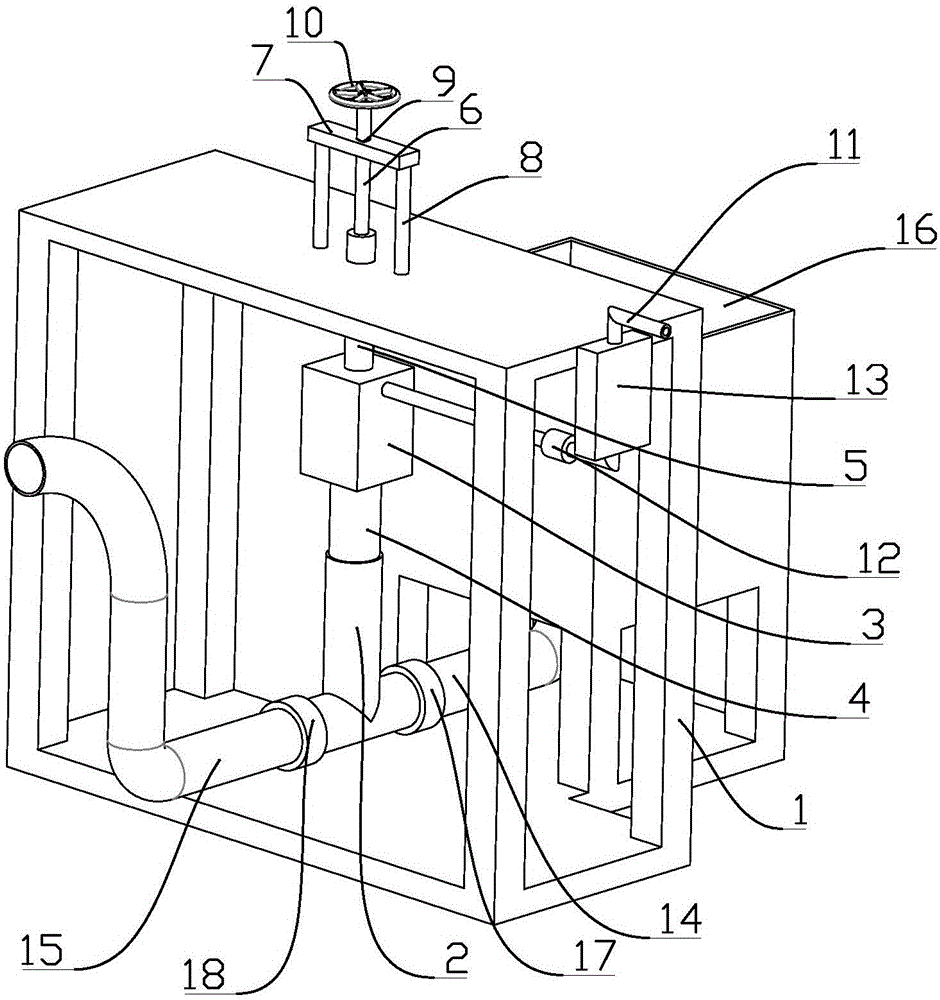

[0013] Such as figure 1 As shown, an adjustment mechanism for a single output of a feeding machine includes a frame 1, a material storage pipe 2 and an ejection cylinder 3, and the described material storage pipe 2 is fixed on the frame 1, and the ejection The ejector rod 4 of the cylinder 3 is connected to the piston of the storage pipe 2, and the ejector cylinder 3 is fixed with a hollow tube 5 at the other end relative to the ejector rod 4, and the hollow tube 5 slides axially with the frame 1 , Circumferential rotation connection, the hollow tube 5 is matched with a screw 6 which is axially fixed to the hollow tube 5 and rotates in the circumferential direction, the screw 6 passes through the horizontal plate 7 above the frame 1, and the horizontal The plate 7 is fixed above the frame 1 through cylindrical struts 8 symmetrically distributed on both sides of the screw 6 , and the horizontal plate 7 is provided with a screw hole 9 matching the screw 6 at the position where t...

Embodiment 2

[0017] Such as figure 1 Shown, a kind of pneumatic feeding device comprises frame 1, material storage pipe 2, ejection cylinder 3, feed pipe 14, discharge pipe 15 and silo 16, and described silo 16 and material storage pipe 2 All are fixed on the frame 1, the bottom outlet of the silo 16 is connected to the lower end of the storage pipe 2 through the feed pipe 14, and the discharge pipe 15 is connected to the lower end of the storage pipe 2. There is a feeding one-way valve 17 that controls feed to flow from the silo 16 to the storage pipe 2 in series on the feed pipe 14, and a feed check valve 17 that controls the feed to flow from the storage pipe 2 to the feed pipe 15 is connected in series. The discharge one-way valve 18 of the one-way flow of the discharge pipe 15, the upper end of the storage pipe 2 is connected with the ejector rod 4 piston of the ejector cylinder 3, and the ejector cylinder 3 is at a position relative to the ejector rod 4 The other end is fixed with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com