Fixed-position welding device for flange and elbow

A positioning welding and flange technology, applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low welding quality, low efficiency of positioning welding, cracking of solder joints, etc., to improve efficiency, ensure quality, and avoid bowing The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

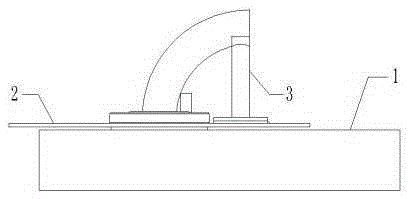

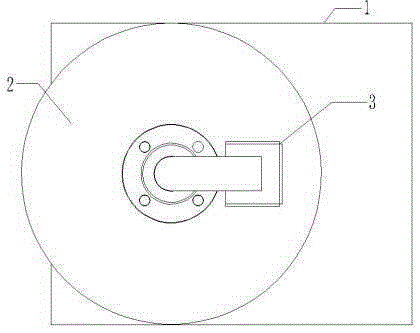

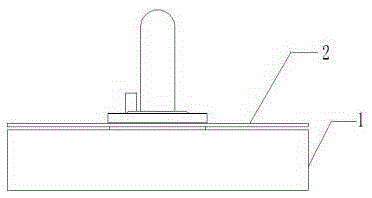

[0008] as attached figure 1 ~ attached Figure 4 , the present invention includes a base (1), an operating turntable (2), a support (3), and a bearing (4). There are holes for installing the bearing (4) on the base (1), and a flange is provided on the operating turntable (2) The positioning column, the operating turntable (2) is installed on the base (1) through the bearing (4), the support (3) is welded and fixed on the operating turntable (2), when the flange and the elbow are welded, the flange is passed through the positioning Put the column on the operating turntable (2), then insert one end of the elbow into the flange hole, and place the other end on the support (3), adjust and fix it by welding at one point, then turn the operating turntable (2), and spot weld the other corner Fixing at one point can effectively improve the efficiency of positioning welding between flange and elbow, and ensure the quality of positioning welding between flange and elbow, so as to avoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com