Fixed-position welding device for seal head and pipe fitting

A technology for positioning welding and pipe fittings, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of poor positioning welding quality, low efficiency, large size deviation, etc., to reduce size deviation, improve efficiency, and ensure positioning. The effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

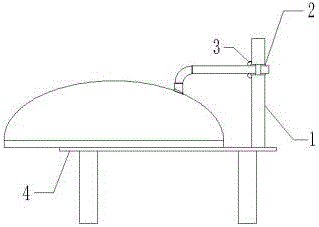

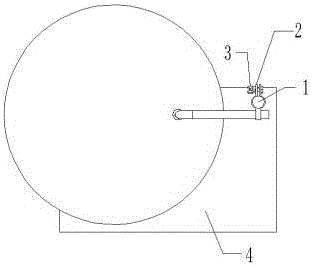

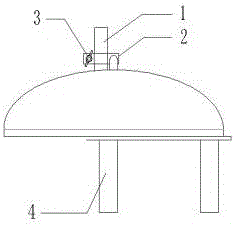

[0008] as attached figure 1 ~ attached Figure 4 , the present invention includes a bracket (1), a clamping positioning block (2), a fastening bolt (3), a workbench (4), the bracket (1) is fixed on the workbench (4), and the clamping positioning block (2) Fix the bolt (3) on the bracket (1). When welding the head and the pipe fitting, first insert the pipe fitting into the bracket (1) and determine the opening position of the pipe fitting on the head. Adjust the height of the bracket (1) up and down and fix it with fastening bolts (3). After positioning, the pipe fittings are directly welded on the head, which effectively improves the efficiency of positioning welding between the head and pipe fittings, ensures the quality of positioning welding, and reduces the size deviation.

[0009] It should be noted that the above embodiments are only used to illustrate the technical solutions of the present invention without limitation. Although the present invention has been described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com