Fast edging machine for round glass

A kind of edge grinding machine and glass technology, which is applied in the direction of machine tools, grinding machines, and grinding workpiece supports suitable for grinding the edge of workpieces, can solve the problems of high technical content, high cost, inconvenient control, etc., and improve work efficiency and structure Simple, the effect of reducing the possibility of glass damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

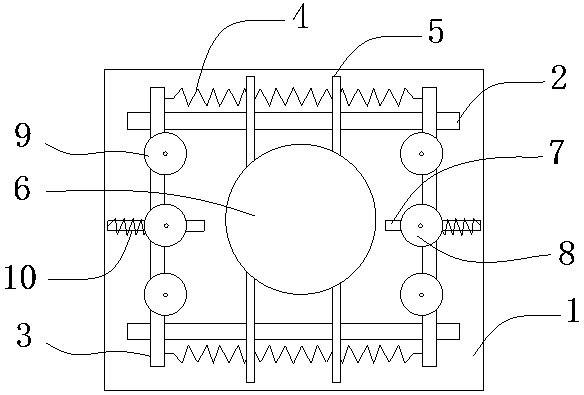

[0016] As shown in the figure, the fast edging machine for round glass in this embodiment includes an underframe 1, and the underframe 1 is provided with two parallel edging wheel guide rails 2, and two independent edging wheel guide rails 2 are movable. The edging wheel frame 3 (the bottom of the edging wheel frame 3 is provided with rollers, so that the edging wheel frame 3 can move freely along the edging wheel guide rail 2), and the two edging wheel frames 3 are connected by a spring 4, so that the two The two edging wheel frames 3 tend to move closer; the bottom frame 1 is provided with two glass guide rails 5 perpendicular to the edging wheel guide rails 2 in the middle of the two edging wheel guide rails 2, and the glass guide rails 5 are equipped with The guide rail 5 is a slide block that moves freely, and the slide block is equipped with a glass support plate 6 through a rotating shaft. The spring 4 is located below the glass guide rail 5 .

[0017] The middle part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com