Uncertainty analysis method for predicting performance of periodic material

A periodic material, uncertain technology, applied in the field of effect analysis, to achieve the effect of great safety and convenience advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0034] Such as Figure 5 As shown, the present invention predicts the uncertainty propagation analysis method of periodic material performance, comprises the following steps:

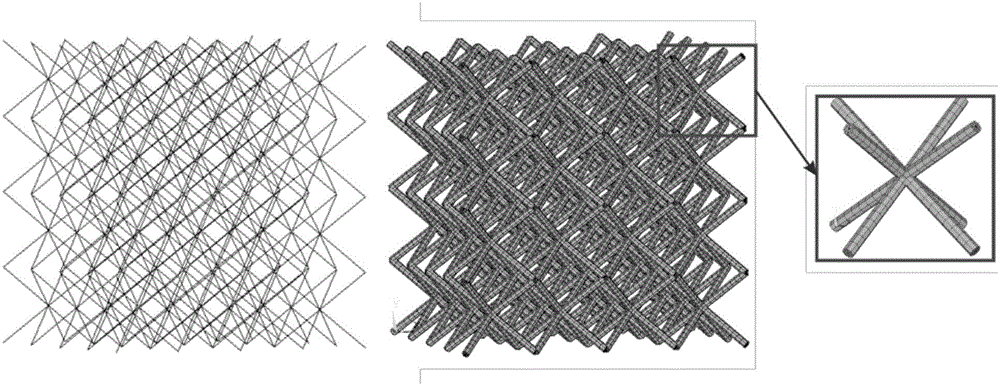

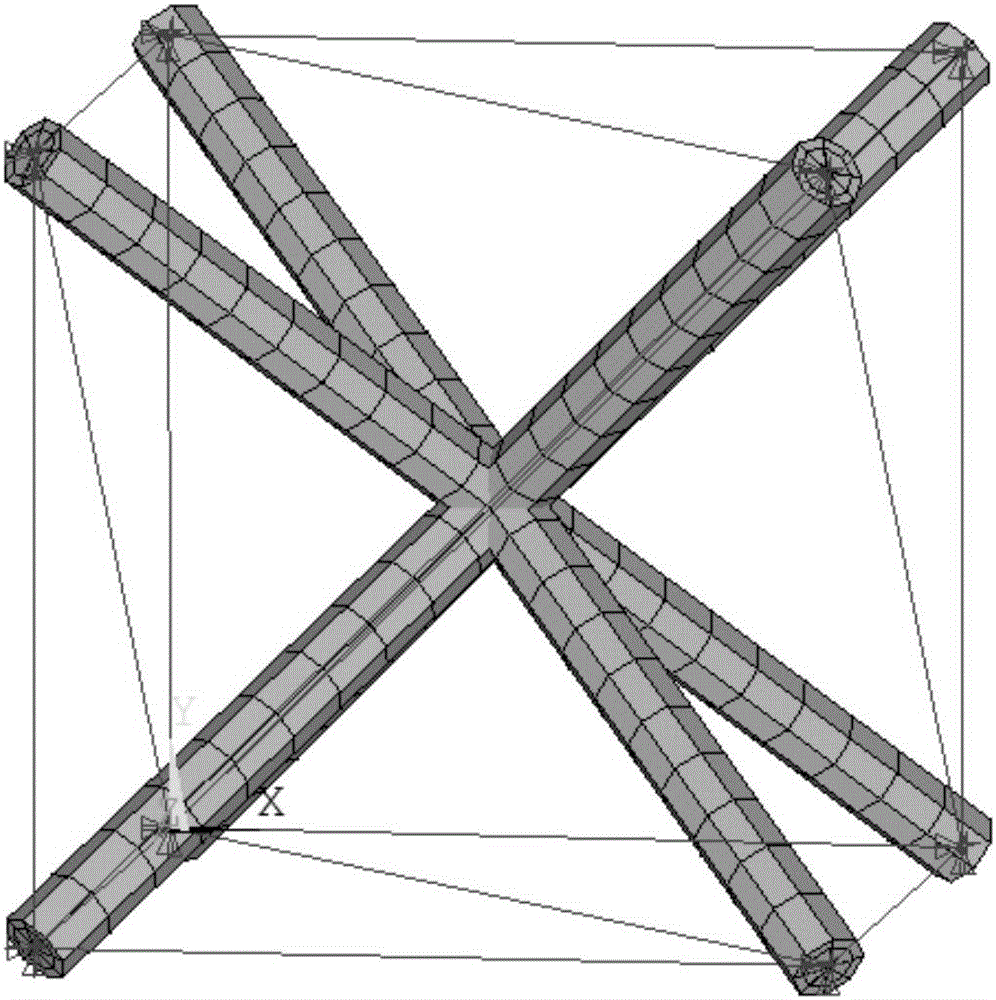

[0035] (1) For the actual target material, according to the microstructure arrangement law in its internal mesoscale, select a suitable cube block as an effective cell, as follows: figure 1 The configuration shown is taken as an example. The selected typical cells can be reorganized in the three-axis direction to reproduce the periodic configuration distribution inside the material. At the same time, the cell should meet the symmetry requirements of the three directions in order to apply subsequent conditions.

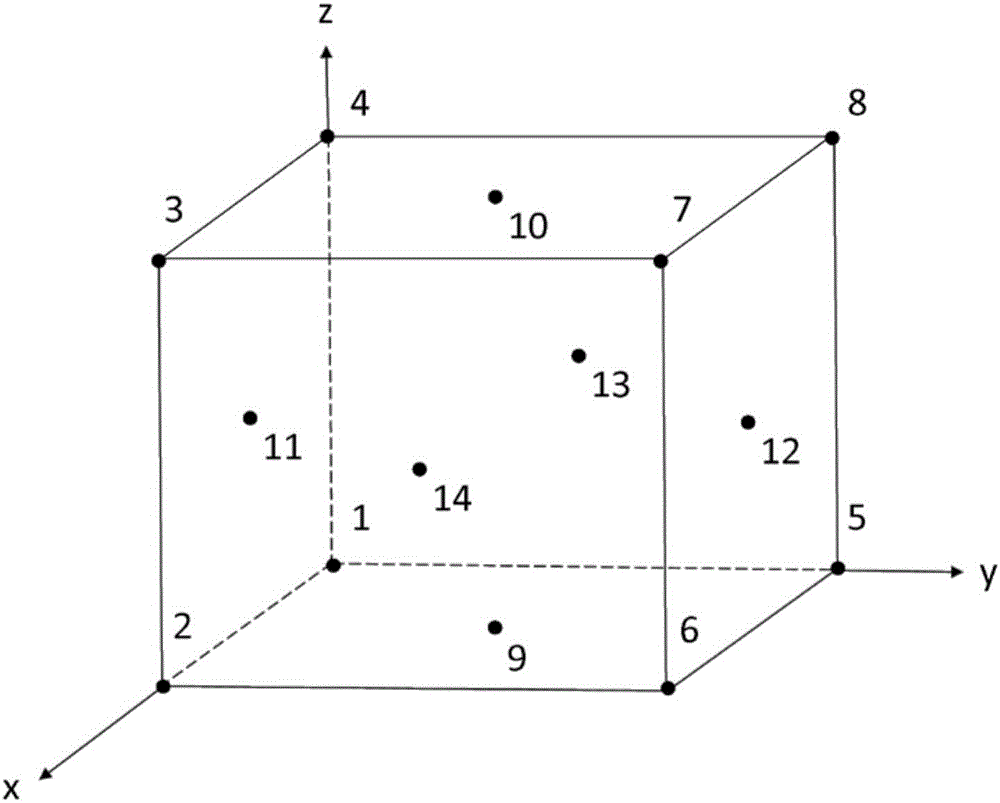

[0036] (2) For the typical cells obtained in the previous step, establish a digital geometric model in the ANSY software pre-processor, take the cube vertices a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com