Test unit for quantitative analysis of a contact pattern on a tooth surface of a gear, method for quantitative analysis and use of the test unit

A technology of contact pattern and test unit, applied in machine gear/transmission mechanism test, image analysis, test of mechanical parts, etc., can solve problems such as analysis limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

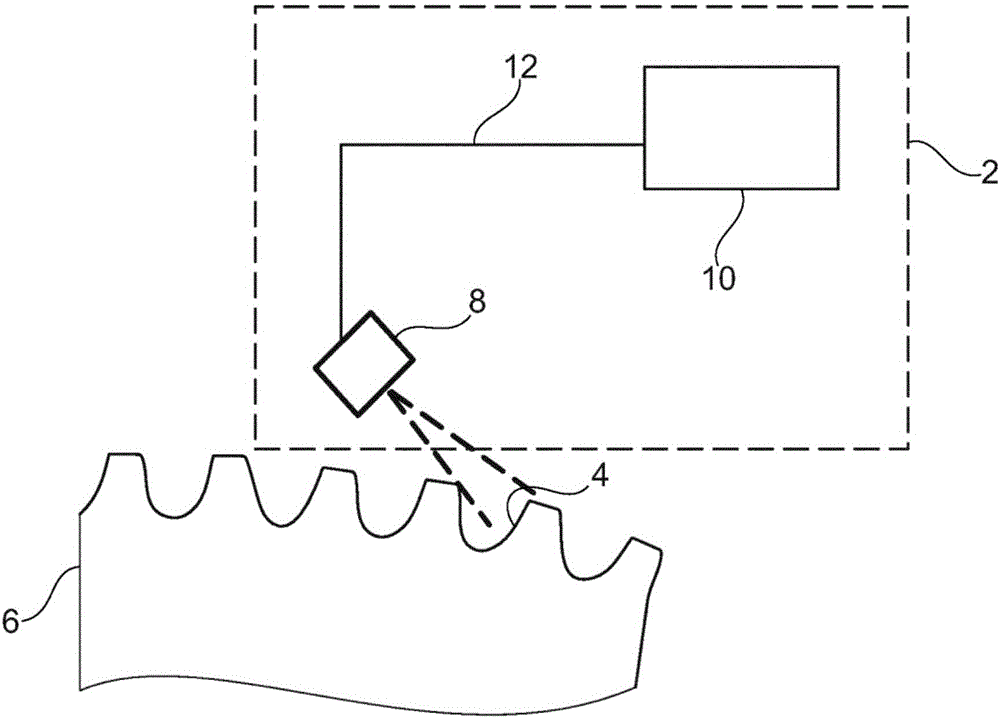

[0026] exist figure 1 In the simplified diagram of , there is a test unit 2 for the quantitative analysis of the contact pattern on the tooth flank 4 of the gear 6 . Just for the simplification of the drawing, the figure 1 Only a section of gear 6 is depicted in . In particular, the gear 6 forms part of a wind generator.

[0027] The testing unit 2 comprises an optoelectronic sensor 8 for capturing images of the contact pattern paint applied on the tooth flank 4 . In particular, the optoelectronic sensor 8 is a camera, for example a digital camera, configured to capture digital images of the tooth flank 4 . The optoelectronic sensor 8 can be a color sensor or a gray scale sensor. For example, a digital color camera or a black-and-white camera, respectively configured to capture a digital color image or a digital grayscale image of the tooth surface 4 , may be used.

[0028]The optoelectronic sensor 8 is coupled to the control unit 10 via a data link 12 . Both the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com